Professional Documents

Culture Documents

GPCA - Good Manuf. Practice (GMP) - Nov. 2019 (v2)

GPCA - Good Manuf. Practice (GMP) - Nov. 2019 (v2)

Uploaded by

hamidCopyright:

Available Formats

You might also like

- Is.3786 2022Document18 pagesIs.3786 2022hamidNo ratings yet

- GMPs For Equipment Utilities FacilitiesDocument6 pagesGMPs For Equipment Utilities FacilitiesEdgardo Ed RamirezNo ratings yet

- Hughes PatriciaDocument60 pagesHughes PatriciaNing KevinNo ratings yet

- Iso 13845Document21 pagesIso 13845Syed Haider Abbas KazmiNo ratings yet

- Financial Analysis On Investment Banks of BDDocument76 pagesFinancial Analysis On Investment Banks of BDAnika TabassumNo ratings yet

- Industri Bioteknologi 2021 - Kumpulan 5Document15 pagesIndustri Bioteknologi 2021 - Kumpulan 5AINAA SYAFIQA BINTI KAMARULZAMANNo ratings yet

- Industri Bioteknologi 2021 - Kumpulan 5Document15 pagesIndustri Bioteknologi 2021 - Kumpulan 5AINAA SYAFIQA BINTI KAMARULZAMANNo ratings yet

- Sep-2016. AIB-GMP Inspection Results ReportDocument20 pagesSep-2016. AIB-GMP Inspection Results ReportPhạm Thanh VấnNo ratings yet

- 2017-11-06 - Intertek Webinar - FDA FCM Compliance Dispensing MachinesDocument32 pages2017-11-06 - Intertek Webinar - FDA FCM Compliance Dispensing MachinesBasvanLeeuwenNo ratings yet

- Randy Kelana: UHAMKA - Agustus 2022Document24 pagesRandy Kelana: UHAMKA - Agustus 2022diinipermanaNo ratings yet

- Actylis LAB PL Jan-2024 Low ResDocument144 pagesActylis LAB PL Jan-2024 Low ResKaushik hazarikaNo ratings yet

- Validation Guide Ulta Prime GF Capsule and Cartridge FiltersDocument16 pagesValidation Guide Ulta Prime GF Capsule and Cartridge Filtersannie_mehtaNo ratings yet

- 1 Fruergaard Advanced Aseptic Processing ISPEDocument57 pages1 Fruergaard Advanced Aseptic Processing ISPEamerican_guy10100% (1)

- GMP Broschuere MW PI Englisch 07-06-2011 5C Kleine DatenDocument8 pagesGMP Broschuere MW PI Englisch 07-06-2011 5C Kleine DatenKerollus KhairyNo ratings yet

- 6 ADC Piramal1Document37 pages6 ADC Piramal1anitaNo ratings yet

- FDHB725UK Hydraulic Filtration SolutionsDocument38 pagesFDHB725UK Hydraulic Filtration Solutionsmona zhangNo ratings yet

- 2017-11-02 - Intertek Webinar - FDA NOL For Recycled PlasticsDocument40 pages2017-11-02 - Intertek Webinar - FDA NOL For Recycled PlasticsBasvanLeeuwenNo ratings yet

- MG Catalog-587276 PDFDocument59 pagesMG Catalog-587276 PDFricardo barronNo ratings yet

- 2013-840 Guidance 11-25-14 Supac Adendum For EquipmentDocument48 pages2013-840 Guidance 11-25-14 Supac Adendum For EquipmentEdy TeranNo ratings yet

- Increase Productivity Rapid Micro Methods PharmaEnvironment Michael WasmannDocument31 pagesIncrease Productivity Rapid Micro Methods PharmaEnvironment Michael WasmannRonald SalasNo ratings yet

- New Guidance On Product Family Adoption For Radiation Sterilization: AAMI TIR 35:2016Document39 pagesNew Guidance On Product Family Adoption For Radiation Sterilization: AAMI TIR 35:2016RakeshNo ratings yet

- AA37N-5. Estándar Niquel. 29-12-2025Document2 pagesAA37N-5. Estándar Niquel. 29-12-2025calidadlaboratoriocgrNo ratings yet

- Presentation - 4 - Industrial Hygiene and Technical SupportDocument25 pagesPresentation - 4 - Industrial Hygiene and Technical SupporttaofikNo ratings yet

- M1-Introduction - Rev 2024Document12 pagesM1-Introduction - Rev 2024EnggerianiNo ratings yet

- AA13N-5. Estándar Cromo. 18-05-2026Document2 pagesAA13N-5. Estándar Cromo. 18-05-2026calidadlaboratoriocgrNo ratings yet

- Finar Limited - Laboratory Chemicals - Price List 2020-2021Document148 pagesFinar Limited - Laboratory Chemicals - Price List 2020-2021finar chemicalsNo ratings yet

- HACCP Training GuideDocument42 pagesHACCP Training GuideSyed HamzaNo ratings yet

- 789 G5500 Rev. 9.2 Quality Manual Final1.UnlockedDocument23 pages789 G5500 Rev. 9.2 Quality Manual Final1.Unlockeddrmohamed120No ratings yet

- Environmental Monitoring: Brazil-PDA March 2020 Anvisa RegulationsDocument65 pagesEnvironmental Monitoring: Brazil-PDA March 2020 Anvisa RegulationsisabelclimaNo ratings yet

