Professional Documents

Culture Documents

36 Dimensions of Armourlng Mat - Rlal

36 Dimensions of Armourlng Mat - Rlal

Uploaded by

Chindhi LaalCopyright:

Available Formats

You might also like

- 108SD 114SD - Repair ManualDocument1,406 pages108SD 114SD - Repair Manuallalo201042361100% (13)

- Rectangular Tank Design ROARKS FORMULADocument40 pagesRectangular Tank Design ROARKS FORMULANavasOT100% (3)

- Muscovite Mica Scrap For, Mica Paper - Specification: Indian StandardDocument5 pagesMuscovite Mica Scrap For, Mica Paper - Specification: Indian StandardAnuradhaPatraNo ratings yet

- Biomaterials Quick Study SheetDocument2 pagesBiomaterials Quick Study SheetWilliam ChanNo ratings yet

- Is 2473Document4 pagesIs 2473Kaushal PanchalNo ratings yet

- Insulator Telegraph and Telephone Lines - Specification: Stalks ForDocument13 pagesInsulator Telegraph and Telephone Lines - Specification: Stalks ForGnanavel GNo ratings yet

- Specification FOR External Micrometer: MarchDocument6 pagesSpecification FOR External Micrometer: MarchAshish DubeyNo ratings yet

- Specification For Radio Frequency Coaxial Cables: IS: 11967 (Part 3/sec 3) - 1988Document3 pagesSpecification For Radio Frequency Coaxial Cables: IS: 11967 (Part 3/sec 3) - 1988Shivangi BhardwajNo ratings yet

- Specification FOR Plain and Master Setting Ring Gauges (Size Range From 1 Up To and Including 315 MM)Document4 pagesSpecification FOR Plain and Master Setting Ring Gauges (Size Range From 1 Up To and Including 315 MM)Ashish DubeyNo ratings yet

- 9483 1993 Reff2020Document7 pages9483 1993 Reff2020Ashish DubeyNo ratings yet

- 9483 1993 Reff2020Document7 pages9483 1993 Reff2020Ashish DubeyNo ratings yet

- 3179 1990 Reff2020Document6 pages3179 1990 Reff2020Ashish DubeyNo ratings yet

- Specification For Fittings For Rigid Non-Metallic F Second Revision) ConduitsDocument16 pagesSpecification For Fittings For Rigid Non-Metallic F Second Revision) ConduitsAvinash MishraNo ratings yet

- Winding Wires For Submersible Motors - Specification: Indian StandardDocument9 pagesWinding Wires For Submersible Motors - Specification: Indian StandardkrixotNo ratings yet

- Specification For Mechanical Bevel Protractors: Indian StandardDocument4 pagesSpecification For Mechanical Bevel Protractors: Indian StandardAshish DubeyNo ratings yet

- Specification FOR External Micrometer: MarchDocument6 pagesSpecification FOR External Micrometer: MarchAnirban DasNo ratings yet

- 8023 1991 Reff2020Document7 pages8023 1991 Reff2020Ashish DubeyNo ratings yet

- Indian Standard': 1$:6137 - 1983 (ReaffipmedDocument4 pagesIndian Standard': 1$:6137 - 1983 (ReaffipmedAshish DubeyNo ratings yet

- 8262 2 1976 Reff2021Document3 pages8262 2 1976 Reff2021Shubham DhupkarNo ratings yet

- 8262 2 1976 Reff2021Document3 pages8262 2 1976 Reff2021Shubham DhupkarNo ratings yet

- Indian Standard: Legal Metrology - Material Measures of LengthDocument9 pagesIndian Standard: Legal Metrology - Material Measures of LengthDiptiNo ratings yet

- Winding Wires For Submersible Motors - Specification: Indian StandardDocument9 pagesWinding Wires For Submersible Motors - Specification: Indian StandardShivangi BhardwajNo ratings yet

- Winding Wires For Submersible Motors - Specification: Indian StandardDocument12 pagesWinding Wires For Submersible Motors - Specification: Indian StandardShivangi BhardwajNo ratings yet

- Methods For'Measuring Case Depth of Steel: Indian StandardDocument7 pagesMethods For'Measuring Case Depth of Steel: Indian Standardsingaravelan narayanasamyNo ratings yet

- Is 9879-1998 (Ra-2021)Document8 pagesIs 9879-1998 (Ra-2021)singaravelan narayanasamyNo ratings yet

- IS 2379 - Pipeline Colour CodeDocument14 pagesIS 2379 - Pipeline Colour CodeNoel Federer SarkarNo ratings yet

- FOR Threadeo Steel Fasteners: (Reaffirmed 2001)Document4 pagesFOR Threadeo Steel Fasteners: (Reaffirmed 2001)Harshith Rao VadnalaNo ratings yet

- 2000 Reff2021 PDFDocument7 pages2000 Reff2021 PDFocsspectroNo ratings yet

- 3179 1990 Reff2020Document6 pages3179 1990 Reff2020Anirban DasNo ratings yet

- IS 8329 - 2000 - AMD5 - Reff 2020Document23 pagesIS 8329 - 2000 - AMD5 - Reff 2020Rishab KejriwalNo ratings yet

