Professional Documents

Culture Documents

Motor Control Center

Motor Control Center

Uploaded by

mostafa HusseinCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- FTX 128 Troubleshooting Manuel REV15 - 5 Feb 2016 PDFDocument223 pagesFTX 128 Troubleshooting Manuel REV15 - 5 Feb 2016 PDFDavy Gonzalez100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- DC Intertrip Relay: Protection Relays ProtectionDocument8 pagesDC Intertrip Relay: Protection Relays ProtectionIsmir PobricNo ratings yet

- HVAC SystemDocument19 pagesHVAC Systemmostafa HusseinNo ratings yet

- Five Stars Hotel: Prof - Dr. Ahmed Hossam-EldinDocument1 pageFive Stars Hotel: Prof - Dr. Ahmed Hossam-Eldinmostafa HusseinNo ratings yet

- Uninterruptable Power SupplyDocument15 pagesUninterruptable Power Supplymostafa HusseinNo ratings yet

- Short Circuit CalculationsDocument8 pagesShort Circuit Calculationsmostafa HusseinNo ratings yet

- 5Document8 pages5mostafa HusseinNo ratings yet

- Panel Boards DesignDocument22 pagesPanel Boards Designmostafa HusseinNo ratings yet

- Power Factor CorrectionDocument6 pagesPower Factor Correctionmostafa HusseinNo ratings yet

- Lightning Protection and Earthing SystemDocument17 pagesLightning Protection and Earthing Systemmostafa HusseinNo ratings yet

- Fire Alarm and Fire FightingDocument15 pagesFire Alarm and Fire Fightingmostafa HusseinNo ratings yet

- Protection of SubstationDocument11 pagesProtection of Substationmostafa HusseinNo ratings yet

- Room AutomationDocument18 pagesRoom Automationmostafa HusseinNo ratings yet

- Aircraft Warning LightsDocument5 pagesAircraft Warning Lightsmostafa HusseinNo ratings yet

- Power Cables DesignDocument7 pagesPower Cables Designmostafa HusseinNo ratings yet

- SCADA SystemDocument9 pagesSCADA Systemmostafa HusseinNo ratings yet

- Elevators DesignDocument16 pagesElevators Designmostafa HusseinNo ratings yet

- Software Program: Appendix EDocument33 pagesSoftware Program: Appendix Emostafa HusseinNo ratings yet

- Surveillance System DesignDocument24 pagesSurveillance System Designmostafa HusseinNo ratings yet

- Sound SystemDocument24 pagesSound Systemmostafa HusseinNo ratings yet

- Balancing Sheet: Appendix ADocument4 pagesBalancing Sheet: Appendix Amostafa HusseinNo ratings yet

- DIALUX Software: Appendix BDocument11 pagesDIALUX Software: Appendix Bmostafa HusseinNo ratings yet

- Waste Water TreatmentDocument7 pagesWaste Water Treatmentmostafa HusseinNo ratings yet

- Clock System: Appendix DDocument21 pagesClock System: Appendix Dmostafa HusseinNo ratings yet

- ReferencesDocument1 pageReferencesmostafa HusseinNo ratings yet

- Transfer Receipt 9Document1 pageTransfer Receipt 9mostafa HusseinNo ratings yet

- Abb Kontrolnik Izolacije Cm-Iws 2sDocument16 pagesAbb Kontrolnik Izolacije Cm-Iws 2sDragomir HoffmannNo ratings yet

- Power Failure Detection (By 5V Power) : Point of Detection ApplicationDocument1 pagePower Failure Detection (By 5V Power) : Point of Detection ApplicationDaniel GatdulaNo ratings yet

- 3 Pole - Changeover Contact: 1.3 Industrial Relays - PluggableDocument7 pages3 Pole - Changeover Contact: 1.3 Industrial Relays - PluggableLikabeus EirlNo ratings yet

- Chasing Timer Control System: SF-9005 User GuideDocument2 pagesChasing Timer Control System: SF-9005 User Guideerick ake baqueiroNo ratings yet

- Manual Esquema Electr. Daf XFDocument605 pagesManual Esquema Electr. Daf XFNachoBallesterosPadial100% (19)

- Cloride Motive Power 21Document13 pagesCloride Motive Power 21mariodajNo ratings yet

- Percentage-Differential: For The Protection of AC Rotating Machinery and Power TransformersDocument4 pagesPercentage-Differential: For The Protection of AC Rotating Machinery and Power TransformersakayhanafiahNo ratings yet

