Professional Documents

Culture Documents

EN Operating Instructions VEGABAR 19 Two Wire 4 20 Ma

EN Operating Instructions VEGABAR 19 Two Wire 4 20 Ma

Uploaded by

Osuntogun QozeemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EN Operating Instructions VEGABAR 19 Two Wire 4 20 Ma

EN Operating Instructions VEGABAR 19 Two Wire 4 20 Ma

Uploaded by

Osuntogun QozeemCopyright:

Available Formats

Operating Instructions

Pressure sensor with metallic measuring

cell

VEGABAR 19

Two-wire 4 … 20 mA

Document ID: 55576

Contents

Contents

1 About this document................................................................................................................ 4

1.1 Function............................................................................................................................ 4

1.2 Target group...................................................................................................................... 4

1.3 Symbols used................................................................................................................... 4

2 For your safety.......................................................................................................................... 5

2.1 Authorised personnel........................................................................................................ 5

2.2 Appropriate use................................................................................................................. 5

2.3 Warning about incorrect use.............................................................................................. 5

2.4 General safety instructions................................................................................................ 5

2.5 Installation and operation in the USA and Canada............................................................ 5

3 Product description.................................................................................................................. 7

3.1 Configuration..................................................................................................................... 7

3.2 Principle of operation........................................................................................................ 8

3.3 Adjustment...................................................................................................................... 10

3.4 Packaging, transport and storage.................................................................................... 10

3.5 Accessories.................................................................................................................... 11

4 Mounting.................................................................................................................................. 12

4.1 General instructions........................................................................................................ 12

4.2 Process pressure measurement...................................................................................... 14

5 Connecting to power supply.................................................................................................. 16

5.1 Preparing the connection................................................................................................ 16

5.2 Connection procedure..................................................................................................... 16

5.3 Wiring plan...................................................................................................................... 19

5.4 Switch-on phase............................................................................................................. 19

6 Diagnostics and servicing..................................................................................................... 21

6.1 Maintenance................................................................................................................... 21

6.2 Rectify faults.................................................................................................................... 21

6.3 Diagnosis, fault messages.............................................................................................. 22

6.4 How to proceed if a repair is necessary........................................................................... 22

7 Dismount................................................................................................................................. 23

7.1 Dismounting steps.......................................................................................................... 23

7.2 Disposal.......................................................................................................................... 23

8 Certificates and approvals..................................................................................................... 24

8.1 EU conformity.................................................................................................................. 24

8.2 NAMUR recommendations............................................................................................. 24

8.3 Environment management system.................................................................................. 24

9 Supplement............................................................................................................................. 25

9.1 Technical data................................................................................................................. 25

9.2 Dimensions..................................................................................................................... 29

9.3 Industrial property rights.................................................................................................. 31

55576-EN-220314

9.4 Licensing information for open source software.............................................................. 31

9.5 Trademark....................................................................................................................... 31

2 VEGABAR 19 • Two-wire 4 … 20 mA

Contents

55576-EN-220314

Safety instructions for Ex areas:

Take note of the Ex specific safety instructions for Ex applications.

These instructions are attached as documents to each instrument

with Ex approval and are part of the operating instructions.

Editing status: 2022-02-22

VEGABAR 19 • Two-wire 4 … 20 mA 3

1 About this document

1 About this document

1.1 Function

This instruction provides all the information you need for mounting,

connection and setup as well as important instructions for mainte-

nance, fault rectification, the exchange of parts and the safety of the

user. Please read this information before putting the instrument into

operation and keep this manual accessible in the immediate vicinity

of the device.

1.2 Target group

This operating instructions manual is directed to trained personnel.

The contents of this manual must be made available to the qualified

personnel and implemented.

1.3 Symbols used

Document ID

This symbol on the front page of this instruction refers to the Docu-

ment ID. By entering the Document ID on www.vega.com you will

reach the document download.

Information, note, tip: This symbol indicates helpful additional infor-

mation and tips for successful work.

Note: This symbol indicates notes to prevent failures, malfunctions,

damage to devices or plants.

Caution: Non-observance of the information marked with this symbol

may result in personal injury.

Warning: Non-observance of the information marked with this symbol

may result in serious or fatal personal injury.

Danger: Non-observance of the information marked with this symbol

results in serious or fatal personal injury.

Ex applications

This symbol indicates special instructions for Ex applications.

• List

The dot set in front indicates a list with no implied sequence.

1 Sequence of actions

Numbers set in front indicate successive steps in a procedure.

Disposal

This symbol indicates special instructions for disposal.

55576-EN-220314

4 VEGABAR 19 • Two-wire 4 … 20 mA

2 For your safety

2 For your safety

2.1 Authorised personnel

All operations described in this documentation must be carried out

only by trained, qualified personnel authorised by the plant operator.

During work on and with the device, the required personal protective

equipment must always be worn.

2.2 Appropriate use

The VEGABAR 19 is a pressure transmitter for process pressure

measurement.

You can find detailed information about the area of application in

chapter " Product description".

Operational reliability is ensured only if the instrument is properly

used according to the specifications in the operating instructions

manual as well as possible supplementary instructions.

2.3 Warning about incorrect use

Inappropriate or incorrect use of this product can give rise to applica-

tion-specific hazards, e.g. vessel overfill through incorrect mounting

or adjustment. Damage to property and persons or environmental

contamination can result. Also, the protective characteristics of the

instrument can be impaired.

2.4 General safety instructions

This is a state-of-the-art instrument complying with all prevailing

regulations and directives. The instrument must only be operated in a

technically flawless and reliable condition. The operator is responsi-

ble for the trouble-free operation of the instrument. When measuring

aggressive or corrosive media that can cause a dangerous situation

if the instrument malfunctions, the operator has to implement suitable

measures to make sure the instrument is functioning properly.

The safety instructions in this operating instructions manual, the na-

tional installation standards as well as the valid safety regulations and

accident prevention rules must be observed by the user.

For safety and warranty reasons, any invasive work on the device

beyond that described in the operating instructions manual may be

carried out only by personnel authorised by the manufacturer. Arbi-

trary conversions or modifications are explicitly forbidden. For safety

reasons, only the accessory specified by the manufacturer must be

used.

To avoid any danger, the safety approval markings and safety tips on

the device must also be observed.

55576-EN-220314

2.5 Installation and operation in the USA and

Canada

This information is only valid for USA and Canada. Hence the follow-

ing text is only available in the English language.

VEGABAR 19 • Two-wire 4 … 20 mA 5

2 For your safety

Installations in the US shall comply with the relevant requirements of

the National Electrical Code (ANSI/NFPA 70).

Installations in Canada shall comply with the relevant requirements of

the Canadian Electrical Code.