- Commitment To Quality in Pharmaceutical Development and Commercial ManufacturingDocument37 pagesCommitment To Quality in Pharmaceutical Development and Commercial ManufacturinghuykhiemNo ratings yet

- Catalogo MINICARTUCHOS-CAPSULAS - INGLSDocument18 pagesCatalogo MINICARTUCHOS-CAPSULAS - INGLSPapaleguas gamesNo ratings yet

- Test - 2 Study Material (CO-3 and CO-4) 2019-2020Document11 pagesTest - 2 Study Material (CO-3 and CO-4) 2019-2020shashi kiranNo ratings yet

- Section 5: Quality Systems Regulation (QSR) and Good Manufacturing Practice (GMP)Document24 pagesSection 5: Quality Systems Regulation (QSR) and Good Manufacturing Practice (GMP)KarishmaNo ratings yet

- 4.2penjaminan Mutu Sediaan Farmasi - Oky YudiswaraDocument29 pages4.2penjaminan Mutu Sediaan Farmasi - Oky YudiswaraMUNIFRIZALNo ratings yet

- ValidationDocument49 pagesValidationmanzoor ansari0% (1)

- Materi Trainning K3Document32 pagesMateri Trainning K3eko SetyawanNo ratings yet

- Pharmaceutical Industries at A Glance: Bandung, September 2016 Ni Nyoman Wiwik SutrisniDocument17 pagesPharmaceutical Industries at A Glance: Bandung, September 2016 Ni Nyoman Wiwik SutrisniBunbun BunNo ratings yet

- 3 Non-Tariff Business Barriers in Soy Industry - by Ms. Chinmayee Deulgaonkar, FoodChain IndiaDocument15 pages3 Non-Tariff Business Barriers in Soy Industry - by Ms. Chinmayee Deulgaonkar, FoodChain IndiashyamalNo ratings yet

- Modul-1 Industrial Pharmacy 2021 Rev1Document13 pagesModul-1 Industrial Pharmacy 2021 Rev1Fadhilah PalensiaNo ratings yet

- CCL Presentation June 2018Document44 pagesCCL Presentation June 2018TRUCAL NABLNo ratings yet

- Bio Engineering Tofflon PDFDocument16 pagesBio Engineering Tofflon PDFVivek ChangdeNo ratings yet

- 18apr2013 CleaningValidationOverviewDocument84 pages18apr2013 CleaningValidationOverviewEdwin Mendoza (VZ)No ratings yet

- MRC 100Document2 pagesMRC 100ERIK OSWALDO CAMACHO VILLANNo ratings yet

- FDAs GMP Inspection With Special Regard To Aseptic Process For Drugs Biologicals PF LeeDocument97 pagesFDAs GMP Inspection With Special Regard To Aseptic Process For Drugs Biologicals PF Leesung man limNo ratings yet

- Buganda BanageDocument61 pagesBuganda BanageNkugwa Mark WilliamNo ratings yet

- European Medical Device Regulations: Preparing For The StormDocument48 pagesEuropean Medical Device Regulations: Preparing For The StormHarold BrausteinNo ratings yet

- 195 Tansuatcauhoicho QADocument92 pages195 Tansuatcauhoicho QANguyễn trọng TuấnNo ratings yet

- Coa D-6428-BL 216071219Document2 pagesCoa D-6428-BL 216071219MiguelNo ratings yet

- Compression of Schedule M To Proposed Schedule M: Part I-ADocument2 pagesCompression of Schedule M To Proposed Schedule M: Part I-ASangram Kendre100% (1)

- Global Market Access Restrictions Through Private StandardsDocument29 pagesGlobal Market Access Restrictions Through Private StandardssukhmenderNo ratings yet

- Pharma Questions PDFDocument71 pagesPharma Questions PDFDipesh BardoliaNo ratings yet

- Good Manufacturing Practices in A Quality World: Manish Joshi Manager Quality Asurance D.P.IDocument73 pagesGood Manufacturing Practices in A Quality World: Manish Joshi Manager Quality Asurance D.P.Imanu4u1984No ratings yet

- Quality Assurance Question BankDocument72 pagesQuality Assurance Question BankMuhammad Noman bin FiazNo ratings yet

- D Ballarín-20211006Document81 pagesD Ballarín-20211006SilviaNo ratings yet

- Food & Beverages EcolabDocument4 pagesFood & Beverages EcolabNorma E. Hernández B.No ratings yet

- Slide 1: Industrial PharmacyDocument5 pagesSlide 1: Industrial PharmacyI KADEK SUNGKAR NUGRAHANo ratings yet

- Group 4 - CGMPDocument30 pagesGroup 4 - CGMPCristine BellenNo ratings yet

- Quality Management System at Pharmaceutical IndustryDocument85 pagesQuality Management System at Pharmaceutical IndustryTissa Novida Aulia ZahraNo ratings yet

- PHSS I-SIG Technical ConfereDocument390 pagesPHSS I-SIG Technical ConferegunneshNo ratings yet

- Gps Summary ChlorineDocument5 pagesGps Summary ChlorinehamidNo ratings yet

- Cefic ICCA Guidance On Process Safety Performance IndicatorsDocument26 pagesCefic ICCA Guidance On Process Safety Performance IndicatorshamidNo ratings yet

