Professional Documents

Culture Documents

Acs 150

Acs 150

Uploaded by

potoculOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acs 150

Acs 150

Uploaded by

potoculCopyright:

Available Formats

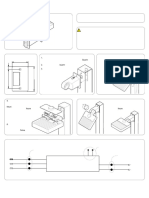

3.

Start to tighten the

screws into the

Frame size Tightening torques

mounting holes.

U1, V1, W1, U2, V2, W2, PE

— 4. Place the drive onto

the mounting screws.

BRK+ and BRK-

ABB MIRCO DRIVES R0…R2 0.8 N·m (7 lbf·in) 1.2 N·m (11 lbf·in)

5. Tighten the mounting

ACS150 drives

00353783 L

screws securely.

To install the

Quick installation and start-up guide drive to a DIN

7. Connect the control cables

rail Default I/O connections

1. Place the top of the The diagram shows the I/O connections when parameter 9902 has value 1

drive onto the DIN (ABB STANDARD).

installation rail in an

angle as shown in I/O connection 4)

figure.

SCR Signal cable shield (screen)

2. Set the drive against

the wall. AI Frequency reference: 0…20 mA

GND Analog input circuit common

3. To remove the drive,

3)

press the release lever +10V Reference voltage: +10 V DC, max. 10 mA

on top of the drive.

+24V Auxiliary voltage output: +24 V DC, max. 200 mA

GND Auxiliary voltage output common

3. Attach the clamping plates COM Digital input common

1. Fasten the clamping DI1 Stop (0) / Start (1)

plate to the plate at

DI2 Forward (0) / Reverse (1)

the bottom of the

drive with the DI3 Constant speed selection 1)

provided screws.

DI4 Constant speed selection 1)

2. Fasten the I/O

DI5 Acceleration and deceleration selection 2)

clamping plate to the

clamping plate with Relay connection 5)

the provided screws. COM Relay output

No fault [Fault (-1)]

4. Measure the NC

insulation resistance NO

Alternative connection for AI1:

Measuring the insulation is typically not required in North America.

Drive: Do not do voltage tolerance or insulation resistance tests on the drive, SCR If you use voltage signal instead or current, switch the IU

because this can cause damage to the drive. selector to U (0…10 V voltage signal), and use this

AI connection instead the one shown above.

Input power cable: Before you connect the input power cable, measure the GND

insulation of the input power cable. Obey the local regulations.

+10V

Motor and motor cable: 1…10 kohm

1. Make sure that the motor cable is connected to the motor and disconnected

from the drive output terminals U2, V2 and W2. 1) See parameter group 12 CONSTANT 2) 0 = ramp times according to parameters

2. Use a voltage of 1000 V DC to measure the SPEEDS: 2202 and 2203. 1 = ramp times according to

Safety instructions insulation resistance between each phase

parameters 2205 and 2206.

DI3 DI4 Operation (parameter) 3) 360 degree grounding under a clamp.

conductor and the protective earth conductor. U1 4) Tightening torque: 0.22 N·m / 2 lbf·in

M 0 0 Set speed through

WARNING! Obey these instructions. If you ignore them, injury or death, The insulation resistance of an ABB motor must V1 integrated potentiometer

5) Tightening torque: 0.5 N·m / 4.4 lbf·in

3~

or damage to the equipment can occur. If you are not a qualified be more than 100 Mohm (at 25 °C/77 °F). For the ohm W1

electrical professional, do not do electrical installation or maintenance insulation resistance of other motors, refer to PE 1 0 Speed 1 (1202)

work. the manufacturer’s documentation. Moisture in 0 1 Speed 2 (1203)

the motor decreases the insulation resistance.

1 1 Speed 3 (1204)

If you think that there is moisture in the motor, 1000 V DC 100 M h

• Keep the drive in its package until you install it. After unpacking, protect the

dry the motor and do the measurement again.

drive from dust, debris and moisture.

• Use the required personal protective equipment: safety shoes with metal toe 5. Select the cables Connection procedure

cap, safety glasses, protective gloves and long sleeves, etc. To prevent inductive coupling, keep the signal wire pairs twisted all the way up

Input power cable: IEC/EN 61800-5-1 requires two protective earth (ground) to the terminals.

• When the drive or connected equipment is energized, do not do work on the conductors. Prefer a symmetrical shielded cable (VFD cable).

drive, motor cable, motor, control cables or control circuits. 5. Strip the outer insulation of the

Motor cable: Use a symmetrical shielded cable (VFD cable) for the best EMC

cable and ground the bare shield

Electrical safety precautions performance and to meet the European EMC requirements.

360 degrees under the clamp.