55576-EN-220314

6 VEGABAR 19 • Two-wire 4 … 20 mA

3 Product description

3 Product description

3.1 Configuration

Scope of delivery The scope of delivery encompasses:

• VEGABAR 19 pressure transmitter

• Information sheet " Documents and software" with:

–– Instrument serial number

–– QR code with link for direct scanning

Note:

Optional instrument features are also described in this operating

instructions manual. The respective scope of delivery results from the

order specification.

Scope of this operating This operating instructions manual applies to the following instrument

instructions versions:

• Hardware version from 1.0.0

• Software version from 1.0.0

Constituent parts

3

Fig. 1: Components of VEGABAR 19

1 Process fitting

2 Electronics housing

3 Plug connector

Type label The type label contains the most important data for identification and

use of the instrument.

55576-EN-220314

VEGABAR 19 • Two-wire 4 … 20 mA 7

3 Product description

VEGABAR 1.

1 PP - 222 2EN s/n 12345678

0044

2

12V...35V

4...20mA

3 IP66/67 TYPE 4X

MWP 10bar (1000kPa)

0...0,1bar (0...10kPa) rel

AL203, FKM, 316L

+

2 1 www.vega.com

4 3 4

D-77761 SCHILTACH,

5

- Made in Germany

Fig. 2: Layout of the type label (example)

1 Instrument type, order and serial number

2 Field for approvals

3 Technical data

4 Assignment

5 QR code for device documentation

Documents and software Move to " www.vega.com" and enter in the search field the serial

number of your instrument.

There you can find the following information about the instrument:

• Order data

• Documentation

• Software

Alternatively, you can find all via your smartphone:

• Scan the QR-code on the type label of the device or

• Enter serial number manually in the VEGA Tools app (available

free of charge in the respective stores)

3.2 Principle of operation

Application area VEGABAR 19 is suitable for applications in virtually all industries. It is

used for the measurement of the following pressure types.

• Gauge pressure

Measured products Measured products are gases, vapours and liquids.

Measured variables The VEGABAR 19 is suitable for the measurement of the following

process variables:

• Process pressure

55576-EN-220314

8 VEGABAR 19 • Two-wire 4 … 20 mA

3 Product description

Fig. 3: Process pressure measurement VEGABAR 19

Measuring system The process pressure acts on the piezoresisitve sensor element via

the process diaphragm. The process pressure causes a resistance

change which is converted into a corresponding output signal and

output as measured value.

1 2

3 4

Fig. 4: Configuration of the measuring system with piezoresistive sensor ele-

ment

1 Sensor element

2 Base element

3 Transmission liquid

4 Process diaphragm

Pressure types Relative pressure: the measuring cell is open to the atmosphere.

The ambient pressure is detected in the measuring cell and compen-

sated. It thus has no influence on the measured value.

Recessed installation The recessed installation is particularly suitable for applications with

gases, vapours and transparent liquids.

55576-EN-220314

VEGABAR 19 • Two-wire 4 … 20 mA 9

3 Product description

Fig. 5: Recessed installation of the measuring cell (example: thread G½, EN 837

manometer connection)

1 Measuring cell

2 Diaphragm

3 Process fitting

3.3 Adjustment

The instrument offers no adjustment options.

3.4 Packaging, transport and storage

Packaging Your instrument was protected by packaging during transport. Its

capacity to handle normal loads during transport is assured by a test

based on ISO 4180.

The packaging consists of environment-friendly, recyclable card-

board. For special versions, PE foam or PE foil is also used. Dispose

of the packaging material via specialised recycling companies.

Transport Transport must be carried out in due consideration of the notes on the

transport packaging. Nonobservance of these instructions can cause

damage to the device.

Transport inspection The delivery must be checked for completeness and possible transit

damage immediately at receipt. Ascertained transit damage or con-

cealed defects must be appropriately dealt with.

Storage Up to the time of installation, the packages must be left closed and

stored according to the orientation and storage markings on the

outside.

Unless otherwise indicated, the packages must be stored only under

the following conditions:

• Not in the open

• Dry and dust free

• Not exposed to corrosive media

• Protected against solar radiation

• Avoiding mechanical shock and vibration

Storage and transport • Storage and transport temperature see chapter " Supplement -

temperature Technical data - Ambient conditions"

55576-EN-220314

• Relative humidity 20 … 85 %

10 VEGABAR 19 • Two-wire 4 … 20 mA

3 Product description

3.5 Accessories

The instructions for the listed accessories can be found in the down-

load area on our homepage.

Welded socket, threaded Welded sockets are used to connect the devices to the process.

and hygienic adapter Threaded and hygienic adapters enable simple adaptation of devices

with standard threaded fittings to process-side hygiene connections.

Mounting accessories The suitable mounting accessories for VEGABAR 19 includes si-

phons, blocking valves and measuring instrument holders.

55576-EN-220314

VEGABAR 19 • Two-wire 4 … 20 mA 11

4 Mounting

4 Mounting

4.1 General instructions

Ambient conditions The instrument is suitable for standard and extended ambient condi-

tions acc. to DIN/EN/IEC/ANSI/ISA/UL/CSA 61010-1. It can be used

indoors as well as outdoors.

Process conditions Note:

For safety reasons, the instrument must only be operated within the

permissible process conditions. You can find detailed information on

the process conditions in chapter " Technical data" of the operating

instructions or on the type label.

Hence make sure before mounting that all parts of the instrument ex-

posed to the process are suitable for the existing process conditions.

These are mainly:

• Active measuring component

• Process fitting

• Process seal

Process conditions in particular are:

• Process pressure

• Process temperature

• Chemical properties of the medium

• Abrasion and mechanical influences

Permissible process The permissible process pressure range is specified by "MWP" (Maxi-

pressure (MWP) - Device mum Working Pressure) on the type label, see chapter " Structure".

The MWP takes the element of the measuring cell and processing

fitting combination with the weakest pressure into consideration and

may applied permanently. The specification refers to a reference

temperature of +20 °C (+68 °F). It also applies when a measuring cell

with a higher measuring range than the permissible pressure range of

the process fitting is installed order-related.

In order to prevent damage to the device, a test pressure may only

exceed the specified MWP briefly by 1.5 times at reference tempera-

ture. The pressure stage of the process fitting as well as the overload

resistance of the measuring cell are taken into consideration here

(see chapter " Technical Data").

In addition, a temperature derating of the process fitting, e. g. with

flanges, can limit the permissible process pressure range according

to the respective standard.

Protection against mois- Protect your instrument against moisture ingress through the following

ture measures:

• Use a suitable connection cable (see chapter " Connecting to

55576-EN-220314

power supply")

• Tighten the cable gland or plug connector

• Lead the connection cable downward in front of the cable entry or

plug connector

12 VEGABAR 19 • Two-wire 4 … 20 mA

4 Mounting

This applies mainly to outdoor installations, in areas where high

humidity is expected (e.g. through cleaning processes) and on cooled

or heated vessels.

