Professional Documents

Culture Documents

Us 2021699

Us 2021699

Uploaded by

havied0 ratings0% found this document useful (0 votes)

15 views5 pagesThe document summarizes a process for manufacturing alkali metal phosphates using alkali metal phosphate mother liquors. The process involves reacting the mother liquors with a phosphoric acid solution containing mono-calcium phosphate. This reaction precipitates calcium sulfate from the solution and produces mono-sodium phosphate. The clear solution is then neutralized with soda ash to produce the desired di-alkali phosphates, allowing recovery and reuse of the alkali metals and phosphates from the mother liquors.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document summarizes a process for manufacturing alkali metal phosphates using alkali metal phosphate mother liquors. The process involves reacting the mother liquors with a phosphoric acid solution containing mono-calcium phosphate. This reaction precipitates calcium sulfate from the solution and produces mono-sodium phosphate. The clear solution is then neutralized with soda ash to produce the desired di-alkali phosphates, allowing recovery and reuse of the alkali metals and phosphates from the mother liquors.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

15 views5 pagesUs 2021699

Us 2021699

Uploaded by

haviedThe document summarizes a process for manufacturing alkali metal phosphates using alkali metal phosphate mother liquors. The process involves reacting the mother liquors with a phosphoric acid solution containing mono-calcium phosphate. This reaction precipitates calcium sulfate from the solution and produces mono-sodium phosphate. The clear solution is then neutralized with soda ash to produce the desired di-alkali phosphates, allowing recovery and reuse of the alkali metals and phosphates from the mother liquors.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 5

Patented Nov.

19, 1935 2,021,699

UNITED STATES PATENT OFFICE

2,021,699

IYANUFACTURE OF PHOSPHATES

Louis Preisman, Wilmington, Del, assignor to

General Chemical Company, New York, N. Y.,

a corporation of New York

Application October 26, 1931, Serial No. 571275

9 Claims. (CI. 23-107)

This invention relates to the manufacture of furnacing, thus eliminating the furnacing opera

alkali metal phosphates and more particularly to tion. With its attendant difficulties, and effecting

a method for the recovery of phosphates and al a Saving Of the material quantities of Sulfuric

kali metals from alkali metal phosphate mother acid heretofore required in the preparation of

liquors, and the subsequent utilization of such the mother liquors for the furnacing operation. 5

recovered alkali metals in the production of al A further object of the invention lies in the pro

kali metal phosphates. In its more specific as Vision of a process in Which the alkali metal sul

pectS, the invention is directed to the recovery fate content of the mother liquors is eliminated

of phosphates and alkali metals from the al from the System by reaction of the liquor with a

kai metal phosphate mother liquors resulting Soluble alkaline earth phosphate such as mono- 10

from the production of alkali metal phosphates calcium phosphate or mono-barium phosphate

by furnacing phosphoric acid and alkali metal with resulting production of alkali metal phos

sulfate with reducing agents, for example as in phate and alkaline earth sulfate, whereby the

the processes of U. S. Patents Nos. 744,128 and Sulfate necessary for precipitation of the alkaline

1,037,837 to E. H. Strickler, and the improvements earth metal is obtained from the hitherto objec- 5

in Such processes as disclosed in U. S. Patents tionable alkali metal Sulfate of the mother liquor

Nos. 1,727,55i and 1,747,588 to W. H. Lohmann. and the alkali metal content of this alkali metal

The mother liquor from the above furnace Sulfate becomes available in the form of alkali

proceSS contains Substantial amounts of tri-al metal phosphate. Another object of the inven

kali metal phosphate contaminated with various tion is directed to the provision of a process for 20

impurities, including alkali metal sulfate. The making alkali metal phosphates in Which the al

latter impurity tends to contaminate the alkali kali metal content of the alkali phosphate nother

metal phosphate product With Sulfate and, if the liquors is utilized to partially neutralize phos

mother liquor is discarded to eliminate sulfate phoric acid, thus effecting a material reduction

25 impurities, a Substantial loSS of alkali metal phos in the quantity of alkali, for example, soda, ash 25

phate ensues. from Outside Sources, previously required for this

ReWorking of di- and tri-alkali metal phoS purpose.

phate mother liquors as constituents of the fur For convenience, the invention will be described

nace mix in the processes of the Strickler patents in connection. With the manufacture of sodium

30 has been proposed, for example, in Levermore phosphates, although the invention is obviously 30

U. S. Patent No. 1,866,657, July 12, 1932. In applicable to the production of other alkali metal

accordance therewith, it has been suggested to phosphates.