1. Clearly identify the work location and equipment. Control cable: Use a double-shielded twisted-pair cable for analog signals. Use a

double- or single-shielded cable for digital, relay and I/O signals. Do not mix 24 V 6. Connect the conductors to the

2. Disconnect all possible voltage sources. Make sure that re-connection is not and 115/230 V signals in the same cable. correct control terminals. Torque

possible. Lock out and tag out. the input signals to 0.22 N·m

• Open the main disconnecting device of the drive. 6. Connect the power cables (2 lbf·in) and relay output to 0.5 N·m

• Disconnect any dangerous external voltages from the control circuits. (4.4 lbf·in).

• After you disconnect power from the drive, always wait 5 minutes to let

Connection diagram (shielded cables)

7. For double-shielded cables, twist

the intermediate circuit capacitors discharge before you continue. also the grounding conductors of

Drive

3. Protect any other energized parts in the work location against contact. each pair in the cable together and

connect the bundle to the SCR terminal (terminal 1).

4. Take special precautions when close to bare conductors.

8. Mechanically attach the control cables on the outside of the drive.

5. Measure that the installation is de-energized. PE U1/L V1/N W1 BRK+ BRK- U2 V2 W2

• Use a multimeter with a minimum impedance of 1 Mohm. 1) 1) 8. Start up the drive

• Make sure that the voltage between the drive input power terminals (U1,

V1, W1) and the ground (PE) is close to 0 V. 2) WARNING! Before you start up the drive, make sure that the installation

• Make sure that the voltage between the drive output terminals (U2, V2, is complete. Make sure that the cover of the drive is in place. Make sure

W2) and the ground (PE) is close to 0 V. also that the motor does not cause danger when it starts. Disconnect

• Make sure that the voltage between the drive DC terminals (BRK+ and 5) the motor from other machinery, if there is a risk of damage or injury.

BRK-) and the ground (PE) is close to 0 V. V1 There is an extensive installation checklist in the drive user’s manual.

U1 W1

6. Install temporary grounding as required by the local regulations. 4)

7. Ask the person in control of the electrical installation work for a permit to

Optional brake Before you start, ensure that you have the motor nameplate data at hand.

resistor 3~

work.

Motor

See the drive user’s manual for the complete safety instructions. 3)

PE L1/L L2/N L3/-

1. Examine the installation area

1 360-degree grounding of the cable shield. Required for the motor cable and brake

The drive is intended for cabinet installation and has a degree of protection of resistor cable, recommended for the input power cable.

IP20 / UL open type as standard. 2 Use a separate grounding cable if the conductivity of the cable shield is not sufficient

Make sure that in the installation area: (smaller than the conductivity of the phase conductor) for the protective grounding, or

there is no symmetrically constructed grounding conductor in the cable.

• There is sufficient space above and below the drive for cooling, and hot air 3 In one-phase installations, connect phase to U1/L, neutral to V1/N and leave W1

does not recirculate. Refer to Free space requirements. disconnected.

• The ambient conditions are suitable. Refer to Ambient conditions. 4 Use two grounding conductors if the cross-section of a single grounding conductor is

less than 10 mm2 Cu or 16 mm2 AI (IEC/EN 61800-5-1). For example, use the cable shield

• The mounting surface is non-flammable and can hold the weight of the drive. in addition to the fourth conductor.

Refer to Dimensions and weights. 5 Use a separate grounding cable (line side) if the conductivity of the fourth conductor or

• Materials near the drive are non-flammable. shield is not sufficient for the protective grounding.

• There are no sources of strong magnetic fields, such as high-current single-

core conductors or contactor coils near the drive. A strong magnetic field

can cause interference in the operation of the drive.

Connection procedure (shielded cables)

2. Install the drive WARNING! Make sure that the drive is compatible with the earthing

system. You can connect all drive types to a symmetrically grounded

You can install the drive with screws or to a DIN rail [Top Hat, W x H = 35 × TN-S system. For other systems, see the drive user’s manual.

7.5 mm (1.4 × 0.3 in)].

• Make sure that there is a minimum of 75 mm (3 in) of free space above and 1. Strip the input

below the drive for cooling air. power cable. Ground

• When placing drives on top of each other in a panel or cabinet, make sure the cable shield (if

that the hot air from the drives below do not directly enter the drive above. any) under the

grounding clamp.

Twist the cable

WARNING! Do not install the drive upside down. Make sure that the

shield into a bundle,

cooling air exhaust (at the top) is above the cooling air inlet (at the

mark it accordingly

bottom).

and connect it to the

grounding terminal.

To install the drive with screws Connect other

grounding

1. Cut out the mounting conductors (PE) to the grounding terminal. Connect the phase conductors to

template from the the U1, V1 and W1 terminals.

package and use it to

mark the locations for 2. Strip the motor cable. Ground the cable shield

the mounting holes. under the grounding clamp. Twist the motor

cable shield into a bundle, mark it accordingly

2. Make the holes for the and connect it to the grounding terminal.

mounting screws and Connect the phase conductors to the U2, V2 and

install suitable plugs or W2 terminals.

anchors.

