Professional Documents

Culture Documents

R620-S1 Animal Anesthesia Machine

R620-S1 Animal Anesthesia Machine

Uploaded by

Andri saik0 ratings0% found this document useful (0 votes)

42 views18 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

42 views18 pagesR620-S1 Animal Anesthesia Machine

R620-S1 Animal Anesthesia Machine

Uploaded by

Andri saikCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 18

RUD

R620-S1 General

|

Animal Anesthesia Machine

= User Manual V1.0

6- Troubleshooting,

6.1 Overdiew

6.2 Saety,

6.3 Machine suas

6.4 Aecard keeping,

6.5 Problem Sahution matrin.

7- Maintenance.

7.1 Oversinw

7.2 Satey, 26

7.3. Annual inspection, ce ba 2 26

7.4 Machine status

7.5 Rucord keeping

2.6 Parts and material

3.7 Cleaning the equipment

8-Preduct information...

BLL Overview.

8.2 Product warranty.

5.3 Product specifications ..

S-Useful information

9.1 Overview a0

9.2 Pressure equivalents a0

9.3 Pressure unit eormersions... a0

5.4 Minimum dbreciar concentration (MAC) anesthetic bevels... a0

1-Introduction

1.1 Overview

First of a, sinceredy thanks for selecting the RISP0-S) animal anesthesia machine made by RWD

Life Science.

Please real this instruction manual and all other auxiliagy materials carefully betoee installing ame

using the product it will be helpful to work with it bemer.

RW teas been always dedicated to improving the peoduct fumetice and the service quality, and

will resorve the rights tn revise the products itself and contents deucribed im the instraction masual

aang tine without sotioe in advance

Jf you find te practical simeations about the supplied poo: do mot agree with the contents

described in the manual, or Baws any questions or idews about our products and service, welecee

fo comiact us, For litest infeemation, please visit oar wob ie (hm ww ruderoo com’) or

enon ws ienmeiotey.

‘This mssual is applicable to

R620-SUIP Veterinary Anesthesia Machine - soflurane, Pour Fill, Cage Mom

Ré20-S1P Veterinary Anesthesia Machine - bboflurane, Pour Fill, Selectasec

RGM-SIIE Veterinary Ancetheria Machine - [uofleruse, Easy Fill, Cage Mount

RM0-SIIE Veterinary Anesthesia Machine -Ianfhunane, Fasy Fill, Selecta

R620-S1SP Veterinary Anesthesia Machine « Seveflurane, Pour Fill, Cage Mount

(B620-S1SP Veterinary Anesthesia Machine «Sevoflurane, Pour Fill, Selectatec:

RGQ0-SISE Vetermary Anesthesia Machine - SevoCarase, Easy Fil, Cage Mount

R620-S1SE Veterinary Anesthesia Machine - Sevotlarame, Fany Fill, Selectnoc

A

1.2 Safety

‘Operssice of ancsthessa system lnvailves axygem gas pressure and the use: potentially hazardous,

svatesia, In onder to prevent injury 4o animale oF opersiors anal dara 40 the anesthesia system,

please read Secriow 2—Safery carefully belive xfiorming. ay af the prucesiorcs comtines in this

manual. Ifyou bave any safely questinns.or comments, please comdact ux for auppont.

A

1.3 Product features

Standard closed circain berathing loop design:

Applicable wn cans, dogs, monkeys, pigs and other animals of 100ky weight or less;

‘Two options available: semi- open ial clase anesitecsia modes,

‘The oxygen flow meter adestihle ranges from | to 4 Limin;

‘Wish nxygen flush finction in replace the system with pune oxygen at a speed of

Loin;

ee eee

‘Wath APL auomutic pressure relief sad ccchusion valve features to protect anim

rosa danwge caused by excessive pmessure

© OO absorber camer (2100 ml imstallod im the front part of the machine that is

easy to observe and dissemble fer changing:

4% Nowly designed vaporizer provides enough flow af anesthetic pas for saioral

‘Support boeh Cage Marwst and Seleetutee

© The concentration of anesthetic pas dum the vaporizer can be sdjessed frum tc 5%

