Professional Documents

Culture Documents

Data Sheet AL-BRONZE

Data Sheet AL-BRONZE

Uploaded by

Aris WicaksonoCopyright:

Available Formats

You might also like

- Vda 260Document9 pagesVda 260Ed Ri83% (6)

- Ds134ns Eco 6r0Document1 pageDs134ns Eco 6r0yadi_baeNo ratings yet

- Section 3: Specification Classification Product DescriptionDocument1 pageSection 3: Specification Classification Product DescriptionFery FebryantoNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationIam FroilanNo ratings yet

- 3.28 & 3.29 Kawat Las Nikko Steel 312 2,6 X 350 MM & 3,2 X 350 MMDocument1 page3.28 & 3.29 Kawat Las Nikko Steel 312 2,6 X 350 MM & 3,2 X 350 MMumarNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationIam FroilanNo ratings yet

- NSN 309post File 2019 12 11 151332Document1 pageNSN 309post File 2019 12 11 151332Gristio PratamaNo ratings yet

- DS125NSSUGARR2Document1 pageDS125NSSUGARR2Frandika PrimayogaNo ratings yet

- Cin 1 Post File 2019 12 17 100704Document1 pageCin 1 Post File 2019 12 17 100704Adrian SetyadharmaNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- RD 360R3Document1 pageRD 360R3Rachmad Budi WNo ratings yet

- RD 360 1post File 2019 12 10 161048Document1 pageRD 360 1post File 2019 12 10 161048Adityo Bambang WNo ratings yet

- CIN2Document1 pageCIN2aditya wicaksonoNo ratings yet

- Section 6: Specification ClassificationDocument1 pageSection 6: Specification ClassificationDimas Wisnu WardanaNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- Aalco Metals LTD - Copper and Copper Alloys CW508L Sheet - 114Document2 pagesAalco Metals LTD - Copper and Copper Alloys CW508L Sheet - 114Mihai ChitibaNo ratings yet

- Section 3: Specification Classification Product DescriptionDocument1 pageSection 3: Specification Classification Product DescriptiontamharNo ratings yet

- Material - (1 4462)Document2 pagesMaterial - (1 4462)Ashutosh PathakNo ratings yet

- SS 316 (0.5 FN) : Stainless Steel ElectrodeDocument1 pageSS 316 (0.5 FN) : Stainless Steel Electrodeflasher_for_nokiaNo ratings yet

- 3.26 & 3.27 Kawat Las Nikko Steel 316 2,6 X 350 MM & 3,2 X 350 MMDocument1 page3.26 & 3.27 Kawat Las Nikko Steel 316 2,6 X 350 MM & 3,2 X 350 MMumarNo ratings yet

- Cu ZN 05Document2 pagesCu ZN 05wjjt6chgtmNo ratings yet

- Betanox D Welding ElectrodeDocument1 pageBetanox D Welding ElectrodearavindpeetaNo ratings yet

- Aalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Document3 pagesAalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Jessicalba LouNo ratings yet

- Spek Electoda Nikko CIN-1Document1 pageSpek Electoda Nikko CIN-1anon_962923083No ratings yet

- Page - 6Document1 pagePage - 6Bharat KumaneNo ratings yet

- Aalco Metals LTD Stainless Steel ASTM A815 S31803 261Document2 pagesAalco Metals LTD Stainless Steel ASTM A815 S31803 261Irvin PajueloNo ratings yet

- Xuper 680 CGSDocument1 pageXuper 680 CGSArbind RajrishiNo ratings yet

- Stainless Steel ASTM A815 S31803: Specifications Alloy DesignationsDocument2 pagesStainless Steel ASTM A815 S31803: Specifications Alloy Designationsallouche_abdNo ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- Stainless Steel 1.4462 (2205) Sheet and Plate: Specifications Alloy DesignationsDocument3 pagesStainless Steel 1.4462 (2205) Sheet and Plate: Specifications Alloy DesignationsPaulNo ratings yet

- Aalco Metals LTD Stainless Steel 14021 Bar 311Document2 pagesAalco Metals LTD Stainless Steel 14021 Bar 311joseocsilvaNo ratings yet

- Nicalloy Mo-12: NON FERROUS (Ni Alloys)Document1 pageNicalloy Mo-12: NON FERROUS (Ni Alloys)krupesh patelNo ratings yet

