Professional Documents

Culture Documents

Assignment - 01: Department of Mechanical Engineering National University of Technology Machine Design II (ME-3442)

Assignment - 01: Department of Mechanical Engineering National University of Technology Machine Design II (ME-3442)

Uploaded by

Muscle TVCopyright:

Available Formats

You might also like

- RIICWD533E Assessment ManualDocument31 pagesRIICWD533E Assessment ManualMuscle TV100% (1)

- Kpi Guideline PDFDocument44 pagesKpi Guideline PDFSteve Demirel100% (1)

- Snake Game Project ReportDocument15 pagesSnake Game Project ReportChoudhary75% (4)

- Description of Composites Coursework: Design and Analysis of A Laminated Composite TubeDocument2 pagesDescription of Composites Coursework: Design and Analysis of A Laminated Composite TubeAnh DoNo ratings yet

- Write To or Retrieve From Media Object - Text by Deepesh - JDE SourceDocument14 pagesWrite To or Retrieve From Media Object - Text by Deepesh - JDE SourceSatishNo ratings yet

- ICE Assignments 3 4 5Document3 pagesICE Assignments 3 4 5benzmr869No ratings yet

- 12154Document20 pages12154NobodyNo ratings yet

- UME 1503 - Assignment-2Document1 pageUME 1503 - Assignment-2yuvalakshmi222No ratings yet

- Faculty of Engineering Science and TechnologyDocument1 pageFaculty of Engineering Science and TechnologyGilt RNo ratings yet

- Meng 310 Exam 01 Spring 2011Document4 pagesMeng 310 Exam 01 Spring 2011Abdulrahman AlzahraniNo ratings yet

- HW 3 AnswersDocument11 pagesHW 3 AnswersCoryna Wan Chun WahNo ratings yet

- ME352 - Case Study 1Document10 pagesME352 - Case Study 1اسعد الماوريNo ratings yet

- All Assignments Questions - Control of AC and DC Drives Fall-2020Document3 pagesAll Assignments Questions - Control of AC and DC Drives Fall-2020TaLhA ChauDhrYNo ratings yet

- MEHB3013 S1 2122 Test 1Document2 pagesMEHB3013 S1 2122 Test 1syedadlan12No ratings yet

- Assignment Feb 21-Ver 1Document8 pagesAssignment Feb 21-Ver 1ostaz onlineNo ratings yet

- ME 321 Final Term Exam OBE Format - CLO MappingDocument7 pagesME 321 Final Term Exam OBE Format - CLO MappingSaad RasheedNo ratings yet

- Machine Design 2 Lecture Midterm ExamDocument3 pagesMachine Design 2 Lecture Midterm ExamNazareno Religioso MateoNo ratings yet

- HNC Eng Sci Assignment 2 Brief 1Document9 pagesHNC Eng Sci Assignment 2 Brief 1Noel JenningsNo ratings yet

- Important Instructions To ExaminersDocument30 pagesImportant Instructions To ExaminersDiyaNegiNo ratings yet

- Subject Code: 17529 SUMMER - 15 EXAMINATION Model AnswerDocument19 pagesSubject Code: 17529 SUMMER - 15 EXAMINATION Model AnswerSuraj KambleNo ratings yet

- 2nd Term CADCAM Q PaperDocument1 page2nd Term CADCAM Q Paperanadinath sharmaNo ratings yet

- Semester Examination: Section - BDocument3 pagesSemester Examination: Section - BNitin TembhurnikarNo ratings yet

- MECH 344 - Final Exam (Winter 2021)Document4 pagesMECH 344 - Final Exam (Winter 2021)Puneet Rudhar100% (1)

- Confidential Ee/Oct 2009/EPE491/KJK559: Instructions To CandidatesDocument2 pagesConfidential Ee/Oct 2009/EPE491/KJK559: Instructions To CandidatesnualdinNo ratings yet