rework tri-alkali metal phosphate mother liquors Briefly, the invention comprises the prepara

by returning the same to the digest tanks in tion of a phosphoric acid Solution, containing

35 which the furnace mix is made up. In this Way soluble calcium as in the form of mono-calcium

it has been possible to utilize relatively largephosphate, preferably by the digestion of phos

quantities of mother liquor and form a Satis phate rock With phosphoric acid containing a

factory furnace mix. However, in order to de Small amount of Sulphuric acid. The acid solu

velop an operating procedure having accurate tion, after the separation therefrom of calcium

40 control of the ratio of alkali metal Sulfate to Sulfate and other undissolved solids, is treated 40

phosphoric anhydride in the furnace mix, it has with Sodium phosphate mother liquor containing

been desirable to convert all the alkali metal Sodium compounds including sodium sulfate,

present in the mother liquors to alkali metal preferably obtained from the processes of the

sulfate by the addition of sulfuric acid. In this aforementioned patents, in quantities such that

45 manner, considerable quantities of Sulfuric acid the Sodium sulfate of the mother liquor reacts 45

were consumed in converting the alkali metal in With the mono-calcium phosphate content of the

the mother liquors to alkali metal sulfate, the acid Solution to precipitate Substantially all of

use of such amounts of acid being, of course, an the sulfate as calcium sulfate, and also such that

additional item of expenSe. the mixed Solution of mother liquor and phos

50 It is the principal object of the present inven phoric acid will contain more than 50% of its 50

tion to provide a method for recovering the phos P2O5 content as phosphoric acid. The reaction

phate and alkali metal content of alkali phos of the sodium sulfate of the mother liquor and

phate mother liquors, and utilizing the Same in the monocalcium phosphate of the acid solution

the subsequent production of alkali metal phoS produces principally mono-sodium phosphate

55 phates without subjecting the mother liquors to and calcium sulfate, and at the same time, the 55

2 2,021,699

tri-Sodium phosphate and the Sodium of the tation, at this stage, of the so-called “white

other sodium compounds in the mother liquor mud', containing phosphates of iron, Calcium,

react With the phosphoric acid to form mono aluminum and Sodium fluosilicate, which precip

Sodium phosphate. After settling and Separa itation interferes with the settling or filtering out

tion of the mud containing chiefly calcium Sul of the calcium sulfate. Although not likely to 5

fate, the resulting clear Solution containing occur in practice, should a situation arise in

mono-sodium phosphate and phosphoric acid is which the quantity of the sodium sulfate in the

further neutralized by the addition of Suitable mother liquor is insufficient to provide in the

quantities of Soda ash to produce the desired di mixed solution of mother liquor and phosphoric

O alkali phosphates. acid reacting proportions of Sodium sulfate and O

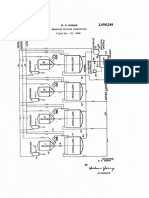

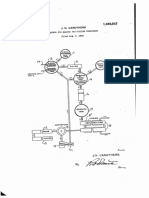

Referring to the accompanying drawing show mono-calcium phosphate, but the remaining al

ing a flow sheet of the improved process, the kaline sodium compounds of the mother liquor

phosphoric acid solution employed for treat are present in quantities great enough to neu

ment of the mother liquor is made up, prefer tralize the acid Solution to Such an extent that

5 ably, by digesting in tank phosphate rock With the mixed solution of mother liquor and phos- lis

phosphoric acid (H3PO4) containing, for exam phoric acid will contain less than 50% of its

ple about 15-17% P2O5 and a Small amount of P2O5 content as phosphoric acid, the proper bal

sulfuric acid, so as to produce a phosphoric acid ance in the mixed solution of mother liquor and

solution containing about 18 to 20% P2O5 and phosphoric acid may be obtained by the addi

20 preferably more than about 3.3% mono-calcium tion thereto of a suitable amount of phosphoric 20

phosphate. A suitable phosphoric acid Solution acid containing no mono-calcium phosphate.

containing the proper amount of mono-calcium For the reason noted above in connection with

phosphate may also be prepared directly by di the prevention of precipitation of the “white

gesting phosphate rock with a deficiency of sul muds', the mixed solution of mother liquor and

