Professional Documents

Culture Documents

Fuel Pump Plunger Replacement

Fuel Pump Plunger Replacement

Uploaded by

Cocoi Solis0 ratings0% found this document useful (0 votes)

86 views10 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

86 views10 pagesFuel Pump Plunger Replacement

Fuel Pump Plunger Replacement

Uploaded by

Cocoi SolisCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 10

Fuel Pump Barrel Assembly

+ Dismantling

1. Close the fuel oil inlet valve.

Open the fuel pump drain cock, enabling

the oil to escape.

Note!

Before dismantling any part of the fuel

pump, make sure that the pump has

been relieved of pressure and that all oil

has been drained off.

2. Dismantle the fuel pump top cover.

See Procedure 909-5.2,

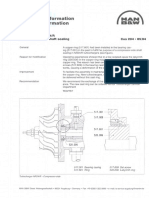

3. Position the lifting tool for the barreV/plunger

assembly (without measuring pin) in such a

manner that the two distance tubes of the

tool rest on the pump barrel

Make sure that the two guide pins in the

bottom of the lifting tool enter the holes in

the top of the plunger.

Secure the lifting tool by screwing the two

screws into the pump barrel.

Loosen the stop ring on the spindle of the

tool and press the spindle down against the

pump plunger.

Turn the spindle in this position until the two.

guide pins engage with the two holes in the

plunger top.

Tighten the centre screw of the spindle

against the plunger,

E

909-6.2

When referring to this page, please quote Procedure M90906 Edition 0220

MAN B&W Diesel A/S.

Page 1 (10)

909-6.2

Fuel Pump Barrel Assembly

Dismantling maw

Remove the pump barrel guide screw from

the pump housing.

Disconnect the links for the timing drive and

the regulating drive. Dismount the union

and pointer for the timing drive and the reg-

ulating drive.

Note the position of the scratch mark on the

lever arm:

Remove the locking plate and the lever

arm.

Mount the extractor tool and connect the

timing toothed rack to the pulling rod by

means of the pin.

Turn the nut at the end of the pulling rod,

whereby the timing rack will move out-

wards.

Continue turning the nut until the pin reach-

@s the outer position of the slot in the tool,

whereby the thread of the fuel pump barrel

goes clear of the timing guide.

Keep the toothed rack in this position during

the overhaul or replacement of the pump

barrel

There is now a distance between the lifting

tool and the pump housing

Page 2 (10)

When referring to this page, please quote Procedure M90906 Edition 0220

MAN B&W Diesel A/S

Fuel Pump Barrel Assembly

+ Dismantling

7. Pull the regulating toothed rack outwards

until the plunger foot has been turned clear

of the bayonet joint in the roller guide.

This can be ascertained by watching the

handles on the spindle of the lifting tool

These will be parallel with the fore-and-aft

direction of the engine when the plunger

has been turned into position.

Remove the cover of the pump base to

make sure that the plunger is able to go

clear of the bayonet joint.

Lift the spindle so that the plunger foot goes

clear of the bayonet joint.

Move the stop ring of the spindle into con-

tact with the upper flange of the tool, and

lock the stop ring in this position by means

of the stop screw.

8 Carefully lift the barrel/plunger assembly

out of the pump housing

Dismount the tool.

Press the plunger upwards to the bottom of

the barrel

Send the barrel/plunger assembly to an

MAN B&W authorized workshop for repair,

or overhaul it on board as described in Pro-

cedure 909-6.3.

e

909-6.2

When referring to this page, please quote Procedure M90906 Edition 0220

MAN B&W Diesel A/S.

Page 3(10)

909-6.3, Fuel Pump Barrel Assembly

Overhaul Baw

1. Place the pump barrel/plunger on a piece of

plywood. Secure the plunger with a couple

of wedges to avoid unwanted movements.

