Professional Documents

Culture Documents

290BPSWING Gear Box Disass

290BPSWING Gear Box Disass

Uploaded by

Ko Zay0 ratings0% found this document useful (0 votes)

37 views2 pagesThis document provides a checklist for disassembling an EC290B prime swing gearbox. It lists 10 steps to remove parts like the hydraulic motor, sun gears, carrier assemblies, screws, snap rings, shaft, bearings, seals and more. For each part, it identifies check points to inspect for wear, damage, or other issues. Any parts found to be worn, damaged or not reusable are noted. Proper cleaning, matching of parts, and care taken to avoid mixing components is emphasized to ensure correct reassembly.

Original Description:

Original Title

290BPSWING Gear Box Disass;

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a checklist for disassembling an EC290B prime swing gearbox. It lists 10 steps to remove parts like the hydraulic motor, sun gears, carrier assemblies, screws, snap rings, shaft, bearings, seals and more. For each part, it identifies check points to inspect for wear, damage, or other issues. Any parts found to be worn, damaged or not reusable are noted. Proper cleaning, matching of parts, and care taken to avoid mixing components is emphasized to ensure correct reassembly.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

37 views2 pages290BPSWING Gear Box Disass

290BPSWING Gear Box Disass

Uploaded by

Ko ZayThis document provides a checklist for disassembling an EC290B prime swing gearbox. It lists 10 steps to remove parts like the hydraulic motor, sun gears, carrier assemblies, screws, snap rings, shaft, bearings, seals and more. For each part, it identifies check points to inspect for wear, damage, or other issues. Any parts found to be worn, damaged or not reusable are noted. Proper cleaning, matching of parts, and care taken to avoid mixing components is emphasized to ensure correct reassembly.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

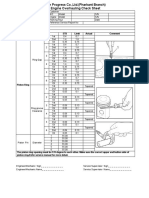

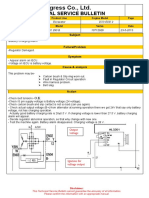

Win Progress.,Co.

Ltd (Pharkant Branch)

EC290BPrime Swing Gearbox Disassemble Check Sheet

Customer Report No.

Machine Model Service date

Machine Sr;No Component Sr No

Working Hour Cause of Problem

Reason Of Overhaul Yes No Remark

Has oil leakage from Gearbox?

Has Been Dissemblied This Gearbox?

Flushing?

Resealing?

Abnormal Function In Gearbox?

Preparation

(i)Thoroughly clean the gearbox assembly prior to disassembly.

(ii)Select a clean work area.

(iii)Match mark attached components to indicate proper positioning during reassembly.

(iv)Take care not to mix the parts of sub assemblies i.e. bushings, bearings, gears and thrust washers

(v)Thoroughly clean all parts and the inside of the casings.

(vi)Inspect and analyze all failures.

(i) Prepare the tools as follow

General Tools:

Spanner(18mm,22mm,24mm),Socket wrench(11mm),Eye bolts(10mm,12mm,16mm,Allen key(5,10,14mm)

Rubber hammer,Screw driver(-),Snap ring pliers(inside,outside),LT-40,LT-165

Parts Status

No Description Check Point Checking Condition Figure

Good RepairN.Good

1 Removal, hydraulic motor

Remove pipe (4) and screws (1).Lift the motor from the gearbox.

Note! Make match marks (A) on hydraulic motor casing,

ring gear (2), and case (3).

Marks (A) are permanent and clearly visible.

pipe Broken or bending

2 Removal,sun gear No.1

Remove,sun gear no,1 (1).

sun gear Wear on teeth surface

3 Removal,first stage carrier ass'y

Remove first carrier assembly from ring gear.

Disassemble first carrier assembly in the following order:

Remove spring pin(1) and then thrust washer (2),

planetary gear (5), needle bearing (4) and thrust washer (2).

Remove pin (3).