- Cad-Cam - Ittd2 - 2020Document3 pagesCad-Cam - Ittd2 - 2020Tafara DarangwaNo ratings yet

- Cutting Temperature and Laser Beam Temperature Effects On Cutting Tool Deformation in Laser-Assisted MachiningDocument6 pagesCutting Temperature and Laser Beam Temperature Effects On Cutting Tool Deformation in Laser-Assisted MachiningrrameshsmitNo ratings yet

- Project Assignment Electric Motor Drives (MKE 1153) Semester II, Session 2009/2010Document4 pagesProject Assignment Electric Motor Drives (MKE 1153) Semester II, Session 2009/2010Nur AdiimahNo ratings yet

- Rotation Problem SetDocument1 pageRotation Problem SetmeytaNo ratings yet

- F-43 PEMP Assignment Problem Statement - ACD2506 - PT13 - TodoDocument5 pagesF-43 PEMP Assignment Problem Statement - ACD2506 - PT13 - TodoSumit MalikNo ratings yet

- DMM2 I Mid 2024Document1 pageDMM2 I Mid 2024Rkrishna ANo ratings yet

- Me192007 - Mechanical - 21 - End SemDocument2 pagesMe192007 - Mechanical - 21 - End SemJayesh KumavatNo ratings yet

- Me8493 - Te-I (Iat 2) QPDocument2 pagesMe8493 - Te-I (Iat 2) QPBhagavathi ShankarNo ratings yet

- Soalan Projek PSPD LatestDocument9 pagesSoalan Projek PSPD LatestAzlan AliNo ratings yet

- R16 B.Tech Mechanical EnggDocument34 pagesR16 B.Tech Mechanical EnggmechhodNo ratings yet

- Irjet V7i3706Document6 pagesIrjet V7i3706smabhibidkar2001No ratings yet

- Ca - 1 - 2020Document2 pagesCa - 1 - 2020Dilshan VimukthiNo ratings yet

- Routine Gmaw Student TaskDocument8 pagesRoutine Gmaw Student Taskapi-200253170No ratings yet

- UTA013 Engineering Design Project-I: TIET, Patiala Mechanical Engineering DepartmentDocument9 pagesUTA013 Engineering Design Project-I: TIET, Patiala Mechanical Engineering DepartmentDevid gakharNo ratings yet

- Set Up Computer System Unit ComponentsDocument4 pagesSet Up Computer System Unit Componentsepi_reveNo ratings yet

- 2nd Order Calculation: EurocodeDocument10 pages2nd Order Calculation: EurocodekeithtianNo ratings yet

- HES3350 Machine Design Semester 1 2012 Assignment 1 Compound Reverted Gear Train Design PDFDocument18 pagesHES3350 Machine Design Semester 1 2012 Assignment 1 Compound Reverted Gear Train Design PDFrisirarocksNo ratings yet

- Sas Lesson 12 Ele 103Document14 pagesSas Lesson 12 Ele 103Arnold GacangNo ratings yet

- 3 EMD Test 2 Sem1 - 21 - 22Document6 pages3 EMD Test 2 Sem1 - 21 - 22nelissa nazriNo ratings yet

- Mid Fall22 SRDocument7 pagesMid Fall22 SR22p0294No ratings yet

- Electrical MaintenanceDocument32 pagesElectrical MaintenanceYogesh BadheNo ratings yet

- Cad-Cam - Ittd3 - 2020Document3 pagesCad-Cam - Ittd3 - 2020Tafara DarangwaNo ratings yet

- Ass.2 2011 Veh Ausama (U 5) .Final2Document11 pagesAss.2 2011 Veh Ausama (U 5) .Final2Osama HassanNo ratings yet

- Hamdard University, FEST North Nazimabad Campus Final Examination, Fall - 2020Document2 pagesHamdard University, FEST North Nazimabad Campus Final Examination, Fall - 2020Zain AliNo ratings yet