Ventilation and pressure Ventilation and pressure compensation for VEGABAR 19 are provided

compensation by an air-permeable, moisture-blocking filter element.

Fig. 6: Position of the filter element

1 Filter element

For effective ventilation, the filter element must always be free of

buildup.

Caution:

Do not use a high-pressure cleaner. The filter element could be dam-

aged, which would allow moisture into the housing.

Screwing in Devices with threaded fitting are screwed into the process fitting with

a suitable wrench via the hexagon.

See chapter " Dimensions" for wrench size.

Warning:

The housing or the electrical connection may not be used for screw-

ing in! Depending on the device version, tightening can cause dam-

age, e. g. to the rotation mechanism of the housing.

Permissible process The permissible process pressure range is stated on the type label.

pressure (MWP) - Mount- The instrument should only be operated with these pressures if the

ing accessory mounting accessory used also fulfils these values. This should be en-

sured by suitable flanges, welded sockets, tension rings with Clamp

connections, sealings, etc.

Temperature limits Higher process temperatures often mean also higher ambient

temperatures. Make sure that the upper temperature limits stated in

chapter " Technical data" for the environment of the electronics hous-

ing and connection cable are not exceeded.

55576-EN-220314

VEGABAR 19 • Two-wire 4 … 20 mA 13

4 Mounting

1

Fig. 7: Temperature ranges

1 Process temperature

2 Ambient temperature

4.2 Process pressure measurement

In gases Keep the following in mind when setting up the measuring system:

• Mount the instrument above the measuring point

Possible condensation can then drain off into the process line.

1

2

3

Fig. 8: Measurement setup for process pressure measurement of gases in

pipelines

1 VEGABAR 19

2 Blocking valve

3 Pipeline

In vapours Keep the following in mind when setting up the measuring system:

• Connect via a siphon

55576-EN-220314

14 VEGABAR 19 • Two-wire 4 … 20 mA

4 Mounting

1 1

2 2

3 3

4 4

Fig. 9: Measurement setup for process pressure measurement of gases in

pipelines

1 VEGABAR 19

2 Blocking valve

3 Siphon in U or circular form

4 Pipeline

A protective accumulation of water is formed through condensation

in the pipe bends. Even in applications with hot steam, a medium

temperature < 100 °C on the transmitter is ensured.

In liquids Keep the following in mind when setting up the measuring system:

• Mount the instrument below the measuring point

The effective pressure line is always filled with liquid and gas bubbles

can bubble up to the process line.

1

Fig. 10: Measurement setup for process pressure measurement of liquids in

pipelines

1 VEGABAR 19

55576-EN-220314

2 Blocking valve

3 Pipeline

VEGABAR 19 • Two-wire 4 … 20 mA 15

5 Connecting to power supply

5 Connecting to power supply

5.1 Preparing the connection

Safety instructions Always keep in mind the following safety instructions:

• Carry out electrical connection by trained, qualified personnel

authorised by the plant operator

• If overvoltage surges are expected, overvoltage arresters should

be installed

Warning:

Only connect or disconnect in de-energized state.

Voltage supply The data for power supply are specified in chapter " Technical data".

Note:

Power the instrument via an energy-limited circuit (power max. 100 W)

acc. to IEC 61010-1, e.g.

• Class 2 power supply unit (acc. to UL1310)

• SELV power supply unit (safety extra-low voltage) with suitable

internal or external limitation of the output current

Keep in mind the following additional factors that influence the operat-

ing voltage:

• Lower output voltage of the power supply unit under nominal load

(e.g. with a sensor current of 20.5 mA or 22 mA in case of fault

signal)

• Influence of additional instruments in the circuit (see load values in

chapter " Technical data")

Connection cable Use cable with round cross section. Depending on the plug connec-

tion, you have to select the outer diameter of the cable respectively so

that the seal effect of the cable gland is ensured.

Depending on the connection method or signal output, the device is

connected with standard two, three or four-wire cable without shield-

ing.

5.2 Connection procedure

Plug according to Proceed as follows:

ISO 4400 1. Loosen the screw on the rear of the plug connector

2. Remove the plug connector and seal from VEGABAR 19

3. Remove the plug insert from the plug housing

55576-EN-220314

16 VEGABAR 19 • Two-wire 4 … 20 mA

5 Connecting to power supply

3

2

Fig. 11: Loosen the plug insert

1 Cable gland

2 Plug insert

3 Plug housing

4. Remove approx. 5 cm of the cable mantle, strip approx. 1 cm

insulation from the individual wires

5. Lead the cable through the cable gland into the plug housing

6. Connect the wire ends to the screw terminals according to the

wiring plan

2

1

3

4

Fig. 12: Connection to the screw terminals

1 Cable gland

2 Plug housing

3 Plug insert

4 Plug seal

7. Snap the plug insert into the plug housing and insert the sensor

seal

8. Plug the plug insert with seal to VEGABAR 19 and tighten the

screw

The electrical connection is finished.

Connection via angle Proceed as follows:

plug connector with 1. Loosen the screw in the cover of the plug connector

hinged cover

55576-EN-220314

2. Open the cover and remove it

3. Press the plug insert downwards

4. Loosen the screws of the strain relief and cable entry

VEGABAR 19 • Two-wire 4 … 20 mA 17

5 Connecting to power supply

1 2 3

3

2

4

Fig. 13: Loosen the plug insert

1 Plug insert

2 Strain relief

3 Cable gland

4 Plug housing

5. Remove approx. 5 cm of the cable mantle, strip approx. 1 cm

insulation from the individual wires

6. Lead the cable through the cable gland into the plug housing

7. Connect the wire ends to the screw terminals according to the

wiring plan

2

1

3

Fig. 14: Connection to the screw terminals

1 Cable gland

2 Cover

3 Plug housing

4 Plug insert

5 Plug seal

8. Snap the plug insert into the plug housing and insert the sensor

seal

Information:

Note the correct arrangement, see illustration

9. Tighten the screws on the strain relief and cable entry

55576-EN-220314

10. Hook in the cover and push onto the plug connection, tighten

cover screw

11. Plug the plug insert with seal to VEGABAR 19 and tighten the

screw

18 VEGABAR 19 • Two-wire 4 … 20 mA

5 Connecting to power supply

The electrical connection is finished.