- Cefic GHS RelatedDocument14 pagesCefic GHS RelatedhamidNo ratings yet

- 6 Process SafetyDocument30 pages6 Process SafetyhamidNo ratings yet

- 5 Healthy SafetyDocument40 pages5 Healthy SafetyhamidNo ratings yet

- 3 Product StewardshipDocument24 pages3 Product StewardshiphamidNo ratings yet

- 6 Alan Izzard Gulf SQAS Middle East and RC ProgressDocument34 pages6 Alan Izzard Gulf SQAS Middle East and RC ProgresshamidNo ratings yet

- 1 Community AwarenessDocument30 pages1 Community AwarenesshamidNo ratings yet

- RC Management Framework 1Document52 pagesRC Management Framework 1hamidNo ratings yet

- Is.1446.2002 Classification of Dangerous GoodsDocument89 pagesIs.1446.2002 Classification of Dangerous GoodshamidNo ratings yet

- Agrarian Reform in The PhilippinesDocument4 pagesAgrarian Reform in The PhilippinesLadymae Barneso SamalNo ratings yet

- Jib Service Crane For RTG-Terminal 2Document7 pagesJib Service Crane For RTG-Terminal 2YasirNo ratings yet

- TestBank Evans Ba2 Tif Ch01Document18 pagesTestBank Evans Ba2 Tif Ch01Khaleel AbdoNo ratings yet

- d200 Users Manual v1 00 00 PDFDocument134 pagesd200 Users Manual v1 00 00 PDFMADHAVI MNo ratings yet

- Reference Letter Template For A FriendDocument6 pagesReference Letter Template For A Friendbd9gjpsn100% (2)

- Aso Mega ListDocument7 pagesAso Mega ListcmlcbhtidNo ratings yet

- Building Maintenance Inspection and Facilities Assessment: Case Study: Office Block A2, University Malaysia PahangDocument11 pagesBuilding Maintenance Inspection and Facilities Assessment: Case Study: Office Block A2, University Malaysia PahangNrsyfqah SuleimanNo ratings yet

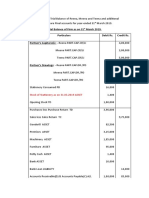

- Local ChargesDocument2 pagesLocal ChargesTra PhungNo ratings yet

- International Accounting Standard 7 Statement of Cash FlowsDocument8 pagesInternational Accounting Standard 7 Statement of Cash Flowsইবনুল মাইজভাণ্ডারীNo ratings yet

- CHARTDocument33 pagesCHARTLindsey Ianna Pablo AndresNo ratings yet

- 12 Points) : A B: Over Co de Ex Out Down Re Ultra UnderDocument2 pages12 Points) : A B: Over Co de Ex Out Down Re Ultra UnderRobert CalcanNo ratings yet

- 09 Yi Accounts Payable Risk AssessmentDocument2 pages09 Yi Accounts Payable Risk AssessmentMalik Khayyam OmerNo ratings yet

- Q4 Partnership Final Accs QuestionsDocument4 pagesQ4 Partnership Final Accs QuestionsIsha KatiyarNo ratings yet

- Fuel Surcharge - UPS - VietnamDocument3 pagesFuel Surcharge - UPS - VietnamJDS JICENo ratings yet

- HTG - Distribution Equipment - OfficialRelease - V1.0Document59 pagesHTG - Distribution Equipment - OfficialRelease - V1.0Altamir Nunes JuniorNo ratings yet

- Chapter 1Document12 pagesChapter 1Sairam PrakashNo ratings yet

- Template IPO Affidavit of Consent FormDocument2 pagesTemplate IPO Affidavit of Consent Formcathy cenonNo ratings yet

- E-Ticket 0706658136310: Kolkata BhubaneswarDocument2 pagesE-Ticket 0706658136310: Kolkata BhubaneswarBanerjee SuvranilNo ratings yet

- JSA Scaffolding (Green) - OSBLDocument20 pagesJSA Scaffolding (Green) - OSBLSiti AminahNo ratings yet

- Do More With Microsoft Teams: Download The Teams App HereDocument1 pageDo More With Microsoft Teams: Download The Teams App HerejcherrandNo ratings yet

- 8 Steps in Accounting CycleDocument2 pages8 Steps in Accounting CycleMarko Zero FourNo ratings yet

- Project Management Environment - Questions (07012020)Document4 pagesProject Management Environment - Questions (07012020)Nadia Rahmeita PrasantiNo ratings yet

- One Warehouse Multiretailer System With Centralized Stock InformationDocument13 pagesOne Warehouse Multiretailer System With Centralized Stock InformationdeevaNo ratings yet

- Case Study Tren Engine ComponentsDocument2 pagesCase Study Tren Engine ComponentsUmar KhattakNo ratings yet

- QOS Improvement in MANET Routing by Route Optimization Through Convergence of Mobile AgentDocument6 pagesQOS Improvement in MANET Routing by Route Optimization Through Convergence of Mobile AgentNader JalalNo ratings yet

- Stages of Digital Transformation in Competency Management - TejaDocument6 pagesStages of Digital Transformation in Competency Management - TejaImmanuel Teja HarjayaNo ratings yet

- Black ScholesDocument3 pagesBlack ScholesAditiNo ratings yet

- Disbursement Voucher (New Orence)Document4 pagesDisbursement Voucher (New Orence)user computerNo ratings yet