3. If applicable, connect the brake resistor cable to

the BRK+ and BRK- terminals. Use a shielded

cable and ground the shield under the

grounding clamp.

4. Mechanically attach the cables on the outside of

the drive.

POWER-UP Fault codes Free space requirements

Apply input power. This is a short list of fault messages. Above Below Sides

00

LOC

The panel powers up into the Output mode. mm in mm in mm in

OUTPUT

. FWD

Hz Fault

F0001

Description

OVERCURRENT - Output current has exceeded trip level.

75 3 75 3 0 0

3AXD00000353783 L

ENTRY OF START-UP DATA F0002 DC OVERVOLT - Excessive intermediate circuit DC voltage.

Select the application macro (parameter 9902 ) F0003 DEV OVERTEMP - Drive IGBT temperature is excessive.

Markings

9902

LOC S

according to how the control cables are

connected. The default value 1 (ABB STANDARD) F0004 SHORT CIRC - Short-circuit in motor cable(s) or motor.

is suitable in most cases. PAR FWD F0006 DC UNDERVOLT - Intermediate circuit DC voltage is not sufficient.

The applicable markings are shown on the type designation label

The general parameter setting procedure in the F0009 MOT OVERTEMP - Motor temperature estimation is too high.

Short parameter mode is described below.

F0016 EARTH FAULT - Drive has detected earth (ground) fault in motor or motor cable.

1. To go to the Main menu, press if the

F0022 INPUT PHASE LOSS - Intermediate circuit DC voltage is oscillating due to

rEF

LOC

bottom line shows OUTPUT; otherwise press

missing input power line phase or blown fuse.

repeatedly until you see MENU at the CE UL RCM EAC WEEE EIP

bottom. MENU FWD

2. Press keys / until you see

Ratings

PAr S

LOC

“PAr S” on the display. Input Output Frame

ACS150- size

MENU FWD I1N I1N I2N I2,1/10 I2max PN

(480 V)

3. Press . The display shows a parameter x = E/U1) A A A A A kW hp

9902

LOC S

of the Short parameter mode.

1-phase UN = 230 V (200…240 V)

PAR FWD 01x-02A4-2 6.1 - 2.4 3.6 4.2 0.37 0.5 R0

4.Find the appropriate parameter with keys 01x-04A7-2 11.4 - 4.7 7.1 8.2 0.75 1 R1

/

9907

LOC S

. 01x-06A7-2 16.1 - 6.7 10.1 11.7 1.1 1.5 R1

PAR FWD 01x-07A5-2 16.8 - 7.5 11.3 13.1 1.5 2 R2

01x-09A8-2 21.0 - 9.8 14.7 17.2 2.2 3 R2

5. Press and hold for about two seconds

500

LOC 3-phase UN = 230 V (200…240 V)

until the parameter value is shown with SET

under the value. . Hz

PAR SET FWD

03x-02A4-2 4.3 - 2.4 3.6 4.2 0.37 0.5 R0

03x-03A5-2 6.1 - 3.5 5.3 6.1 0.55 0.75 R0

6.Change the value with keys / 03x-04A7-2 7.6 - 4.7 7.1 8.2 0.75 1 R1

600

LOC

. The value changes faster while you

keep the key pressed down. . Hz

PAR SET FWD

03x-06A7-2

03x-07A5-2

11.8

12.0

-

-

6.7

7.5

10.1

11.3

11.7

13.1

1.1

1.5

1.5

2

R1

R1

7. Save the parameter value by pressing . 03x-09A8-2 14.3 - 9.8 14.7 17.2 2.2 3 R2

9907

LOC S

3-phase UN = 400/480 V (380…480 V)

PAR FWD 03x-01A2-4 2.2 1.8 1.2 1.8 2.1 0.37 0.5 R0

03x-01A9-4 3.6 3.0 1.9 2.9 3.3 0.55 0.75 R0

Enter the motor data from the motor nameplate.

9905

LOC S 03x-02A4-4 4.1 3.4 2.4 3.6 4.2 0.75 1 R1

• motor nominal voltage (9905)

• motor nominal current (9906) 03x-03A3-4 6.0 5.0 3.3 5.0 5.8 1.1 1.5 R1

• motor nominal frequency (9907) PAR FWD

03x-04A1-4 6.9 5.8 4.1 6.2 7.2 1.5 2 R1

03x-05A6-4 9.6 8.0 5.6 8.4 9.8 2.2 3 R1

Set the maximum value for external reference

1105

LOC S 03x-07A3-4 11.6 9.7 7.3 11.0 12.8 3 4 R1

REF1 (1105).

03x-08A8-4 13.6 11.3 8.8 13.2 15.4 4 5 R1

PAR FWD

00353783.xls J

Set constant speeds 1, 2 and 3 (1202, 1203, 1204). I1N continuous rms input current (for dimensioning cables and fuses)

1202

LOC S

I1N (480 V) continuous rms input current (for dimensioning cables and fuses) for drives with

480 V input voltage

PAR FWD I2N continuous rms current. 50% overload is allowed for one minute every ten

minutes.