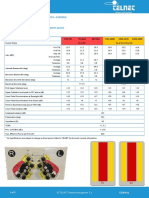

5.3 Wiring plan

M12 x 1 plug

+

2 1

1

3 4

-

Fig. 15: Wiring plan - two-wire 4 … 20 mA - M12 x 1 plug

1 Voltage supply and signal output

Contact, plug connector Function/Polarity

1 Voltage supply, signal output/+

2 Free

3 Voltage supply, signal output/-

4 Free

Plug according to

ISO 4400 +

1 2 1

3

-

Fig. 16: Wiring plan - two-wire 4 … 20 mA - plug according to ISO 4400

1 Voltage supply and signal output

Contact, plug connector Function/Polarity

1 Voltage supply, signal output/+

2 Voltage supply, signal output/-

3 Free

Electrically connected with metal housing

55576-EN-220314

5.4 Switch-on phase

After switching on, the device first carries out a self-check:

• Internal check of the electronics

• The output signal jumps to the set fault current

VEGABAR 19 • Two-wire 4 … 20 mA 19

5 Connecting to power supply

The current measured value is then output on the signal cable.

55576-EN-220314

20 VEGABAR 19 • Two-wire 4 … 20 mA

6 Diagnostics and servicing

6 Diagnostics and servicing

6.1 Maintenance

Maintenance If the device is used properly, no special maintenance is required in

normal operation.

Precaution measures In some applications, product buildup on the diaphragm can influence

against buildup the measuring result. Depending on the sensor and application, take

precautions to ensure that heavy buildup, and especially a hardening

thereof, is avoided.

Cleaning The cleaning helps that the type label and markings on the instrument

are visible.

Take note of the following:

• Use only cleaning agents which do not corrode the housings, type

label and seals

• Use only cleaning methods corresponding to the housing protec-

tion rating

6.2 Rectify faults

Reaction when malfunc- The operator of the system is responsible for taking suitable meas-

tion occurs ures to rectify faults.

Causes of malfunction The device offers maximum reliability. Nevertheless, faults can occur

during operation. These may be caused by the following, e.g.:

• Sensor

• Process

• Voltage supply

• Signal processing

Fault rectification The first measures are:

• Evaluation of fault messages

• Checking the output signal

• Treatment of measurement errors

A smartphone/tablet with the adjustment app or a PC/notebook with

the software PACTware and the suitable DTM offer you further com-

prehensive diagnostic possibilities. In many cases, the causes can be

determined in this way and the faults eliminated.

Reaction after fault recti- Depending on the reason for the fault and the measures taken, the

fication steps described in chapter " Setup" must be carried out again or must

be checked for plausibility and completeness.

24 hour service hotline Should these measures not be successful, please call in urgent cases

55576-EN-220314

the VEGA service hotline under the phone no. +49 1805 858550.

The hotline is also available outside normal working hours, seven

days a week around the clock.

VEGABAR 19 • Two-wire 4 … 20 mA 21

6 Diagnostics and servicing

Since we offer this service worldwide, the support is provided in

English. The service itself is free of charge, the only costs involved are

the normal call charges.

6.3 Diagnosis, fault messages

4 … 20 mA signal Connect a multimeter in the suitable measuring range according to

the wiring plan. The following table describes possible errors in the

current signal and helps to eliminate them:

Error Cause Rectification

4 … 20 mA signal missing Electrical connection faulty Check connection, correct, if necessary

Voltage supply missing Check cables for breaks; repair if nec-

essary

Operating voltage too low, load resist- Check, adapt if necessary

ance too high

Current signal greater than Sensor electronics defective Replace device or send in for repair de-

22 mA, less than 3.6 mA pending on device version

6.4 How to proceed if a repair is necessary

You can find an instrument return form as well as detailed information

about the procedure in the download area of our homepage. By doing

this you help us carry out the repair quickly and without having to call

back for needed information.

In case of repair, proceed as follows:

• Print and fill out one form per instrument

• Clean the instrument and pack it damage-proof

• Attach the completed form and, if need be, also a safety data

sheet outside on the packaging

• Ask the agency serving you to get the address for the return ship-

ment. You can find the agency on our homepage.

55576-EN-220314

22 VEGABAR 19 • Two-wire 4 … 20 mA

7 Dismount

7 Dismount

7.1 Dismounting steps

To remove the device, carry out the steps in chapters " Mounting" and

" Connecting to power suplly" in reverse.

Warning:

When dismounting, pay attention to the process conditions in vessels

or pipelines. There is a risk of injury, e.g. due to high pressures or tem-

peratures as well as aggressive or toxic media. Avoid this by taking

appropriate protective measures.

7.2 Disposal

Pass the instrument on to a specialised recycling company and do not

use the municipal collecting points.

Remove any batteries in advance, if they can be removed from the

device, and dispose of them separately.

If personal data is stored on the old device to be disposed of, delete it

before disposal.

If you have no way to dispose of the old instrument properly, please

contact us concerning return and disposal.

55576-EN-220314

VEGABAR 19 • Two-wire 4 … 20 mA 23

8 Certificates and approvals

8 Certificates and approvals

8.1 EU conformity

The device fulfils the legal requirements of the applicable EU direc-

tives. By affixing the CE marking, we confirm the conformity of the

instrument with these directives.

The EU conformity declaration can be found on our homepage.

Due to the design of its process fittings, the device does not subject

of EU pressure device directive if it is operated at process pressures

≤ 200 bar.

8.2 NAMUR recommendations

NAMUR is the automation technology user association in the process

industry in Germany. The published NAMUR recommendations are

accepted as the standard in field instrumentation.

The device fulfils the requirements of the following NAMUR recom-

mendations:

• NE 21 – Electromagnetic compatibility of equipment

• NE 43 – Signal level for fault information from measuring transduc-

ers

For further information see www.namur.de.

8.3 Environment management system

Protection of the environment is one of our most important duties.

That is why we have introduced an environment management system

with the goal of continuously improving company environmental pro-

tection. The environment management system is certified according

to DIN EN ISO 14001. Please help us fulfil this obligation by observ-

ing the environmental instructions in chapters " Packaging, transport

and storage", " Disposal" of these operating instructions.

55576-EN-220314

24 VEGABAR 19 • Two-wire 4 … 20 mA

9 Supplement

9 Supplement

9.1 Technical data

Note for approved instruments

The technical data in the respective safety instructions which are included in delivery are valid for

approved instruments (e.g. with Ex approval). These data can differ from the data listed herein, for

example regarding the process conditions or the voltage supply.

All approval documents can be downloaded from our homepage.