- UnlockedDocument1 pageUnlockedRAFIQUE UL ISLAMNo ratings yet

- Piston Strength Analysis Using FEM: Swati S Chougule, Vinayak H KhatawateDocument8 pagesPiston Strength Analysis Using FEM: Swati S Chougule, Vinayak H KhatawateRam TirumalasettiNo ratings yet

- Model Answer Paper Winter 2019Document15 pagesModel Answer Paper Winter 2019Vaishali TurambekarNo ratings yet

- Winter - 16 Examination Model Answer Subject CodeDocument15 pagesWinter - 16 Examination Model Answer Subject CodeDiyaNegiNo ratings yet

- Fy Ee Sem II Bme 22214 QP Model AnswersDocument49 pagesFy Ee Sem II Bme 22214 QP Model Answers1345Pranmya LadEENo ratings yet

- 26 12 2023 (Morning)Document9 pages26 12 2023 (Morning)UPS1971No ratings yet

- ASSESSMENT BRIEF 2021-2022: Date of Submission: 15Document10 pagesASSESSMENT BRIEF 2021-2022: Date of Submission: 15enghesham2014No ratings yet

- STEMII Assignment Final Version SpringDocument12 pagesSTEMII Assignment Final Version SpringSsos.mowNo ratings yet

- Computer Integrated Manufacturing 15ME62TDocument15 pagesComputer Integrated Manufacturing 15ME62TRaghuraj DanadamNo ratings yet

- Dtsi TechnologyDocument32 pagesDtsi TechnologySaurabh SinghNo ratings yet

- Combustion Lecture Midterm ExamDocument3 pagesCombustion Lecture Midterm ExamNazareno Religioso MateoNo ratings yet

- Curriculum For Two Years PartyDocument7 pagesCurriculum For Two Years PartytaridanNo ratings yet

- Mid SMR23 JRDocument5 pagesMid SMR23 JR22p0294No ratings yet

- Plate Format For PPEDocument11 pagesPlate Format For PPEdominiqueNo ratings yet

- Beo 4Document2 pagesBeo 4Muscle TVNo ratings yet

- National University of TechnologyDocument2 pagesNational University of TechnologyMuscle TVNo ratings yet

- 29 Sarmad Nadeem Numerical Anaylsis Lab Report 1Document4 pages29 Sarmad Nadeem Numerical Anaylsis Lab Report 1Muscle TVNo ratings yet

- Lecture 02 Bending in BeamDocument74 pagesLecture 02 Bending in BeamMuscle TVNo ratings yet

- Task 2Document5 pagesTask 2Muscle TVNo ratings yet

- Pulse Connect Secure (PCS) 9.0Rx - 9.1R4: New Feature IntroductionDocument37 pagesPulse Connect Secure (PCS) 9.0Rx - 9.1R4: New Feature IntroductionNetsys BilisimNo ratings yet

- Method Statement For External Painting Work With Using Suspended PlatformDocument22 pagesMethod Statement For External Painting Work With Using Suspended PlatformĐặng Quang HuyNo ratings yet

- STEP 1: Server PC SettingsDocument3 pagesSTEP 1: Server PC SettingsJason EchevariaNo ratings yet

- Python Programming 3 Books in 1Document269 pagesPython Programming 3 Books in 1n7tpubhzx100% (2)

- Compressor Unit Technical Data Sheet - I15.1-7.5-VDocument10 pagesCompressor Unit Technical Data Sheet - I15.1-7.5-VMohamed MusaNo ratings yet

- Assignment On Strategic Management: Submitted To: Prof. S.P. SinghDocument17 pagesAssignment On Strategic Management: Submitted To: Prof. S.P. SinghVikram MayuriNo ratings yet

- Videojet - UDI PrintersDocument2 pagesVideojet - UDI PrintersSACHIN KUMARNo ratings yet

- Bomb Defusing Robotic Arm Using Gesture Control IJERTV4IS020105Document5 pagesBomb Defusing Robotic Arm Using Gesture Control IJERTV4IS020105VirajReddyNo ratings yet