- Electronics Devices and Circuits LabDocument3 pagesElectronics Devices and Circuits LabsamactrangNo ratings yet

- DT Gen-Technical Data Sheet - DTG1000B-2023Document1 pageDT Gen-Technical Data Sheet - DTG1000B-2023chris connorsNo ratings yet

- True Absolute EncoderDocument30 pagesTrue Absolute EncoderSzelSzabNo ratings yet

- Smart String Inverter: Efficient Safe Reliable SmartDocument2 pagesSmart String Inverter: Efficient Safe Reliable SmartRamon OrellanaNo ratings yet

- CHABUADocument1 pageCHABUAbedanta duttaNo ratings yet

- 227878fa enDocument187 pages227878fa enGeraldo ViníciusNo ratings yet

- High Efficiency Battery ChargerDocument4 pagesHigh Efficiency Battery ChargersanilNo ratings yet

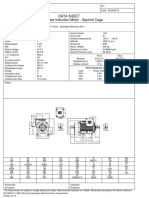

- Data Sheet Three-Phase Induction Motor - Squirrel CageDocument1 pageData Sheet Three-Phase Induction Motor - Squirrel CagePriyo Jati WahyonoNo ratings yet

- Product Datasheet: Trip Unit Micrologic 2.2 For Compact NSX 160/250 Circuit Breakers, Electronic, Rating 160A, 3 Poles 3dDocument3 pagesProduct Datasheet: Trip Unit Micrologic 2.2 For Compact NSX 160/250 Circuit Breakers, Electronic, Rating 160A, 3 Poles 3dGokul VenugopalNo ratings yet

- Section 4 Electric Motors Unit 19 Motor ControlsDocument23 pagesSection 4 Electric Motors Unit 19 Motor ControlsMyka Hibe EsureñaNo ratings yet

- Prisma PlusDocument28 pagesPrisma PlusCuong NguyenNo ratings yet

- Hi 8596 - V Rev L PDFDocument12 pagesHi 8596 - V Rev L PDFVarshaNo ratings yet

- Transformer PDFDocument70 pagesTransformer PDFumair rashidNo ratings yet

- Sentry Range of UL Approved: Automatic Battery ChargersDocument2 pagesSentry Range of UL Approved: Automatic Battery ChargersEler Ghat100% (1)

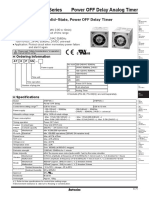

- Power OFF Delay Analog Timer AT8PSN/AT8PMN Series: FeaturesDocument3 pagesPower OFF Delay Analog Timer AT8PSN/AT8PMN Series: FeaturesryudistianaNo ratings yet

- Upgrading of On-Load Tap-Changer Types UCG/UCL To Vacuum Types VUCG/VUCLDocument4 pagesUpgrading of On-Load Tap-Changer Types UCG/UCL To Vacuum Types VUCG/VUCLKushtrim MalaNo ratings yet

- Gma EDocument5 pagesGma EDull Rahim100% (1)

- Pull Rope Switch PDFDocument4 pagesPull Rope Switch PDFTony IbraNo ratings yet

- ML7430E/ML7435E: Electric Linear Actuators For Modulating ControlDocument4 pagesML7430E/ML7435E: Electric Linear Actuators For Modulating ControlMarco ReNo ratings yet

- Topic 1 - Electronics FundamentalsDocument12 pagesTopic 1 - Electronics FundamentalsKiro Da rareNo ratings yet

- Template Label RTN Project XLDocument10 pagesTemplate Label RTN Project XLENALNo ratings yet

Motor Control Center

Motor Control Center

Uploaded by

mostafa HusseinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Motor Control Center

Motor Control Center

Uploaded by

mostafa HusseinCopyright:

Available Formats

Chapter 15

Motor Control Center

Chapter 15 [MCC]

15.1. Introduction

Distribution systems used in large commercial and industrial applications can be complex.

Power may be distributed through various switchboards, transformers, and panelboards.

Power distributed throughout a commercial or industrial application is used for a variety of

applications such as heating, cooling, lighting, and motor-driven machinery.