Note! Match mark gears (5), pins (3) and carrier (6). Do not

remove pins (3) if not worn or damaged.Do not reuse spring pins (1).

tap pin spring Wearing on face

thrust washer Wearing on face

planetary gear Wear on teeth surface

needle bearing Wear or damage

thrust washer Wearing on face

pin Wearing on face

4 Removal, 2nd sun gear

Remove ring gear (1) and dowel pin(2).

Remove sun gear No.2 (3) and thrust ring (4).

Remove carrier assembly No.2(5) from shaft.

Disassemble carrier assembly No.2 in the following order:

Remove sun gear No.2 (4)

sun gear(3) Wear on teeth surface

thrust ring (4) Wear on tooth

Parts Status

No Description Check Point Checking Condition Figure

Good RepairN.Good

5 Removal, carrier ass'y No.2 and

Tap spring pin (5) into pin (1). Remove pin (1). Remove

planetary gear (3) and washer_thrust (4) bushing(2).

Note! Match mark gears (3), pins (1), and carrier (6).Do not

mix the gears,thrustwashers, bushings and pins.Do not reuse

spring pin (5). To remove spring pin (5), tap it into pin (1).

After removing pin (1), remove the spring pin.

pin(1) Wearing on face

planetary gear(3) Wearing on face

thrust washer(4) Wear on teeth surface

bushing(2) Wearing on face

carrier(6) Wearing on face

6 Removal, screw and cover

Remove screw(7) and cover(6).

screw Crack or damage

7 Removal, snap ring

Remove snap ring(2).

snap ring Twisting or damage

8 Removal, shaft

Press shaft(1) from case(4).

9 Removal, spherical bearing

Press spherical bearing(3) from hosing

Remove ball bearing(5),ring(8),collar(9),seal(10)

Note! If it is difficult to remove spherical

bearing ,use a bearing puller.

spherical bearing Wear on teeth surface

ring Wearing on face

collar Wearing on face

shaft Wear on teeth surface

10 Remove, oil seal

Remove oil seal.

Note! Do not reuse the O-ring.

Oil seal Do not reused

11 Removal,spherical bearing

Removal spherical bearing(5).

spherical bearing Wear on teeth surface

Service Person Sign_ _ _ _ _ _ _ Supervisor Sign_ _ _ _ _ _ _

Service Person Name_ _ _ _ _ _ _ Supervisor Name_ _ _ _ _ _ _

You might also like

- Safety Standard - Positive Isolation-Rev-11Document111 pagesSafety Standard - Positive Isolation-Rev-11Amit Balot100% (5)

- Cf90 Airend Overhaul Manual Product Code HJDocument8 pagesCf90 Airend Overhaul Manual Product Code HJManuel Parreño100% (5)

- SM - Volvo Ec210b LC Ec210blc ExcavatorDocument18 pagesSM - Volvo Ec210b LC Ec210blc ExcavatorNikitko Dmitry33% (3)

- Erbe ICC 200 - Service GuidelineDocument3 pagesErbe ICC 200 - Service Guidelineibss_mcmNo ratings yet

- MSA ProcedureDocument3 pagesMSA ProcedureAnkur0% (1)

- Transmision Wa500 Shop ManualDocument51 pagesTransmision Wa500 Shop ManualPatricio GuerreroNo ratings yet

- G GROUP 5 SWING DEVICE (Up To #0062) : 1. Removal and Install of MotorDocument46 pagesG GROUP 5 SWING DEVICE (Up To #0062) : 1. Removal and Install of MotorLenomar Bessa de PaulaNo ratings yet

- Group 3 Disassembly and AssemblyDocument5 pagesGroup 3 Disassembly and AssemblyAndré TarginoNo ratings yet

- TM 10-3930-669-34 Forklift Truck 6K Drexel MDL R60SL-DC Part 3Document65 pagesTM 10-3930-669-34 Forklift Truck 6K Drexel MDL R60SL-DC Part 3AdvocateNo ratings yet