- Utp 34 NDocument1 pageUtp 34 NbrayanNo ratings yet

- Aalco Metals LTD Aluminium Alloy 1050A H14 Sheet 57Document2 pagesAalco Metals LTD Aluminium Alloy 1050A H14 Sheet 57SathishbhaskarNo ratings yet

- Copper and Copper Alloys CW614N Brass Flat Bar and Profiles: Specifications Supplied FormsDocument2 pagesCopper and Copper Alloys CW614N Brass Flat Bar and Profiles: Specifications Supplied FormsAnonymous v7XdaQuNo ratings yet

- Cuznpb2 LeadedDocument3 pagesCuznpb2 Leadedwjjt6chgtmNo ratings yet

- Aalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Document2 pagesAalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Agung SulisNo ratings yet

- Ga-24 Aws E7024Document1 pageGa-24 Aws E7024Bang OchimNo ratings yet

- Data MP35N Rev-2Document2 pagesData MP35N Rev-2Nishant MehtaNo ratings yet

- Zeron 100 PDFDocument5 pagesZeron 100 PDFNAVANEETHNo ratings yet

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 pageL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55No ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- EN1.4462-0509 Original EngDocument2 pagesEN1.4462-0509 Original Eng4455jappNo ratings yet

- E7018 1 Eutherme lh1 PDFDocument1 pageE7018 1 Eutherme lh1 PDFAnonymous dxsNnL6S8hNo ratings yet

- Cu ZN 15Document2 pagesCu ZN 15wjjt6chgtmNo ratings yet

- D and H NewDocument37 pagesD and H NewBharat AhirNo ratings yet

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDocument7 pages22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeOnM deptNo ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- Oxford Alloy A (ENiCrFe-2)Document1 pageOxford Alloy A (ENiCrFe-2)brunizzaNo ratings yet

- Cu ZN 20Document2 pagesCu ZN 20wjjt6chgtmNo ratings yet

- CERTILAS EN Edition2023 320Document1 pageCERTILAS EN Edition2023 320Alireza KhodabandehNo ratings yet

- Zeron SmawDocument4 pagesZeron SmawJoe FizzoNo ratings yet

- Dissimilar Metal Weldingv2 HERBST PDFDocument23 pagesDissimilar Metal Weldingv2 HERBST PDFAnonymous q2HC0zyfa2No ratings yet

- GMM Mag.Document1 pageGMM Mag.Ehsan KhanNo ratings yet

- Wb4606e E312-17Document1 pageWb4606e E312-17cwiksjNo ratings yet

- Aalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355Document2 pagesAalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355novkovic1984No ratings yet

- Electronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionFrom EverandElectronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionNo ratings yet

- Decorative High Gloss Enamel Paints - Specification: Draft ProposalDocument18 pagesDecorative High Gloss Enamel Paints - Specification: Draft ProposalAris WicaksonoNo ratings yet

- Material Safety Data Sheet: TM TMDocument6 pagesMaterial Safety Data Sheet: TM TMAris WicaksonoNo ratings yet

- 14 Cast Heat Resistant Alloy HH Type I and Type II ASTM A 447 and ASTM A 297Document5 pages14 Cast Heat Resistant Alloy HH Type I and Type II ASTM A 447 and ASTM A 297Aris WicaksonoNo ratings yet

- 6030P Daiko CuMn13AlDocument1 page6030P Daiko CuMn13AlAris WicaksonoNo ratings yet

- Qingzhe Li, Ranfeng Qiu, Zhongbao Shen, Longlong Hou, Lihu CuiDocument5 pagesQingzhe Li, Ranfeng Qiu, Zhongbao Shen, Longlong Hou, Lihu CuiAris WicaksonoNo ratings yet

- 90cual Mig WireDocument1 page90cual Mig WireAris WicaksonoNo ratings yet

- Effect of Welding Sequence and The Transverse GeomDocument18 pagesEffect of Welding Sequence and The Transverse GeomAris WicaksonoNo ratings yet

- Microsoft Word - PAGES00 - 27-ThirdDraftDocument1 pageMicrosoft Word - PAGES00 - 27-ThirdDraftAris WicaksonoNo ratings yet

- Shop Fabrication of Structural SteelDocument12 pagesShop Fabrication of Structural SteelAris WicaksonoNo ratings yet

- Revofil R308Lt: Stainless Filler MetalDocument1 pageRevofil R308Lt: Stainless Filler MetalAris WicaksonoNo ratings yet