15.2. Basic motor control

Wherever motors are used, they must be controlled. In Basics of Control

Components you learned how various control products are used to control the

operation of motors. The most basic type of AC motor control, for example, involves

turning the motor on and off. This is often accomplished by using a motor starter,

which is made up of a contactor and an overload relay. The contactor’s contacts are

closed to start the motor and opened to stop the motor. This is accomplished

electromechanically using start and stop pushbuttons or other pilot devices wired to

5 Stars Hotel Page 300

Chapter 15 [MCC]

control the contactor. The overload relay protects the motor by disconnecting power to

the motor when an overload condition exists. An overload could occur, for instance,

when a conveyor is jammed. Although the overload relay provides protection from

overloads, it does not provide short-circuit protection for the wiring providing power

to the motor. For this reason, a circuit breaker or fuses are also used.

Typically one motor starter controls one motor. When only a few geographically

dispersed AC motors are used, the circuit protection and control components may be

located in a panel near the motor.

5 Stars Hotel Page 301

Chapter 15 [MCC]

In many commercial and industrial applications quite a few electric motors are

required, and it is often desirable to control some or all of the motors from a central

location. The apparatus designed for this function is the motor control center (MCC).

Motor control centers are simply physical groupings of combination starters in one

assembly. A combination starter is a single enclosure containing the motor starter and

the fuses or circuit breaker.

5 Stars Hotel Page 302

Chapter 15 [MCC]

15.3. Motor control centers

NEMA Definition

NEMA defines a motor control center in ICS-2-322 as being a floor-mounted assembly

of one or more enclosed vertical sections having a horizontal common power bus and

principally containing combination motor control units. These units are mounted one

above the other in the vertical sections. The sections may incorporate vertical buses

connected to the common power bus, thus extending the common power supply to the

individual units. Units may also connect directly to the common power bus by suitable

wiring.

According to the NEMA definition, motor control centers:

Ø Are floor-mounted assemblies

Ø Have one or more enclosed vertical sections

Ø Have a common horizontal power bus

Ø May incorporate vertical buses connected to the common bus

Ø Principally contain combination motor control units

5 Stars Hotel Page 303

Chapter 15 [MCC]

15.4. Need for circuit protection

15.4.1. Over loading

Current flow in a conductor always generates heat. The greater the current flow in any

one size conductor, the hotter the conductor. Excess heat is damaging to electrical

components and conductor insulation. For that reason conductors have a rated,

continuous current-carrying capacity or ampacity.

Over current protection devices, such as fuses, are used to protect conductors from

excessive current flow.

5 Stars Hotel Page 304

Chapter 15 [MCC]

15.5. Over current protection devices

An over current-protection device must be able to recognize the difference

between an over current and short circuit and respond in the proper way. Slight over

currents can be allowed to continue for some period of time; but as the current

magnitude increases, the protection device must open faster. Short circuits must be

interrupted instantly.

15.5.1. Fusible disconnect switch

A fusible disconnect switch is one type of device used to provide over current

protection. Properly sized fuses located in the switch open the circuit when an over

current condition exists.

15.5.2. Fuse

A fuse is a one-shot device. The heat produced by over current causes the current

carrying element to melt open, disconnecting the load from the source voltage.

5 Stars Hotel Page 305

Chapter 15 [MCC]

15.5.3. Circuit breakers

Another device used for over current protection is a circuit breaker. The National

Electrical Code® defines a circuit breaker as a device designed to open and close a

circuit by non automatic means, and to open the circuit automatically on a

predetermined over current without damage to itself when properly applied within its

rating.

Circuit breakers provide a manual means of energizing and de-energizing a circuit. In

addition, circuit breakers provide automatic over current protection of a circuit. A

circuit breaker allows a circuit to be reactivated quickly after a short circuit or overload

is cleared. Since it merely needs to be reset there is nothing to replace after a short

circuit.

5 Stars Hotel Page 306

Chapter 15 [MCC]

A) Ampere rating

Like fuses, every circuit breaker has a specific ampere, voltage, and fault-current

interruption rating. The ampere rating is the maximum continuous current a circuit

breaker can carry without exceeding its rating. As a general rule, the circuit breaker

ampere rating should not exceed the conductor ampere rating. For example, if the

conductor is rated for 20 amps, the circuit breaker ra ng should not exceed 20 amps.

Siemens breakers are rated on the basis of using 60° C or 75° C conductors. This means

that even if a conductor with a higher temperature rating were used, the ampacity of

the conductor must be figured on its 60° C or 75° C rating.

There are some specific circumstances when the ampere rating is permitted to be

greater than the current-carrying capacity of the circuit. For example, motor and

welder circuits can exceed conductor ampacity to allow for inrush currents and duty

cycles within limits established by NEC®.