Set the minimum value (%) corresponding to the

I2,1/10 maximum (50% overload) current allowed for one minute every ten minutes

1301

LOC S

minimum signal for AI(1) (1301). Typical settings:

0% for 0…20 mA (or 0…10 V) signal I2max maximum output current. Available for two seconds at start, otherwise as long

20% for 4…20 mA (or 2…10 V) signal as allowed by the drive temperature.

PAR FWD

PN typical motor power. The kilowatt ratings apply to most IEC 4-pole motors. The

Set the maximum limit for the drive output horsepower ratings apply to most NEMA 4-pole motors.

2008

LOC S

frequency (2008). This is equal to power line

frequency, typically. That is: 50 or 60 Hz.

PAR FWD Fuses and typical power cable sizes

Select the motor stop function (2102). The table list the fuses for protection against short-circuits in the input power

2102

LOC S cable or drive. The table also shows typical power cable sizes.

1 = Stop by cutting off the motor power supply.

Motor coasts to stop.

2 = Stop along ramp defined by parameter. ACS150-…x Fuses Size of CU conductor in cablings

PAR FWD

= E/U gG UL Supply Motor PE Brake

DIRECTION OF THE MOTOR ROTATION Class T (U1, V1, W1) (U2, V2, W2) (BRK+ and

Check the direction of the motor rotation. (600 V) BRK-)

1202

LOC S

A A mm2 AWG mm2 AWG mm2 AWG mm2 AWG

1. Turn the potentiometer fully

counterclockwise. 1-phase UN = 230 V (200…240 V)

PAR FWD

2. If the drive is in remote control (REM shown on 01x-02A4-2 10 10 2.5 14 0.75 18 2.5 14 2.5 14

the left), switch to local control by pressing

LOC

REM .

01x-04A7-2 16 20 2.5 14 0.75 18 2.5 14 2.5 14

3. Press to start the motor. 01x-06A7-2 16/20 1) 25 2.5 10 1.5 14 2.5 10 2.5 12

4.Turn the potentiometer slightly clockwise until

01x-07A5-2 20/25 1) 30 2.5 10 1.5 14 2.5 10 2.5 12

the motor rotates. forward reverse

5. Check that the actual direction of the motor is 01x-09A8-2 25/35 1) 35 6 10 2.5 12 6 10 6 12

the same as indicated on the display (FWD 3-phase UN = 230 V (200…240 V)

means forward and REV reverse).

6.Press to stop the motor. 03x-02A4-2 10 10 2.5 14 0.75 18 2.5 14 2.5 14

To change the direction of the motor rotation: 03x-03A5-2 10 10 2.5 14 0.75 18 2.5 14 2.5 14

1. Disconnect input power from the drive, and 03x-04A7-2 10 15 2.5 14 0.75 18 2.5 14 2.5 14

wait 5 minutes for the intermediate circuit

03x-06A7-2 16 15 2.5 12 1.5 14 2.5 12 2.5 12

capacitors to discharge. Lock out and tag out.

Measure the voltage between each input 03x-07A5-2 16 15 2.5 12 1.5 14 2.5 12 2.5 12

terminal (U1, V1 and W1) and earth with a 03x-09A8-2 16 20 2.5 12 2.5 12 2.5 12 2.5 12

multimeter to ensure that the drive is

discharged. 3-phase UN = 400/480 V (380…480 V)

2. Exchange the position of two motor cable 03x-01A2-4 10 10 2.5 14 0.75 18 2.5 14 2.5 14

phase conductors at the drive output

terminals or at the motor connection box. 03x-01A9-4 10 10 2.5 14 0.75 18 2.5 14 2.5 14

3. Verify your work by applying input power and 03x-02A4-4 10 10 2.5 14 0.75 18 2.5 14 2.5 14

repeating the check as described above.

03x-03A3-4 10 10 2.5 12 0.75 18 2.5 12 2.5 12

ACCELERATION/DECELERATION TIMES 03x-04A1-4 16 15 2.5 12 0.75 18 2.5 12 2.5 12

Set the acceleration time 1 (2202) and 03x-05A6-4 16 15 2.5 12 1.5 14 2.5 12 2.5 12

2202

LOC S

deceleration time 1 (2203).

03x-07A3-4 16 20 2.5 12 1.5 14 2.5 12 2.5 12

PAR FWD 03x-08A8-4 20 25 2.5 12 2.5 12 2.5 12 2.5 12

FINAL CHECK 00353783.xls J

1) If 50% overload capacity is needed, use the larger fuse alternative.