(bofluranc) and 0 w 5% (Sevoflurane), withowt effect by floctuation of flux,

temperamre, finw rie and promune. The safety locking device well prevems

accidental volatilization of anesthetic agent,

‘© Dusl-chamel flowmeter is optional;

© Compact and easy ww clean;

1.4 Facility requirements

“Totble 1-1 provides the faeility requirements meceseary to ensure relisbile operation and safety of

‘the anesthesia xystem,

‘Taible 1-1 Facatity Requirements

‘Working aren | Large enough w accommodate the anesthesia system,

he

Storage: termpersure «1

Earvirunment | Operating temperature: 1035. 1°

Rclative bumidity: $-90'% RE, non.comdesaing

1.5 System standard features

Solid metal support for assembling of Golowing |

component |

Conizol the oxygen flow rate, Ture the G2 flowmeter

contol valve to regebite the oxygen flow between

U.1-4 Limin, Another Mewmecier assembly can be

ohled for eoeatrocting 1 dual-fowmeter system,

3 | Handle [Used fir control to: mave the device

sd he pr yf gas mnt

fic | Spall seas eames tel pays the presaue of gut mins in

‘Used for phicimg the endotracheal tube! mask

| areathing circuit blocking | commecaor, Meanwhile dhe pik locks the Kreathing

plug ‘crea, U's useful for system leak detection, austin

sytem pressure and flushing circuit,

a ea aD

Press to deliver the oxygen directly to berathing

6 | 02 fush but ‘circuit Mi generally used to fhush the anewtbetic gas

‘in system or in-cenergency,

Pall he circuit switch to the direction of the FB, the

ssvailnble cincust of system is rebeathing circuit (1am,

007 the thumly switch im the non-retresthing circuit ts

svn waste gas sunning fats the circuit)

7 | Circuit switch

Pull dhe circuit switch ta the direction of the NIE, the

avaiable circuit of system is sonsreteesthing circuit

(turn off @e APL valve to avoid waste pas sunning

int the rebeathing. circuit)

Use far conmecting aoa breathing bag when using the

B | Reterathing circuit pot | amsthesta mysicm ima rebreathing —cireuil

condi guration

converts a kage ancsihctic ages inte a vapor which

is added to oxygen, The masthetic vapor is macasured

jm volume percest {vol $e. A dial an top of the

‘vaporizer allows th opcraior to select the amount a

‘vapor administered tn the animal. We suggest that

commect with RW sepebary i calibrate,

9 | Vaporizer The vaporizer is the most complicated anf expensive

‘part af Go anesthesia system. Moce atientinn shawl be

Pai to its maimiemance and operation.

ay Please use the correct anesthetic agent

following the tg on the vaporiter. The

some may cause the damage the

‘iment and animal

Operator can detcemise the inspirainry pressure for

veniilating, the animal by adjesing the APL. valve

whale aibserving the sysiem's pressure jaupe, The

‘mose the APL valve is closed, the higher the researc

will be. When the pressure af gas mixture excteds the

10 | APL vale ‘setting, the gas will be expuned threagh APL valve to

bheep the pecoure stable. Uswslly, the outlet af the

‘valve is counecieg 10. gas filter camister,

In case of emexyency, press the Inob an the valve to:

chose it immediate

‘The ome-wuy valle is made up with Anata discs and

nickcl-plated brass valve iw cousrol gas flow ditection

= fem ccarculstion in sysicm It makes sare the

1 | gratin xpi | SE cai mem Kc athe

oe Alostable diss jo wp and shown as wait becaths, aa

eperator cam condinm the respirainry status with the

foataise aise

‘Used for conmecting oo a breathing time echem usinye the

ancsihesis ys aeleathing circuit

‘eomfiguratiom,

Breathing bag mount

(Used far comsecting ta 1 rcbecathing circuit, which is

Remerally appiiesbe bo anima over ? kg.