Generally the ampere ra ng of a circuit breaker is selected at 125% of the con nuous

load current. This usually corresponds to the conductor ampacity which is also selected

at 125% of con nuous load current. For example, a 125 amp circuit breaker would be

selected for a load of 100 amps.

B) Voltage rating

The voltage rating of the circuit breaker must be at least equal to the supply voltage.

The voltage rating of a circuit breaker can be higher than the supply voltage, but never

lower. For example, a 480 VAC circuit breaker could be used on a 240 VAC circuit. A 240

VAC circuit breaker could not be used on a 480 VAC circuit. The voltage rating is a

function of the circuit breaker’s ability to suppress the internal arc that occurs when

the circuit breaker’s contacts open.

5 Stars Hotel Page 307

Chapter 15 [MCC]

Ø Fault current

Circuit breakers are also rated according to the level of fault

A) Interrupting rating

current they can interrupt. When applying a circuit breaker, one must be selected to

sustain the largest potential short-circuit current which can occur in the selected

applica on. Siemens circuit breakers have interrup ng ra ngs from 10,000 to 200,000

amps.

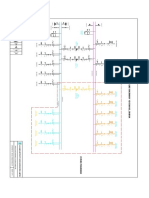

B) General assembly

The motor control center is made up of a steel structure to contain the combination

motor control units, wire ways, internal wiring, and bus bars. From the NEMA

definition it can be seen that a motor control center is a floor-mounted assembly made

up of enclosed vertical sections. One vertical section may stand alone as a complete

motor control center, or several sections may be bolted and bussed together. Vertical

sections are generally 20” wide by 90” high.

5 Stars Hotel Page 308

Chapter 15 [MCC]

15.6. Horizontal and vertical buses

A bus is a conductor that serves as a common connection for two or more circuits. It is

represented schematically by a straight line with a number of connections made to it.

In power circuits, such as motor control centers, a bus is made of a heavy-duty metal

bar. These bars provide power to each of the combination motor control units. The

vertical bus is connected to a corresponding horizontal bus and is isolated from the

other bus bars.

5 Stars Hotel Page 309

Chapter 15 [MCC]

15.7. NEMA phase arrangement

NEMA requires bus bars to have phases in sequence so that an installer can have the

same fixed phase arrangement at each termination point in any motor control center.

The following diagram illustrates accepted NEMA phase arrangements. It is possible to

have a non-NEMA phase sequence; however, this would have to be clearly marked.

It should be noted that the NEMA phase arrangement illustrated in the previous

drawing is viewed from the front. The vertical bus bars appear to be in reverse order

when viewed from the rear. Some motor control centers can have devices installed on

the front and rear of the motor control center.

5 Stars Hotel Page 310

Chapter 15 [MCC]

15.8. Combina on motor control units

Motor control centers principally contain combination motor control units. NEMA ICS-

1-322 states that . . .

A combination motor control unit shall include externally operable circuit

disconnecting means, branch-circuit over current protection, and a magnetic motor

controller with associated auxiliary devices when used. The disconnecting means and

branch-circuit over current protection shall consist of a fusible disconnecting device or

circuit breaker. If the latter is used, it shall either be an inverse time (thermal-

magnetic or dual magnetic) or an instantaneous magnetic type. The motor controller

shall include motor and branch-circuit protection unless equivalent protection is

otherwise provided.

A combination motor control unit takes all the elements required to control an AC

motor and combines them into one unit. The combination motor control unit in the

following example uses a molded case circuit breaker to provide circuit disconnecting

means and branch-circuit over current protection. The circuit breaker is opened and

closed using the operating handle located on the front of the unit. The magnetic motor

starter is used to start and stop an AC motor and provide over current protection for

the motor. Pilot devices, located on the door, serve to provide an operator means to

start and stop the motor as well as provide visual indication of the motor’s status.

5 Stars Hotel Page 311

Chapter 15 [MCC]

15.9. Motor starters

The motor starter is the heart of the combination motor control unit. Motor starters

consist of a contactor and an overload relay. The contactor portion of a motor starter

provides the means to remotely start and stop a motor. The overload relay protects the

motor from overload conditions.

15.10 MCC ratings

In addition to the various ratings of individual components used in motor control

centers, the overall ratings of the motor control center must also be considered

1) Voltage Rating

2) Horizontal Bus

3) Current Rating of tin or optional

silver

4) Vertical bus

5 Stars Hotel Page 312

Chapter 15 [MCC]

15.11 How to order MCCs

When ordering a motor control center several questions need to be answered. The

following information will be useful.