- Removal/installation Recommendations: Identification of NTN-SNR Wheel Bearing KIT R140.77Document7 pagesRemoval/installation Recommendations: Identification of NTN-SNR Wheel Bearing KIT R140.77Ioan PascaNo ratings yet

- Group 3 Disassembly and AssemblyDocument5 pagesGroup 3 Disassembly and AssemblyAndré TarginoNo ratings yet

- 50k SvcmanDocument9 pages50k SvcmanhernanNo ratings yet

- ANILLOS PentastarDocument1 pageANILLOS PentastarStarsky UrblejoNo ratings yet

- Front Wheel Spindle HousingsDocument6 pagesFront Wheel Spindle HousingsRafael RahealNo ratings yet

- Group 9 Boom, Arm and Bucket CylinderDocument17 pagesGroup 9 Boom, Arm and Bucket CylinderHậu MinhNo ratings yet

- TM 9-2330-397-14P M1112 Trailer, Tank, Water 400 Gallon Part 3Document130 pagesTM 9-2330-397-14P M1112 Trailer, Tank, Water 400 Gallon Part 3AdvocateNo ratings yet

- D50K Digger To SN 58699 Obsolete Service ManualDocument10 pagesD50K Digger To SN 58699 Obsolete Service ManualpppopNo ratings yet

- 071-030-0001 (SL1) - Maintain An MK19 Machine GunDocument16 pages071-030-0001 (SL1) - Maintain An MK19 Machine Gungearhead1No ratings yet

- C014 Assembly-Disassembly ManualDocument21 pagesC014 Assembly-Disassembly Manualwillyan100% (2)

- Orbitrol Repairing1Document30 pagesOrbitrol Repairing1Islam ShoukryNo ratings yet

- Amarillo 1000 1800 Repair ManualDocument32 pagesAmarillo 1000 1800 Repair ManualmuazmaslanNo ratings yet

- 2012 Fork Service ManualDocument36 pages2012 Fork Service ManualFer SabidongNo ratings yet

- Fax 001Document14 pagesFax 001daniel ignatNo ratings yet

- 7-9 Arme y Desarme CilindrosDocument19 pages7-9 Arme y Desarme Cilindroslevinton jose tobias genesNo ratings yet

- Group 9 Boom, Arm and Bucket Cylinder (Up To #1621)Document34 pagesGroup 9 Boom, Arm and Bucket Cylinder (Up To #1621)ANDREI26No ratings yet

- ForkDocument15 pagesForkcalvofernandavidNo ratings yet

- Transmission CaseDocument14 pagesTransmission CaseJeff PascoeNo ratings yet

- EC210 - Track Motor, DisassemblyDocument14 pagesEC210 - Track Motor, DisassemblyPreett Rajin MenabungNo ratings yet

- Dana Spicer WJ Dana44Document35 pagesDana Spicer WJ Dana44Stefano MirabelliNo ratings yet

- Sk75sr-3e S5yt0023e02 Shop Manual - Part3Document300 pagesSk75sr-3e S5yt0023e02 Shop Manual - Part3PHÁT NGUYỄN THẾ100% (4)

- Telescoping Cylinder - Remove and Install: S/N - 3RN4015-UP S/N - 3PN2027-UP S/N - 5WM6021-UPDocument14 pagesTelescoping Cylinder - Remove and Install: S/N - 3RN4015-UP S/N - 3PN2027-UP S/N - 5WM6021-UPdaryanto widodoNo ratings yet

- Eaton: Model 74318 and 74348 Piston Motors Fixed Displacement, Valve Plate DesignDocument9 pagesEaton: Model 74318 and 74348 Piston Motors Fixed Displacement, Valve Plate Designluisbravo1264No ratings yet

- Manitou Tower ServiceDocument35 pagesManitou Tower ServiceKélio Wolfrane Santos MachadoNo ratings yet

- Disc Si Placute Frana FataDocument7 pagesDisc Si Placute Frana FatabijjNo ratings yet