- Lanka Bangla FinanceDocument31 pagesLanka Bangla FinanceJacobHauheng0% (1)

GPCA - Good Manuf. Practice (GMP) - Nov. 2019 (v2)

GPCA - Good Manuf. Practice (GMP) - Nov. 2019 (v2)

Uploaded by

hamidOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GPCA - Good Manuf. Practice (GMP) - Nov. 2019 (v2)

GPCA - Good Manuf. Practice (GMP) - Nov. 2019 (v2)

Uploaded by

hamidCopyright:

Available Formats

Insert picture

Good Manufacturing Practice

(GMP): Principles &

Guideline

Abdallah Abu-Haidar – SABIC,

GPCA’S Product Stewardship

Task Force Chairman

San Francisco Zoo officials said the

enclosure for a Siberian tiger that killed a

San Jose teenager and injured two friends in

Carlos Sousa Jr., 17,

rampage had a wall lower than they initially of San Jose.

stated and below industry recommendations.

Wall around tiger

enclosure 12.5 feet is

4 feet lower than

recommended by

experts

Responsible Care: The Competitive Advantage

Driver for Product Qualification - Applications

{ADDED VALUE - $$$}

Objectives: Increase the added value by

meeting the critical applications requirements

and satisfy markets and customers demands.

Process: Define the prerequisites and process for

certifying & qualifying the product to meet Product {Medical}

Stewardship guidelines and legal requirements.

{Electronics}

{Food Contact}

Responsible Care: The Competitive Advantage

2

GMP Regulatory Agencies

A good manufacturing practice (GMP) is a system that conforms to the guidelines set by the

regulatory agencies that control authorization and licensing for the production and sale of

food, beverages, and pharmaceutical products.

USA:

Food and Drug Administration (FDA), under Title 21 CFR. The

regulations use the phrase "current good manufacturing practices"

(CGMP) to describe these guidelines.

Europe:

COMMISSION REGULATION (EC) No 2023/2006 of 22 December

2006 on good manufacturing practice for materials and articles

intended to come into contact with food

Responsible Care: The Competitive Advantage

Definition

Materials and articles.... shall be

manufactured in compliance with good

manufacturing practice so that, under

normal or foreseeable conditions of use,

they do not………………

endanger human health (i.e. prevent

harm from occurring to the end user)

change in the composition of the

food

allow contaminations in the end

product

tamper with the organoleptic

characteristics

Responsible Care: The Competitive Advantage

GMP Qualification

1.What do you produce (polymers, chemicals, fertilizers, metals, etc.?

2.What applications (i.e. market segments – Food, Medical)?

3.Odd applications (e.g. UREA for Cattle Feed)

4.Do your customers have specific needs (declarations)?

Responsible Care: The Competitive Advantage

Driver for Qualification - Product Application

OTHERS AUTOMOTIVE

• FURNITURE COMPONENTS • INSTRUMENT PANELS

• SHEETS • AUTO TAIL LIGHT

• MEDICAL DEVICES • REFLECTORS

SIGNS LIGHTING

• ADVERTISEMENT PANELS • LENS FOR LED LIGHT

• INTERIOR EMERGENCY SIGN Application • STREETLIGHT COVER

Segments

FABRICATION/ DISPLAYS

HOUSEWARES

• LIGHT GUIDE PLATE • PACKAGING

• LED SCREENS

• KITCHEN-WARE

• TOUCH SCREENS

GLAZING / BUILDING APPLIANCES

• ROOFING ELECTRICAL • SMALL APPLIANCE

• INTERIOR DECORATION COMPONENTS

• HOUSING

Responsible Care: The Competitive Advantage

GMP Scope: Basic Information Required

Finished Safety and Compliance Check

Products

[Grades] Composition (Additive Package) for each grade

Qualify

Finished 118W Irganox 1010 Slip Agent Antiblock Zinc Str.

Products 218W 500 2000 1000 700

for Specific

PP510P

Applications Other Information

PVC 57S

Catalyst Feedstock (purity)

PS100

Processing Conditions Support Chemicals

Product

Qualification

Responsible Care: The Competitive Advantage

GMP Scope: Additives Testing

Composition (Additive Package) for each grade

Irganox 1010 Slip Agent Antiblock Zinc Str.

500 2000 1000 700

Purpose: Ensure that the quantities of all chemical

components are acceptable under certain use

conditions (temperature, pressure, etc.)

Three Levels to Qualify the Chemical Components and their volumes:

1. Based on historical data

2. Computer simulation

3. Conduct migration test under specified testing protocol

Responsible Care: The Competitive Advantage

GMP Scope: Regulatory Check

Purpose: Ensure that all chemical components are not banned neither restricted in the markets

of intended sales

Regulatory Affairs

to check with the

authorities if the

chemicals used

are banned or

restricted

Responsible Care: The Competitive Advantage

GMP Scope: Production System Verification

Feed Stock

Process

Additives

Processing Aids

Finished

Catalysts Products

Support Chemicals

Others……..