1) Voltage, frequency, number of phases, and available fault current of power

supply

2) Incoming power requirements (main circuit breaker, main fusible switch, main

lugs only, or splicing to existing MCC)

3) Amp rating of the horizontal bus and finish material (tin or silver)

4) Voltage rating and source of control power

5) Size, type (aluminum or copper), number per phase and location of incoming cables or

bus-way and outgoing cables

6) Enclosure

Ø Type, finish

Ø Accessibility (front, rear, or both)

Ø Clearance for door swing

Ø Restrictions on height, width, and depth

7) Horsepower rating and motor design of motors to be controlled

8) Ampacity of feeder tap units and unit disconnect devices

9) Type of disconnect for units: thermal-magnetic, instantaneous trip, or

fusible

10) Ground bus requirements

11) Type of control circuit for units

5 Stars Hotel Page 313

Chapter 15 [MCC]

12) Vertical bus requirements (finish, isolated/insulated, amp rating)

13) Class and Type of wiring

14) Addi onal equipment requirements (transformers, panel boards, transfer switches,

PLCs, etc.)

15) Preferred layout of units

16) Special features, codes, or restric ons Customer specifications

5 Stars Hotel Page 314

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- FTX 128 Troubleshooting Manuel REV15 - 5 Feb 2016 PDFDocument223 pagesFTX 128 Troubleshooting Manuel REV15 - 5 Feb 2016 PDFDavy Gonzalez100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- DC Intertrip Relay: Protection Relays ProtectionDocument8 pagesDC Intertrip Relay: Protection Relays ProtectionIsmir PobricNo ratings yet

- HVAC SystemDocument19 pagesHVAC Systemmostafa HusseinNo ratings yet

- Five Stars Hotel: Prof - Dr. Ahmed Hossam-EldinDocument1 pageFive Stars Hotel: Prof - Dr. Ahmed Hossam-Eldinmostafa HusseinNo ratings yet

- Uninterruptable Power SupplyDocument15 pagesUninterruptable Power Supplymostafa HusseinNo ratings yet

- Short Circuit CalculationsDocument8 pagesShort Circuit Calculationsmostafa HusseinNo ratings yet

- 5Document8 pages5mostafa HusseinNo ratings yet

- Panel Boards DesignDocument22 pagesPanel Boards Designmostafa HusseinNo ratings yet

- Power Factor CorrectionDocument6 pagesPower Factor Correctionmostafa HusseinNo ratings yet

- Lightning Protection and Earthing SystemDocument17 pagesLightning Protection and Earthing Systemmostafa HusseinNo ratings yet

- Fire Alarm and Fire FightingDocument15 pagesFire Alarm and Fire Fightingmostafa HusseinNo ratings yet

- Protection of SubstationDocument11 pagesProtection of Substationmostafa HusseinNo ratings yet

- Room AutomationDocument18 pagesRoom Automationmostafa HusseinNo ratings yet

- Aircraft Warning LightsDocument5 pagesAircraft Warning Lightsmostafa HusseinNo ratings yet

- Power Cables DesignDocument7 pagesPower Cables Designmostafa HusseinNo ratings yet

- SCADA SystemDocument9 pagesSCADA Systemmostafa HusseinNo ratings yet

- Elevators DesignDocument16 pagesElevators Designmostafa HusseinNo ratings yet

- Software Program: Appendix EDocument33 pagesSoftware Program: Appendix Emostafa HusseinNo ratings yet

- Surveillance System DesignDocument24 pagesSurveillance System Designmostafa HusseinNo ratings yet

- Sound SystemDocument24 pagesSound Systemmostafa HusseinNo ratings yet

- Balancing Sheet: Appendix ADocument4 pagesBalancing Sheet: Appendix Amostafa HusseinNo ratings yet

- DIALUX Software: Appendix BDocument11 pagesDIALUX Software: Appendix Bmostafa HusseinNo ratings yet

- Waste Water TreatmentDocument7 pagesWaste Water Treatmentmostafa HusseinNo ratings yet

- Clock System: Appendix DDocument21 pagesClock System: Appendix Dmostafa HusseinNo ratings yet

- ReferencesDocument1 pageReferencesmostafa HusseinNo ratings yet

- Transfer Receipt 9Document1 pageTransfer Receipt 9mostafa HusseinNo ratings yet

- Abb Kontrolnik Izolacije Cm-Iws 2sDocument16 pagesAbb Kontrolnik Izolacije Cm-Iws 2sDragomir HoffmannNo ratings yet