- IS 906 I Specification For Fire Hose Delivery Couplings, Branch Pipe, Nozzles and Nozzle Spanner - SpecificaionDocument12 pagesIS 906 I Specification For Fire Hose Delivery Couplings, Branch Pipe, Nozzles and Nozzle Spanner - SpecificaionHemal BhagatNo ratings yet

- Methods of Sampling For Paints, Varnishes A ND Related: Indian StandardDocument6 pagesMethods of Sampling For Paints, Varnishes A ND Related: Indian StandardselvaNo ratings yet

- IS: 11967 (Part 3/secl) - 1988: (Reaffirmed 20 20)Document3 pagesIS: 11967 (Part 3/secl) - 1988: (Reaffirmed 20 20)Shivangi BhardwajNo ratings yet

- Specification FOR Injection Moulded PVC Socket Fittings With Solvent Cement Joints For Water SuppliesDocument8 pagesSpecification FOR Injection Moulded PVC Socket Fittings With Solvent Cement Joints For Water SuppliesCIPET TESTING - AGARTALANo ratings yet

- Technical Supply Conditions For Gauges: 1 IS: 7018 (Part 2) - 1983 Indian StandardDocument6 pagesTechnical Supply Conditions For Gauges: 1 IS: 7018 (Part 2) - 1983 Indian StandardAshish DubeyNo ratings yet

- Method For Emission Spectrometric Analysis of Austenitic and Ferritic Stainless Steels Point To Plane Technique (First Revision)Document8 pagesMethod For Emission Spectrometric Analysis of Austenitic and Ferritic Stainless Steels Point To Plane Technique (First Revision)DiptiNo ratings yet

- Is 10810 - 6 - 1984 Ra 2016Document3 pagesIs 10810 - 6 - 1984 Ra 2016Swati SharmaNo ratings yet

- Digitalmeasuringinstrumentsfor Measurementandcontrol: Indian StandardDocument7 pagesDigitalmeasuringinstrumentsfor Measurementandcontrol: Indian StandardAshish DubeyNo ratings yet

- Digital-Miyiiisukinginstrumentsfor Measurementandcontrol: Indian StandardDocument10 pagesDigital-Miyiiisukinginstrumentsfor Measurementandcontrol: Indian StandardAshish DubeyNo ratings yet

- 2 1993 Reff2020Document10 pages2 1993 Reff2020Parth PatelNo ratings yet

- Specification FOR Injection Moulded PVC Socket Fittings With Solvent Cement Joints For Water SuppliesDocument2 pagesSpecification FOR Injection Moulded PVC Socket Fittings With Solvent Cement Joints For Water Suppliesanurag singhNo ratings yet

- 7876 1975 Reff2020Document18 pages7876 1975 Reff2020Ashish DubeyNo ratings yet

- 1984 Reff2020Document4 pages1984 Reff2020Ashish DubeyNo ratings yet

- 2000 Reff2021Document7 pages2000 Reff2021Ersatz IdiotaNo ratings yet

- 1405 2010 Reff2021 PDFDocument20 pages1405 2010 Reff2021 PDFocsspectroNo ratings yet

- Specification FOR Injection Moulded PVC Socket Fittings With Solvent Cement Joints For Water SuppliesDocument3 pagesSpecification FOR Injection Moulded PVC Socket Fittings With Solvent Cement Joints For Water SuppliesCIPET TESTING - AGARTALANo ratings yet

- Electric Traction Lifts: Indian StandardDocument12 pagesElectric Traction Lifts: Indian StandardDebabrata PalNo ratings yet

- 2008 Reff2021Document10 pages2008 Reff2021Archana ShuklaNo ratings yet

- Reaffirmed 2001Document8 pagesReaffirmed 2001Gnanavel GNo ratings yet

- Is 101 - 3 - 2Document11 pagesIs 101 - 3 - 2Ruby MalhotraNo ratings yet

- Dimensions For Porcelain Transformer Bushings For Use in Heavily Polluted ATMOSPHERES 12/17.5 KV, 24 KV AND 36 KVDocument12 pagesDimensions For Porcelain Transformer Bushings For Use in Heavily Polluted ATMOSPHERES 12/17.5 KV, 24 KV AND 36 KVGnanavel G100% (1)

- Specification FOR Radio Frequency Coaxial Cables: Indian StandardDocument4 pagesSpecification FOR Radio Frequency Coaxial Cables: Indian StandardShivangi BhardwajNo ratings yet

- 1995 Reff2020Document7 pages1995 Reff2020Ashish DubeyNo ratings yet

- 2010 AMD3 Reff2021Document24 pages2010 AMD3 Reff2021Roushan KumarNo ratings yet

- Methods of Grading and Visual Classification of Muscovite Mica SplittingsDocument8 pagesMethods of Grading and Visual Classification of Muscovite Mica SplittingsAnuradhaPatraNo ratings yet