- Datasheet Tellabs 6325 EDGE NodeDocument2 pagesDatasheet Tellabs 6325 EDGE NodeBoby Rahmadi100% (1)

- MSMV Steam Turbine Centrifugal Compressor YR Turbine Lube & Seal SystemDocument1 pageMSMV Steam Turbine Centrifugal Compressor YR Turbine Lube & Seal Systemadam yassineNo ratings yet

- SAP ARIBA ConfigsDocument65 pagesSAP ARIBA ConfigsSudhakar PatnamNo ratings yet

- Power Platform 2021 Release Wave 1 PlanDocument162 pagesPower Platform 2021 Release Wave 1 Planbhargavreddy3veerapaNo ratings yet

- LtpoDocument2 pagesLtpololaNo ratings yet

- Atpg GD PDFDocument608 pagesAtpg GD PDFAnitesh Sharma50% (2)

- Presentation On Grameen-Phone & Banglalink (MGT)Document28 pagesPresentation On Grameen-Phone & Banglalink (MGT)Samira Khan100% (1)

- Reinforcement Steel BarDocument64 pagesReinforcement Steel BardesignNo ratings yet

- Mirage Installation With DSKDocument15 pagesMirage Installation With DSKRodolfo AlbinoNo ratings yet

- S77 Power Curve enDocument3 pagesS77 Power Curve enGI DNo ratings yet

- Refinery Power OutageDocument16 pagesRefinery Power Outagepradeep.spaceman100% (2)

- 10-Bit Digital-To-Analog Converters: Features DescriptionDocument22 pages10-Bit Digital-To-Analog Converters: Features Descriptionwolvering2009No ratings yet

- Unily 8 Ways Guide PDFDocument12 pagesUnily 8 Ways Guide PDFVanes PilavNo ratings yet

- 7 - Claudia - Cloud Intelligence For Decision Making Support and AnalysisDocument1 page7 - Claudia - Cloud Intelligence For Decision Making Support and Analysisyo makNo ratings yet

- 08 BSCM v3.2 MasterDocument74 pages08 BSCM v3.2 MasterMostafaNo ratings yet

- 2020 State of DevOps ReportDocument54 pages2020 State of DevOps ReportproguiNo ratings yet

- DBMS MCQDocument94 pagesDBMS MCQJohn J100% (1)

- Essentials of Communication Electronics: EngineeringDocument1 pageEssentials of Communication Electronics: EngineeringAwaisMushtaqNo ratings yet

- OpenGL InstallationDocument3 pagesOpenGL Installationkaleab tesfayeNo ratings yet

Assignment - 01: Department of Mechanical Engineering National University of Technology Machine Design II (ME-3442)

Assignment - 01: Department of Mechanical Engineering National University of Technology Machine Design II (ME-3442)

Uploaded by

Muscle TVOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assignment - 01: Department of Mechanical Engineering National University of Technology Machine Design II (ME-3442)

Assignment - 01: Department of Mechanical Engineering National University of Technology Machine Design II (ME-3442)

Uploaded by

Muscle TVCopyright:

Available Formats

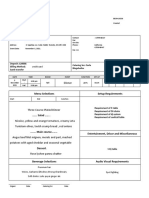

Department of Mechanical Engineering

National University of Technology

Machine Design II (ME-3442)

Assignment -01

Fall-2022

Instructor: Engr. Ali Raza Marks= 40 [CLO-3] [PLO-3]

Name: ________________ Student ID ____________

Instructions:

Use A4 pages for the assignment solution.

Plagiarism is strictly prohibited.

This is an individual work and students are not allowed to work in groups.

Assignments received after due date would not be accepted.

Mathematical derivations and expressions should be defined clearly.

Step by step solution is mandatary to achieve full marks.

Use this page as first page and number all the pages.

Draw clear figures where necessary.