- Power Failure Detection (By 5V Power) : Point of Detection ApplicationDocument1 pagePower Failure Detection (By 5V Power) : Point of Detection ApplicationDaniel GatdulaNo ratings yet

- 3 Pole - Changeover Contact: 1.3 Industrial Relays - PluggableDocument7 pages3 Pole - Changeover Contact: 1.3 Industrial Relays - PluggableLikabeus EirlNo ratings yet

- Chasing Timer Control System: SF-9005 User GuideDocument2 pagesChasing Timer Control System: SF-9005 User Guideerick ake baqueiroNo ratings yet

- Manual Esquema Electr. Daf XFDocument605 pagesManual Esquema Electr. Daf XFNachoBallesterosPadial100% (19)

- Cloride Motive Power 21Document13 pagesCloride Motive Power 21mariodajNo ratings yet

- Percentage-Differential: For The Protection of AC Rotating Machinery and Power TransformersDocument4 pagesPercentage-Differential: For The Protection of AC Rotating Machinery and Power TransformersakayhanafiahNo ratings yet

- Electronics Devices and Circuits LabDocument3 pagesElectronics Devices and Circuits LabsamactrangNo ratings yet

- DT Gen-Technical Data Sheet - DTG1000B-2023Document1 pageDT Gen-Technical Data Sheet - DTG1000B-2023chris connorsNo ratings yet

- True Absolute EncoderDocument30 pagesTrue Absolute EncoderSzelSzabNo ratings yet

- Smart String Inverter: Efficient Safe Reliable SmartDocument2 pagesSmart String Inverter: Efficient Safe Reliable SmartRamon OrellanaNo ratings yet

- CHABUADocument1 pageCHABUAbedanta duttaNo ratings yet

- 227878fa enDocument187 pages227878fa enGeraldo ViníciusNo ratings yet

- High Efficiency Battery ChargerDocument4 pagesHigh Efficiency Battery ChargersanilNo ratings yet

- Data Sheet Three-Phase Induction Motor - Squirrel CageDocument1 pageData Sheet Three-Phase Induction Motor - Squirrel CagePriyo Jati WahyonoNo ratings yet

- Product Datasheet: Trip Unit Micrologic 2.2 For Compact NSX 160/250 Circuit Breakers, Electronic, Rating 160A, 3 Poles 3dDocument3 pagesProduct Datasheet: Trip Unit Micrologic 2.2 For Compact NSX 160/250 Circuit Breakers, Electronic, Rating 160A, 3 Poles 3dGokul VenugopalNo ratings yet

- Section 4 Electric Motors Unit 19 Motor ControlsDocument23 pagesSection 4 Electric Motors Unit 19 Motor ControlsMyka Hibe EsureñaNo ratings yet

- Prisma PlusDocument28 pagesPrisma PlusCuong NguyenNo ratings yet

- Hi 8596 - V Rev L PDFDocument12 pagesHi 8596 - V Rev L PDFVarshaNo ratings yet

- Transformer PDFDocument70 pagesTransformer PDFumair rashidNo ratings yet

- Sentry Range of UL Approved: Automatic Battery ChargersDocument2 pagesSentry Range of UL Approved: Automatic Battery ChargersEler Ghat100% (1)

- Power OFF Delay Analog Timer AT8PSN/AT8PMN Series: FeaturesDocument3 pagesPower OFF Delay Analog Timer AT8PSN/AT8PMN Series: FeaturesryudistianaNo ratings yet

- Upgrading of On-Load Tap-Changer Types UCG/UCL To Vacuum Types VUCG/VUCLDocument4 pagesUpgrading of On-Load Tap-Changer Types UCG/UCL To Vacuum Types VUCG/VUCLKushtrim MalaNo ratings yet

- Gma EDocument5 pagesGma EDull Rahim100% (1)

- Pull Rope Switch PDFDocument4 pagesPull Rope Switch PDFTony IbraNo ratings yet

- ML7430E/ML7435E: Electric Linear Actuators For Modulating ControlDocument4 pagesML7430E/ML7435E: Electric Linear Actuators For Modulating ControlMarco ReNo ratings yet

- Topic 1 - Electronics FundamentalsDocument12 pagesTopic 1 - Electronics FundamentalsKiro Da rareNo ratings yet

- Template Label RTN Project XLDocument10 pagesTemplate Label RTN Project XLENALNo ratings yet