Materials and weights

Materials, wetted parts

Process fitting, measuring diaphragm 316L

Seal for process fitting (in the scope of delivery)

ƲƲ Thread G½ (EN 837), (manometer Klingersil C-4400

connection)

ƲƲ Thread G½, inside G¼ (ISO 228-1) Klingersil C-4400

Materials, non-wetted parts

Electronics housing 316L

M12 x 1 plug connector

ƲƲ Contact support PA

ƲƲ Contacts CuZn, nickel layer and 0.8 µm gold-plated

Plug connector according to ISO 4400

ƲƲ Contact, housing plug PA

ƲƲ Lid screw StSt

ƲƲ Contact surface Sn

ƲƲ Plug seal Silicone

Weight approx. 0.25 kg (0.55 lbs)

Torques

Max. torques

ƲƲ Thread G½ (EN 837), manometer 50 Nm (36.88 lbf ft)

connection

ƲƲ Thread G½, inside G¼ (ISO 228-1) 50 Nm (36.88 lbf ft)

Input variable

The specifications are only an overview and refer to the measuring cell. Limitations due to the

material and version of the process fitting as well as the selected pressure type are possible. The

specifications on the nameplate apply. 1)

Nominal measuring ranges and overload capability in bar/kPa

55576-EN-220314

Nominal range Overload capacity, max. pressure Overload capacity, min. pressure

0 … +0.4 bar/0 … +40 kPa +4 bar/+400 kPa -1 bar/-100 kPa

1)

Data on overload capability apply for reference temperature.

VEGABAR 19 • Two-wire 4 … 20 mA 25

9 Supplement

Nominal range Overload capacity, max. pressure Overload capacity, min. pressure

0 … +1 bar/0 … +100 kPa +4 bar/+400 kPa -1 bar/-100 kPa

0 … +2.5 bar/0 … +250 kPa +10 bar/+1000 kPa -1 bar/-100 kPa

0 … +5 bar/0 … +500 kPa +20 bar/+2000 kPa -1 bar/-100 kPa

0 … +10 bar/0 … +1000 kPa +40 bar/+4000 kPa -1 bar/-100 kPa

0 … +25 bar/0 … +2500 kPa +120 bar/+12 MPa -1 bar/-100 kPa

0 … +60 bar/0 … +6000 kPa +200 bar/+20 MPa -1 bar/-100 kPa

0 … +100 bar/0 … +10 MPa +200 bar/+20 MPa -1 bar/-100 kPa

Nominal measuring ranges and overload capacity in psi

Nominal range Overload capacity, max. pressure Overload capacity, min. pressure

0 … +5 psig +60 psig -14.5 psig

0 … +15 psig +60 psig -14.5 psig

0 … +30 psig +145 psig -14.5 psig

0 … +75 psig +290 psig -14.5 psig

0 … +150 psig +580 psig -14.5 psig

0 … +300 psig +1740 psig -14.5 psig

0 … +900 psig +2900 psig -14.5 psig

0 … +1450 psig +2900 psig -14.5 psig

Switch-on phase

Start-up time with operating voltage UB ≤ 1 s

Starting current for run-up time ≤ 3.6 mA

Output variable - two-wire 4 … 20 mA

Output signal 4 … 20 mA - passive

Connection technology Two-wire

Range of the output signal 3.8 … 20.5 mA

Signal resolution 5 µA

Fault signal output current 3.6 mA

Load See load resistance under Power supply

Transferred measured value Pressure

Dynamic behaviour output

Dynamic characteristics - Current output 2)

55576-EN-220314

2)

Depending on medium and temperature

26 VEGABAR 19 • Two-wire 4 … 20 mA

9 Supplement

100 %

90 %

1 2

10 %

tT tA t

tS

Fig. 17: Behaviour the current output in case of sudden change of the process variable. tT: dead time; tA: rise time;

tS: jump response time

1 Process variable

2 Output signal

Size Time

Dead time ≤ 30 ms

Rise time (10 … 90 %) approx. 15 ms

Step response time (ti: 0 s, 10 … 90 %) approx. 45 ms

Reference conditions and influencing variables (according to DIN EN 60770-1)

Reference conditions according to DIN EN 61298-1

ƲƲ Temperature +18 … +30 °C (+64 … +86 °F)

ƲƲ Relative humidity 45 … 75 %

ƲƲ Air pressure 860 … 1060 mbar/86 … 106 kPa (12.5 … 15.4 psi)

Determination of characteristics Limit point adjustment according to IEC 61298-2

Characteristic curve Linear

Reference installation position upright, diaphragm points downward

Influence of the installation position ≤ 5 mbar/0.5 kPa (0.073 psig)

Deviation (according to IEC 60770) 3)

Deviation < 0.5 %

Influence of the medium or ambient temperature

Average temperature coefficient of the < 0.15 %/10 K

zero signal 4)

Long-term stability (according to DIN 16086)

Long-term drift of the zero signal 5) < 0.15 %/year

55576-EN-220314

3)

Relating to the nominal measuring range, incl. non-linearity, hysteresis and non-reproducibility.

4)

In the compensated temperature range of -40 … +100 °C (-40 … +212 °F), reference temperature 20 °C

(68 °F).

5)

Relating to the nominal measuring range.

VEGABAR 19 • Two-wire 4 … 20 mA 27

9 Supplement

Ambient conditions

Ambient temperature -40 … +70 °C (-40 … +158 °F)

Storage and transport temperature -40 … +70 °C (-40 … +158 °F)

Mechanical environmental conditions

Vibrations (oscillations) Class 4M8 acc. to IEC 60271-3-4 (5 g at 4 … 200 Hz)

Impacts (mechanical shock) Class 6M4 acc. to IEC 60271-3-6 (50 g, 2.3 ms)

Impact resistance IK06 acc. to IEC 62262

Process conditions

Process temperature -40 … +100 °C (-40 … +212 °F)

Permissible process pressure see specification " MWP" on the type label 6)

Electromechanical data

Angled plug connector

ƲƲ Version 4-pin according to ISO 4400

ƲƲ Cable gland M16 x 1.5 (for cable diameter 4.5 … 10 mm)

ƲƲ Screw terminals for cable cross- up to 1.5 mm² (AWG 16)

section

ƲƲ Conductor version Massive wire or strand

Round plug connector 4-pole with M12 x 1 screw connection

Voltage supply

Operating voltage UB 12 … 35 V DC

Reverse voltage protection Integrated

Permissible residual ripple

ƲƲ for UN 12 V DC (12 V < UB < 18 V) ≤ 0.7 Veff (16 … 400 Hz)

ƲƲ for UN 24 V DC (18 V < UB < 35 V) ≤ 1.0 Veff (16 … 400 Hz)

Load resistor

ƲƲ Calculation (UB - Umin)/0.022 A

ƲƲ Example - for UB= 24 V DC (24 V - 12 V)/0.022 A = 545 Ω

Electrical protective measures 7)

Potential separation Electronics potential free up to 500 V AC

Protection rating

Connection technology Protection according to Protection according to UL 50

EN 60529/IEC 529

M12 x 1 plug IP66/IP67

Type 4X

Plug according to ISO 4400 IP65

55576-EN-220314

Altitude above sea level 5000 m (16404 ft)

6)

MWP: Maximum Working Pressure

7)

Achieving a UL-approved degree of protection requires the use of UL-certified plugs or connection sets. This is

fulfilled when using the supplied plug according to ISO 4400.