- Thermoplastics Pipes and Fittings - Methods of Test (: Indian StandardDocument65 pagesThermoplastics Pipes and Fittings - Methods of Test (: Indian StandardVikash MudgilNo ratings yet

- Non-Destructive Integrity Testing of Piles (NDT) - GuidelinesDocument11 pagesNon-Destructive Integrity Testing of Piles (NDT) - Guidelineshardik sorathiyaNo ratings yet

- 3wriw: Indian StandardDocument6 pages3wriw: Indian StandardkrixotNo ratings yet

- IS-12437 Zirconium PowderDocument8 pagesIS-12437 Zirconium PowderAnuradhaPatraNo ratings yet

- Lndian Standard: Clay Roofing Tiles, Mangalore Pattern - Specification (Document11 pagesLndian Standard: Clay Roofing Tiles, Mangalore Pattern - Specification (Sooraj Matter LabNo ratings yet

- Bicycles - Pedal Assembly - Specification: Indian StandardDocument7 pagesBicycles - Pedal Assembly - Specification: Indian StandardYoginder SainiNo ratings yet

- Specification For Optical Bevel Protractors: Indian StandardDocument3 pagesSpecification For Optical Bevel Protractors: Indian StandardAshish DubeyNo ratings yet

- Joint Photographic Experts Group: Unlocking the Power of Visual Data with the JPEG StandardFrom EverandJoint Photographic Experts Group: Unlocking the Power of Visual Data with the JPEG StandardNo ratings yet

- PCMC To PhugewadiDocument1 pagePCMC To PhugewadiChindhi LaalNo ratings yet

- Excel RecoveryDocument2 pagesExcel RecoveryChindhi LaalNo ratings yet

- 632042a9eea39c3b6e370a9e All SignDocument37 pages632042a9eea39c3b6e370a9e All SignChindhi LaalNo ratings yet

- 35 Determination of Tin in Lead Alloy For SH - AthlngDocument2 pages35 Determination of Tin in Lead Alloy For SH - AthlngChindhi LaalNo ratings yet

- 34 Measur - Ment of Thickness of Metallic SheathDocument1 page34 Measur - Ment of Thickness of Metallic SheathChindhi LaalNo ratings yet

- 31 Oil Resistance TestDocument2 pages31 Oil Resistance TestChindhi LaalNo ratings yet

- 32 Carbon Content Test For Poly - ThyleneDocument2 pages32 Carbon Content Test For Poly - ThyleneChindhi LaalNo ratings yet

- 33 Water Absorption Test (Gravimetric)Document2 pages33 Water Absorption Test (Gravimetric)Chindhi LaalNo ratings yet

- NALCERDocument1 pageNALCERHitesh PaliwalNo ratings yet

- Barrier MTL 5511Document1 pageBarrier MTL 5511Cma Anita Singh GautamNo ratings yet

- Intro:: SCI 403 J. Marinay Physics IDocument11 pagesIntro:: SCI 403 J. Marinay Physics IKRISTELLE GEM CABANIGNo ratings yet

- O.cloud and Rain AnswerDocument6 pagesO.cloud and Rain AnswerJaisnava GhoshNo ratings yet

- Rotor-Dynamics Analysis ProcessDocument16 pagesRotor-Dynamics Analysis ProcessLaksh ManNo ratings yet

- Microstrip Patch Antennas For Gps ApplicationsDocument4 pagesMicrostrip Patch Antennas For Gps ApplicationsMibha MohanNo ratings yet

- 1-INRODUCTION TO MICROWAVE ENGINEERING-10-Jul-2019Material - I - 10-Jul-2019 - 1 - IntroductionDocument6 pages1-INRODUCTION TO MICROWAVE ENGINEERING-10-Jul-2019Material - I - 10-Jul-2019 - 1 - Introductionabhignan routhuNo ratings yet

- Lec 9 Other MethodsDocument22 pagesLec 9 Other MethodsarafatasgharNo ratings yet

- Top Ten Mysteries of The UniverseDocument42 pagesTop Ten Mysteries of The Universeლალიაშვილი გიორგიNo ratings yet

- BEE-C410: B. Tech. Semester Iv Examination, 2021Document5 pagesBEE-C410: B. Tech. Semester Iv Examination, 2021NamanNo ratings yet

- Sonate Opus 3: A Violoncello Solo & BassoDocument25 pagesSonate Opus 3: A Violoncello Solo & BassoAIDANo ratings yet

- The DL8000 Preset ControllerDocument8 pagesThe DL8000 Preset ControllerMarcio Vieira Santana100% (1)

- Handout 1844 AC1844 Introduction To Animation in AutoCAD 2012 Class HandoutDocument25 pagesHandout 1844 AC1844 Introduction To Animation in AutoCAD 2012 Class HandoutBahrul AliemNo ratings yet