Rehreathing circuit part

‘The sbeorbent canister is filled wath a preukar carbon

dlicxay sfsoebert material eg. caleiure lime. 1 uses a

coaxial ga flow path to provide for eae efficient me

of absurtent, while reducing flow sexiaanee The

chemical reaction that takes place im the canister

creates heat and bumidity, which i added 1 the

delivery of anesthesia 1 the sndirnal

2-Safety

2.1 Overview

“This section provides bask safety information necessary for aperaing your R620-S1 mesthesia

system, Please comiact ws for more suppor! iE nee ny quesdions cr comments

2.2 Intended use

The anesthesia system is intended for veterinary use only. All the operation and matinienamce

shemale fallow ther instructions of this eeamual

Misuse of your system may result in injury 10 animals and opermors cr damage wi srupesty

Misuse inahades

© Using inappropriate pax and anesthetic apents

© | Making usauthorined modifications to the equipment

© Opensting the systems using sas pressure exceeding maximum ratings

AOfiexmcrammance |

2.3 Description of safety symbols

The following types of aymbots sre includes in

ppvtesntiail asa,

OE SE |

A [Ssizasmmimem |

2.4 Basic safety precautions and practices

aml swith nvies that alert the resales to.

‘This section pravides requirements necessary to) ensure safe and reliable operation of your

B82081 anesthesia system,

2.4.1 Animal and operator safety

© Always keopa backup anesthesia delivery plan is case of an emergency occur

© Any persom responsible for the installation or operation of the system shod be

‘hosrughily Cambiar with this operator’s massa

© Toenewre proper famctinn of your system, perform a pre-or checkout proccslare im

accontmce with Section 4 —Spriem setup and Sreaion 5 — Cperasion.

©) Thessystem mustabeays be atiended by a veterinarian or trained anesthesia techni

© Afr guarantee perio, amma! service inspections to enwure penper operation x

recommendind. Oly HWD-certified technicians abil he permitted to service the

system of replace internal parts,

© Keg open flanies und combustibhes (ep. ether and acetone) away fiom the anesthesia

system,

‘Do net place any heavy things on the anesthesia system.

© Make sure that the oxygen Iiese does sot cross walkways and wishes, This may present 3

tripping hazard.

Wearing persomal protective oopsipencnts is sezzested.

© Make sure the oxygen hose is securely ewanceted to the system befure starting.

procedure

© Make sure that any cuboled gas containing anesthetic ic recovered or vented outside of

the operating rosen. A waste gas evacuation sysiem must be usr

© RW0 reconmends the use of an clestrocaningrapls, and oquipmced capable a

rmanitoring the animal's raise, axygen (Oy) saturation, carbon dhaxide (CO) level, andl

anesthetic agent Bevel at all times when operating the system,

© Remove the rystem fiom service if say indications of impropes Gasction exist.

© Never pour water ur any other uals into the anesthetic vaporizer. Fill vaporizer only

with the anesthetic agent dor which itis designed

© Avoid use of oil or grease cm any anesthesia or respiratory equipmscnt where unypen 1s

used, An exphosian may occur.

LA.2 Preventing eyatem and facility damage

© Lexmaiately comiain andl ehcan up spilled anesthetic.

© Isoflurane is very caustic and may dull te paint fist of the system if spillage occurs

spillage showld occur, alow it to crapoeate. Dw not atbornpé to wipe it with » cloth,

© Do sot place heavy on top of the anesthesia cqpsipement,

© Follow all recommended system maintesance procedures specified im Seesian 7—

Maintenance.

© Keep approprisie distance frum the wall to ensure a stable gas apply

243 Facility environment brealth

© Liammedinicty contain and clean wp omy spilled anesthetic agent.

© Uf the systems is use ina cosfined space, ensure that there is adequate ventilation.

© Dhipose offany hazardous materials and items contaminated with hazanious materials

shouild be im sceordance with local regulations.

‘15 System malfunction

Ie your systern doe not operate jruperly, eefer to Seerion & — Frwmblestooing whch inc lusies

descriptions, possible causes, and sugpesind solutions,

3.3.2 Asscuiling main support and vaporizer

3-Unpacking and assembling

3.1 Overview

This section peowides the unpacking and asucmbling procedure far your R620-S! anesthesia

system.

3.2 Unpacking the system

Your system is shipped in bones that have been carefily packed atthe i

‘Se system tw you When you receive your system, please do-the following:

© Check the shipping documents to ensure that all nes ave bees received

@ Examine the shipping boxes for damage. Immediately make a damage claim 10 the

commie ifthere is sericus daasaige and contact RWDD, Taking photo is supzeste fer

Ieoeping the evidence

© Carefully open cach box and remeve each individeal component, Save all fe

packing materials for future shipments.