- Sertifikat Kawat Las GtawDocument4 pagesSertifikat Kawat Las GtawAris WicaksonoNo ratings yet

- Keysight - N9010A - Functional TestDocument42 pagesKeysight - N9010A - Functional TestAris WicaksonoNo ratings yet

- Defects - Imperfections in Welds - Lack of Sidewall and Interrun Fusion.Document4 pagesDefects - Imperfections in Welds - Lack of Sidewall and Interrun Fusion.Aris WicaksonoNo ratings yet

- Detech - Price ListDocument1 pageDetech - Price ListAris WicaksonoNo ratings yet

- Price List Wintech AccesoriesDocument9 pagesPrice List Wintech AccesoriesAris WicaksonoNo ratings yet

- Harjavalta PDFDocument8 pagesHarjavalta PDFluthfi dali ahmadNo ratings yet

- Inorganic Chemistry ExpDocument46 pagesInorganic Chemistry Exppc355chyi100% (3)

- Structure and Performance of Selective Hydrogenation CatalystsDocument37 pagesStructure and Performance of Selective Hydrogenation CatalystsManojNo ratings yet

- Materials Workshop For The Refining & Petrochemical IndustryDocument281 pagesMaterials Workshop For The Refining & Petrochemical IndustrysantiagoNo ratings yet

- Safety and Health in Chemical IndustriesDocument18 pagesSafety and Health in Chemical IndustriesMubarak AhmadNo ratings yet

- Cobalt: Cobalt Is A Chemical Element With The Symbol CoDocument22 pagesCobalt: Cobalt Is A Chemical Element With The Symbol CoVysakh VasudevanNo ratings yet

- The Rotating Cylinder Electrode PDFDocument11 pagesThe Rotating Cylinder Electrode PDFbuvanseaNo ratings yet

- En 006Document30 pagesEn 006Cristian TorrezNo ratings yet

- An International Peer-Reviewed Journal A Publication of The ... - SMEDocument60 pagesAn International Peer-Reviewed Journal A Publication of The ... - SMETrương Tấn DươngNo ratings yet

- The Products We Rely OnDocument14 pagesThe Products We Rely Onjaslinda_jamalNo ratings yet

- Spa Plating ManualDocument105 pagesSpa Plating Manualpetethefrench100% (1)

- Wanta 2016 IOP Conf. Ser. Mater. Sci. Eng. 162 012018Document6 pagesWanta 2016 IOP Conf. Ser. Mater. Sci. Eng. 162 012018Gugus HandikaNo ratings yet

- Science of The Total Environment: Scott J. MarkichDocument10 pagesScience of The Total Environment: Scott J. MarkichEko RaharjoNo ratings yet

- UTP Bestseller PDFDocument28 pagesUTP Bestseller PDFdaha333No ratings yet

- TH 150Document12 pagesTH 150Minh Hong PhamNo ratings yet

- Grades of Steel With Reference To ALL Design StandardsDocument58 pagesGrades of Steel With Reference To ALL Design StandardsThefairman UnkownNo ratings yet

- Control of Eta Carbide Formation in Tungsten Carbide Powders Sputter-Coated With (Fe/Ni/Cr)Document8 pagesControl of Eta Carbide Formation in Tungsten Carbide Powders Sputter-Coated With (Fe/Ni/Cr)Sinan YıldızNo ratings yet

- Alloys (TM)Document4 pagesAlloys (TM)linguy007No ratings yet

- 475 477Document1 page475 477cytech6619No ratings yet

- WWW Human Resonance Org Quantum Trapping2 HTMLDocument20 pagesWWW Human Resonance Org Quantum Trapping2 HTMLntsethNo ratings yet

- Electrolytic Tin Plate (TP) MSDSDocument6 pagesElectrolytic Tin Plate (TP) MSDSSrikanth Srikanti0% (1)

- Quantitative ResearchDocument36 pagesQuantitative Researchmarkervinarguillas6No ratings yet

- Newletter No 46 ThermocouplesDocument5 pagesNewletter No 46 ThermocouplesAbhijith S AnchanNo ratings yet

- Marina A. Ermakova, Dmitry Yu. Ermakov, Andrey L. Chuvilin, and Gennady G. KuvshinovDocument15 pagesMarina A. Ermakova, Dmitry Yu. Ermakov, Andrey L. Chuvilin, and Gennady G. Kuvshinovjocy1989No ratings yet