- E283C2Document22 pagesE283C2Steven YuNo ratings yet

- Fall ProtectionDocument93 pagesFall ProtectionMaicon Vinicius SilvaNo ratings yet

- Deoliveira 2016Document43 pagesDeoliveira 2016Yina Paola Estrada OtaloraNo ratings yet

- Cold Rolled Steel StripDocument40 pagesCold Rolled Steel StripshelarsanjayNo ratings yet

- 600VPR-310/520 Voltage Protection Relay: FeaturesDocument2 pages600VPR-310/520 Voltage Protection Relay: FeaturesHama AieaNo ratings yet

- Cisco Gigabit Ethernet Transceiver Modules - CiscoDocument91 pagesCisco Gigabit Ethernet Transceiver Modules - CiscoGeorge LuísNo ratings yet

- Introduction On SpectrophotometerDocument7 pagesIntroduction On SpectrophotometerbubNo ratings yet

- Networking - Xmind - Mind Mapping AppDocument2 pagesNetworking - Xmind - Mind Mapping AppLuis ValleNo ratings yet

- Response of Second Order System and Response To Step ForceDocument50 pagesResponse of Second Order System and Response To Step Forceedmar peregrinNo ratings yet

- Elements of Heat TransferDocument456 pagesElements of Heat TransferRandy SihombingNo ratings yet

- Deep Sea Electronics: Model 5220 Installation and Configuration InstructionsDocument2 pagesDeep Sea Electronics: Model 5220 Installation and Configuration Instructionsdhani_is100% (1)

- Tek TVS600Series UM 070991600Document398 pagesTek TVS600Series UM 070991600Lorraine PriceNo ratings yet

- Electronic Dice With Slow DownDocument13 pagesElectronic Dice With Slow DownDaniel BermodezNo ratings yet

- Santiago City, Philippines: University of La Salette Inc College of Engineering and ArchitectureDocument11 pagesSantiago City, Philippines: University of La Salette Inc College of Engineering and ArchitectureDonalyn RnqlloNo ratings yet

36 Dimensions of Armourlng Mat - Rlal

36 Dimensions of Armourlng Mat - Rlal

Uploaded by

Chindhi LaalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

36 Dimensions of Armourlng Mat - Rlal

36 Dimensions of Armourlng Mat - Rlal

Uploaded by

Chindhi LaalCopyright:

Available Formats

Free Standard provided by BIS via BSB Edge Private Limited to finolex cables ltd -

urse(chaitanya.deshpande@finolex.com) 106.220.88.75 [for non-commercial use only].

(Reaffirmed 2012)

UDC 621’315-222 : 006’78

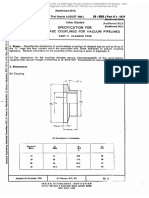

IS : 110810 ( Part 36 ) - 1984

( First Reprint MARCH 1998)

( Reaffirmed

( Reaffirmed 2001

1996 ) )

Indian Standard (Reaffirmed 2011)

(Reaffirmed 2016)

METHODS OF TEST FOR CABLES

PART 36 DIMENSIONS OF ARMOURING (Reaffirmed 2010)

MATERIAL

(Reaffirmed 2015)

. Scope - Covers method for measurement of dimensions of materials used for armouring of

+Xtric cables, as purchased or as taken out from the finished cable, without removing the zinc

(Reaffirmed 2009)

:oating in the case of galvanized materials.

Note - Armouring materials are generally in the form of wire, strip or tape. Measurements (Reaffirmed 2014)

for the following

dimensions are covered:

a) Wire: Diameter;

(Reaffirmed 2008)

b) Strip : Outer width, thickness and radius of curvature; and

c) Tape : Width and thickness

(Reaffirmed 2013)

!. Significance - Armouring of electric cables has to perform the following functions:

a) Mechanical protection against accidental damage,

(Reaffirmed 2007)

b) Ability to withstand pulling force while laying, and

c) To provide a path for earth fault current. (Reaffirmed 2012)

All these parameters have a bearing on the dimensions of the armour. This test is carried

jut to check whether the armour has the designed dimensions for any particular application.

(Reaffirmed 2006)

1. Terminology - See IS : 3975 - 1979 ‘Specification for mild steel wires, strips and tapes for

Irmouring of cables ( first revision ) ‘. (Reaffirmed 2011)

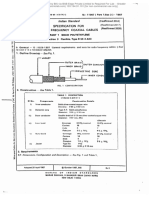

1. Apparatus

(Reaffirmed 2005)

1.1 Vernier Calliper - Suitable for inside as well as outside measurements with a least count

)f 0.01 mm.

(Reaffirmed 2010)

1.2 Micrometer Screw Gauge - Fitted with ratchet-head, least count 0’01 mm.

4.2.1 The moveable nose of the micrometer shall have plane circular face whereas the fixed

lose shall have~a plane circular face, ball point or needle point as follows:

a) Wire : Plane circular face, (Reaffirmed 2009)

b) Strip : Ball point or needle point, and

c) Tape : Plane circular face or ball point.