The start-up is now completed. If you want to

Ambient conditions

9902

LOC S

save your setting as a user macro, scroll to

Parameter 9902 and select value -1 (USER S1

SAVE). PAR FWD Requirement During operation (installed for stationary use)

Installation altitude 0…2000 m (0…6562 ft) above sea level (with output derating

Check that there are no faults or alarms shown above 1000 m [3281 ft])

on the display. Surrounding air -10…+50 °C (14…122 °F). If the temperature is more than 40 °C

The drive is now ready for use. temperature (104 °F), output derating is necessary. No frost permitted.

Relative humidity 0…95% without condensation

Contamination levels No conductive dust permitted

(IEC 60721-3-3: 2002)

Shock (IEC 60068-2-27, Not permitted

ISTA 1A)

Free fall Not permitted

Dimensions and weights

IP20 (cabinet) / UL open

Frame H1 H2 H3 W D Weight

size mm in mm in mm in mm in mm in kg lb

R0 169 6.65 202 7.95 239 9.41 70 2.76 142 5.59 1.1 2.4

R1 169 6.65 202 7.95 239 9.41 70 2.76 142 5.59 1.3/1.21) 2.9/2.61)

R2 169 6.65 202 7.95 239 9.41 105 4.13 142 5.59 1.5 3.3

IP20 / NEMA 1

Related documents

Frame H4 H5 W D - Weight

ACS150 user’s manual ACS150 manual list size mm in mm in mm in mm in - - kg lb

R0 257 10.12 280 11.02 70 2.76 142 5.59 - - 1.5 3.3

R1 257 10.12 280 11.02 70 2.76 142 5.59 - - 1.7/1.61) 3.7/3.51)

R2 257 10.12 282 11.10 105 4.13 142 5.59 - - 1.9 4.2

3AXD00000353783 L

1) 200 V unit weight / 400 V unit weight

IP20 (cabinet) / UL open

H1 height without fastenings or clamping plate

3AFE68576032 9AKK107680A5637 H2 height with fastening and without clamping plate

H3 height with fastenings and clamping plate

W width

3AXD50000625970 Rev A EN 2020-04-21 D depth

© Copyright 2020 ABB. All rights reserved. IP20 / NEMA 1 (drive with optional MUL-xx kit installed)

H4 height with fastenings and connection box

H5 height with fastenings, connection box and hood

You might also like

- CAT EP18k Controller TroubleshootingDocument135 pagesCAT EP18k Controller TroubleshootingMelwyn Fernandes90% (10)

- SJ-20170222143308-003-ZXONE 7000 Quick Installation GuideDocument36 pagesSJ-20170222143308-003-ZXONE 7000 Quick Installation GuidedbeneditoNo ratings yet

- DM-27 Part2Document14 pagesDM-27 Part2Adrian CantaragiuNo ratings yet

- NW4000 Pre-Survey FormDocument42 pagesNW4000 Pre-Survey FormSuresh KumarNo ratings yet

- Automated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsFrom EverandAutomated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsNo ratings yet

- NKF-770 TD Exchange Procedure (JLN-550Ver1 0)Document11 pagesNKF-770 TD Exchange Procedure (JLN-550Ver1 0)Abel Francisco Villadiego CaballeroNo ratings yet

- Cable Harness Assembly: DFA Product Simpli IcationDocument3 pagesCable Harness Assembly: DFA Product Simpli IcationSharun JacobNo ratings yet

- ManualDocument2 pagesManualHans DosalNo ratings yet

- En Acs355 Qisg C A3Document2 pagesEn Acs355 Qisg C A3Ousséma DridiNo ratings yet

- MVP Inst CardDocument1 pageMVP Inst CardOscar Behrens ZepedaNo ratings yet

- Smt-76246 - Led Light Bar WiringDocument4 pagesSmt-76246 - Led Light Bar WiringWilliam SelokaNo ratings yet

- YORK VRF Old Fashion Wired Remote Controller JCWA10NEWQ - Installation & Operation Manual - H7W02215 PDFDocument12 pagesYORK VRF Old Fashion Wired Remote Controller JCWA10NEWQ - Installation & Operation Manual - H7W02215 PDFFadul Chamie TietjenNo ratings yet

- WEG Molded Case Circuit Breakers: User's ManualDocument12 pagesWEG Molded Case Circuit Breakers: User's ManualfelipeNo ratings yet

- M7635C - 7608 - 7612 QigDocument2 pagesM7635C - 7608 - 7612 QigVictor BitarNo ratings yet

- Kits Mpguino Assemble GASOLINE ECONOMY KITDocument10 pagesKits Mpguino Assemble GASOLINE ECONOMY KITMC. Rene Solis R.No ratings yet

- Combinacion Diales MecanicosDocument5 pagesCombinacion Diales MecanicosHo MeGaNo ratings yet

- Actuator-Sensor-Interface: I/O Modules For Operation in The Field (IP 65/67)Document7 pagesActuator-Sensor-Interface: I/O Modules For Operation in The Field (IP 65/67)chochoroyNo ratings yet