Remove and discard the sealing rings from

the barrel,

2. Pull the plunger carefully out of the barrel.

Carefully clean the plunger (for example in

clean kerosene) and dry it with a soft non-

fluffy cloth

Check the plunger for wear or seizure

marks. Also inspect the top of the plunger

for cavitation marks.

3. Clean the bores in the upper end of the

plunger and blow dry with compressed air

Clean the barrel and dry it with a non-flufty

cloth,

For evaluation of the plunger/barrel condi-

tion see Volume |, Chapter 706.

Check the barrel for wear or seizure marks.

Note!

The plunger and the barrel are matched

parts and cannot be replaced individu-

ally.

Page 4 (10) When referring to this page, please quote Procedure M90906 Edition 0220

MAN B&W Diesel A/S

Fuel Pump Barrel Assembly

4, Before mounting new sealing rings on the

barrel, heat them to 200-220°C for at least

five minutes.

Note!

Take care not to exceed the temperature

limits.

5. When mounting the new sealing rings on

the lower end of the pump barrel, the inner

sealing ring must be mounted first.

Mount the guide stick in the barrel and po-

sition the big cone on the barrel

Place the spring-loaded sealing ring on the

cone with the spring facing upwards, see

the sketch.

Use the pusher tool to push the sealing ring

into the groove.

6. When mounting the sealing ring in the outer

groove, place the spacer tool inside the

cone to obtain the correct distance to the

groove, and repeat the above procedure,

After mounting the sealing rings, compress

them by pressing the “sizer” tool over the

sealing rings,

wy Overhaul

909-6.3

When referring to this page, please quote Procedure M90906 Edition 0220

MAN B&W Diesel A/S.

Page 5 (10)

909-6.3

Fuel Pump Barrel Assembly

Overhaul Baw

Mount the guide stick and cone on the top

end of the barrel and mount the uppermost

sealing ring in the same way as above.

Make sure that the spring faces down-

wards, see the sketch.

Lubricate the plunger with molybdenum di-

sulphide (MoS)

Carefully slide the plunger into the barrel

and press it to the bottom.

Note!

Do not use force as this will damage the

sliding surfaces of the plunger or barrel

If the barrel assembly is not to be mounted

immediately, all openings must be covered

with plastic to prevent dirt from entering the

barrel assembly during storage.

Page 6 (10)

When referring to this page, please quote Procedure M90906 Edition 0220

MAN B&W Diesel A/S

Fuel Pump Barrel Assembly 909-6.4

J Mounting

1. Place the supplied measuring pin - which

is of the same length as the plunger — on

the spindle of the lifting tool, and fasten it

by tightening the centre screw of the spin=

dle. Loosen the stop ring on the spindle.

Place the tool on the pump housing, and

press the spindle down until the pointed

end of the measuring pin is in contact with

the thrust piece of the roller guide,

Then press the stop ring down until it

reaches the flange of the tool and lock it

there by tightening the screw of the stop

ring against the spindle.

The stop ring is to remain tightened in this.

position until the plunger has been correctly

mounted.

The engine must not be turned until the

mounting of the barrel/plunger assembly

has been completed.

2. Dismount the tool from the pump housing

and remove the measuring pin from the

spindle. Then mount the tool on the barrel/

plunger assembly which is ready for mount-

ing.

Secure the tool to the barrel by tightening

the two screws, and attach the plunger to

the spindle of the tool by tightening the cen-

tre screw of the spindle. The tool is thus

fixed on the barrel in such a way that its cor

rect positioning is ensured during mount-

ing

Before mounting the barreV/plunger in the

pump housing, lubricate the thread for the

timing guide and all sealing rings with mo-

lybdenum disulphide.

Using the spindle of the tool, pull the plung

er as high up in the barrel as possible, at

the same time turning the spindle so as to

Position the plunger foot correctly in relation

to the cutout of the regulating guide,

When referring to this page, please quote Procedure M90906 Edition 0220 Page 7 (10)

MAN B&W Diesel A/S.