25 furic acid. However the acid solution is made phosphoric acid should contain more than 50% 2 s

up, the calcium sulfate, formed by the reaction of its P2O5 content as phosphoric acid. On com

of the phosphate rock and phosphoric or Sul pletion of the reactions resulting from the addi

furic acid, together with other insoluble impuri tion of the mother liquor to the phosphoric acid

ties are separated from the Solution after the solution, the liquor containing, for example,

30 digestion by settling and decantation, or by other about 0.9 to 1.0% Soluble SO3 and about 0.3 to 30

suitable means in a separator . While the 0.5% CaO is filtered or settled in a separator 4

acid solution collecting in tank 2 should, as to effect removal of the calcium sulfate and other

noted, contain preferably more than 3.3% mono insoluble impurities. There is no interference

calcium phosphate, acid Solutions containing less with the settling or filtering of calcium sulfate

35 than 3.3% may be utilized. and other insoluble impurities in the absence of 3 5

The tri-sodium phosphate mother liquors ob “White muds'.

tained in the practice of the processes of the Indications are that the reactions between the

above noted patents contain in addition to tri phosphoric acid Solution and the mother liquor

sodium phosphate various quantities of other seem to take place as follows:

40 sodium compounds such as sodium sulfate

(Na2SO4), sodium carbonate (Na2CO3), Sodium

aluminate (NaAlO2), sodium hydroxide (NaOH),

together with Small amounts of organic matter,

arsenic and other soluble impurities.

45 The clear phosphoric acid solution of tank 2 On the addition of the mother liquor to the acid 45

containing mono-calcium phosphate obtained by solution, from which the calcium sulfate and

the digestion of phosphate rock and phosphoric other insolubles have been separated, the reac

acid is now treated in a vat or tank 3 with tri tions between the tri-sodium phosphate, sodium

sodium phosphate mother liquor in quantities hydroxide and Sodium carbonate appear to be as

50 sufficient so that in the resulting solution, the indicated producing respectively mono-sodium 50

sulfate of the sodium sulfate of the mother liq phosphate. According to (2), it will be seen that

uor reacts with the calcium of the calcium mono the sodium sulfate of the mother liquor precipi

phosphate of the acid solution and so that the tates the calcium of the mono-calcium phosphate

remaining total alkaline sodium compounds in as calcium sulfate, the sodium sulfate thus act

55 the mother liquor will neutralize the acid solu ing to replace the sulfuric acid formerly used in 55

tion to such an extent that the mixed Solution the precipitation of the calcium of the calcium

of mother liquor and phosphoric acid will con phosphate. Considering the reaction of the

tain more than 50% of its P2O5 content as phos mother liquor as a whole with the phosphoric

phoric acid. The sulfate of the sodium sulfate acid solution, it will be seen primarily that the

60 of the mother liquor and the calcium of the sodium contained in the mother liquor acts to 60

mono-calcium phosphate react to produce cal produce mono-Sodium phosphate, and the Sul

cium sulfate, and the phosphoric acid of the acid fate of the Sodium Sulfate operates to precipitate

Solution reacts with the tri-sodium phosphate the calcium of the mono-calcium phosphate as

and other sodium compounds such as Sodium car Calcium Sulfate. The important features of the

bonate and Sodium hydroxide to form mono-so reaction are that the sodium content of the 65

dium phosphate. The purpose of regulating the mother liquor is utilized directly to partially neu

amount of mother liquor added to the phosphoric tralize phosphoric acid with the twofold advan

acid solution so that the total alkaline sodium tage that no Sulfuric acid is necessary to first con

compounds in the nother liquor, aside from the vert the Sodium compounds to the sulfate, as

70 neutral Sodium Sulfate, Will neutralize the phos When furnacing the mother liquor, and that be- 70

phoric acid solution to such an extent that the cause of the use of the sodium content to par

mixed Solution of mother liquor and phosphoric tially neutralize phosphoric acid, the quantities

acid will contain more than 50% of its P2O5 con of Soda ash necessary for subsequent neutraliza

tent as phosphoric acid, the remainder being tion to obtain the desired ultimate di-alkali prod

75 mono-sodium phosphate, is to prevent precipi uct are greatly reduced. Additionally, since the is

2,021,699 3

Sulfate of the sodium sulfate of the mother liquor lized', unless otherwise modified, is intended to

effects precipitation of the calcium of the define any degree of neutralization of a phos

calcium mono-phosphate, this eliminates the ne phoric acid Solution, and is not limited to indi

cessity of employing sulfuric acid to bring about cate complete neutralization.

the precipitation of the calcium as has been prac I claim: 5

ticed. 1. In the manufacture of alkali metal phos

On completion of the reaction between the phates involving the furnacing of a mix contain

