Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

20 viewsMI31001 Underground Coal Mining MA 2015

MI31001 Underground Coal Mining MA 2015

Uploaded by

Sunilquestions

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MI31005 Ass2 2019 SolnsDocument3 pagesMI31005 Ass2 2019 SolnsSunilNo ratings yet

- MI31007 Quantitative Decision Making MA 2016Document2 pagesMI31007 Quantitative Decision Making MA 2016SunilNo ratings yet

- MI31007 Quantitative Decision Making EA 2015Document3 pagesMI31007 Quantitative Decision Making EA 2015SunilNo ratings yet

- MI30013 Minng Machinery EA 2018Document3 pagesMI30013 Minng Machinery EA 2018SunilNo ratings yet

- MI31005 Ass1 2019 SolnsDocument6 pagesMI31005 Ass1 2019 SolnsSunilNo ratings yet

- MI31005 Ventilation & Climate Control MA 2016Document4 pagesMI31005 Ventilation & Climate Control MA 2016SunilNo ratings yet

- MI31007 Quantitative Decision Making EA 2018Document4 pagesMI31007 Quantitative Decision Making EA 2018SunilNo ratings yet

- MI30013 Mining Machinery MA 2015Document1 pageMI30013 Mining Machinery MA 2015SunilNo ratings yet

- MI31004 Economics of Mining Enterprises ES 2017Document3 pagesMI31004 Economics of Mining Enterprises ES 2017SunilNo ratings yet

- MI21007 Elements of Rock Mechanics MA 2016Document2 pagesMI21007 Elements of Rock Mechanics MA 2016SunilNo ratings yet

- MI31001 Underground Coal Mining EA 2015Document1 pageMI31001 Underground Coal Mining EA 2015SunilNo ratings yet

- MI31004 Economics of Mining Enterprises ES 2016Document2 pagesMI31004 Economics of Mining Enterprises ES 2016SunilNo ratings yet

- MI30013 Mining Machinery EA 2015Document4 pagesMI30013 Mining Machinery EA 2015SunilNo ratings yet

- Ore SamplingDocument8 pagesOre SamplingSunilNo ratings yet

- MI21007 Elements of Rock Mechanics EA 2015Document3 pagesMI21007 Elements of Rock Mechanics EA 2015SunilNo ratings yet

- MI21007 Elements of Rock Mechanics MA 2018Document4 pagesMI21007 Elements of Rock Mechanics MA 2018SunilNo ratings yet

- MI30013 Machinery For Mining MA 2016Document2 pagesMI30013 Machinery For Mining MA 2016SunilNo ratings yet

- Geological MapsDocument8 pagesGeological MapsSunil100% (1)

- MI21007 Elememts Rock Mechanics EA 2018Document4 pagesMI21007 Elememts Rock Mechanics EA 2018SunilNo ratings yet

- Geological MapsDocument8 pagesGeological MapsSunilNo ratings yet

- Geological MapsDocument1 pageGeological MapsSunilNo ratings yet

- Changes in Coal Mine RegulationsDocument56 pagesChanges in Coal Mine RegulationsSunil0% (1)

- SubsidenceDocument20 pagesSubsidenceSunil100% (1)

MI31001 Underground Coal Mining MA 2015

MI31001 Underground Coal Mining MA 2015

Uploaded by

Sunil0 ratings0% found this document useful (0 votes)

20 views1 pagequestions

Original Title

MI31001_Underground_Coal_Mining_MA_2015

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentquestions

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

20 views1 pageMI31001 Underground Coal Mining MA 2015

MI31001 Underground Coal Mining MA 2015

Uploaded by

Sunilquestions

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 1

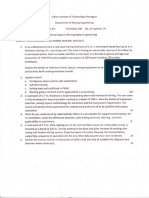

tig Indian Institute of Technology Kharagpur

DEPARTMENT OF MINING. ENGINEERING

Mid. Serr ester Examinatic a (Autum 1 2018) ‘Time: 2 Hours Full Mark: 30 No. of students: 74

'S Semester: © Tech (Miningy’ Dus. Degree (ki ungé Safety Engine ring)

‘Subject: Underground Goal Mining (MI31001)

(Answer al! questions)

1A panel of bord and pilar working has 5 development headings, each 42 m wide, The

development of seam is carried out by basting, folowed by loading with SOL and transpot

tiuough belt conveyor. The seam is developed to its ful stratigraphic seam thickness of 24 m

‘On average, 4 rounds of blast per face are achieved ina day. 19 holes per face are Blasted in

cone round. Depth and diameter ofthe shot holes are 1.6 m and 32 mm respectively, Each shot

hole s charged with one capsule of explosive containing explosive mixture of 400 9, Average

pull por blast is 90%. Average face availabilty is 80%, Calculate:

2) Coal production per day from the development headings of the panel

'b) Blasting ratio (powder factor)

Density of coal is 1.4 t °. The mine works in 3 shifts per day.