- Groundwater DepletionDocument13 pagesGroundwater DepletionAyush GogiaNo ratings yet

- Waste Water Test Report ETL (ZDHC)Document23 pagesWaste Water Test Report ETL (ZDHC)Abid HasanNo ratings yet

- Magnetic and Electrical Properties of Nickel NanopDocument9 pagesMagnetic and Electrical Properties of Nickel NanopNguyen Ngoc MinhNo ratings yet

- Research Paper Mining in PalawanDocument5 pagesResearch Paper Mining in Palawanhkdxiutlg100% (1)

- 2 Mhz2 Series Air GrippersDocument17 pages2 Mhz2 Series Air GrippersAlex VegaNo ratings yet

Data Sheet AL-BRONZE

Data Sheet AL-BRONZE

Uploaded by

Aris WicaksonoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet AL-BRONZE

Data Sheet AL-BRONZE

Uploaded by

Aris WicaksonoCopyright:

Available Formats

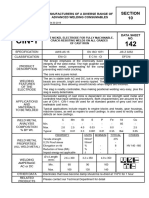

MANUFACTURERS OF A DIVERSE RANGE OF SECTION

ADVANCED WELDING CONSUMABLES 10

WI-0304 DS152 AL-BRONZE, Rev. 1, Date 01.11.2012

A NICKEL AND MANGANESE DATA SHEET

ENHANCED ALUMINIUM BRONZE ELECTRODE NO.

AL-BRONZE FOR WELDING A WIDE RANGE OF

COPPER-BASED ALLOYS AND BRONZE 152

SPECIFICATION AWS A5.6

CLASSIFICATION ECuMnNiAl

A chemically basic flux coated MMA electrode that deposits an aluminium

bronze weld metal which as a result of additional Mn and Ni alloying gives

PRODUCT superior resistance to corrosion, erosion and cavitation.

DESCRIPTION The flux is extruded onto an alloyed core wire with a blend of silicates that

ensures both coating strength and a coating resistant to subsequent moisture

absorption.

The electrode is designed for use on DC+. The arc is strong and stable

WELDING resistance to porosity is excellent, provided a back-step strike and re-strike

technique is used. The fairly viscous slag is readily controllable permitting

FEATURES

positional welding and under most circumstances is readily detached. The weld

OF THE appearance has a distinctive bronze texture.

ELECTRODE

On heavy sections high pre-heat temperatures are essential.

Designed for the rectification of initial casting defect and the build up / repair of

APPLICATIONS worn broken castings.

The alloy possesses superior corrosion resistance to standard aluminium

AND

bronzes and may be used to weld such materials and dissimilar welds between

MATERIALS bronzes and steels.

TO BE WELDED The alloy is also suited for welding wrought aluminium bronze products,

particularly when resistance to sea water corrosion is a major consideration.

Fe Mn Si AI Pb Ni Cu Others

WELD METAL

MIN 2.0 11 - 5.0 - 1.0 -

ANALYSIS

COMPOSITION MAX 6.0 13 1.5 7.5 0.02 2.5 0.50

% BY Wt. TYPICAL 3.0 12.5 0.6 5.5 0.01 2.2 Bal. 0.2

PROPERTY UNITS MINIMUM TYPICAL OTHERS

WELD METAL Tensile strength N/mm2 520 650 Weld Metal Hardness

PROPERTIES 2 (More than 3 layers) :

(ALL WELD METAL) 0.2% Proof stress N/mm - 450 75 – 85 HRB

Elongation on 4d % 15 20 140 – 170 HV

∅ (mm) 3.2 4.0

WELDING

AMPERAGE MIN 90 110

DC+ MAX 110 150

OTHER DATA Electrodes that have become damp should be re-dried at 110oC for 1 hour.

RELATED

Please contact our Technical Department for detail.