Several constituents in the mother liquor and the ing a phosphate radical and an alkali metal Sul

phosphoric acid solution containing calcium fate in the presence of a reducing agent with the

0 phosphate, the liquor is allowed to settle or is production from the furnaced product of alkali, 10

filtered to effect separation of the calcium sulfate metal phosphate and mother liquor containing

and other insoluble impurities from the solution alkali metal compounds including an alkali metal

now containing a mixture of phosphates. The Sulfate, the method of recovering the alkali metal

clear Solution is then further neutralized in tank content of the mother liquor which comprises

15 5 With soda, ash in the usual manner to produce treating the mother liquor with a phosphoric 15

the desired di-alkali phosphate. The neutraliza acid Solution containing soluble calcium phos

tion of the clear solution with soda ash precipi phate whereby the Sulfate of the alkali sulfate

tates as white mud not only the remaining in is removed from Solution and phosphoric acid is

purities present in the phosphoric acid, but also neutralized.

20 the impurities originally present in the trisodium 2. In the manufacture of alkali metal phos- 20

phosphate mother liquor, Such as sodium alu phates involving the furnacing of a mix contain

iminate and other Soluble metals. The White mud ing a phosphate radical and an alkali metal Sull

may be separated by filter 6 from the disodium fate in the presence of a reducing agent With

phosphate liquor. The process thus purifies the the production fron the furnaced product of al

25 trisodium phosphate mother liquor, and utilizes kali metal phosphate and nother liquor Con- 25

the sodium content of the mother liquor as a sub taining alkali metal compounds including an al

stitute for a part of the Soda ash required to neu kali metal Sulfate, the method of recovering the

tralize the phosphoric acid. alkali metal content of the nother liquor which

In the event that the arSenic and organic comprises treating the nother liquor With a

30 impurities in the mother liquor rise above per phosphoric acid solution containing mono-cal- 30

missible limits, as indicated by the final products, cium phosphate whereby the sulfate of the al

a portion of the mother liquor may be reworked kali metal Sulfate is precipitated and phosphoric

by subjecting the same to the furnacing opera acid is partially neutralized, Separating Solid res

tion of the Strickler patents. Such furnacing idues from the solution and further neutralizing

35 operation eliminates arsenic and organic matter, the solution by the addition of an alkali metal 35

and thus reduces the quantity of these impuri thereto.

ties in the mother liquor circuit to below the per 3. In the manufacture of Sodium phosphates

missible amounts. involving the furnacing of a mix containing a

It will thus be seen that the invention provides phosphate radical aid sodium sulfate in the

40 a process for the treatment of mother liquors presence of a reducing agent with the production 40

containing tri-Sodium phosphate and Sodium. from the furnaced product of a sodium phos

compounds by Which the phosphates and Sodium phate and mother liquor containing Sodium com

of the liquors may be recovered and the Sodium pounds including Sodium. Sulfate, the method of

utilized for the neutralization of phosphoric acid recovering the Sodium content of the mother

45 Without the necessity of Subjecting the entire liquor which comprises treating the mother 45

bulk of the mother liquor to a furnacing opera liquor with a phosphoric acid Solution contain

tion. As to the major portion of the mother ing mono-calcium phosphate whereby the Sulfate

liquor, the furnacing operation is eliminated. of the Sodium. Sulfate is renoved from Solution,

The invention makes provision for the economic and the Sodium content of the liquor is utilized

utilization of large quantities of alkali metal to neutralize phosphoric acid. 50

phosphate mother liquor Without furnacing. The 4. In the manufacture of Sodium phosphates

comparatively large amounts of Sulfuric acid involving the furnacing of a mix containing a

heretofore employed in making up the furnace phosphate radical and Sodium sulfate in the

mix to utilize the mother liquors are Saved. The presence of a reducing agent with the produc

Sodium content of the mother liquor is employed tion from the furnaced product of a SodiumphOS- 55

to partially neutralize the phosphoric acid, thus phate and mother liquor containing Sodium com

reducing to a large degree the amount of Soda, pounds including Sodium Sulfate, the method of

ash Subsequently required to effect the ultimate recovering the Sodium content of the mother

neutralization of the acid to the desired extent. liquor which comprises treating the mother liq

60 Further, the sulfate of the sodium sulfate of the uor with a phosphoric acid solution containing 60

mother liquor is utilized to effect precipitation more than about 3.3% mono-calcium phosphate

of the calcium of the calcium phosphate of the Whereby the sulfate of the Sodium sulfate is

acid solution in this way replacing the Sulfuric precipitated as calcium Sulfate and the phos

acid heretofore used for this purpose. phoric acid partially neutralized, separating solid