- Group 9 Boom, Arm and Bucket CylinderDocument17 pagesGroup 9 Boom, Arm and Bucket CylinderJorge Iván Villaseñor LozanoNo ratings yet

- Steering Tie RodDocument2 pagesSteering Tie RodRafael RahealNo ratings yet

- D6NXL TransmicionDocument32 pagesD6NXL Transmicionhgjrujtnt srthytntynNo ratings yet

- XL Series Actuators 1: Installation, Operating and Maintenance InstructionsDocument8 pagesXL Series Actuators 1: Installation, Operating and Maintenance InstructionsFranco M. CaverzanNo ratings yet

- Remove Injection Pump c4. 4 SN s1mDocument2 pagesRemove Injection Pump c4. 4 SN s1mBadrus AqmarNo ratings yet

- CF90 Airend OverhaulDocument7 pagesCF90 Airend OverhaulHernan Elias Padilla MonroyNo ratings yet

- G Group 5 Swing Device: 1. Removal and Install of MotorDocument21 pagesG Group 5 Swing Device: 1. Removal and Install of MotorrodineiNo ratings yet

- EC480D - Swing Gearbox, DisassemblyDocument7 pagesEC480D - Swing Gearbox, Disassemblyeck yuwanNo ratings yet

- Group 14 Work Equipment: 1. StructureDocument4 pagesGroup 14 Work Equipment: 1. StructureChristian VicenteNo ratings yet

- 13-14.. Service Manual LoboDocument16 pages13-14.. Service Manual LoboRusonegroNo ratings yet

- D Transmission2010Document37 pagesD Transmission2010Akrae AcrNo ratings yet

- Group 5 Swing Device ( #0408) : 1. Removal and Install of MotorDocument48 pagesGroup 5 Swing Device ( #0408) : 1. Removal and Install of Motordeniden2013No ratings yet

- Manual Serviço Motor - Parte 3Document19 pagesManual Serviço Motor - Parte 3Carlos GarcesNo ratings yet

- Motor M14 ControlDocument6 pagesMotor M14 ControlROBERSON ROMERÒNo ratings yet

- 8 7 PDFDocument54 pages8 7 PDFHector Renzo Zarate RodriguezNo ratings yet

- BMW X2 F39 Clutch Actuator 2Document21 pagesBMW X2 F39 Clutch Actuator 2Περικλής ΖυγούραςNo ratings yet

- Hyundai 999Document55 pagesHyundai 999Said GedeonNo ratings yet

- Artison FB15C-25C SERVICE MANUALDocument82 pagesArtison FB15C-25C SERVICE MANUALAdrian RangelNo ratings yet

- Overhaul 4 & 5 SpeedDocument22 pagesOverhaul 4 & 5 SpeedJeff PascoeNo ratings yet

- MT955 TeDocument8 pagesMT955 TeMosqq CharriNo ratings yet

- Group 10 Rear AxleDocument42 pagesGroup 10 Rear AxleTaha RdmanNo ratings yet

- Air Starting Motor - Disassemble (SENR1126-36)Document11 pagesAir Starting Motor - Disassemble (SENR1126-36)redminote12pro.5garNo ratings yet

- Group 13 Boom, Arm, Bucket and Dozer CylinderDocument21 pagesGroup 13 Boom, Arm, Bucket and Dozer CylinderChristian VicenteNo ratings yet

- Group 9 Boom, Arm and Bucket CylinderDocument17 pagesGroup 9 Boom, Arm and Bucket CylinderkrisnantoNo ratings yet

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsFrom EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Zaxis-5G Maintenance Guide: Hitachi Construction Machinery Asia & Pacific Pte LTDDocument13 pagesZaxis-5G Maintenance Guide: Hitachi Construction Machinery Asia & Pacific Pte LTDKo ZayNo ratings yet

- SpecificationsDocument4 pagesSpecificationsKo ZayNo ratings yet

- Common Rail Diagnostics: Hitachi Construction Machinery Asia & Pacific Pte. LTDDocument11 pagesCommon Rail Diagnostics: Hitachi Construction Machinery Asia & Pacific Pte. LTDKo ZayNo ratings yet