909-6.4

Fuel Pump Barrel Assembly

Mounting maw

3. Pull the regulating toothed rack as far out

as possible and check that the extractor

tool is mounted correctly on the timing

toothed rack when this is in its outer posi=

tion.

4, Check that the slot in the barrel coincides

with the hole for the guide screw.

Lower the barrel assembly carefully into the

pump housing.

Ifnecessary, turn the regulating guide a lite

tle (using the toothed rack) to make the foot.

and the regulating block of the plunger fit

properly in the cutout of the regulating

guide.

Lowering the barrel assembly so far down

‘ ~ into pump housing thatthe sealing rings

\ oh of the barrel are about to enter the bore in

g the pump hovsing

u Then continue pressing down the barrel/

By DO9-29 plunger assembly until the barrel assembly

fests on top of te timing guide, Tere wil

pea gop petnnon the 2a vi the pump

rouse

com

;

3

Page 8 (10) When referring to this page, please quote Procedure M90906 Edition 0220

MAN B&W Diesel A/S

Fuel Pump Barrel Assembly

J Mounting

5. Loosen the nut on the extractor, disconnect

the pulling rod from the timing toothed rack,

and remove the extractor.

Engaging the thread of the fuel pump barre!

with the timing guide is accomplished by

pressing-in the toothed rack. (A pressure of

about 30 kg may be required).

Check that the toothed rack is correctly en=

gaged by pressing-in the rack. When doing

this, the pump barrel shall move down-

wards.

The top flange of the tool is now resting on

the top of the pump housing.

6. After ‘landing’ the barrel assembly, pross

the plunger down into contact with the

thrust piece of the roller guide.

Check that the stop disc of the spindle is in

full contact with the flange of the tool, as

when measuring

It necessary, turn the regulating guide a lit-

tle (using the toothed rack) to make the

plunger foot fit properly in the cutout of the

roller guide. Inspect the position of the

plunger foot through the inspection hole.

‘When the plunger is in place, press the reg-

Ulating rod in, thereby turning the plunger

by means of the regulating guide and caus-

ing the plunger foot to “interlock” with the

bayonet joint of the roller guide.

Check that the plunger is correctly engaged

by pulling at the spindle of the lifting tool

When doing this, it must not be possible to

lift the spindle.

Mount the inspection hole cover.

909-64

When referring to this page, please quote Procedure M90906 Edition 0220

MAN B&W Diesel A/S.

Page 9 (10)

909-6.4 Fuel Pump Barrel Assembly

Mounting maw

7. Mount the pointer and union for the timing

rack.

Mount the links for the timing drive and the

regulating drive in place in accordance with

the marks.

8. Mount the guide screw for the pump barrel

in the pump housing,

Remove the centre screw from the plunger,

and remove the tool

9. Mount the fuel pump top cover and the be-

longing pipes. See Procedure 909-5.4.

10. Close the fuel pump drain cock.

Open the fuel oil inlet vaive.

Page 10 (10) When referring to this page, please quote Procedure M90906 Edition 0220

MAN B&W Diesel A/S

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pci 348Document3 pagesPci 348Cocoi SolisNo ratings yet

- Cus 204 EDocument1 pageCus 204 ECocoi SolisNo ratings yet

- 2-Stroke Table of ContentDocument12 pages2-Stroke Table of ContentCocoi SolisNo ratings yet

- Definitionof Action CodesDocument2 pagesDefinitionof Action CodesCocoi SolisNo ratings yet

- Howto Search in PDF FilesDocument5 pagesHowto Search in PDF FilesCocoi SolisNo ratings yet

- Cus 198 EDocument1 pageCus 198 ECocoi SolisNo ratings yet

- Cus 223 EDocument2 pagesCus 223 ECocoi SolisNo ratings yet

- Cus 224 EDocument2 pagesCus 224 ECocoi SolisNo ratings yet

- Cus 312 EDocument2 pagesCus 312 ECocoi SolisNo ratings yet

- Top CoverDocument3 pagesTop CoverCocoi SolisNo ratings yet