1.3 Corvafore Gauges - Suitable for measuring radii of curvature in the range 5 to 50 mm,

3.5 mm accuracy. (Reaffirmed 2008)

j. Material - No material other than the test speciman is required for performing this test.

6. Test Specimen

(Reaffirmed 2007)

6.1 The test specimen shall be a piece~of wire, strip or tapa, as the case may be, of 300 mm length.

It shall be free from scratches, dents and other external irregularities.

6.2 If the test specimen is to be cut from a coil, it shall be taken from the outer end after discard-

ing a minimum length of 300 mm.

7. Conditioning - No conditioning of test specimen is required. (Reaffirmed 2006)

8. Procedure

8.1 The test specimen shall be cleaned to remove extraneous coafings, if any, without damaging

the test spemcimen. (Reaffirmed 2005)

8.2 lf the test specimen is drawn from the finished cables it shall be made reasonably straight to

the extent possible without damaging it.

8.3 The test specimen shall be marked at three equidistant points ( say 50 mm ) from the ends ano

at the middle. The set of measurements made at these points shall be recorded and used to deter-

mine the average.

Adopted 14 March 1984 @ August 1985, BIS Gr 1

I I

BUREAU OF INDIAN STANDARDS

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI llOOQ2

Free Standard provided by BIS via BSB Edge Private Limited to finolex cables ltd -

urse(chaitanya.deshpande@finolex.com) 106.220.88.75 [for non-commercial use only].

IS : 10810 ( Part 36 ) - 1984

8.4 The measurements shall Abe made in the following manner:

a) Wire - At each marked point diameter shall be measured in two directions at right angles

to each other.

b) Sfrip- At each marked point outer width shall be measured with outside arms of vernier

calliper or by micrometer, the thickness shall be measured by micrometer and

radius by curvature gauge.

c) Tape - At each marked point, the width shall be measured by vernier cailiper and the

thickness shall be measured by micrometer in the centre of the tape width up to

30 mm and at 20 mm from the edge of the tape with larger widths.

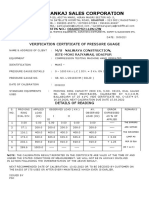

9. Tabulation of Observations

Measurement Wire Strip Tape

r--h-_ c--- _____h--_--_-~ r-- ---_y

Diameter Width Thickness Radius of Width Thickness

X Y Curvature

mm mm mm mm mm mm mm

PI

P2

P3

Note - X and Y are diameters measured in two directions at right angles to each other.

10. Calculations

10.1 Average values of respective dimensions shall be calculated as follows:

a) For Diameter of Wire:

zx+zy mm

Average value - ,

6

b) For Dimensions of Strip and Tape:

Pl + P2 + P3 mm

Average value - .

3

11. Report

11.i Test for Dimensions of Armouring Material

Specimen : From Coil/From ~Finished Cable/Coil No./Cable No.

11.2 Resulfs

Reference specification

Type of Material Dimensions Observed Specified

r--_--_zL_-_- VT

Nominal Minimum Maximum

WIRE D_iarneter

Width

STRIP Thickness

Radius of Curvature

Width

TAPE

Thickness

11.3 Conclusion - Specimen meets/does not meet the requirements of the specification.

Reprography Unit, BIS,‘New Delhi, India

You might also like

- 108SD 114SD - Repair ManualDocument1,406 pages108SD 114SD - Repair Manuallalo201042361100% (13)

- Rectangular Tank Design ROARKS FORMULADocument40 pagesRectangular Tank Design ROARKS FORMULANavasOT100% (3)

- Muscovite Mica Scrap For, Mica Paper - Specification: Indian StandardDocument5 pagesMuscovite Mica Scrap For, Mica Paper - Specification: Indian StandardAnuradhaPatraNo ratings yet

- Biomaterials Quick Study SheetDocument2 pagesBiomaterials Quick Study SheetWilliam ChanNo ratings yet

- Is 2473Document4 pagesIs 2473Kaushal PanchalNo ratings yet

- Insulator Telegraph and Telephone Lines - Specification: Stalks ForDocument13 pagesInsulator Telegraph and Telephone Lines - Specification: Stalks ForGnanavel GNo ratings yet

- Specification FOR External Micrometer: MarchDocument6 pagesSpecification FOR External Micrometer: MarchAshish DubeyNo ratings yet

- Specification For Radio Frequency Coaxial Cables: IS: 11967 (Part 3/sec 3) - 1988Document3 pagesSpecification For Radio Frequency Coaxial Cables: IS: 11967 (Part 3/sec 3) - 1988Shivangi BhardwajNo ratings yet

- Specification FOR Plain and Master Setting Ring Gauges (Size Range From 1 Up To and Including 315 MM)Document4 pagesSpecification FOR Plain and Master Setting Ring Gauges (Size Range From 1 Up To and Including 315 MM)Ashish DubeyNo ratings yet