- ReturnDocument27 pagesReturnKo ZayNo ratings yet

- Hydraulic SymbolsDocument15 pagesHydraulic SymbolsKo ZayNo ratings yet

- Upperstructure: Section 2Document193 pagesUpperstructure: Section 2Ko ZayNo ratings yet

- SpecificationsDocument9 pagesSpecificationsKo ZayNo ratings yet

- Performance Test For Zx670-3: Unit Actual Value Standard Value RemarkDocument2 pagesPerformance Test For Zx670-3: Unit Actual Value Standard Value RemarkKo ZayNo ratings yet

- Specifications Zaxis650LcDocument10 pagesSpecifications Zaxis650LcKo ZayNo ratings yet

- Boom Can't DownDocument1 pageBoom Can't DownKo ZayNo ratings yet

- Isuzu Parts Catalog 4HK1Document62 pagesIsuzu Parts Catalog 4HK1Ko Zay100% (1)

- D12C EngAss, Diss (Piston)Document1 pageD12C EngAss, Diss (Piston)Ko ZayNo ratings yet

- SpecificationsDocument5 pagesSpecificationsKo ZayNo ratings yet

- Boom Cylinder Creeping &driftDocument2 pagesBoom Cylinder Creeping &driftKo ZayNo ratings yet

- Boom Raise Function SlowDocument1 pageBoom Raise Function SlowKo ZayNo ratings yet

- 290BPSWING Gearbox AssDocument2 pages290BPSWING Gearbox AssKo ZayNo ratings yet

- D12D Eng Ass and Disass (Piston)Document1 pageD12D Eng Ass and Disass (Piston)Ko ZayNo ratings yet

- SB020Document2 pagesSB020Ko ZayNo ratings yet

- Hitachizaxiszx75us 3excavatorservicerepairmanual 171124075345Document71 pagesHitachizaxiszx75us 3excavatorservicerepairmanual 171124075345Ko Zay100% (1)

- Boom Cylinder Can't LiftDocument2 pagesBoom Cylinder Can't LiftKo ZayNo ratings yet

- Training Manual Electrical: Cable Systems - Cable Termination Revised March 2006 Page 1 of 18Document18 pagesTraining Manual Electrical: Cable Systems - Cable Termination Revised March 2006 Page 1 of 18Ko ZayNo ratings yet

- Win Progress Co., LTD.: Technical Service BulletinDocument3 pagesWin Progress Co., LTD.: Technical Service BulletinKo ZayNo ratings yet

- 6.section C - ElectricsDocument225 pages6.section C - ElectricsKo Zay100% (5)

- Electrical Assessment QuestionsDocument24 pagesElectrical Assessment QuestionsKo ZayNo ratings yet

- FS Curtis FAC 28B 28BC Instruction Manual KubotaDocument69 pagesFS Curtis FAC 28B 28BC Instruction Manual KubotaKo ZayNo ratings yet

- Win Progress Co., LTD.: Technical Service BulletinDocument2 pagesWin Progress Co., LTD.: Technical Service BulletinKo ZayNo ratings yet

- Weichai Engine PrintDocument52 pagesWeichai Engine PrintKo ZayNo ratings yet

- Damage Crank Shaft BearingDocument2 pagesDamage Crank Shaft BearingKo ZayNo ratings yet

- Win Progress Co., LTD.: Technical Service BulletinDocument2 pagesWin Progress Co., LTD.: Technical Service BulletinKo ZayNo ratings yet

- Engine Oil Pressure Alarm 128 Pid 100 FMI 1Document2 pagesEngine Oil Pressure Alarm 128 Pid 100 FMI 1Ko ZayNo ratings yet

- BITUMEN ProjectDocument26 pagesBITUMEN ProjectAbood Buriahi100% (2)