- USSLxxxWPL Installation InstructionDocument6 pagesUSSLxxxWPL Installation InstructionHarlen Joan Pardo BergaminNo ratings yet

- Iq 4Document12 pagesIq 4Jose ManuelNo ratings yet

- Wall Mount Enclosure Installation Instructions: 920i Programmable HMI Indicator/ControllerDocument6 pagesWall Mount Enclosure Installation Instructions: 920i Programmable HMI Indicator/ControllerNijam JabbarNo ratings yet

- ELSB - Cat - Product News - 2020 - Preview - 21-10-2020Document242 pagesELSB - Cat - Product News - 2020 - Preview - 21-10-2020PRABHU SHANKAR MNo ratings yet

- 92W Module Series: FWAVE Solar ModulesDocument2 pages92W Module Series: FWAVE Solar Modulestjt_062560No ratings yet

- XMC Odu V200 - QigDocument51 pagesXMC Odu V200 - QigAlexander PischulinNo ratings yet

- Cold Shrink: QSG - AP SerieDocument2 pagesCold Shrink: QSG - AP SerieAVA VANo ratings yet

- Terminating Head 58247 - 1 For MTA - 156 Receptacle Connectors Using Discrete WireDocument5 pagesTerminating Head 58247 - 1 For MTA - 156 Receptacle Connectors Using Discrete WiremaorNo ratings yet

- Serial Controller Installation & Interface GuideDocument40 pagesSerial Controller Installation & Interface GuideViệt Thảo TrầnNo ratings yet

- Advance CR BF Manual 1308-1 eDocument2 pagesAdvance CR BF Manual 1308-1 ehikmah jevie yusriNo ratings yet

- Acs355 Drives Quick Inst Guide A ScreenDocument10 pagesAcs355 Drives Quick Inst Guide A ScreenJanaka Bandara EkanayakaNo ratings yet

- DKE318 ch05Document61 pagesDKE318 ch05giri00767098No ratings yet

- Acs 880 Guia RapidaDocument88 pagesAcs 880 Guia Rapidaarmando olivaresNo ratings yet

- Field Termination-CAT6A Keystone ModuleDocument4 pagesField Termination-CAT6A Keystone ModuleInfas YahyaNo ratings yet

- Conector SondaDocument25 pagesConector SondaCesar MarquesNo ratings yet

- Certificado Conformidad CarpinterDocument8 pagesCertificado Conformidad CarpinterJefferson VargasNo ratings yet

- LH-3000 InterconnectDocument3 pagesLH-3000 InterconnecttuyenNo ratings yet

- Series Border Installation GuideDocument1 pageSeries Border Installation GuideSpenNo ratings yet

- Pc-Ar 2007Document12 pagesPc-Ar 2007Augusto OrellanaNo ratings yet

- IM&OM - PC-AR - enDocument12 pagesIM&OM - PC-AR - enzodenapeNo ratings yet

- Scope Component Test UnitDocument4 pagesScope Component Test UnitLee LeeNo ratings yet

- DX-40, DX-60, DX-40 PLUS, DX-60 PLUS: FeaturesDocument4 pagesDX-40, DX-60, DX-40 PLUS, DX-60 PLUS: FeaturesIulia GvrNo ratings yet

- Samsung Dvd-V3650 Chassis Diva Training ManualDocument202 pagesSamsung Dvd-V3650 Chassis Diva Training ManualPaulo Henrique SNo ratings yet

- AV485Document4 pagesAV485AF VMNo ratings yet

- Wideband O2 Sensor - Part2Document10 pagesWideband O2 Sensor - Part2René100% (1)

- ZXCTN 6120S Quick Installation Guide: Safety InstructionsDocument23 pagesZXCTN 6120S Quick Installation Guide: Safety InstructionsYuniar Mita RuswandiNo ratings yet

- Model 750 Gas Meter Installation, Commissioning and Maintenance ManualDocument2 pagesModel 750 Gas Meter Installation, Commissioning and Maintenance ManualHtoo MyatNo ratings yet

- Installation & Technical Information: Code No: Voltage: Light Source: CurrentDocument2 pagesInstallation & Technical Information: Code No: Voltage: Light Source: CurrentsdfkjgskfNo ratings yet

- Ethernet Assembly Plug Assembly Instruction Manual: Parts ConfigurationDocument1 pageEthernet Assembly Plug Assembly Instruction Manual: Parts ConfigurationIvan Paul Medellin CastroNo ratings yet

- xmc3 Qig r11Document46 pagesxmc3 Qig r11JuanNo ratings yet

- bp2517 Triaxial CCLD Accelerometer Types 4529-BDocument8 pagesbp2517 Triaxial CCLD Accelerometer Types 4529-BategNo ratings yet