© Check the packing list or iavoice w ensure all oedered enmponenns cacered age included

In cage there is any doubt or noed any belp, contact RW or hocal dealer immediately.

ry for sale delivery of

ye vaporizer (a showed as below

The installing method for cage mou

33 Assembling the system

3. Assembling hase

The installing method fir stlectatce type vaporincr is showed ax below: 3.33 Assembling moniter (ray ancl gas falter canister

4

yystem setup

4.1 Overview

‘This section provides the setup peocedares: required ko peepare your TH620-81 anesthe

for veterinary surgical procedures,

sysiem

4.2 Materials and supplies

‘Oxygen supply source

Connection tube for anyyen source sd Mrwmcter

An

brew

(00; absorbent

.

.

.

© Breathing bag

.

© Anesthetic aper

.

Wresch Tor tightening cxcypen suyply ting.

I system prepara

4.1 Setting up the system

0 Pasi wall bse used

2) Pill the OO; abenther canister with absarbent as follows:

© Loosen the fixing knob and remove the abseeber

om the eysteen in the rea where

© Pill the absurbers canister with CO sihsorbent. Do

texcend the maximum capacity seal

3) Sysnem leak checking,

© Chose ali the open end of anesthesia system.

© Make sure volume percent dial is on the anesthetic vaporiner to he zexu (0)

position,

© Chose the APL valve completely by clackwise totaling: regulate

v

© Open oxygen source, adjust the moedle oxygen repalator between 44) to $0 pai

‘by clockwise rotating reputstor.

© Tum oa the oxygen flowmeter control valve, increase the flow mwte up 19 1

LLimin, The systesn pressure will inceease with onyiren Mowed into system,

‘Operator can also increase the pressure by pressing axyges Mush button, Turn off

the flowmeter coninl valve when the needle of pressure gauge goes up to about 30

cm ().

© Observe the needle of pressure gauge, there is me Teak in the syste if the

roclle drops down within 2emnH;0 in Ns. Ch the ether hand, system beaks if the

secdle drops down more than 2em!1/(in 14s, operator needs to check all the

consection in the system. In case these is uny doubt or need any help, comtact RT

2 local deader dmncdianely

4.4.2 Filling the anesthetic vaporizer

User choose different vaporiner, the anesthetic filling method is also different, KWL

supply two kinds of filleng type vuperizer-Pour Fill and Easy Fill

432.41 Pour Fill

1) Tum sed remawe the scaling ap of the vaporizer. [ho mot leave any debris.

2) Carefully pour appropriate agent into the filler post. Otserve the agent level sight

iiss on vaporizer Keep mgest level issike tube hetwers the tu mk.

3) Tighten te sealing cap,

4.3.22 Baey Fill

1) Tom and remove the sealingcap 2) Mount am adaptor onto the isoflurane

of the vaporizer. Check the black hnoctle, insert ints filler part along tie

sealing. ing groove, and pes it x the end

o Be

3) Observe the agent level sight glass 4) ‘Tighien the sealing cap.

on the vaporizer. Kieep the agent =

Jewel inside the tube between Ge am

Paw makes —

5- Operation

5.1 Overview

“This secmen provides the paocedures sed infomation needed Wo successfully operate your

20-81 anesthesia system.

A

5.2 Pre-use checkout

Perform the pee-use checkin procedure before cech wen of your anesthesia system as follows:

© Ensure anesthetic agent is fille into the vapeeiser,

(Make sure the weperiaer valume-percent dil is set wn zens (0)

© Confiam that the absorbeat hac: mot cxpineel,

‘© Ensare the oxygen source is connected with anesthesia system. closely.

“© Envere the pressure of oxygen supply is between 40-50 esi and i is enoup during the

vompicie: experimcen.

© Make sere the O; contral valve works property

© Contin thea the breathing sinsuit is clear and clan and check the wentilation and

‘leanliness of the experimental emvirunmer.