- Adobe Illustrator CS5 Skills Workshop Fashion Design Level 4 - Lesson 1 2011 - 2012Document21 pagesAdobe Illustrator CS5 Skills Workshop Fashion Design Level 4 - Lesson 1 2011 - 2012Maria-Cătălina IliașNo ratings yet

- Applied Thermal Engineering: SciencedirectDocument15 pagesApplied Thermal Engineering: SciencedirectmaxmanfrenNo ratings yet

- Kerala's Baby Steps Toward Sanitation - The Vilappilasala PlantDocument5 pagesKerala's Baby Steps Toward Sanitation - The Vilappilasala PlantDr.Thrivikramji.K.P.No ratings yet

- Introduction: Classification of Layout, Advantages and Limitations of Different LayoutsDocument14 pagesIntroduction: Classification of Layout, Advantages and Limitations of Different LayoutsPadmavathi Putra LokeshNo ratings yet

- CRT2324 Deh-P900rDocument89 pagesCRT2324 Deh-P900rbiophanteraNo ratings yet

- Appendix H Planet Gear Bearing Analysis ReportDocument13 pagesAppendix H Planet Gear Bearing Analysis ReportCarloK98No ratings yet

- 15A10 - Superstructures I (Topside)Document23 pages15A10 - Superstructures I (Topside)Viktor DươngNo ratings yet

- Variable Refrigerant Volume Tech OlogyDocument68 pagesVariable Refrigerant Volume Tech Ologyvarshneyrk@rediffmail.com100% (1)

- Basic CarpentryDocument36 pagesBasic CarpentrySharmen QuijoteNo ratings yet

- Pradeep Jha June-2019Document13 pagesPradeep Jha June-2019mkpNo ratings yet

- Rain Drainage SystemDocument2 pagesRain Drainage SystembabuNo ratings yet

- Papermaking Factors Affecting Lateral Web Position During CommercDocument146 pagesPapermaking Factors Affecting Lateral Web Position During CommercVan PhamNo ratings yet

- Ebook Security+ CompTiaDocument614 pagesEbook Security+ CompTianorfl100% (1)

- Compact Sub Station BrochureDocument8 pagesCompact Sub Station BrochureAnimesh SahaNo ratings yet

- Kik-kop-40-Pe-ge-0016-0 - Linear Actuator Override Tool Operation & Maintenance ManualDocument27 pagesKik-kop-40-Pe-ge-0016-0 - Linear Actuator Override Tool Operation & Maintenance ManualKhalid AliNo ratings yet

- Man BWDocument24 pagesMan BWDhanie KhruxzNo ratings yet

- Sherwin Williams - Heatflex Hi-Temp 1200 DatasheetDocument4 pagesSherwin Williams - Heatflex Hi-Temp 1200 DatasheetAce AceNo ratings yet

- 132 KV Substation Specs PDFDocument338 pages132 KV Substation Specs PDFkumawat.sunilNo ratings yet

- Grinding Lab 2Document9 pagesGrinding Lab 2Ming QuanNo ratings yet

- Control SystemDocument3 pagesControl SystemsryunkNo ratings yet

- Ignition Electrode and Ceramic Igniter Catalog 2020Document26 pagesIgnition Electrode and Ceramic Igniter Catalog 2020FKKNo ratings yet

- Off-Line Quasi-Resonant Switching Regulators: STR-X6769Document9 pagesOff-Line Quasi-Resonant Switching Regulators: STR-X6769Alfredo Valencia RodriguezNo ratings yet

- Documents - Pub - Keeping The Resistance in Basf Dispersions Pigments Solutions and High QualityDocument24 pagesDocuments - Pub - Keeping The Resistance in Basf Dispersions Pigments Solutions and High QualityLong An ĐỗNo ratings yet

- Philips 43pus7303Document20 pagesPhilips 43pus7303Vladimir ShestNo ratings yet

- Api 671Document6 pagesApi 671ecsuperalNo ratings yet

- ShearWallDesign Manual2016Document82 pagesShearWallDesign Manual2016Alfia BanoNo ratings yet