28 VEGABAR 19 • Two-wire 4 … 20 mA

9 Supplement

Protection class III

Pollution degree 2

9.2 Dimensions

Housing and connections

36 mm

(1.38")

34 mm

(1.34")

23 mm

(0.91")

11,5 mm

11,5 mm

(0.45")

(0.45")

ø 32 mm ø 32 mm

(1.26") (1.26")

1 2

Fig. 18: VEGABAR 19 housing

1 M12 x 1 plug connector

2 Plug connector according to ISO 4400

VEGABAR 19, threaded fitting not front-flush

80 mm

(3.15")

85 mm

(3.35")

83 mm

(3.27")

SW 27 mm SW 27 mm

20 mm

(0.79")

SW 27 mm

25 mm

(0.98")

23 mm

(0.91")

(1.06") (1.06") (1.06")

G½ G½ ½ NPT

20 mm

(0.79")

(0.12")

3 mm

ø 3 mm G¼ ¼ NPT

(0.12") ø 17,5 mm

ø 6 mm

(0.69")

(0.24")

DU DN LF

Fig. 19: VEGABAR 19, threaded fitting not front-flush

DU Thread G½ (EN 837), manometer connection

DN Thread G½, inside G¼ (ISO 228-1)

LF Thread ½ NPT, inside ¼ NPT (ASME B1.20.1)

55576-EN-220314

VEGABAR 19 • Two-wire 4 … 20 mA 29

9 Supplement

VEGABAR 19, threaded fitting front-flush

SW 41 mm

82 mm

(3.22")

88 mm

(3.46")

SW 27 mm

20,5 mm

(1.06") (1.61")

22 mm

(0.87")

(0.81")

G½ G1

10,5 mm

10,5 mm

(0.41")

ø 18 mm

(0.41")

ø 30 mm

ø27 mm (0.71") (1.18")

ø 40 mm

(1.06")

(1.57")

LU/3P C5/3Q

Fig. 20: VEGABAR 19, threaded fitting front-flush

LU/3P Thread G½ (ISO 228-1); front-flush, with O-ring

C5/3Q Thread G1 (ISO 228-1), front-flush

55576-EN-220314

30 VEGABAR 19 • Two-wire 4 … 20 mA

9 Supplement

9.3 Industrial property rights

VEGA product lines are global protected by industrial property rights. Further information see

www.vega.com.

VEGA Produktfamilien sind weltweit geschützt durch gewerbliche Schutzrechte.

Nähere Informationen unter www.vega.com.

Les lignes de produits VEGA sont globalement protégées par des droits de propriété intellec-

tuelle. Pour plus d'informations, on pourra se référer au site www.vega.com.

VEGA lineas de productos están protegidas por los derechos en el campo de la propiedad indus-

trial. Para mayor información revise la pagina web www.vega.com.

Линии продукции фирмы ВЕГА защищаются по всему миру правами на интеллектуальную

собственность. Дальнейшую информацию смотрите на сайте www.vega.com.

VEGA系列产品在全球享有知识产权保护。

进一步信息请参见网站< www.vega.com。

9.4 Licensing information for open source software

Open source software components are also used in this device. A documentation of these compo-

nents with the respective license type, the associated license texts, copyright notes and disclaimers

can be found on our homepage.

9.5 Trademark

All the brands as well as trade and company names used are property of their lawful proprietor/

originator.

55576-EN-220314

VEGABAR 19 • Two-wire 4 … 20 mA 31

Printing date:

55576-EN-220314

All statements concerning scope of delivery, application, practical use and operat-

ing conditions of the sensors and processing systems correspond to the information

available at the time of printing.

Subject to change without prior notice

© VEGA Grieshaber KG, Schiltach/Germany 2022

VEGA Grieshaber KG

Am Hohenstein 113 Phone +49 7836 50-0

77761 Schiltach E-mail: info.de@vega.com

Germany www.vega.com

You might also like

- 2002 Subaru WRX Wiring DiagramDocument154 pages2002 Subaru WRX Wiring Diagramsiolfor100% (2)

- (SVM-IR2-EN) - Ichroma II - Rev.00 (20160229)Document36 pages(SVM-IR2-EN) - Ichroma II - Rev.00 (20160229)Thăng Long TN100% (1)

- Chevrolet MyLink Video Interface ManualDocument28 pagesChevrolet MyLink Video Interface ManualkoloristaNo ratings yet

- Volkswagen Golf Service & Repair Manual: Removing and Installing Mechatronic Unit For Dual Clutch Gearbox - J743Document21 pagesVolkswagen Golf Service & Repair Manual: Removing and Installing Mechatronic Unit For Dual Clutch Gearbox - J743Ronaldo SilvaNo ratings yet

- PRESS C1100/C1085: Technical Training CourseDocument63 pagesPRESS C1100/C1085: Technical Training CoursememetNo ratings yet

- EN Operating Instructions VEGABAR 18Document32 pagesEN Operating Instructions VEGABAR 18rpatelacc74No ratings yet

- EN VEGAWELL 52 4 20 MaDocument40 pagesEN VEGAWELL 52 4 20 MaHelder Pascoal Macuacua MacuacuaNo ratings yet

- Operating Instructions VEGAMIP R61 Receiving Unit RelayDocument48 pagesOperating Instructions VEGAMIP R61 Receiving Unit RelayjanvierNo ratings yet

- EN Display and Adjustment Module PLICSCOMDocument28 pagesEN Display and Adjustment Module PLICSCOMMatthew MamzicNo ratings yet

- Im 40694 en Vegamip r61 Receiving Unit Transistor 2020 05 20Document48 pagesIm 40694 en Vegamip r61 Receiving Unit Transistor 2020 05 20Afzal ImamNo ratings yet

- Vegawave 63 Level Switch Manual 1704935428Document36 pagesVegawave 63 Level Switch Manual 1704935428Meer Ahmad BazliNo ratings yet

- EN Operating Instructions VEGAMIP T61 Emitting UnitDocument32 pagesEN Operating Instructions VEGAMIP T61 Emitting Unitleandro martinsNo ratings yet

- en Vegacap 63 Relay (DPDT)Document36 pagesen Vegacap 63 Relay (DPDT)Inférus AdvenæNo ratings yet

- EN VEGACAP 65 Relay (DPDT)Document44 pagesEN VEGACAP 65 Relay (DPDT)rajatNo ratings yet

- EN VEGASWING 51 Transistor (PNP)Document32 pagesEN VEGASWING 51 Transistor (PNP)diego zuñigaNo ratings yet

- EN VEGAVIB 61 Transistor (NPN PNP)Document36 pagesEN VEGAVIB 61 Transistor (NPN PNP)yoquins22No ratings yet