5.3 Anesthesia procedure

2) Tum the Openiiral valve counterciockwise snd observe the positicm of float to set a

satable flow rate

3) Press the dial lock key and tan the dial so rt the concentra

ie Pressing cf ial

Jock hey is necessary only when the concentmtion & set trom po

4) Connect berathing circuit 10 end

macheal tube or anesthesia mask, and peovide

anesthetic gas to animal. Operator can chang the anesthesia depth by changing the

eonce n of amesthetic gua churing surgery,

5.4 Using the oxygen flush button

I the snimal seeds high concentrations of oxygen instantaneously, operator can activate the

onygen tush Duman. Once aetivited, the Gow meter an ancsthotic vaporizer are bypassed and

‘oxygen is administered to the pation! without mcsihctics. As soon as the axygen Mash button is

released, the presed anesthesia will again be adesinistered

tum off the switch in the nos-relvesihing circail fo avaid waste xs running into the

i

Pll the circuit switeh to the ditection of the NRE, the available circuit of system is

natbecathing circeit (tum off the APL. valve to avoid waste gas Tusning

it

phe vetmeathin

5.6 Adjusting the highest pressure in system

@ Tum the APL valve coumterclockwise to completely open, make sure the

nendlle of pressure gaage has dropped down to 2090;

© Remowe the breathing bag, and comecs the exhaled port of rebweathing circuit

to breathing bag moune

© Tum on the oxygen flowmarer contrel valve, increase he flow rate up 1

Lenin. The sysiem pressure will increase with onygen flawed into nystem

© Thm the the APL valve clockwise to lacrease system pressure, and pay

mention to the meedle of pressure gauge Styp tating

ened rt to ber ever 20) cal

i reaches a

© Tum olf the flowmeter, and reconnec! the breathing bag and rebyea

5.7 Post-anesthesia procedure

(Dace the snestheaia peucedure is completed, perform the following steps in oeder:

1) Tum GFF the vaporizes by tering the wohume-peroent dial clockwise in zerw (8).

2) Remove berating circuit from endotracheal tube wr eu, atl ul the eeeneco onto the plug

othe mais support aesthesis syssern

3) Pressthe onypen Bush bution for 2-8 seconds and sepaccze the breathing bag bo purge the

Systema of anesthesie gas weal cab ei

4) Curalfthe oxygen sepply source,

5) Openthe APL valve by turning it counterclockwise,

fi) Reson the usnd time of abuorbent in the C1» absorber canis OF anal time ix cver Hh

chanye the absinber as described in Sectien ¢ - System Serup.

7) ithe system will be vacant for a omg time, deais theanesthesie agen insice the vaporizer ms

described is Section 7— Maintenance

) Thoroughly clean the anesthesia system as described in Sretiom 7— Misvmtenance

6- Troubleshooting

6.1 Overview

This section will help you determine the origin of common peoblemsfalanms you may experiomce

swith your REDO.S1 anesthesia oystem sad recommended conective actions, Of you experience

peobécms are not listed in this section, at continue experiescing the problem after eying thie

suggested conmective mcions, plese contact RIE ar your Local desler kar support.

6.2 Safety

Sear toubleshooting, procedures aay invellve the use of earasdis eclerials and costact swith

biological hazards. Always follow all applicable local regulations and the material manafacterer’s

Moncrial Safety Theta Shoct (MSTNS) recommendations Dering we paocodarr, basic: personal

peoiective is necessary, such as wearing gloves, mack and eye protection.

6.3 Machine status

‘Unless otherwise specified, the anesthesia system may be comnected to gas supplies during the

performance of the troubkeshowting peoceduers descnbed im this manual Make ware the pas

supplies and vaporizer are tuned aff befare the paocedare

6.4 Record keeping

Aeceont of problems and thelr resolution should be kept. Such reconts should include the date,

‘te nature of the problem encountered, ane the actions thal resolved the pecblem,

6.5 Problem — Solution matrix

‘Table 61 contains probleme thal may occer during operation of your R6QUSt anesthesia eystem

and their conective actions. you comiiaue experiencing a prubleas aller trying the suppestesl

sconective actions pleases conise! [EW oe local dealer for spot

(Press the dil Lack ey ce the waynes nel

aljent he dba to the desined wslumer-percont

oF anmsthetic

i eee ring a th peter

fs tulhy chewed.