PRODUCTS

You might also like

- Vda 260Document9 pagesVda 260Ed Ri83% (6)

- Ds134ns Eco 6r0Document1 pageDs134ns Eco 6r0yadi_baeNo ratings yet

- Section 3: Specification Classification Product DescriptionDocument1 pageSection 3: Specification Classification Product DescriptionFery FebryantoNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationIam FroilanNo ratings yet

- 3.28 & 3.29 Kawat Las Nikko Steel 312 2,6 X 350 MM & 3,2 X 350 MMDocument1 page3.28 & 3.29 Kawat Las Nikko Steel 312 2,6 X 350 MM & 3,2 X 350 MMumarNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationIam FroilanNo ratings yet

- NSN 309post File 2019 12 11 151332Document1 pageNSN 309post File 2019 12 11 151332Gristio PratamaNo ratings yet

- DS125NSSUGARR2Document1 pageDS125NSSUGARR2Frandika PrimayogaNo ratings yet

- Cin 1 Post File 2019 12 17 100704Document1 pageCin 1 Post File 2019 12 17 100704Adrian SetyadharmaNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- RD 360R3Document1 pageRD 360R3Rachmad Budi WNo ratings yet

- RD 360 1post File 2019 12 10 161048Document1 pageRD 360 1post File 2019 12 10 161048Adityo Bambang WNo ratings yet

- CIN2Document1 pageCIN2aditya wicaksonoNo ratings yet

- Section 6: Specification ClassificationDocument1 pageSection 6: Specification ClassificationDimas Wisnu WardanaNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- Aalco Metals LTD - Copper and Copper Alloys CW508L Sheet - 114Document2 pagesAalco Metals LTD - Copper and Copper Alloys CW508L Sheet - 114Mihai ChitibaNo ratings yet

- Section 3: Specification Classification Product DescriptionDocument1 pageSection 3: Specification Classification Product DescriptiontamharNo ratings yet

- Material - (1 4462)Document2 pagesMaterial - (1 4462)Ashutosh PathakNo ratings yet

- SS 316 (0.5 FN) : Stainless Steel ElectrodeDocument1 pageSS 316 (0.5 FN) : Stainless Steel Electrodeflasher_for_nokiaNo ratings yet

- 3.26 & 3.27 Kawat Las Nikko Steel 316 2,6 X 350 MM & 3,2 X 350 MMDocument1 page3.26 & 3.27 Kawat Las Nikko Steel 316 2,6 X 350 MM & 3,2 X 350 MMumarNo ratings yet

- Cu ZN 05Document2 pagesCu ZN 05wjjt6chgtmNo ratings yet

- Betanox D Welding ElectrodeDocument1 pageBetanox D Welding ElectrodearavindpeetaNo ratings yet

- Aalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Document3 pagesAalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Jessicalba LouNo ratings yet

- Spek Electoda Nikko CIN-1Document1 pageSpek Electoda Nikko CIN-1anon_962923083No ratings yet

- Page - 6Document1 pagePage - 6Bharat KumaneNo ratings yet

- Aalco Metals LTD Stainless Steel ASTM A815 S31803 261Document2 pagesAalco Metals LTD Stainless Steel ASTM A815 S31803 261Irvin PajueloNo ratings yet

- Xuper 680 CGSDocument1 pageXuper 680 CGSArbind RajrishiNo ratings yet

- Stainless Steel ASTM A815 S31803: Specifications Alloy DesignationsDocument2 pagesStainless Steel ASTM A815 S31803: Specifications Alloy Designationsallouche_abdNo ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- Stainless Steel 1.4462 (2205) Sheet and Plate: Specifications Alloy DesignationsDocument3 pagesStainless Steel 1.4462 (2205) Sheet and Plate: Specifications Alloy DesignationsPaulNo ratings yet

- Aalco Metals LTD Stainless Steel 14021 Bar 311Document2 pagesAalco Metals LTD Stainless Steel 14021 Bar 311joseocsilvaNo ratings yet

- Nicalloy Mo-12: NON FERROUS (Ni Alloys)Document1 pageNicalloy Mo-12: NON FERROUS (Ni Alloys)krupesh patelNo ratings yet

- Utp 34 NDocument1 pageUtp 34 NbrayanNo ratings yet

- Aalco Metals LTD Aluminium Alloy 1050A H14 Sheet 57Document2 pagesAalco Metals LTD Aluminium Alloy 1050A H14 Sheet 57SathishbhaskarNo ratings yet

- Copper and Copper Alloys CW614N Brass Flat Bar and Profiles: Specifications Supplied FormsDocument2 pagesCopper and Copper Alloys CW614N Brass Flat Bar and Profiles: Specifications Supplied FormsAnonymous v7XdaQuNo ratings yet

- Cuznpb2 LeadedDocument3 pagesCuznpb2 Leadedwjjt6chgtmNo ratings yet

- Aalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Document2 pagesAalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Agung SulisNo ratings yet