Question-01

Design a journal bearing for a centrifugal pump from the following data:

Load on the journal = 20 000 N; Speed of the journal = 900 r.p.m.; Type of oil is SAE 10, for which the

absolute viscosity at 55°C = 0.017 kg / m-s; Ambient temperature of oil = 15.5°C; Maximum bearing

pressure for the pump = 1.5 N / mm 2. Calculate also mass of the lubricating oil required for artificial

cooling, if rise of temperature of oil be limited to 10°C. Heat dissipation coefficient = 1232 W/m2 /°C.

Question-02

The load on the journal bearing is 150 kN due to turbine shaft of 300 mm diameter running at 1800 r.p.m.

Determine the following:

1. Length of the bearing if the allowable bearing pressure is 1.6 N/mm2, and

2. Amount of heat to be removed by the lubricant per minute if the bearing temperature is 60°C and

viscosity of the oil at 60°C is 0.02 kg/m-s and the bearing clearance is 0.25 mm

Question-03

A 80 mm long journal bearing supports a load of 2800 N on a 50 mm diameter shaft. The bearing has a

radial clearance of 0.05 mm and the viscosity of the oil is 0.021 kg / m-s at the operating temperature. If the

bearing is capable of dissipating 80 J/s, determine the maximum safe speed.

Question-04

The thrust of propeller shaft is absorbed by 6 collars. The rubbing surfaces of these collars have outer

diameter 300 mm and inner diameter 200 mm. If the shaft runs at 120 r.p.m., the bearing pressure amounts

to 0.4 N/mm2. The coefficient of friction may be taken as 0.05. Assuming that the pressure is uniformly

distributed, determine the power absorbed by the collars.

You might also like

- RIICWD533E Assessment ManualDocument31 pagesRIICWD533E Assessment ManualMuscle TV100% (1)

- Kpi Guideline PDFDocument44 pagesKpi Guideline PDFSteve Demirel100% (1)

- Snake Game Project ReportDocument15 pagesSnake Game Project ReportChoudhary75% (4)

- Description of Composites Coursework: Design and Analysis of A Laminated Composite TubeDocument2 pagesDescription of Composites Coursework: Design and Analysis of A Laminated Composite TubeAnh DoNo ratings yet

- Write To or Retrieve From Media Object - Text by Deepesh - JDE SourceDocument14 pagesWrite To or Retrieve From Media Object - Text by Deepesh - JDE SourceSatishNo ratings yet

- ICE Assignments 3 4 5Document3 pagesICE Assignments 3 4 5benzmr869No ratings yet

- 12154Document20 pages12154NobodyNo ratings yet

- UME 1503 - Assignment-2Document1 pageUME 1503 - Assignment-2yuvalakshmi222No ratings yet

- Faculty of Engineering Science and TechnologyDocument1 pageFaculty of Engineering Science and TechnologyGilt RNo ratings yet

- Meng 310 Exam 01 Spring 2011Document4 pagesMeng 310 Exam 01 Spring 2011Abdulrahman AlzahraniNo ratings yet

- HW 3 AnswersDocument11 pagesHW 3 AnswersCoryna Wan Chun WahNo ratings yet

- ME352 - Case Study 1Document10 pagesME352 - Case Study 1اسعد الماوريNo ratings yet

- All Assignments Questions - Control of AC and DC Drives Fall-2020Document3 pagesAll Assignments Questions - Control of AC and DC Drives Fall-2020TaLhA ChauDhrYNo ratings yet

- MEHB3013 S1 2122 Test 1Document2 pagesMEHB3013 S1 2122 Test 1syedadlan12No ratings yet

- Assignment Feb 21-Ver 1Document8 pagesAssignment Feb 21-Ver 1ostaz onlineNo ratings yet

- ME 321 Final Term Exam OBE Format - CLO MappingDocument7 pagesME 321 Final Term Exam OBE Format - CLO MappingSaad RasheedNo ratings yet