Responsible Care: The Competitive Advantage

FCD (Food Contact Declaration)

Responsible Care: The Competitive Advantage

Corporate Vs. 3rd Party Certification

3rd Party Certification is required for products related

to medical and pharmaceutical applications

INCIPIENTS – Medical Product EXCIPIENTS – Medical Product That do

That go Inside the Body (3rd Party) not go Inside the Body (No 3rd Party)

Responsible Care: The Competitive Advantage

Example of 3 rd Party Certification

Responsible Care: The Competitive Advantage

GMP and ISO

ISO is a quality system to ensure that products are

produced according to documented procedures and

specifications

……….. 'good manufacturing

practice' ensures that products are consistently

suitable for the intended use (i.e. Food Contact Legal

Requirements).

{ISO procedures can be an excellent carrier

for GMP}.

Responsible Care: The Competitive Advantage

GMP Qualification Guideline

GMP Guidelines

1 Quality Assurance System and Quality Policy

2 Management Leadership and Personnel

3 Hygiene Policy and Pest Control

4 Documentation, Labelling, Document Retention and Traceability

5 Starting and/or Raw Material Specifications and Acceptance

6 Contamination Prevention

7 Management of Change

8 Storage, Packaging, Warehousing, and Transportation

9 Work Contracted Out

10 Finished Products Quality Control and Specifications

11 Complaint handling, Product Recall and Incident Management

12 Regular Internal and Suppliers Audits

Responsible Care: The Competitive Advantage

GMP Product Stewardship Movie

Responsible Care: The Competitive Advantage

1. Quality Assurance System and Quality Policy

Support Documents, Evidences, and

Aspects

Practices

a. Quality Policy; Comprehensive GMP

consistently produce Procedure

materials for food contact in

compliance with the Plant certifications (ex.

applicable regulations ISO9001:2008)

b. Active participation of Well defined structure [lead

management and personnel & attend meetings]

c. QC Department to Product quality check

independently QC is independent from the

approve/reject all materials Production and the Business

in the process. Departments

Responsible Care: The Competitive Advantage

2. Management Leadership and Personnel

Aspects Support Documents, Evidences, and Practices

a. Management responsibilities Designate site GMP coordinator with support

are assigned, defined, and personnel from different functions [Organization

documented Chart]

b. The concerned personnel Support evidence of training for operators AND

should have the education, Contractors (training material, attendance list,

training and proper experience frequency)

Responsible Care: The Competitive Advantage

3. Hygiene Policy and Pest Control

Aspects Support Documents, Evidences, and Practices

a. Maintain adequate hygiene Maintain good indoor and outdoor housekeeping, with

measures for personnel, adequate washing facilities for personnel

factories, warehouses, and

transportation Frequency of inspection supported by documents

Identify the responsible department for Pest Control

b. A pest control program

The Process is governed by a written procedure

should be available

Observations (rats, mice, snakes, cats, dogs, etc.)

Responsible Care: The Competitive Advantage

4. Documentation, Labelling, Document Retention and Traceability

Support Documents, Evidences, and

Aspects

Practices

a. Records of Product formulation,

specifications, operating parameters, Easy access to concerned personnel only

and other critical information

b. Procedures for tracing incoming Provide traceability procedure to trace

starting material to outgoing food one step up and one step down by

contact material using batch record procedure

Responsible Care: The Competitive Advantage

5. Starting and/or Raw Material Specifications and Acceptance – Cont’d

Support Documents,

Aspects

Evidences, and Practices

Storage locations and

conditions

d. Carefully store and

Bags, drums, & boxes are

handle material to

clearly labeled

prevents their mix-up

and/or adulteration Eliminate potentials of

picking the wrong

material from the WH

e. Identify out of spec Procedure to remove

material and dispose and isolate rejected

properly material

Responsible Care: The Competitive Advantage

6. Contamination Prevention

Support Documents, Evidences,

Aspects

and Practices

a. Contamination

Risk Assessment and Risk

prevention system based

Mitigation Procedure

on risk assessment.

b. Water that comes into Use of DM water with no

contact with the food minerals and relinquish the

contact materials should system with the same quality

be of suitable quality. water

c. The equipment Separate production lines or

designed to mitigate apply stringent measures

contaminations (water wash, purge, etc.)

Centrifugal Dryer

Responsible Care: The Competitive Advantage

7. Management of Change (MOC)

Aspects Support Documents, Evidences, and Practices

a. MOC to track all relevant changes;

• Processing conditions

• Formulations MOC contains thorough process for

• RM spec changes changes stipulated

• Suppliers changes Auditors might review the MOC

• Operating outside the processing document

windows

• Etc.

Identify the party responsible for

b. Process identifying the impact of

technically assessing the changes before

changes on finished products

changes are accepted

Responsible Care: The Competitive Advantage

8. Storage, Packaging, Warehousing, and Transportation

Aspects Support Documents, Evidences, and Practices

Physically separate different types of chemicals

a. There is sufficient and (catalysts, additives, etc.) in the same warehouse

well managed storage for Use closed loop system in transferring chemicals to

raw materials. the processing area

Apply FIFO to better manage inventory rotation

b. Good storage

conditions to avoid Use air conditioned or well ventilated warehouse

adulteration of materials

c. Clean Silo's and bulk Use dedicated equipment or apply water wash

trucks Inspect containers before loading

d. Ensure printing and Use automated labeling system connected to your

labels are correct IT Tool (e.g. SAP)

Responsible Care: The Competitive Advantage

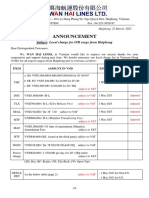

9. Work Contracted Out (Contractors Management)

Support Documents, Evidences, and

Aspects

Practices

a. Any contracted out manufacturing operation

(e.g., warehousing, toll manufacturing, sanitation Check if contracts are

services, transportation services, on-site available and whether the

contractors) shall be subject to a written contract contracted companies

and should be performed according to 'good apply GMP or follow

manufacturing practice' comparable to the one similar standards.

assured by the own operation.