- Vegaflex Fxe80hDocument20 pagesVegaflex Fxe80hAhmed KhanNo ratings yet

- EN VEGASWING 61 Relay (DPDT)Document40 pagesEN VEGASWING 61 Relay (DPDT)Fredy TorresNo ratings yet

- EN VEGASWING 66 RelayDocument40 pagesEN VEGASWING 66 Relayfm429vm7x2No ratings yet

- EN VEGASWING 63 Relay (DPDT)Document40 pagesEN VEGASWING 63 Relay (DPDT)Cristian WechslerNo ratings yet

- Vegawave 63Document36 pagesVegawave 63TranQuocThinhNo ratings yet

- EN VEGASWING 63 Two WireDocument48 pagesEN VEGASWING 63 Two WireLucas FiordelisiNo ratings yet

- Screenshot 2022-08-09 at 21.26.11Document40 pagesScreenshot 2022-08-09 at 21.26.11ionutNo ratings yet

- Operating Instructions: Vibrating Level Switch For Liquids With Extreme Process Temperatures and PressuresDocument36 pagesOperating Instructions: Vibrating Level Switch For Liquids With Extreme Process Temperatures and PressuresWilly SantosNo ratings yet

- en Vegadis 61Document28 pagesen Vegadis 61Jacek JasińskiNo ratings yet

- VEGACONNECT4 (Manual En)Document24 pagesVEGACONNECT4 (Manual En)Anh TúNo ratings yet

- EN VEGAMET 391 4 20 Ma HARTDocument68 pagesEN VEGAMET 391 4 20 Ma HARTCarl HatchNo ratings yet

- Operating Instructions: Signal Conditioning and Display Instrument For Level SensorsDocument56 pagesOperating Instructions: Signal Conditioning and Display Instrument For Level SensorscnmengineeringNo ratings yet

- Operating Instructions Vegaswing 63 Two WireDocument40 pagesOperating Instructions Vegaswing 63 Two Wirepandyaharshil9213No ratings yet

- 4 20mAHART Two WireCoaxialProbe 42279 enDocument80 pages4 20mAHART Two WireCoaxialProbe 42279 enSalah HamoNo ratings yet

- VEGA Level Sensor VEGAPULS 68 Radar Level Sensor Operating InstructionsDocument76 pagesVEGA Level Sensor VEGAPULS 68 Radar Level Sensor Operating Instructionsabhishek.chattopadhyayNo ratings yet

- VEGA Level Sensor VEGAFLEX 81 Guided Wave Radar Level Sensor Operating InstructionsDocument80 pagesVEGA Level Sensor VEGAFLEX 81 Guided Wave Radar Level Sensor Operating InstructionsDavid CoralesNo ratings yet

- EN PACTware DTM CollectionDocument28 pagesEN PACTware DTM CollectionChristianVillagranNo ratings yet

- en Vegator 132Document32 pagesen Vegator 132vilsonNo ratings yet

- en VEGATOR 121 Single Channel Signal Conditioning Instrument For Level DetectionDocument28 pagesen VEGATOR 121 Single Channel Signal Conditioning Instrument For Level DetectionmhafizanNo ratings yet

- Z System - Zener Barrier ManualDocument32 pagesZ System - Zener Barrier ManualHernan PatarroyoNo ratings yet

- en PACTware DTM CollectionDocument28 pagesen PACTware DTM Collectionanon_646888899No ratings yet

- EN VEGADIS 82 4 20 MaDocument44 pagesEN VEGADIS 82 4 20 MaAdriano LuizNo ratings yet

- Operating Instructions: Ultrasonic Sensor For Continuous Level MeasurementDocument56 pagesOperating Instructions: Ultrasonic Sensor For Continuous Level MeasurementArief SetyawanNo ratings yet

- Tdoct7025 EngDocument26 pagesTdoct7025 Engntiiac201No ratings yet

- EN Supplementary Instructions Alignment Device For Radar Sensors VEGAPULS 10 20 30 Series VEGDocument16 pagesEN Supplementary Instructions Alignment Device For Radar Sensors VEGAPULS 10 20 30 Series VEGAgus Dani RamdaniNo ratings yet

- (Datasheet Plicscom XB) 0900766b803fbaddDocument36 pages(Datasheet Plicscom XB) 0900766b803fbaddJhon PiterNo ratings yet

- VEGA Level Sensor VEGAFLEX 81 Guided Wave Radar Level Sensor Operating InstructionsDocument80 pagesVEGA Level Sensor VEGAFLEX 81 Guided Wave Radar Level Sensor Operating InstructionsAri KristianNo ratings yet

- LC-40D X3 CL Lc-40D XR CL: Instruction ManualDocument144 pagesLC-40D X3 CL Lc-40D XR CL: Instruction Manualred WolfNo ratings yet

- Commissioning Procedures: Vegaflex 61Document22 pagesCommissioning Procedures: Vegaflex 61peters petersNo ratings yet

- K-System Isolated Barriers: ManualDocument52 pagesK-System Isolated Barriers: ManualPaul Ramos CarcaustoNo ratings yet

- LC-40B X3 CL: Instruction ManualDocument126 pagesLC-40B X3 CL: Instruction Manualred WolfNo ratings yet

- SD01929GEN - 0218 - Tank Side MonitorDocument28 pagesSD01929GEN - 0218 - Tank Side MonitorIndra SUdirmanNo ratings yet

- 228-92355F SPD-40SPD-40V Im enDocument152 pages228-92355F SPD-40SPD-40V Im enALEJANDRA PAOLA QUINTERO LINERONo ratings yet

- EN MINITRAC 31 4 20 Ma HART Four WireDocument88 pagesEN MINITRAC 31 4 20 Ma HART Four WireJames DickinsonNo ratings yet

- Sd02603den 0121Document32 pagesSd02603den 0121Rafael Leivas LucenaNo ratings yet

- Tdoct0187x EngDocument52 pagesTdoct0187x EngHema IbraNo ratings yet

- d102277 Ac Stag LPG Qmax BasicDocument28 pagesd102277 Ac Stag LPG Qmax BasicJulijus AleknaNo ratings yet

- Digital Indicator Model DI25: Operating InstructionsDocument44 pagesDigital Indicator Model DI25: Operating InstructionsGoran NajdovskiNo ratings yet

- Instruction Manual SPD-M40Document106 pagesInstruction Manual SPD-M40Cuong NguyenNo ratings yet

- Sd02604den 0121Document32 pagesSd02604den 0121Rafael Leivas LucenaNo ratings yet

- EN VEGACONNECT 4 With Connection Box Interface Converter USB HART I CDocument24 pagesEN VEGACONNECT 4 With Connection Box Interface Converter USB HART I CJairo PérezNo ratings yet