- Ga-24 Aws E7024Document1 pageGa-24 Aws E7024Bang OchimNo ratings yet

- Data MP35N Rev-2Document2 pagesData MP35N Rev-2Nishant MehtaNo ratings yet

- Zeron 100 PDFDocument5 pagesZeron 100 PDFNAVANEETHNo ratings yet

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 pageL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55No ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- EN1.4462-0509 Original EngDocument2 pagesEN1.4462-0509 Original Eng4455jappNo ratings yet

- E7018 1 Eutherme lh1 PDFDocument1 pageE7018 1 Eutherme lh1 PDFAnonymous dxsNnL6S8hNo ratings yet

- Cu ZN 15Document2 pagesCu ZN 15wjjt6chgtmNo ratings yet

- D and H NewDocument37 pagesD and H NewBharat AhirNo ratings yet

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDocument7 pages22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeOnM deptNo ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- Oxford Alloy A (ENiCrFe-2)Document1 pageOxford Alloy A (ENiCrFe-2)brunizzaNo ratings yet

- Cu ZN 20Document2 pagesCu ZN 20wjjt6chgtmNo ratings yet

- CERTILAS EN Edition2023 320Document1 pageCERTILAS EN Edition2023 320Alireza KhodabandehNo ratings yet

- Zeron SmawDocument4 pagesZeron SmawJoe FizzoNo ratings yet

- Dissimilar Metal Weldingv2 HERBST PDFDocument23 pagesDissimilar Metal Weldingv2 HERBST PDFAnonymous q2HC0zyfa2No ratings yet

- GMM Mag.Document1 pageGMM Mag.Ehsan KhanNo ratings yet

- Wb4606e E312-17Document1 pageWb4606e E312-17cwiksjNo ratings yet

- Aalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355Document2 pagesAalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355novkovic1984No ratings yet

- Electronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionFrom EverandElectronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionNo ratings yet

- Decorative High Gloss Enamel Paints - Specification: Draft ProposalDocument18 pagesDecorative High Gloss Enamel Paints - Specification: Draft ProposalAris WicaksonoNo ratings yet

- Material Safety Data Sheet: TM TMDocument6 pagesMaterial Safety Data Sheet: TM TMAris WicaksonoNo ratings yet

- 14 Cast Heat Resistant Alloy HH Type I and Type II ASTM A 447 and ASTM A 297Document5 pages14 Cast Heat Resistant Alloy HH Type I and Type II ASTM A 447 and ASTM A 297Aris WicaksonoNo ratings yet

- 6030P Daiko CuMn13AlDocument1 page6030P Daiko CuMn13AlAris WicaksonoNo ratings yet

- Qingzhe Li, Ranfeng Qiu, Zhongbao Shen, Longlong Hou, Lihu CuiDocument5 pagesQingzhe Li, Ranfeng Qiu, Zhongbao Shen, Longlong Hou, Lihu CuiAris WicaksonoNo ratings yet

- 90cual Mig WireDocument1 page90cual Mig WireAris WicaksonoNo ratings yet

- Effect of Welding Sequence and The Transverse GeomDocument18 pagesEffect of Welding Sequence and The Transverse GeomAris WicaksonoNo ratings yet

- Microsoft Word - PAGES00 - 27-ThirdDraftDocument1 pageMicrosoft Word - PAGES00 - 27-ThirdDraftAris WicaksonoNo ratings yet

- Shop Fabrication of Structural SteelDocument12 pagesShop Fabrication of Structural SteelAris WicaksonoNo ratings yet

- Revofil R308Lt: Stainless Filler MetalDocument1 pageRevofil R308Lt: Stainless Filler MetalAris WicaksonoNo ratings yet

- Sertifikat Kawat Las GtawDocument4 pagesSertifikat Kawat Las GtawAris WicaksonoNo ratings yet

- Keysight - N9010A - Functional TestDocument42 pagesKeysight - N9010A - Functional TestAris WicaksonoNo ratings yet

- Defects - Imperfections in Welds - Lack of Sidewall and Interrun Fusion.Document4 pagesDefects - Imperfections in Welds - Lack of Sidewall and Interrun Fusion.Aris WicaksonoNo ratings yet

- Detech - Price ListDocument1 pageDetech - Price ListAris WicaksonoNo ratings yet

- Price List Wintech AccesoriesDocument9 pagesPrice List Wintech AccesoriesAris WicaksonoNo ratings yet