Responsible Care: The Competitive Advantage

11. Complaint Handling, Product Recall, and Incident Management

Aspects Support Documents, Evidences, and Practices

Complaints Handling Procedure with specific

a. Record and investigate ownership and responsibilities

complaints, including product

Risk Assessment process

recall.

Corrective actions followed and implemented

b. Non-conforming or recalled

A system to immediately detect and isolate the

products are not released

off-spec material, label properly, and block in

without extensive investigation

the IT System

and proper authorization.

c. Keep a sample of every lot

Retained samples (quantity, storage period, usage

for future investigations (if

in complaints investigations, etc.)

needed)

Responsible Care: The Competitive Advantage

12. Regular Internal and Supplier Audits

Support Documents, Evidences, and

Aspects

Practices

a. Conduct regular internal Plant to provide evidence for

audits or self-assessments conducting yearly internal audits to

in order to monitor the ensure proper follow-ups and systems

implementation of 'Good checks are in place to maintain GMP

Manufacturing Practice'. compliance.

Responsible Care: The Competitive Advantage

Thank You

gpca.org.ae info@gpca.org.ae GulfPetChem @GulfPetChem GPCA GPCAOrg

You might also like

- Is.3786 2022Document18 pagesIs.3786 2022hamidNo ratings yet

- GMPs For Equipment Utilities FacilitiesDocument6 pagesGMPs For Equipment Utilities FacilitiesEdgardo Ed RamirezNo ratings yet

- Hughes PatriciaDocument60 pagesHughes PatriciaNing KevinNo ratings yet

- Iso 13845Document21 pagesIso 13845Syed Haider Abbas KazmiNo ratings yet

- Financial Analysis On Investment Banks of BDDocument76 pagesFinancial Analysis On Investment Banks of BDAnika TabassumNo ratings yet

- Industri Bioteknologi 2021 - Kumpulan 5Document15 pagesIndustri Bioteknologi 2021 - Kumpulan 5AINAA SYAFIQA BINTI KAMARULZAMANNo ratings yet

- Industri Bioteknologi 2021 - Kumpulan 5Document15 pagesIndustri Bioteknologi 2021 - Kumpulan 5AINAA SYAFIQA BINTI KAMARULZAMANNo ratings yet

- Sep-2016. AIB-GMP Inspection Results ReportDocument20 pagesSep-2016. AIB-GMP Inspection Results ReportPhạm Thanh VấnNo ratings yet

- 2017-11-06 - Intertek Webinar - FDA FCM Compliance Dispensing MachinesDocument32 pages2017-11-06 - Intertek Webinar - FDA FCM Compliance Dispensing MachinesBasvanLeeuwenNo ratings yet

- Randy Kelana: UHAMKA - Agustus 2022Document24 pagesRandy Kelana: UHAMKA - Agustus 2022diinipermanaNo ratings yet

- Actylis LAB PL Jan-2024 Low ResDocument144 pagesActylis LAB PL Jan-2024 Low ResKaushik hazarikaNo ratings yet

- Validation Guide Ulta Prime GF Capsule and Cartridge FiltersDocument16 pagesValidation Guide Ulta Prime GF Capsule and Cartridge Filtersannie_mehtaNo ratings yet

- 1 Fruergaard Advanced Aseptic Processing ISPEDocument57 pages1 Fruergaard Advanced Aseptic Processing ISPEamerican_guy10100% (1)

- GMP Broschuere MW PI Englisch 07-06-2011 5C Kleine DatenDocument8 pagesGMP Broschuere MW PI Englisch 07-06-2011 5C Kleine DatenKerollus KhairyNo ratings yet

- 6 ADC Piramal1Document37 pages6 ADC Piramal1anitaNo ratings yet

- FDHB725UK Hydraulic Filtration SolutionsDocument38 pagesFDHB725UK Hydraulic Filtration Solutionsmona zhangNo ratings yet

- 2017-11-02 - Intertek Webinar - FDA NOL For Recycled PlasticsDocument40 pages2017-11-02 - Intertek Webinar - FDA NOL For Recycled PlasticsBasvanLeeuwenNo ratings yet

- MG Catalog-587276 PDFDocument59 pagesMG Catalog-587276 PDFricardo barronNo ratings yet

- 2013-840 Guidance 11-25-14 Supac Adendum For EquipmentDocument48 pages2013-840 Guidance 11-25-14 Supac Adendum For EquipmentEdy TeranNo ratings yet

- Increase Productivity Rapid Micro Methods PharmaEnvironment Michael WasmannDocument31 pagesIncrease Productivity Rapid Micro Methods PharmaEnvironment Michael WasmannRonald SalasNo ratings yet

- New Guidance On Product Family Adoption For Radiation Sterilization: AAMI TIR 35:2016Document39 pagesNew Guidance On Product Family Adoption For Radiation Sterilization: AAMI TIR 35:2016RakeshNo ratings yet