- Machine Design 2 Lecture Midterm ExamDocument3 pagesMachine Design 2 Lecture Midterm ExamNazareno Religioso MateoNo ratings yet

- HNC Eng Sci Assignment 2 Brief 1Document9 pagesHNC Eng Sci Assignment 2 Brief 1Noel JenningsNo ratings yet

- Important Instructions To ExaminersDocument30 pagesImportant Instructions To ExaminersDiyaNegiNo ratings yet

- Subject Code: 17529 SUMMER - 15 EXAMINATION Model AnswerDocument19 pagesSubject Code: 17529 SUMMER - 15 EXAMINATION Model AnswerSuraj KambleNo ratings yet

- 2nd Term CADCAM Q PaperDocument1 page2nd Term CADCAM Q Paperanadinath sharmaNo ratings yet

- Semester Examination: Section - BDocument3 pagesSemester Examination: Section - BNitin TembhurnikarNo ratings yet

- MECH 344 - Final Exam (Winter 2021)Document4 pagesMECH 344 - Final Exam (Winter 2021)Puneet Rudhar100% (1)

- Confidential Ee/Oct 2009/EPE491/KJK559: Instructions To CandidatesDocument2 pagesConfidential Ee/Oct 2009/EPE491/KJK559: Instructions To CandidatesnualdinNo ratings yet

- Cad-Cam - Ittd2 - 2020Document3 pagesCad-Cam - Ittd2 - 2020Tafara DarangwaNo ratings yet

- Cutting Temperature and Laser Beam Temperature Effects On Cutting Tool Deformation in Laser-Assisted MachiningDocument6 pagesCutting Temperature and Laser Beam Temperature Effects On Cutting Tool Deformation in Laser-Assisted MachiningrrameshsmitNo ratings yet

- Project Assignment Electric Motor Drives (MKE 1153) Semester II, Session 2009/2010Document4 pagesProject Assignment Electric Motor Drives (MKE 1153) Semester II, Session 2009/2010Nur AdiimahNo ratings yet

- Rotation Problem SetDocument1 pageRotation Problem SetmeytaNo ratings yet

- F-43 PEMP Assignment Problem Statement - ACD2506 - PT13 - TodoDocument5 pagesF-43 PEMP Assignment Problem Statement - ACD2506 - PT13 - TodoSumit MalikNo ratings yet

- DMM2 I Mid 2024Document1 pageDMM2 I Mid 2024Rkrishna ANo ratings yet

- Me192007 - Mechanical - 21 - End SemDocument2 pagesMe192007 - Mechanical - 21 - End SemJayesh KumavatNo ratings yet

- Me8493 - Te-I (Iat 2) QPDocument2 pagesMe8493 - Te-I (Iat 2) QPBhagavathi ShankarNo ratings yet

- Soalan Projek PSPD LatestDocument9 pagesSoalan Projek PSPD LatestAzlan AliNo ratings yet

- R16 B.Tech Mechanical EnggDocument34 pagesR16 B.Tech Mechanical EnggmechhodNo ratings yet

- Irjet V7i3706Document6 pagesIrjet V7i3706smabhibidkar2001No ratings yet

- Ca - 1 - 2020Document2 pagesCa - 1 - 2020Dilshan VimukthiNo ratings yet

- Routine Gmaw Student TaskDocument8 pagesRoutine Gmaw Student Taskapi-200253170No ratings yet

- UTA013 Engineering Design Project-I: TIET, Patiala Mechanical Engineering DepartmentDocument9 pagesUTA013 Engineering Design Project-I: TIET, Patiala Mechanical Engineering DepartmentDevid gakharNo ratings yet

- Set Up Computer System Unit ComponentsDocument4 pagesSet Up Computer System Unit Componentsepi_reveNo ratings yet

- 2nd Order Calculation: EurocodeDocument10 pages2nd Order Calculation: EurocodekeithtianNo ratings yet