- 9483 1993 Reff2020Document7 pages9483 1993 Reff2020Ashish DubeyNo ratings yet

- 9483 1993 Reff2020Document7 pages9483 1993 Reff2020Ashish DubeyNo ratings yet

- 3179 1990 Reff2020Document6 pages3179 1990 Reff2020Ashish DubeyNo ratings yet

- Specification For Fittings For Rigid Non-Metallic F Second Revision) ConduitsDocument16 pagesSpecification For Fittings For Rigid Non-Metallic F Second Revision) ConduitsAvinash MishraNo ratings yet

- Winding Wires For Submersible Motors - Specification: Indian StandardDocument9 pagesWinding Wires For Submersible Motors - Specification: Indian StandardkrixotNo ratings yet

- Specification For Mechanical Bevel Protractors: Indian StandardDocument4 pagesSpecification For Mechanical Bevel Protractors: Indian StandardAshish DubeyNo ratings yet

- Specification FOR External Micrometer: MarchDocument6 pagesSpecification FOR External Micrometer: MarchAnirban DasNo ratings yet

- 8023 1991 Reff2020Document7 pages8023 1991 Reff2020Ashish DubeyNo ratings yet

- Indian Standard': 1$:6137 - 1983 (ReaffipmedDocument4 pagesIndian Standard': 1$:6137 - 1983 (ReaffipmedAshish DubeyNo ratings yet

- 8262 2 1976 Reff2021Document3 pages8262 2 1976 Reff2021Shubham DhupkarNo ratings yet

- 8262 2 1976 Reff2021Document3 pages8262 2 1976 Reff2021Shubham DhupkarNo ratings yet

- Indian Standard: Legal Metrology - Material Measures of LengthDocument9 pagesIndian Standard: Legal Metrology - Material Measures of LengthDiptiNo ratings yet

- Winding Wires For Submersible Motors - Specification: Indian StandardDocument9 pagesWinding Wires For Submersible Motors - Specification: Indian StandardShivangi BhardwajNo ratings yet

- Winding Wires For Submersible Motors - Specification: Indian StandardDocument12 pagesWinding Wires For Submersible Motors - Specification: Indian StandardShivangi BhardwajNo ratings yet

- Methods For'Measuring Case Depth of Steel: Indian StandardDocument7 pagesMethods For'Measuring Case Depth of Steel: Indian Standardsingaravelan narayanasamyNo ratings yet

- Is 9879-1998 (Ra-2021)Document8 pagesIs 9879-1998 (Ra-2021)singaravelan narayanasamyNo ratings yet

- IS 2379 - Pipeline Colour CodeDocument14 pagesIS 2379 - Pipeline Colour CodeNoel Federer SarkarNo ratings yet

- FOR Threadeo Steel Fasteners: (Reaffirmed 2001)Document4 pagesFOR Threadeo Steel Fasteners: (Reaffirmed 2001)Harshith Rao VadnalaNo ratings yet

- 2000 Reff2021 PDFDocument7 pages2000 Reff2021 PDFocsspectroNo ratings yet

- 3179 1990 Reff2020Document6 pages3179 1990 Reff2020Anirban DasNo ratings yet

- IS 8329 - 2000 - AMD5 - Reff 2020Document23 pagesIS 8329 - 2000 - AMD5 - Reff 2020Rishab KejriwalNo ratings yet

- IS 906 I Specification For Fire Hose Delivery Couplings, Branch Pipe, Nozzles and Nozzle Spanner - SpecificaionDocument12 pagesIS 906 I Specification For Fire Hose Delivery Couplings, Branch Pipe, Nozzles and Nozzle Spanner - SpecificaionHemal BhagatNo ratings yet

- Methods of Sampling For Paints, Varnishes A ND Related: Indian StandardDocument6 pagesMethods of Sampling For Paints, Varnishes A ND Related: Indian StandardselvaNo ratings yet

- IS: 11967 (Part 3/secl) - 1988: (Reaffirmed 20 20)Document3 pagesIS: 11967 (Part 3/secl) - 1988: (Reaffirmed 20 20)Shivangi BhardwajNo ratings yet

- Specification FOR Injection Moulded PVC Socket Fittings With Solvent Cement Joints For Water SuppliesDocument8 pagesSpecification FOR Injection Moulded PVC Socket Fittings With Solvent Cement Joints For Water SuppliesCIPET TESTING - AGARTALANo ratings yet

- Technical Supply Conditions For Gauges: 1 IS: 7018 (Part 2) - 1983 Indian StandardDocument6 pagesTechnical Supply Conditions For Gauges: 1 IS: 7018 (Part 2) - 1983 Indian StandardAshish DubeyNo ratings yet

- Method For Emission Spectrometric Analysis of Austenitic and Ferritic Stainless Steels Point To Plane Technique (First Revision)Document8 pagesMethod For Emission Spectrometric Analysis of Austenitic and Ferritic Stainless Steels Point To Plane Technique (First Revision)DiptiNo ratings yet

- Is 10810 - 6 - 1984 Ra 2016Document3 pagesIs 10810 - 6 - 1984 Ra 2016Swati SharmaNo ratings yet