- AA37N-5. Estándar Niquel. 29-12-2025Document2 pagesAA37N-5. Estándar Niquel. 29-12-2025calidadlaboratoriocgrNo ratings yet

- Presentation - 4 - Industrial Hygiene and Technical SupportDocument25 pagesPresentation - 4 - Industrial Hygiene and Technical SupporttaofikNo ratings yet

- M1-Introduction - Rev 2024Document12 pagesM1-Introduction - Rev 2024EnggerianiNo ratings yet

- AA13N-5. Estándar Cromo. 18-05-2026Document2 pagesAA13N-5. Estándar Cromo. 18-05-2026calidadlaboratoriocgrNo ratings yet

- Finar Limited - Laboratory Chemicals - Price List 2020-2021Document148 pagesFinar Limited - Laboratory Chemicals - Price List 2020-2021finar chemicalsNo ratings yet

- HACCP Training GuideDocument42 pagesHACCP Training GuideSyed HamzaNo ratings yet

- 789 G5500 Rev. 9.2 Quality Manual Final1.UnlockedDocument23 pages789 G5500 Rev. 9.2 Quality Manual Final1.Unlockeddrmohamed120No ratings yet

- Environmental Monitoring: Brazil-PDA March 2020 Anvisa RegulationsDocument65 pagesEnvironmental Monitoring: Brazil-PDA March 2020 Anvisa RegulationsisabelclimaNo ratings yet

- Commitment To Quality in Pharmaceutical Development and Commercial ManufacturingDocument37 pagesCommitment To Quality in Pharmaceutical Development and Commercial ManufacturinghuykhiemNo ratings yet

- Catalogo MINICARTUCHOS-CAPSULAS - INGLSDocument18 pagesCatalogo MINICARTUCHOS-CAPSULAS - INGLSPapaleguas gamesNo ratings yet

- Test - 2 Study Material (CO-3 and CO-4) 2019-2020Document11 pagesTest - 2 Study Material (CO-3 and CO-4) 2019-2020shashi kiranNo ratings yet

- Section 5: Quality Systems Regulation (QSR) and Good Manufacturing Practice (GMP)Document24 pagesSection 5: Quality Systems Regulation (QSR) and Good Manufacturing Practice (GMP)KarishmaNo ratings yet

- 4.2penjaminan Mutu Sediaan Farmasi - Oky YudiswaraDocument29 pages4.2penjaminan Mutu Sediaan Farmasi - Oky YudiswaraMUNIFRIZALNo ratings yet

- ValidationDocument49 pagesValidationmanzoor ansari0% (1)

- Materi Trainning K3Document32 pagesMateri Trainning K3eko SetyawanNo ratings yet

- Pharmaceutical Industries at A Glance: Bandung, September 2016 Ni Nyoman Wiwik SutrisniDocument17 pagesPharmaceutical Industries at A Glance: Bandung, September 2016 Ni Nyoman Wiwik SutrisniBunbun BunNo ratings yet

- 3 Non-Tariff Business Barriers in Soy Industry - by Ms. Chinmayee Deulgaonkar, FoodChain IndiaDocument15 pages3 Non-Tariff Business Barriers in Soy Industry - by Ms. Chinmayee Deulgaonkar, FoodChain IndiashyamalNo ratings yet

- Modul-1 Industrial Pharmacy 2021 Rev1Document13 pagesModul-1 Industrial Pharmacy 2021 Rev1Fadhilah PalensiaNo ratings yet

- CCL Presentation June 2018Document44 pagesCCL Presentation June 2018TRUCAL NABLNo ratings yet

- Bio Engineering Tofflon PDFDocument16 pagesBio Engineering Tofflon PDFVivek ChangdeNo ratings yet

- 18apr2013 CleaningValidationOverviewDocument84 pages18apr2013 CleaningValidationOverviewEdwin Mendoza (VZ)No ratings yet

- MRC 100Document2 pagesMRC 100ERIK OSWALDO CAMACHO VILLANNo ratings yet

- FDAs GMP Inspection With Special Regard To Aseptic Process For Drugs Biologicals PF LeeDocument97 pagesFDAs GMP Inspection With Special Regard To Aseptic Process For Drugs Biologicals PF Leesung man limNo ratings yet

- Buganda BanageDocument61 pagesBuganda BanageNkugwa Mark WilliamNo ratings yet

- European Medical Device Regulations: Preparing For The StormDocument48 pagesEuropean Medical Device Regulations: Preparing For The StormHarold BrausteinNo ratings yet

- 195 Tansuatcauhoicho QADocument92 pages195 Tansuatcauhoicho QANguyễn trọng TuấnNo ratings yet

- Coa D-6428-BL 216071219Document2 pagesCoa D-6428-BL 216071219MiguelNo ratings yet

- Compression of Schedule M To Proposed Schedule M: Part I-ADocument2 pagesCompression of Schedule M To Proposed Schedule M: Part I-ASangram Kendre100% (1)

- Global Market Access Restrictions Through Private StandardsDocument29 pagesGlobal Market Access Restrictions Through Private StandardssukhmenderNo ratings yet

- Pharma Questions PDFDocument71 pagesPharma Questions PDFDipesh BardoliaNo ratings yet

- Good Manufacturing Practices in A Quality World: Manish Joshi Manager Quality Asurance D.P.IDocument73 pagesGood Manufacturing Practices in A Quality World: Manish Joshi Manager Quality Asurance D.P.Imanu4u1984No ratings yet