2 Discuss how the dimension of the following elements vary while designing @ bord and pillar

working: (a) Pill size; (0) Width of galery, (c) Size of barir ilar, and (4) Size of pane!

43 Percentage extraction of a developed bord and pilr working at a depth of 200 m is 25. The

pillar size is 25m X 25m and height ofthe pila fs 3m. Overtying stata pressure increases with

depth at tho rate of 0.025 MPafm. Calculate (a) load on 2 pilar and (6) factor of safety. (Pilar

strength, Sis estimated by using empirical formula $= 7.2 A" wh;

4 Reoal seam of 3 m thickness at a depth of 250 m with moderately cavable roof needs to be

‘edracted to achieve an average production of 500 tonne per day. Explain the layout, method of

work, equipment selection and all relevant operational criteria for the above, with output

calculation and underground OMS achievable for the extraction.

15. Discuss the following (with figures wherever necessary)

(a) Immediate forward support (IFS) in power support

(©) Wooden dowel and its applicability

(©) Highwalt mining with special reference to Indian experience

= 00K =

6)

6

6)

@)

(2x3)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MI31005 Ass2 2019 SolnsDocument3 pagesMI31005 Ass2 2019 SolnsSunilNo ratings yet

- MI31007 Quantitative Decision Making MA 2016Document2 pagesMI31007 Quantitative Decision Making MA 2016SunilNo ratings yet

- MI31007 Quantitative Decision Making EA 2015Document3 pagesMI31007 Quantitative Decision Making EA 2015SunilNo ratings yet

- MI30013 Minng Machinery EA 2018Document3 pagesMI30013 Minng Machinery EA 2018SunilNo ratings yet

- MI31005 Ass1 2019 SolnsDocument6 pagesMI31005 Ass1 2019 SolnsSunilNo ratings yet

- MI31005 Ventilation & Climate Control MA 2016Document4 pagesMI31005 Ventilation & Climate Control MA 2016SunilNo ratings yet

- MI31007 Quantitative Decision Making EA 2018Document4 pagesMI31007 Quantitative Decision Making EA 2018SunilNo ratings yet

- MI30013 Mining Machinery MA 2015Document1 pageMI30013 Mining Machinery MA 2015SunilNo ratings yet

- MI31004 Economics of Mining Enterprises ES 2017Document3 pagesMI31004 Economics of Mining Enterprises ES 2017SunilNo ratings yet

- MI21007 Elements of Rock Mechanics MA 2016Document2 pagesMI21007 Elements of Rock Mechanics MA 2016SunilNo ratings yet

- MI31001 Underground Coal Mining EA 2015Document1 pageMI31001 Underground Coal Mining EA 2015SunilNo ratings yet

- MI31004 Economics of Mining Enterprises ES 2016Document2 pagesMI31004 Economics of Mining Enterprises ES 2016SunilNo ratings yet

- MI30013 Mining Machinery EA 2015Document4 pagesMI30013 Mining Machinery EA 2015SunilNo ratings yet

- Ore SamplingDocument8 pagesOre SamplingSunilNo ratings yet

- MI21007 Elements of Rock Mechanics EA 2015Document3 pagesMI21007 Elements of Rock Mechanics EA 2015SunilNo ratings yet

- MI21007 Elements of Rock Mechanics MA 2018Document4 pagesMI21007 Elements of Rock Mechanics MA 2018SunilNo ratings yet

- MI30013 Machinery For Mining MA 2016Document2 pagesMI30013 Machinery For Mining MA 2016SunilNo ratings yet

- Geological MapsDocument8 pagesGeological MapsSunil100% (1)

- MI21007 Elememts Rock Mechanics EA 2018Document4 pagesMI21007 Elememts Rock Mechanics EA 2018SunilNo ratings yet

- Geological MapsDocument8 pagesGeological MapsSunilNo ratings yet

- Geological MapsDocument1 pageGeological MapsSunilNo ratings yet

- Changes in Coal Mine RegulationsDocument56 pagesChanges in Coal Mine RegulationsSunil0% (1)

- SubsidenceDocument20 pagesSubsidenceSunil100% (1)