65 The process is not limited to the treatment residues from the resulting solution, and further 65

of trisodium phosphate in other liquors produced neutralizing the solution by the addition of

in the processes of the Strickler patents. The Sodium carbonate thereto.

invention is applicable to the treatment of 5. The method of producing Sodium phosphate

mother iiquors resulting from the manufacture which comprises forming a phosphoric acid solu

70 of alkali metal phosphates where such liquors tion containing monocalcium phosphate, treat- 70

contain sodium in combinations. Such for exam ing the solution with such quantities of sodium

ple as tri-sodium or di-Sodium phosphate from phosphate mother liquor containing sodium com

which the sodium may be utilized for the neu pounds including sodium sulfate that the total

tralization of phosphoric acid. alkaline sodium compounds in the mother liquor

75 In the appended claims, the term "neutra Will neutralize the acid solution to Such an ex-75

4 2,021,699

tent that the mixed solution of mother liquor phoric acid partially neutralized, separating solid

and phosphoric acid. Will contain more than 50% residues from the resulting solution, and further

of its P2O5 content as phosphoric acid, whereby neutralizing the solution by the addition of Sodi

calcium sulfate is precipitated and sodium phos um carbonate thereto,

phate is produced. 8. The method for producing alkali metal

6. The method of producing Sodium phos phosphate which comprises forming a phoS

phate which comprises forming a phosphoric acid phoric acid Solution containing mono-calcium

Solution containing monocalcium phosphate, phosphate, treating the Solution with such quan

treating the solution. With such quantities of tities of alkali metal phosphate mother liquor

O Sodium phosphate mother liquor containing sodi containing alkali metal compounds including al 0.

lum compounds including Sodium Sulfate that the kali metal Sulfate that the total alkaline metal

Sodium Sulfate of the mother liquor and the compounds in the mother liquor will neutralize

mono-calcium phosphate content of the acid so the acid Solution to Such an extent that the

lution are present in reacting proportions and mixed solution of mother liquor and phosphoric

5 that the total alkaline Sodium compounds in the acid. Will contain more than 50% of its P2O5 con 5

mother liquor will neutralize the acid solution to tent as phosphoric acid, whereby calcium sul

Such an extent that the mixed Solution of mother fate is precipitated and alkali metal phosphate

liquor and phosphoric acid will contain more is produced.

than 50% of its P2O5 content as phosphoric acid, 9. The method for producing alkali metal

20 Whereby calcium sulfate is precipitated and sodi phosphate which comprises forming a phosphoric 20

um phosphate is produced. acid solution containing mono-calcium phos

7. The method of producing sodium phos phate, treating the solution with such quantities

phates which comprises forming a phosphoric of alkali metal phosphate mother liquor contain

acid Solution containing more than about 3.3% ing the alkali metal compounds including alkali

25 mono-calcium phosphate, treating the solution metal sulfate that the alkali metal sulfate of the 25

With Such quantities of tri-sodium phosphate mother liquor and the mono-calcium phosphate

mother liquor containing Sodium compounds in content of the acid solution are present in react

cluding sodium sulfate that the Sodium sulfate ing proportions and that the total alkaline al

of the mother liquor and the mono-calcium phoS kali metal compounds in the mother liquor will 30

30 phate are present in reacting proportions and neutralize the acid Solution to such an extent

that the total alkaline sodium compounds in the

mother liquor will neutralize the acid solution to that the mixed solution of mother liquor and

such an extent that the mixed solution of mother phosphoric acid will contain more than 50% of

liquor and phosphoric acid will contain more its P2O5 content as phosphoric acid, whereby cal

35 than 50% of its P2O5 content as phosphoric acid, cium sulfate is precipitated and alkali metal 35

whereby the sulfate of the Sodium sulfate is phosphate is produced.

precipitated as calcium sulfate and the phoS LOUIS PREISMAN.