‘Camiact WDD or local dealer or servicing.

‘Camaset RED ox hac dealer Sor servicing

Replace prsaune gauge Chmlact FWD a

lbocal dein for wervicing.

Table #1 ROZ0SS anesthesia sytem: Probie — Solari

[ll aporener with the appropri anesthetic

gem

8. Vapor te

sty EB ene tsi noe when the

sevice

>, Amestietic oe ome. |

nanan | Miss he dia oinzense the vane: percent

set tow bow a)

cur | rat ‘Ck ein system compere Ke

feaks, teary, eles, cts Financ the

ee ce eciee | MATIC ue mabe de

- wath the srsarreal

ates 1. Chex 002 aboot and place if

con ee

2.Ched proper natn uf empresa

ro, ‘exist Weld

¢ Look armund ?

ee “Make ar he ein. ap om he voperiner

vapories filler oily

1. Aesthetic

ig | Met al orkut yd pera

Asimatvegpivet | | ante

tats dep a

a ‘Cimtset RVD) local tke fin serving.

carne

‘Open the APL vale.

a a i

: pertat ABEL | Check aml choos the ile pt of API. vb.

abe ic logged

‘Gane flowing bu | a, Fring bag,

Deeathang berg dimes Remon the Ieeenatthiny bag

rot inflate preted

“Chan fhvw is raring

ia pee cae TNS | omiace RWDD or local dear or serving

tecaihing bog,

Tables RO20ST anesthesia cysteam: Pralem —Salstawe Noirs feaatieuest

‘Oyen gas supply valve

embers 2 Replace empty gas cinder.

[sme = =

1. nua gas supply Ise sees

©. Ghas supply hose | theceyfinder or facty pas system.

is discormected 2. Ensue the i seqpy lane i secon

‘seemecieal te aretha ystern

i any ‘ar te wnt va nc,

‘eat nue co

Aho re. 5

Cas aap ‘Chm the ptm de an alieraie oxygen

fegulatex malfamtion | apy,

corrypen nw aaa | Tie lower vale ks

ae nemerranciunwe ¥ tnorease the wa ype

‘hes aie,

dt i

eis emt fly aed

sapere let

2. Worify tht net ports at astro

Dey animal ais, te,

7- Maintenance

7.1 Overview

This sccsion provides the maintenance prmcedares to heep your RAIS) anesthesia systems in

pond operating condition.

7.2 Safety

Some maintenance procedures may involve the use of Bazamdous materials and contact with

biological hazards. Always follow all applicable local repslstinns and dhe material mamuéacaases"s

Material Safety Data Sheet (MSDS) recommendations, During the procedure, basic personal

prodcctive iemecessary, such as wearing phoves, mas aed eye pre

7.3 Annual inspection

WD recommends that your RADO-SE mesthesia system be inspected

‘Contact WED ar your local dealer far service

7.4 Machine status

rally for prope Ganctiee,

Unless uihcrwise specified, the ancstiesla system may be conncctcd in gas supplics during the

performance of the maintenance procstbares described in this ste However, make sre the

oxygen supply is OFF andthe vaporinet is set to 2ez0 Vohume geroent.

7.4 Record keeping

A record of system service and muimtesasce should be bepl. Such records should include service

and maintenance dates, purl membors of any replaced parts, dates when consumables ane

replenished, and eiler pertieet dita

7.6 Parts and materials

‘Contact RWTD of your local dealer if pars ov materials are needed during the maintenance.

7.7 Cleaning the equipment

7.7.1 Required materials and supplies

© Germicidal cleaner

© CO) ahsoehent material

© Waser and clean cloth

© Personal Protective Tiquipment (masks, eye protection, glaves, ew.)

7.7.2 Weekly maintenance

|. Wipe all serfaces of the system with « cloth dianpencd with gretnicil cleaning

‘solution.

2, Reems hair, hist, ata debris thom all vaporizes surfaves: expecially arennal the

‘volume pescent dial and the meethetic Fill port,

3..Check the CO ahsorber canister for exhausted absorbess, Wit total use: ime is user

Oh, replace i as follows:

1 Remove the canister from the mom of the mackie and shake aut the spent sesorberd,

1b, Wash the canister in waem water, and dry thoroughly.