- SM630Document26 pagesSM630haythamNo ratings yet

- Manual Transmisor PEPERDocument16 pagesManual Transmisor PEPERvictor felipe araya valenciaNo ratings yet

- Manual: Functional SafetyDocument24 pagesManual: Functional SafetymhaioocNo ratings yet

- Operating Instructions: Software For Adjustment of Communication-Capable Sensors and ControllersDocument32 pagesOperating Instructions: Software For Adjustment of Communication-Capable Sensors and Controllersclaudio.vidal.oxzoNo ratings yet

- Im 28776 en Vegason 62 4 20 Ma Hart Two Wire 2019 03 12Document64 pagesIm 28776 en Vegason 62 4 20 Ma Hart Two Wire 2019 03 12Richard Mayk teodoroNo ratings yet

- Special Documentation Proline Promass 300 Hart: Web ServerDocument28 pagesSpecial Documentation Proline Promass 300 Hart: Web Serveralan renato silalahiNo ratings yet

- Mechanical Engineering MS 22 23Document2 pagesMechanical Engineering MS 22 23Osuntogun QozeemNo ratings yet

- 6ES73211BH020AA0 Datasheet enDocument2 pages6ES73211BH020AA0 Datasheet enOsuntogun QozeemNo ratings yet

- EN Specification Sheet VEGABAR 19 Two Wire 4 20 MaDocument2 pagesEN Specification Sheet VEGABAR 19 Two Wire 4 20 MaOsuntogun QozeemNo ratings yet

- 6GK51080BA002AC2 Datasheet enDocument3 pages6GK51080BA002AC2 Datasheet enOsuntogun QozeemNo ratings yet

- 6ES75163AN020AB0 Datasheet enDocument9 pages6ES75163AN020AB0 Datasheet enOsuntogun QozeemNo ratings yet

- 6ES73317KF020AB0 Datasheet enDocument4 pages6ES73317KF020AB0 Datasheet enOsuntogun QozeemNo ratings yet

- Instructions ENDocument21 pagesInstructions ENOsuntogun QozeemNo ratings yet

- Short Rack TSX47 4067 40 TSXRKN52 Telemecanique Schneider Automation ManualDocument4 pagesShort Rack TSX47 4067 40 TSXRKN52 Telemecanique Schneider Automation ManualOsuntogun QozeemNo ratings yet

- Industrial Communications Booklet July 2019Document74 pagesIndustrial Communications Booklet July 2019Osuntogun QozeemNo ratings yet

- 3RF21201AA02 Datasheet enDocument5 pages3RF21201AA02 Datasheet enOsuntogun QozeemNo ratings yet

- Adamu Ishaku Akyala PH.D: Molecular Biologist and A Public Health ExpertDocument2 pagesAdamu Ishaku Akyala PH.D: Molecular Biologist and A Public Health ExpertOsuntogun QozeemNo ratings yet

- s7300 fm351 Operating Instructions en en-USDocument228 pagess7300 fm351 Operating Instructions en en-USOsuntogun QozeemNo ratings yet

- C47E OMM Inspection ChecksheetsDocument13 pagesC47E OMM Inspection ChecksheetsturboshaftNo ratings yet

- Air Slide TableDocument132 pagesAir Slide TableRaquel AlexandreNo ratings yet

- Datasheet - DT50-P2113 - 1047314 - en - SickDocument6 pagesDatasheet - DT50-P2113 - 1047314 - en - SickAmila BalasooriyaNo ratings yet

- Manual-R12 Assembly PRUSA I3 Step by StepDocument98 pagesManual-R12 Assembly PRUSA I3 Step by StepAndré BathistaNo ratings yet

- DELTA CU3 AS-interface 2.1: Operating ManualDocument37 pagesDELTA CU3 AS-interface 2.1: Operating ManualAlberto MoraNo ratings yet

- CONTRINEX Background Suppression SensorsDocument17 pagesCONTRINEX Background Suppression SensorsMemik TylnNo ratings yet

- 2010 Chevrolet Captiva Sport X3 (LY7)Document4 pages2010 Chevrolet Captiva Sport X3 (LY7)PANHA MENNo ratings yet

- DS ANT TNA352A33rDocument3 pagesDS ANT TNA352A33rEdelNo ratings yet

- Ultra-Compact: Digital CMOS Laser SensorDocument28 pagesUltra-Compact: Digital CMOS Laser SensorwillianlazzaretticreNo ratings yet

- LCD Multimeter PDFDocument14 pagesLCD Multimeter PDFJose David CastroNo ratings yet

- Installation Manual Imeon 36 Rev A2 5b35d306097c475f228b4b25Document36 pagesInstallation Manual Imeon 36 Rev A2 5b35d306097c475f228b4b25ThePanafricanist PageNo ratings yet

- Functional Description: Q Q Q Q QDocument6 pagesFunctional Description: Q Q Q Q QAgus YulfizarNo ratings yet

- 219-295-Complete MRB PDFDocument220 pages219-295-Complete MRB PDFMuthazhagan SaravananNo ratings yet

- SmartModule1000A01 Quick GuideDocument14 pagesSmartModule1000A01 Quick Guidenguyen cuongNo ratings yet

- Testing of Electrical Installations GuideDocument6 pagesTesting of Electrical Installations GuideroyclhorNo ratings yet

- Sierra CaladoraDocument13 pagesSierra CaladoraMaritza HernandezNo ratings yet

- Manual Porter Cable 6 Gallon (Manual)Document60 pagesManual Porter Cable 6 Gallon (Manual)Validaciones VicarNo ratings yet

- Instrucciones Classic z22 enDocument13 pagesInstrucciones Classic z22 enAlex AduviriNo ratings yet

- 7VE5xx1 Catalog SIP2004s enDocument2 pages7VE5xx1 Catalog SIP2004s enWalter CataldoNo ratings yet

- Led TV: Service ManualDocument76 pagesLed TV: Service ManualZigma FNo ratings yet

- Stream Error CodesDocument32 pagesStream Error CodesGod FaithNo ratings yet

- Dell Latitude 7480 Owner's ManualDocument57 pagesDell Latitude 7480 Owner's ManualTirtha DasNo ratings yet

- mh50-20 MOTOMANDocument78 pagesmh50-20 MOTOMANLiferi ConstantinNo ratings yet

- Sid2Sid Installation GuideDocument23 pagesSid2Sid Installation Guidedatura64No ratings yet

- Manual Elcometer 280Document96 pagesManual Elcometer 280jairht29No ratings yet

- ABB Schalt-Und Steuerungstechnik: Hardware Intelligent Decentralized Automation SystemDocument40 pagesABB Schalt-Und Steuerungstechnik: Hardware Intelligent Decentralized Automation SystemEvandro PavesiNo ratings yet