You might also like

- Lean AssessmentDocument18 pagesLean AssessmentMani Rathinam Rajamani100% (6)

- Fire Water System CalculationDocument7 pagesFire Water System Calculationikram100% (1)

- Paper - ML Proceso Outotec de Lixiviacion A Presion PDFDocument11 pagesPaper - ML Proceso Outotec de Lixiviacion A Presion PDFJesus Ururi100% (1)

- Fluid Dynamics-MCQ'sDocument13 pagesFluid Dynamics-MCQ'sfrost50% (2)

- Us2094573-Production of Potassumsulphate Ammonium Sulphate Double SaltDocument2 pagesUs2094573-Production of Potassumsulphate Ammonium Sulphate Double Saltkvsj2001No ratings yet

- Us 1961127Document6 pagesUs 1961127fredyNo ratings yet

- US3689216Document5 pagesUS3689216PABLO URIZ CEREZONo ratings yet

- Mm'mon FOR MAKIN: Filed Aug. 8, 1925Document4 pagesMm'mon FOR MAKIN: Filed Aug. 8, 1925arufatoNo ratings yet

- United States Patent: Meng Et A) - (45) Date of Patent: May 20, 2008Document9 pagesUnited States Patent: Meng Et A) - (45) Date of Patent: May 20, 2008Cristhian Moscoso AchahuancoNo ratings yet

- US3416887Document6 pagesUS3416887khairulNo ratings yet

- Us 744128Document2 pagesUs 744128haviedNo ratings yet

- Jackson, 1957Document12 pagesJackson, 1957diogoneNo ratings yet

- Us 2375054Document3 pagesUs 2375054haviedNo ratings yet

- Us3338674 PhosphoricDocument4 pagesUs3338674 PhosphoricM.zuhair asifNo ratings yet

- LD2668T41956F45Document49 pagesLD2668T41956F45bitisa5368No ratings yet

- Facturing Fertilizer Containing Potassium, Nitrogen, and Phosphorous CompoundsDocument1 pageFacturing Fertilizer Containing Potassium, Nitrogen, and Phosphorous CompoundsBharat A. KaduNo ratings yet

- United States Patent Office: Production of Disopum PhosphateDocument2 pagesUnited States Patent Office: Production of Disopum PhosphatefredyNo ratings yet

- 1912 Process of Making Precipitated Barium SulphateDocument2 pages1912 Process of Making Precipitated Barium SulphateDeluxe pNo ratings yet

- Logs:: ConcentratorDocument9 pagesLogs:: ConcentratorEniNo ratings yet

- United States Patent Office: Patented Jan. I9, 1954Document2 pagesUnited States Patent Office: Patented Jan. I9, 1954JavierNo ratings yet

- UNITED Starts: Patented Apr. 16, 1935Document2 pagesUNITED Starts: Patented Apr. 16, 1935shalsinia chantalNo ratings yet

- SuperphosphatesDocument2 pagesSuperphosphatesS.P.No ratings yet

- United States: Patent OfficeDocument3 pagesUnited States: Patent OfficefredyNo ratings yet

- Removal of Fluorine From Wet Process Phosphoric AcidDocument2 pagesRemoval of Fluorine From Wet Process Phosphoric AcidAdios ANo ratings yet

- United States Patent 0 "Ice: Patented May 9, 1972Document4 pagesUnited States Patent 0 "Ice: Patented May 9, 1972Nguyễn Thanh TùngNo ratings yet

- Matrix Acidizing of Sandstone4Document5 pagesMatrix Acidizing of Sandstone4HelyaNo ratings yet

- The Main Purposes of Chemical Applications:: CausticDocument11 pagesThe Main Purposes of Chemical Applications:: CausticMahmoud AbdelaalNo ratings yet

- United States: Patent OfficeDocument3 pagesUnited States: Patent OfficedyahnuritaNo ratings yet

- United States Patent Office.: Feso, - Mgo-Ho Mgso, - Fe (Oh)Document2 pagesUnited States Patent Office.: Feso, - Mgo-Ho Mgso, - Fe (Oh)Fernando MiyazakiNo ratings yet

- J. Biol. Chem.-1933-Folin-111-25Document16 pagesJ. Biol. Chem.-1933-Folin-111-25Nitya Nurul FadilahNo ratings yet

- United States Patent (191: Inoue Et A) - (11) Patent Number: (45) Date of PatentDocument4 pagesUnited States Patent (191: Inoue Et A) - (11) Patent Number: (45) Date of PatentShrutiNo ratings yet

- A Safe Method For Preparation of Uncontaminated Hydrazoic AcidDocument1 pageA Safe Method For Preparation of Uncontaminated Hydrazoic Acidgeovani2No ratings yet

- Successive Processes For Purification and Extraction of Phosphoric Acid Produced by Wet ProcessDocument11 pagesSuccessive Processes For Purification and Extraction of Phosphoric Acid Produced by Wet ProcessCedric Omar Hdz RiescoNo ratings yet