- Esenselite 2x2 Cut SheetDocument2 pagesEsenselite 2x2 Cut Sheetamey.sankheNo ratings yet

- 2090-Series Power and Feedback Cables: Installation InstructionsDocument12 pages2090-Series Power and Feedback Cables: Installation InstructionsMisael PiñaNo ratings yet

- Quick Guide: Replacement of The SUN2000 - (8KTL-12KTL) andDocument25 pagesQuick Guide: Replacement of The SUN2000 - (8KTL-12KTL) andWagner FerreiraNo ratings yet

- HMS-2000-4T Quick Installation Guide: 1. AccessoriesDocument2 pagesHMS-2000-4T Quick Installation Guide: 1. AccessoriesOscar Fernando Roque PardoNo ratings yet

- 993012G InstallDocument16 pages993012G InstallHomer McOwenNo ratings yet

- En Acs560 Qisg JDocument306 pagesEn Acs560 Qisg JTashmeet SinghNo ratings yet

- Base Station/Repeater Antenna: CP22E Specifications AssemblyDocument2 pagesBase Station/Repeater Antenna: CP22E Specifications AssemblyChris GuarinNo ratings yet

- 2198-In010 - En-P 2198-K57CK-D15MDocument4 pages2198-In010 - En-P 2198-K57CK-D15MMaximilianoAlvarezNo ratings yet

- Crankshaft Front SealDocument4 pagesCrankshaft Front SealFredy QuistialNo ratings yet

- 1734 In510 - en P PDFDocument12 pages1734 In510 - en P PDFAraik AmbartsumyanNo ratings yet

- (3AUA0000001558) - ACS550-U1 - QS - REVF FG KNDDocument2 pages(3AUA0000001558) - ACS550-U1 - QS - REVF FG KNDPrdptiwariNo ratings yet

- OptiX PTN 910E-F Quick Installation Guide 04Document16 pagesOptiX PTN 910E-F Quick Installation Guide 04AbdulrahmanNo ratings yet

- Quick Installation Guide: RTN XMC Odu V200Document51 pagesQuick Installation Guide: RTN XMC Odu V200Emanuel GabrielNo ratings yet

- Stream Pump FSP 2000Document11 pagesStream Pump FSP 2000potoculNo ratings yet

- Gardena: WWW - Devicemanuals.euDocument10 pagesGardena: WWW - Devicemanuals.eupotoculNo ratings yet

- UVC-pond Filter F 3000Document9 pagesUVC-pond Filter F 3000potoculNo ratings yet

- BTP 600Document9 pagesBTP 600potoculNo ratings yet

- Filter Set 5000Document6 pagesFilter Set 5000potoculNo ratings yet

- WWW - Devicemanuals.eu: GebrauchsanweisungDocument10 pagesWWW - Devicemanuals.eu: GebrauchsanweisungpotoculNo ratings yet

- FFP 3000 5000Document10 pagesFFP 3000 5000potoculNo ratings yet

- 18000SP InoxDocument11 pages18000SP InoxpotoculNo ratings yet

- Turbotrimmer AccuCut 400 LiDocument10 pagesTurbotrimmer AccuCut 400 LipotoculNo ratings yet

- 6000 5 Inox LCDDocument17 pages6000 5 Inox LCDpotoculNo ratings yet

- Anti Frost Pump IP300Document17 pagesAnti Frost Pump IP300potoculNo ratings yet

- 9000 S InoxDocument6 pages9000 S InoxpotoculNo ratings yet

- Filter Set 3000Document6 pagesFilter Set 3000potoculNo ratings yet

- SL AutomaticDocument10 pagesSL AutomaticpotoculNo ratings yet

- WWW - Devicemanuals.eu: GardenaDocument6 pagesWWW - Devicemanuals.eu: GardenapotoculNo ratings yet

- WWW - Devicemanuals.eu: GardenaDocument6 pagesWWW - Devicemanuals.eu: GardenapotoculNo ratings yet

- Battery Pump 1500 1Document11 pagesBattery Pump 1500 1potoculNo ratings yet

- WWW - Devicemanuals.eu: GardenaDocument8 pagesWWW - Devicemanuals.eu: GardenapotoculNo ratings yet

- 7000 SLDocument10 pages7000 SLpotoculNo ratings yet

- 5000 3SGPDocument7 pages5000 3SGPpotoculNo ratings yet

- 6500 SPDocument10 pages6500 SPpotoculNo ratings yet

- WWW - Devicemanuals.eu: 6000 S Art. 1777 6000 SP Art. 1790Document12 pagesWWW - Devicemanuals.eu: 6000 S Art. 1777 6000 SP Art. 1790potoculNo ratings yet

- WWW - Devicemanuals.eu: GardenaDocument10 pagesWWW - Devicemanuals.eu: GardenapotoculNo ratings yet