©, Wipe the canister gasket, lneaied an the emierside of the machine, with a clean ebuth

‘dampened with germicidal cleaner, Make sare these is wo alsothent resithee remaining.

on the gasket surface.

Pill the canister with fresh CO; absorbent material to withia 2-3 em off the top dye:

Reinstall the canister firmly,

4 Perform » peruse checkout as specified in Sersian 5 — Operation.

§. Check the cleanliness of the oxyn sepply.

6 Check anesthesia system leaks at specified in Section 4 Systema setup

7.7.3 Draining the vaparizer

WC the system will be wacand fr a long time, drain the anesthetic agent inside the

vaporizer.

1) Make sure the oxygen sapply is CFF and vaporiees in set to 2crm.

Th Make muee the anesthesia wysiems is in a well-ventilated area.

3) Astich a drain tube to the drain port, Place the other end oF the tabe in a

receptacle i ratch the drained anesthetic agent.

ln

4) Loosen the scaling cap, then loascn the bolton serew with a screwdriver to make

(ee snewthtie agent flex nahurlly

5) Whea the anesthetic agent siops deuining from the vaporizer, tighten the bettom

ese cd sealing ap,

ce

! a

'

6) Remove the drain tube and deal with the waste anesthetic agent ancersing te the

‘regulations

8-Product information

8.1 Overview

‘This section provides the warranty infomation, fratwres ad speciticmions of RA20-81 anesthesia

sytem

8.2 Product warranty

‘This warmaty is only applicable n those new products purchased fom KW or dealers axthosined

bby EWE, as well as the first person to whom it extras.

9-Useful information Notes

9.1 Overview

“This section provides information that may be helpful tn the users-of R620-S1 anesthesia sysiems,

9.2 Pressure equivalents

1 ata = 1033 cmfl,C) ~ 760 meal ~ ‘Mil Tore— 1019 maby = 14.7 ps

I pi = W03 cmnlO = $17 mmbig = 68.9 mb = 69 kPa

1 minty = 1.36 enuf = 1.33 eds

1 emaHI20 = 0.756 amg = 1081 eb

9.3 Pressure unit conversions

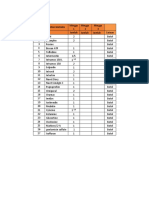

‘Table 9-1 Pressure unitaonversions

Pee

100450

1 aa2ini0?

Lange?

9.4 Minimum alveolar concentration (MAC) anesthetic

levels

Table 9:2 MAC levels

rLJD

RWD Life Science

Add: 6540 Lask Eilvd, San Diego,CA 92121, USA.

Add: No.1) Hi Tech North Rd, Nan Shan Dist, Shenshen, P.R.Chana.

Tels O01 858-000-4602 BO6-TS5-2611 1286

Email; salesjajraststen com

Website: www: ruddsteo. com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 389 FullDocument9 pages389 FullAndri saikNo ratings yet

- RWD Catalog 2018Document62 pagesRWD Catalog 2018Andri saikNo ratings yet

- Isolation and Identification of Feline Calicivirus and Feline Herpesvirus in Southern BrazilDocument10 pagesIsolation and Identification of Feline Calicivirus and Feline Herpesvirus in Southern BrazilAndri saikNo ratings yet

- Abd-Eldaim2009 Article DevelopmentAndValidationOfATaqDocument6 pagesAbd-Eldaim2009 Article DevelopmentAndValidationOfATaqAndri saikNo ratings yet

- Factors Associated With Upper Respiratory Tract D-Wageningen University and Research 36580Document5 pagesFactors Associated With Upper Respiratory Tract D-Wageningen University and Research 36580Andri saikNo ratings yet

- 8 Table4 1Document2 pages8 Table4 1Andri saikNo ratings yet

- Obat InjectDocument1 pageObat InjectAndri saikNo ratings yet

- Feline Calicivirus Ag Test: Cat No.: W81201Document1 pageFeline Calicivirus Ag Test: Cat No.: W81201Andri saikNo ratings yet

- Dokumen - Tips - Grooming Kucing Dan Anjing BeresDocument4 pagesDokumen - Tips - Grooming Kucing Dan Anjing BeresAndri saikNo ratings yet