- History of Fluorine Recovery ProcessesDocument21 pagesHistory of Fluorine Recovery ProcessesFajar Zona100% (1)

- United States Patent Office: Patented Sept. 1, 1959Document4 pagesUnited States Patent Office: Patented Sept. 1, 1959هیمن مNo ratings yet

- US2321218Document3 pagesUS2321218shirazizadehsinaNo ratings yet

- Phytic Acid: From The Piusbury Company, Minneapolis, MinnesotaDocument4 pagesPhytic Acid: From The Piusbury Company, Minneapolis, MinnesotaMd Jahidul IslamNo ratings yet

- Experiment 5 - 6 POST LAB DISCUSSIONDocument6 pagesExperiment 5 - 6 POST LAB DISCUSSIONMina BiancaNo ratings yet

- H3PO4Document23 pagesH3PO4Leo Edrik Cortez VidalNo ratings yet

- Translate Paten US5976485Document24 pagesTranslate Paten US5976485Lenywulandari AyundaNo ratings yet

- Us2656248 PDFDocument4 pagesUs2656248 PDFchuckannabelleNo ratings yet

- United States Patent Office: Patented Dec. 23, 1952Document7 pagesUnited States Patent Office: Patented Dec. 23, 1952Chrionny AlumediNo ratings yet

- Storage: o - InzoDocument4 pagesStorage: o - InzoOscar SobradosNo ratings yet

- Us 3109732Document4 pagesUs 3109732Ahmed RabeaNo ratings yet

- Other Phosphate Fertilizers - Part 1: Enriched SuperphosphateDocument10 pagesOther Phosphate Fertilizers - Part 1: Enriched SuperphosphatetegararazaqNo ratings yet

- United States Patent 0: Patented August 16, 1966 2Document4 pagesUnited States Patent 0: Patented August 16, 1966 2trinh xuan hiepNo ratings yet

- US2703272Document3 pagesUS2703272Mohammed Faiq MohammedNo ratings yet

- Phosphoric Acid Flow Sheet of Dihydrate ProcessDocument3 pagesPhosphoric Acid Flow Sheet of Dihydrate ProcessPrakash Mylar100% (1)

- United States Patent 0: '3, l50, l74 ICCDocument2 pagesUnited States Patent 0: '3, l50, l74 ICCMuhammadAmdadulHoqueNo ratings yet

- Iron Oxide - Edta - Ammonia ReactionDocument4 pagesIron Oxide - Edta - Ammonia ReactionSkolastika ErnaNo ratings yet

- Acid SulfuricDocument2 pagesAcid SulfuricVvvv VoNo ratings yet

- Full Ebook of Hell S Paradise Jigokuraku Vol 1 Kaku Yuji Online PDF All ChapterDocument69 pagesFull Ebook of Hell S Paradise Jigokuraku Vol 1 Kaku Yuji Online PDF All Chapterpervenhacham100% (11)

- 2096682530-Ich 305 Phosphorus Based ChemicalsDocument9 pages2096682530-Ich 305 Phosphorus Based ChemicalsDennis JosephNo ratings yet

- Fosfato Simple 2Document4 pagesFosfato Simple 2Jose CortezNo ratings yet

- US3036885Document2 pagesUS3036885pradipNo ratings yet

- Atent Offitce: Patented July '5, 1927Document2 pagesAtent Offitce: Patented July '5, 1927Yustinus Selis ToronNo ratings yet

- Sulphite Pulping11Document7 pagesSulphite Pulping11Kho kho Lovers MGNo ratings yet

- Nov. 15, 1955 J. T. Rutherford 2,723,995: (NH4) 2SO4Document3 pagesNov. 15, 1955 J. T. Rutherford 2,723,995: (NH4) 2SO4sefssefNo ratings yet

- Mixed Fertilizer PlantsDocument15 pagesMixed Fertilizer Plantspsnmurthy333No ratings yet

- Process For Preparing Both Barium Sulfate and Calcium Chloride From Waste Ardealite DregsDocument6 pagesProcess For Preparing Both Barium Sulfate and Calcium Chloride From Waste Ardealite DregsAgam WirasaniNo ratings yet

- Arsenal Philadelphia, Pa. 19137: FrankfordDocument23 pagesArsenal Philadelphia, Pa. 19137: FrankfordPutri PramodyaNo ratings yet