- HES3350 Machine Design Semester 1 2012 Assignment 1 Compound Reverted Gear Train Design PDFDocument18 pagesHES3350 Machine Design Semester 1 2012 Assignment 1 Compound Reverted Gear Train Design PDFrisirarocksNo ratings yet

- Sas Lesson 12 Ele 103Document14 pagesSas Lesson 12 Ele 103Arnold GacangNo ratings yet

- 3 EMD Test 2 Sem1 - 21 - 22Document6 pages3 EMD Test 2 Sem1 - 21 - 22nelissa nazriNo ratings yet

- Mid Fall22 SRDocument7 pagesMid Fall22 SR22p0294No ratings yet

- Electrical MaintenanceDocument32 pagesElectrical MaintenanceYogesh BadheNo ratings yet

- Cad-Cam - Ittd3 - 2020Document3 pagesCad-Cam - Ittd3 - 2020Tafara DarangwaNo ratings yet

- Ass.2 2011 Veh Ausama (U 5) .Final2Document11 pagesAss.2 2011 Veh Ausama (U 5) .Final2Osama HassanNo ratings yet

- Hamdard University, FEST North Nazimabad Campus Final Examination, Fall - 2020Document2 pagesHamdard University, FEST North Nazimabad Campus Final Examination, Fall - 2020Zain AliNo ratings yet

- UnlockedDocument1 pageUnlockedRAFIQUE UL ISLAMNo ratings yet

- Piston Strength Analysis Using FEM: Swati S Chougule, Vinayak H KhatawateDocument8 pagesPiston Strength Analysis Using FEM: Swati S Chougule, Vinayak H KhatawateRam TirumalasettiNo ratings yet

- Model Answer Paper Winter 2019Document15 pagesModel Answer Paper Winter 2019Vaishali TurambekarNo ratings yet

- Winter - 16 Examination Model Answer Subject CodeDocument15 pagesWinter - 16 Examination Model Answer Subject CodeDiyaNegiNo ratings yet

- Fy Ee Sem II Bme 22214 QP Model AnswersDocument49 pagesFy Ee Sem II Bme 22214 QP Model Answers1345Pranmya LadEENo ratings yet

- 26 12 2023 (Morning)Document9 pages26 12 2023 (Morning)UPS1971No ratings yet

- ASSESSMENT BRIEF 2021-2022: Date of Submission: 15Document10 pagesASSESSMENT BRIEF 2021-2022: Date of Submission: 15enghesham2014No ratings yet

- STEMII Assignment Final Version SpringDocument12 pagesSTEMII Assignment Final Version SpringSsos.mowNo ratings yet

- Computer Integrated Manufacturing 15ME62TDocument15 pagesComputer Integrated Manufacturing 15ME62TRaghuraj DanadamNo ratings yet

- Dtsi TechnologyDocument32 pagesDtsi TechnologySaurabh SinghNo ratings yet

- Combustion Lecture Midterm ExamDocument3 pagesCombustion Lecture Midterm ExamNazareno Religioso MateoNo ratings yet

- Curriculum For Two Years PartyDocument7 pagesCurriculum For Two Years PartytaridanNo ratings yet

- Mid SMR23 JRDocument5 pagesMid SMR23 JR22p0294No ratings yet

- Plate Format For PPEDocument11 pagesPlate Format For PPEdominiqueNo ratings yet

- Beo 4Document2 pagesBeo 4Muscle TVNo ratings yet

- National University of TechnologyDocument2 pagesNational University of TechnologyMuscle TVNo ratings yet

- 29 Sarmad Nadeem Numerical Anaylsis Lab Report 1Document4 pages29 Sarmad Nadeem Numerical Anaylsis Lab Report 1Muscle TVNo ratings yet

- Lecture 02 Bending in BeamDocument74 pagesLecture 02 Bending in BeamMuscle TVNo ratings yet

- Task 2Document5 pagesTask 2Muscle TVNo ratings yet

- Pulse Connect Secure (PCS) 9.0Rx - 9.1R4: New Feature IntroductionDocument37 pagesPulse Connect Secure (PCS) 9.0Rx - 9.1R4: New Feature IntroductionNetsys BilisimNo ratings yet