- Digitalmeasuringinstrumentsfor Measurementandcontrol: Indian StandardDocument7 pagesDigitalmeasuringinstrumentsfor Measurementandcontrol: Indian StandardAshish DubeyNo ratings yet

- Digital-Miyiiisukinginstrumentsfor Measurementandcontrol: Indian StandardDocument10 pagesDigital-Miyiiisukinginstrumentsfor Measurementandcontrol: Indian StandardAshish DubeyNo ratings yet

- 2 1993 Reff2020Document10 pages2 1993 Reff2020Parth PatelNo ratings yet

- Specification FOR Injection Moulded PVC Socket Fittings With Solvent Cement Joints For Water SuppliesDocument2 pagesSpecification FOR Injection Moulded PVC Socket Fittings With Solvent Cement Joints For Water Suppliesanurag singhNo ratings yet

- 7876 1975 Reff2020Document18 pages7876 1975 Reff2020Ashish DubeyNo ratings yet

- 1984 Reff2020Document4 pages1984 Reff2020Ashish DubeyNo ratings yet

- 2000 Reff2021Document7 pages2000 Reff2021Ersatz IdiotaNo ratings yet

- 1405 2010 Reff2021 PDFDocument20 pages1405 2010 Reff2021 PDFocsspectroNo ratings yet

- Specification FOR Injection Moulded PVC Socket Fittings With Solvent Cement Joints For Water SuppliesDocument3 pagesSpecification FOR Injection Moulded PVC Socket Fittings With Solvent Cement Joints For Water SuppliesCIPET TESTING - AGARTALANo ratings yet

- Electric Traction Lifts: Indian StandardDocument12 pagesElectric Traction Lifts: Indian StandardDebabrata PalNo ratings yet

- 2008 Reff2021Document10 pages2008 Reff2021Archana ShuklaNo ratings yet

- Reaffirmed 2001Document8 pagesReaffirmed 2001Gnanavel GNo ratings yet

- Is 101 - 3 - 2Document11 pagesIs 101 - 3 - 2Ruby MalhotraNo ratings yet

- Dimensions For Porcelain Transformer Bushings For Use in Heavily Polluted ATMOSPHERES 12/17.5 KV, 24 KV AND 36 KVDocument12 pagesDimensions For Porcelain Transformer Bushings For Use in Heavily Polluted ATMOSPHERES 12/17.5 KV, 24 KV AND 36 KVGnanavel G100% (1)

- Specification FOR Radio Frequency Coaxial Cables: Indian StandardDocument4 pagesSpecification FOR Radio Frequency Coaxial Cables: Indian StandardShivangi BhardwajNo ratings yet

- 1995 Reff2020Document7 pages1995 Reff2020Ashish DubeyNo ratings yet

- 2010 AMD3 Reff2021Document24 pages2010 AMD3 Reff2021Roushan KumarNo ratings yet

- Methods of Grading and Visual Classification of Muscovite Mica SplittingsDocument8 pagesMethods of Grading and Visual Classification of Muscovite Mica SplittingsAnuradhaPatraNo ratings yet

- Thermoplastics Pipes and Fittings - Methods of Test (: Indian StandardDocument65 pagesThermoplastics Pipes and Fittings - Methods of Test (: Indian StandardVikash MudgilNo ratings yet

- Non-Destructive Integrity Testing of Piles (NDT) - GuidelinesDocument11 pagesNon-Destructive Integrity Testing of Piles (NDT) - Guidelineshardik sorathiyaNo ratings yet

- 3wriw: Indian StandardDocument6 pages3wriw: Indian StandardkrixotNo ratings yet

- IS-12437 Zirconium PowderDocument8 pagesIS-12437 Zirconium PowderAnuradhaPatraNo ratings yet

- Lndian Standard: Clay Roofing Tiles, Mangalore Pattern - Specification (Document11 pagesLndian Standard: Clay Roofing Tiles, Mangalore Pattern - Specification (Sooraj Matter LabNo ratings yet

- Bicycles - Pedal Assembly - Specification: Indian StandardDocument7 pagesBicycles - Pedal Assembly - Specification: Indian StandardYoginder SainiNo ratings yet

- Specification For Optical Bevel Protractors: Indian StandardDocument3 pagesSpecification For Optical Bevel Protractors: Indian StandardAshish DubeyNo ratings yet

- Joint Photographic Experts Group: Unlocking the Power of Visual Data with the JPEG StandardFrom EverandJoint Photographic Experts Group: Unlocking the Power of Visual Data with the JPEG StandardNo ratings yet

- PCMC To PhugewadiDocument1 pagePCMC To PhugewadiChindhi LaalNo ratings yet

- Excel RecoveryDocument2 pagesExcel RecoveryChindhi LaalNo ratings yet

- 632042a9eea39c3b6e370a9e All SignDocument37 pages632042a9eea39c3b6e370a9e All SignChindhi LaalNo ratings yet