- Int4D Ustrlal: and Engineering ChemistryDocument11 pagesInt4D Ustrlal: and Engineering Chemistryاحمد الدلالNo ratings yet

- Us 3607021Document4 pagesUs 3607021haviedNo ratings yet

- Us 744128Document2 pagesUs 744128haviedNo ratings yet

- Us 2375054Document3 pagesUs 2375054haviedNo ratings yet

- J. N. CarothersDocument4 pagesJ. N. CarothershaviedNo ratings yet

- Kelompok 8 - Bacterial FermentationDocument17 pagesKelompok 8 - Bacterial FermentationhaviedNo ratings yet

- ISO VA DocumentDocument20 pagesISO VA DocumentgsaiprasathNo ratings yet

- ECS HFC-227ea - Modular DIOM - October 2014-06-236116-001 - Rev - BADocument152 pagesECS HFC-227ea - Modular DIOM - October 2014-06-236116-001 - Rev - BALuis RicaldiNo ratings yet

- Catalogo TangitDocument19 pagesCatalogo Tangitjlop57e8r78No ratings yet

- Weidmuller DRM Relays PDFDocument6 pagesWeidmuller DRM Relays PDFryreddyNo ratings yet

- CSC Portal FrameDocument11 pagesCSC Portal FramePhilip AmankwahNo ratings yet

- PVC Sewer Pipe Install GuideDocument30 pagesPVC Sewer Pipe Install GuideArik AprilliyantoNo ratings yet

- Conexion de TelefonoDocument10 pagesConexion de TelefonoMario Enrique Morales LemusNo ratings yet

- Grade 7 Science: Pure Substances and MixturesDocument30 pagesGrade 7 Science: Pure Substances and MixturesGian Marc EnalisanNo ratings yet

- CHAPTER 1 - Fundamental and History of Refrigeration and Air ConditioningDocument7 pagesCHAPTER 1 - Fundamental and History of Refrigeration and Air ConditioningMeet ShahNo ratings yet

- SsipDocument14 pagesSsipdhyan shahNo ratings yet

- MPS Itp Api 5CT K55 PSL 1 - Khi R0Document22 pagesMPS Itp Api 5CT K55 PSL 1 - Khi R0Alfian ImaduddinNo ratings yet

- MECH - Valvula de Compuerta OSY XZ41XDocument1 pageMECH - Valvula de Compuerta OSY XZ41XAlfredo BravoNo ratings yet

- Finishing of Nonwovens - For MajorsDocument2 pagesFinishing of Nonwovens - For MajorsDeepankerBhateja100% (1)

- MC 10169699 0001Document10 pagesMC 10169699 0001Artemio Garcia BarrientosNo ratings yet

- Photo LithographyDocument31 pagesPhoto LithographyTanvir AhmadNo ratings yet

- BaddiDocument8 pagesBaddiabhishekNo ratings yet

- TK 51916-18-OP Direct Drive DSR Operators Manual Rev 12 06-16 - ML PDFDocument334 pagesTK 51916-18-OP Direct Drive DSR Operators Manual Rev 12 06-16 - ML PDFRaphael GamaNo ratings yet

- Rescue Boat Mantenance & Operating Instruction Yz4.5saDocument5 pagesRescue Boat Mantenance & Operating Instruction Yz4.5saDanial AbdullahNo ratings yet

- Easy 3000 Installation ManualDocument52 pagesEasy 3000 Installation ManualHalit Yalçınkaya100% (1)

- Properties of Light-Weight Extruded Concrete With Hollow Glass MicrospheresDocument6 pagesProperties of Light-Weight Extruded Concrete With Hollow Glass MicrospheresSergioNo ratings yet

- Improve Contaminant Control in Ethylene Production: Hpimpact TechnologyDocument6 pagesImprove Contaminant Control in Ethylene Production: Hpimpact TechnologyVenkatesan DevendranNo ratings yet

- CT Eccentricities (AASHTO)Document14 pagesCT Eccentricities (AASHTO)saashiNo ratings yet

- Br380jg-1e0 Cen00175-04 201306 PDFDocument5 pagesBr380jg-1e0 Cen00175-04 201306 PDFNanda Josenia SainukaNo ratings yet

- Epco 1010Document1 pageEpco 1010Bhavik Dhami100% (3)

- Astm B231 - 2011 - 152386622537Document11 pagesAstm B231 - 2011 - 152386622537reza acbariNo ratings yet

- Introduction To Engineering MechanicsDocument7 pagesIntroduction To Engineering Mechanicsapi-248483124No ratings yet