- 4000 6 InoxDocument10 pages4000 6 InoxpotoculNo ratings yet

- 3000 4 Electronic PlusDocument14 pages3000 4 Electronic PluspotoculNo ratings yet

- 3000 3 JetDocument12 pages3000 3 JetpotoculNo ratings yet

- Automower 305 ENDocument66 pagesAutomower 305 ENpotoculNo ratings yet

- Husqvarna T540 XP IiDocument36 pagesHusqvarna T540 XP IipotoculNo ratings yet

- Automower 230 ACX 220 AC ENDocument76 pagesAutomower 230 ACX 220 AC ENpotoculNo ratings yet

- OnePlus Nord CE 2Document118 pagesOnePlus Nord CE 2potoculNo ratings yet

- 1HYB800001-042A-OM Manual (1-Pole) PDFDocument193 pages1HYB800001-042A-OM Manual (1-Pole) PDFFredy MedranoNo ratings yet

- QNET ROTPEN User ManualDocument26 pagesQNET ROTPEN User ManualSuryabhan SinghNo ratings yet

- Active Front SteeringDocument19 pagesActive Front SteeringENIC-AITCG100% (2)

- Electric Circuits and Machines Electronics EngineeringDocument4 pagesElectric Circuits and Machines Electronics EngineeringArjun KhatiwadaNo ratings yet

- On-Line MCSA To Diagnose Shorted Turns in Low Voltage Stator Windings of 3-Phase Induction Motors Prior To FailureDocument8 pagesOn-Line MCSA To Diagnose Shorted Turns in Low Voltage Stator Windings of 3-Phase Induction Motors Prior To FailureJairo CorimanyaNo ratings yet

- Brushless DC Motor Uses Slotless DesignDocument7 pagesBrushless DC Motor Uses Slotless DesigntutulungoqwertyNo ratings yet

- Is 6362 1995Document22 pagesIs 6362 1995HVHBVNo ratings yet

- Zu Series Electric PumpDocument6 pagesZu Series Electric PumpMAINTENANCE PH KGPS projectNo ratings yet

- Brake Motor Manual E - MM0202EDocument27 pagesBrake Motor Manual E - MM0202EThinh Nguyen100% (1)

- Lovely Professional University: TOPIC: - " "Document7 pagesLovely Professional University: TOPIC: - " "Ravinder SinghNo ratings yet

- OM0401 Overview of Turbine Version GDocument41 pagesOM0401 Overview of Turbine Version Gمحمد خالد100% (1)

- WEG Installation, Operation and Maintenance ManualDocument55 pagesWEG Installation, Operation and Maintenance ManualMichael HailuNo ratings yet

- N1 AM E01 20130222 AlarmDocument82 pagesN1 AM E01 20130222 AlarmThanh TranNo ratings yet

- Strickland ManualDocument54 pagesStrickland ManualJorge Alonso Fernandez100% (1)

- Centrifugal Fan - General InstructionDocument13 pagesCentrifugal Fan - General InstructionVuong GiaNo ratings yet

- Main CentrifugeDocument77 pagesMain CentrifugeLELISA GELANA100% (1)

- Magnetism ElectromagnetismDocument58 pagesMagnetism ElectromagnetismRomulo TindoyNo ratings yet

- 123638E Datasheet enDocument8 pages123638E Datasheet enNguyen Quoc ChienNo ratings yet

- Discovery of BLDC Motor: Brushless vs. Brushed DC MotorDocument9 pagesDiscovery of BLDC Motor: Brushless vs. Brushed DC MotorNoni MaheshwariNo ratings yet

- LSBLGF140S-F 说明书 - 英文 -Document20 pagesLSBLGF140S-F 说明书 - 英文 -Kenneth Gerald RodriguezNo ratings yet

- Trip Analysis Recommendation For The FY 2020-21 (660 MW Units)Document45 pagesTrip Analysis Recommendation For The FY 2020-21 (660 MW Units)sudhakarautomatic9940No ratings yet

- Conversion de Energia Electromagnetica - MitDocument414 pagesConversion de Energia Electromagnetica - MitneoslayferNo ratings yet

- Wood Ward GovernorDocument38 pagesWood Ward Governornack89No ratings yet

- Mooring Winch Windlass - Pusnes - 320EW-350EWDocument11 pagesMooring Winch Windlass - Pusnes - 320EW-350EWjohn smith100% (1)

- SEW-Eurodrive UnitDocument4 pagesSEW-Eurodrive UnitYohn Deivi Espinoza ZarateNo ratings yet

- Heat Pump: Gea RedastrumDocument56 pagesHeat Pump: Gea RedastrumTín LêNo ratings yet

- CNC Design Coil Winder Software Manual ARM MKII V1 0Document51 pagesCNC Design Coil Winder Software Manual ARM MKII V1 0waldo100100% (1)

- Petra CatalogueDocument8 pagesPetra Catalogue113314No ratings yet