- Harjavalta PDFDocument8 pagesHarjavalta PDFluthfi dali ahmadNo ratings yet

- Inorganic Chemistry ExpDocument46 pagesInorganic Chemistry Exppc355chyi100% (3)

- Structure and Performance of Selective Hydrogenation CatalystsDocument37 pagesStructure and Performance of Selective Hydrogenation CatalystsManojNo ratings yet

- Materials Workshop For The Refining & Petrochemical IndustryDocument281 pagesMaterials Workshop For The Refining & Petrochemical IndustrysantiagoNo ratings yet

- Safety and Health in Chemical IndustriesDocument18 pagesSafety and Health in Chemical IndustriesMubarak AhmadNo ratings yet

- Cobalt: Cobalt Is A Chemical Element With The Symbol CoDocument22 pagesCobalt: Cobalt Is A Chemical Element With The Symbol CoVysakh VasudevanNo ratings yet

- The Rotating Cylinder Electrode PDFDocument11 pagesThe Rotating Cylinder Electrode PDFbuvanseaNo ratings yet

- En 006Document30 pagesEn 006Cristian TorrezNo ratings yet

- An International Peer-Reviewed Journal A Publication of The ... - SMEDocument60 pagesAn International Peer-Reviewed Journal A Publication of The ... - SMETrương Tấn DươngNo ratings yet

- The Products We Rely OnDocument14 pagesThe Products We Rely Onjaslinda_jamalNo ratings yet

- Spa Plating ManualDocument105 pagesSpa Plating Manualpetethefrench100% (1)

- Wanta 2016 IOP Conf. Ser. Mater. Sci. Eng. 162 012018Document6 pagesWanta 2016 IOP Conf. Ser. Mater. Sci. Eng. 162 012018Gugus HandikaNo ratings yet

- Science of The Total Environment: Scott J. MarkichDocument10 pagesScience of The Total Environment: Scott J. MarkichEko RaharjoNo ratings yet

- UTP Bestseller PDFDocument28 pagesUTP Bestseller PDFdaha333No ratings yet

- TH 150Document12 pagesTH 150Minh Hong PhamNo ratings yet

- Grades of Steel With Reference To ALL Design StandardsDocument58 pagesGrades of Steel With Reference To ALL Design StandardsThefairman UnkownNo ratings yet

- Control of Eta Carbide Formation in Tungsten Carbide Powders Sputter-Coated With (Fe/Ni/Cr)Document8 pagesControl of Eta Carbide Formation in Tungsten Carbide Powders Sputter-Coated With (Fe/Ni/Cr)Sinan YıldızNo ratings yet

- Alloys (TM)Document4 pagesAlloys (TM)linguy007No ratings yet

- 475 477Document1 page475 477cytech6619No ratings yet

- WWW Human Resonance Org Quantum Trapping2 HTMLDocument20 pagesWWW Human Resonance Org Quantum Trapping2 HTMLntsethNo ratings yet

- Electrolytic Tin Plate (TP) MSDSDocument6 pagesElectrolytic Tin Plate (TP) MSDSSrikanth Srikanti0% (1)

- Quantitative ResearchDocument36 pagesQuantitative Researchmarkervinarguillas6No ratings yet

- Newletter No 46 ThermocouplesDocument5 pagesNewletter No 46 ThermocouplesAbhijith S AnchanNo ratings yet

- Marina A. Ermakova, Dmitry Yu. Ermakov, Andrey L. Chuvilin, and Gennady G. KuvshinovDocument15 pagesMarina A. Ermakova, Dmitry Yu. Ermakov, Andrey L. Chuvilin, and Gennady G. Kuvshinovjocy1989No ratings yet

- Groundwater DepletionDocument13 pagesGroundwater DepletionAyush GogiaNo ratings yet

- Waste Water Test Report ETL (ZDHC)Document23 pagesWaste Water Test Report ETL (ZDHC)Abid HasanNo ratings yet

- Magnetic and Electrical Properties of Nickel NanopDocument9 pagesMagnetic and Electrical Properties of Nickel NanopNguyen Ngoc MinhNo ratings yet

- Research Paper Mining in PalawanDocument5 pagesResearch Paper Mining in Palawanhkdxiutlg100% (1)

- 2 Mhz2 Series Air GrippersDocument17 pages2 Mhz2 Series Air GrippersAlex VegaNo ratings yet