- 35 Determination of Tin in Lead Alloy For SH - AthlngDocument2 pages35 Determination of Tin in Lead Alloy For SH - AthlngChindhi LaalNo ratings yet

- 34 Measur - Ment of Thickness of Metallic SheathDocument1 page34 Measur - Ment of Thickness of Metallic SheathChindhi LaalNo ratings yet

- 31 Oil Resistance TestDocument2 pages31 Oil Resistance TestChindhi LaalNo ratings yet

- 32 Carbon Content Test For Poly - ThyleneDocument2 pages32 Carbon Content Test For Poly - ThyleneChindhi LaalNo ratings yet

- 33 Water Absorption Test (Gravimetric)Document2 pages33 Water Absorption Test (Gravimetric)Chindhi LaalNo ratings yet

- NALCERDocument1 pageNALCERHitesh PaliwalNo ratings yet

- Barrier MTL 5511Document1 pageBarrier MTL 5511Cma Anita Singh GautamNo ratings yet

- Intro:: SCI 403 J. Marinay Physics IDocument11 pagesIntro:: SCI 403 J. Marinay Physics IKRISTELLE GEM CABANIGNo ratings yet

- O.cloud and Rain AnswerDocument6 pagesO.cloud and Rain AnswerJaisnava GhoshNo ratings yet

- Rotor-Dynamics Analysis ProcessDocument16 pagesRotor-Dynamics Analysis ProcessLaksh ManNo ratings yet

- Microstrip Patch Antennas For Gps ApplicationsDocument4 pagesMicrostrip Patch Antennas For Gps ApplicationsMibha MohanNo ratings yet

- 1-INRODUCTION TO MICROWAVE ENGINEERING-10-Jul-2019Material - I - 10-Jul-2019 - 1 - IntroductionDocument6 pages1-INRODUCTION TO MICROWAVE ENGINEERING-10-Jul-2019Material - I - 10-Jul-2019 - 1 - Introductionabhignan routhuNo ratings yet

- Lec 9 Other MethodsDocument22 pagesLec 9 Other MethodsarafatasgharNo ratings yet

- Top Ten Mysteries of The UniverseDocument42 pagesTop Ten Mysteries of The Universeლალიაშვილი გიორგიNo ratings yet

- BEE-C410: B. Tech. Semester Iv Examination, 2021Document5 pagesBEE-C410: B. Tech. Semester Iv Examination, 2021NamanNo ratings yet

- Sonate Opus 3: A Violoncello Solo & BassoDocument25 pagesSonate Opus 3: A Violoncello Solo & BassoAIDANo ratings yet

- The DL8000 Preset ControllerDocument8 pagesThe DL8000 Preset ControllerMarcio Vieira Santana100% (1)

- Handout 1844 AC1844 Introduction To Animation in AutoCAD 2012 Class HandoutDocument25 pagesHandout 1844 AC1844 Introduction To Animation in AutoCAD 2012 Class HandoutBahrul AliemNo ratings yet

- E283C2Document22 pagesE283C2Steven YuNo ratings yet

- Fall ProtectionDocument93 pagesFall ProtectionMaicon Vinicius SilvaNo ratings yet

- Deoliveira 2016Document43 pagesDeoliveira 2016Yina Paola Estrada OtaloraNo ratings yet

- Cold Rolled Steel StripDocument40 pagesCold Rolled Steel StripshelarsanjayNo ratings yet

- 600VPR-310/520 Voltage Protection Relay: FeaturesDocument2 pages600VPR-310/520 Voltage Protection Relay: FeaturesHama AieaNo ratings yet

- Cisco Gigabit Ethernet Transceiver Modules - CiscoDocument91 pagesCisco Gigabit Ethernet Transceiver Modules - CiscoGeorge LuísNo ratings yet

- Introduction On SpectrophotometerDocument7 pagesIntroduction On SpectrophotometerbubNo ratings yet

- Networking - Xmind - Mind Mapping AppDocument2 pagesNetworking - Xmind - Mind Mapping AppLuis ValleNo ratings yet

- Response of Second Order System and Response To Step ForceDocument50 pagesResponse of Second Order System and Response To Step Forceedmar peregrinNo ratings yet

- Elements of Heat TransferDocument456 pagesElements of Heat TransferRandy SihombingNo ratings yet

- Deep Sea Electronics: Model 5220 Installation and Configuration InstructionsDocument2 pagesDeep Sea Electronics: Model 5220 Installation and Configuration Instructionsdhani_is100% (1)

- Tek TVS600Series UM 070991600Document398 pagesTek TVS600Series UM 070991600Lorraine PriceNo ratings yet

- Electronic Dice With Slow DownDocument13 pagesElectronic Dice With Slow DownDaniel BermodezNo ratings yet

- Santiago City, Philippines: University of La Salette Inc College of Engineering and ArchitectureDocument11 pagesSantiago City, Philippines: University of La Salette Inc College of Engineering and ArchitectureDonalyn RnqlloNo ratings yet