- Method Statement For External Painting Work With Using Suspended PlatformDocument22 pagesMethod Statement For External Painting Work With Using Suspended PlatformĐặng Quang HuyNo ratings yet

- STEP 1: Server PC SettingsDocument3 pagesSTEP 1: Server PC SettingsJason EchevariaNo ratings yet

- Python Programming 3 Books in 1Document269 pagesPython Programming 3 Books in 1n7tpubhzx100% (2)

- Compressor Unit Technical Data Sheet - I15.1-7.5-VDocument10 pagesCompressor Unit Technical Data Sheet - I15.1-7.5-VMohamed MusaNo ratings yet

- Assignment On Strategic Management: Submitted To: Prof. S.P. SinghDocument17 pagesAssignment On Strategic Management: Submitted To: Prof. S.P. SinghVikram MayuriNo ratings yet

- Videojet - UDI PrintersDocument2 pagesVideojet - UDI PrintersSACHIN KUMARNo ratings yet

- Bomb Defusing Robotic Arm Using Gesture Control IJERTV4IS020105Document5 pagesBomb Defusing Robotic Arm Using Gesture Control IJERTV4IS020105VirajReddyNo ratings yet

- Datasheet Tellabs 6325 EDGE NodeDocument2 pagesDatasheet Tellabs 6325 EDGE NodeBoby Rahmadi100% (1)

- MSMV Steam Turbine Centrifugal Compressor YR Turbine Lube & Seal SystemDocument1 pageMSMV Steam Turbine Centrifugal Compressor YR Turbine Lube & Seal Systemadam yassineNo ratings yet

- SAP ARIBA ConfigsDocument65 pagesSAP ARIBA ConfigsSudhakar PatnamNo ratings yet

- Power Platform 2021 Release Wave 1 PlanDocument162 pagesPower Platform 2021 Release Wave 1 Planbhargavreddy3veerapaNo ratings yet

- LtpoDocument2 pagesLtpololaNo ratings yet

- Atpg GD PDFDocument608 pagesAtpg GD PDFAnitesh Sharma50% (2)

- Presentation On Grameen-Phone & Banglalink (MGT)Document28 pagesPresentation On Grameen-Phone & Banglalink (MGT)Samira Khan100% (1)

- Reinforcement Steel BarDocument64 pagesReinforcement Steel BardesignNo ratings yet

- Mirage Installation With DSKDocument15 pagesMirage Installation With DSKRodolfo AlbinoNo ratings yet

- S77 Power Curve enDocument3 pagesS77 Power Curve enGI DNo ratings yet

- Refinery Power OutageDocument16 pagesRefinery Power Outagepradeep.spaceman100% (2)

- 10-Bit Digital-To-Analog Converters: Features DescriptionDocument22 pages10-Bit Digital-To-Analog Converters: Features Descriptionwolvering2009No ratings yet

- Unily 8 Ways Guide PDFDocument12 pagesUnily 8 Ways Guide PDFVanes PilavNo ratings yet

- 7 - Claudia - Cloud Intelligence For Decision Making Support and AnalysisDocument1 page7 - Claudia - Cloud Intelligence For Decision Making Support and Analysisyo makNo ratings yet

- 08 BSCM v3.2 MasterDocument74 pages08 BSCM v3.2 MasterMostafaNo ratings yet

- 2020 State of DevOps ReportDocument54 pages2020 State of DevOps ReportproguiNo ratings yet

- DBMS MCQDocument94 pagesDBMS MCQJohn J100% (1)

- Essentials of Communication Electronics: EngineeringDocument1 pageEssentials of Communication Electronics: EngineeringAwaisMushtaqNo ratings yet

- OpenGL InstallationDocument3 pagesOpenGL Installationkaleab tesfayeNo ratings yet