- Quality Assurance Question BankDocument72 pagesQuality Assurance Question BankMuhammad Noman bin FiazNo ratings yet

- D Ballarín-20211006Document81 pagesD Ballarín-20211006SilviaNo ratings yet

- Food & Beverages EcolabDocument4 pagesFood & Beverages EcolabNorma E. Hernández B.No ratings yet

- Slide 1: Industrial PharmacyDocument5 pagesSlide 1: Industrial PharmacyI KADEK SUNGKAR NUGRAHANo ratings yet

- Group 4 - CGMPDocument30 pagesGroup 4 - CGMPCristine BellenNo ratings yet

- Quality Management System at Pharmaceutical IndustryDocument85 pagesQuality Management System at Pharmaceutical IndustryTissa Novida Aulia ZahraNo ratings yet

- PHSS I-SIG Technical ConfereDocument390 pagesPHSS I-SIG Technical ConferegunneshNo ratings yet

- Gps Summary ChlorineDocument5 pagesGps Summary ChlorinehamidNo ratings yet

- Cefic ICCA Guidance On Process Safety Performance IndicatorsDocument26 pagesCefic ICCA Guidance On Process Safety Performance IndicatorshamidNo ratings yet

- Cefic GHS RelatedDocument14 pagesCefic GHS RelatedhamidNo ratings yet

- 6 Process SafetyDocument30 pages6 Process SafetyhamidNo ratings yet

- 5 Healthy SafetyDocument40 pages5 Healthy SafetyhamidNo ratings yet

- 3 Product StewardshipDocument24 pages3 Product StewardshiphamidNo ratings yet

- 6 Alan Izzard Gulf SQAS Middle East and RC ProgressDocument34 pages6 Alan Izzard Gulf SQAS Middle East and RC ProgresshamidNo ratings yet

- 1 Community AwarenessDocument30 pages1 Community AwarenesshamidNo ratings yet

- RC Management Framework 1Document52 pagesRC Management Framework 1hamidNo ratings yet

- Is.1446.2002 Classification of Dangerous GoodsDocument89 pagesIs.1446.2002 Classification of Dangerous GoodshamidNo ratings yet

- Agrarian Reform in The PhilippinesDocument4 pagesAgrarian Reform in The PhilippinesLadymae Barneso SamalNo ratings yet

- Jib Service Crane For RTG-Terminal 2Document7 pagesJib Service Crane For RTG-Terminal 2YasirNo ratings yet

- TestBank Evans Ba2 Tif Ch01Document18 pagesTestBank Evans Ba2 Tif Ch01Khaleel AbdoNo ratings yet

- d200 Users Manual v1 00 00 PDFDocument134 pagesd200 Users Manual v1 00 00 PDFMADHAVI MNo ratings yet

- Reference Letter Template For A FriendDocument6 pagesReference Letter Template For A Friendbd9gjpsn100% (2)

- Aso Mega ListDocument7 pagesAso Mega ListcmlcbhtidNo ratings yet

- Building Maintenance Inspection and Facilities Assessment: Case Study: Office Block A2, University Malaysia PahangDocument11 pagesBuilding Maintenance Inspection and Facilities Assessment: Case Study: Office Block A2, University Malaysia PahangNrsyfqah SuleimanNo ratings yet

- Local ChargesDocument2 pagesLocal ChargesTra PhungNo ratings yet

- International Accounting Standard 7 Statement of Cash FlowsDocument8 pagesInternational Accounting Standard 7 Statement of Cash Flowsইবনুল মাইজভাণ্ডারীNo ratings yet

- CHARTDocument33 pagesCHARTLindsey Ianna Pablo AndresNo ratings yet

- 12 Points) : A B: Over Co de Ex Out Down Re Ultra UnderDocument2 pages12 Points) : A B: Over Co de Ex Out Down Re Ultra UnderRobert CalcanNo ratings yet

- 09 Yi Accounts Payable Risk AssessmentDocument2 pages09 Yi Accounts Payable Risk AssessmentMalik Khayyam OmerNo ratings yet

- Q4 Partnership Final Accs QuestionsDocument4 pagesQ4 Partnership Final Accs QuestionsIsha KatiyarNo ratings yet

- Fuel Surcharge - UPS - VietnamDocument3 pagesFuel Surcharge - UPS - VietnamJDS JICENo ratings yet

- HTG - Distribution Equipment - OfficialRelease - V1.0Document59 pagesHTG - Distribution Equipment - OfficialRelease - V1.0Altamir Nunes JuniorNo ratings yet

- Chapter 1Document12 pagesChapter 1Sairam PrakashNo ratings yet

- Template IPO Affidavit of Consent FormDocument2 pagesTemplate IPO Affidavit of Consent Formcathy cenonNo ratings yet

- E-Ticket 0706658136310: Kolkata BhubaneswarDocument2 pagesE-Ticket 0706658136310: Kolkata BhubaneswarBanerjee SuvranilNo ratings yet

- JSA Scaffolding (Green) - OSBLDocument20 pagesJSA Scaffolding (Green) - OSBLSiti AminahNo ratings yet

- Do More With Microsoft Teams: Download The Teams App HereDocument1 pageDo More With Microsoft Teams: Download The Teams App HerejcherrandNo ratings yet

- 8 Steps in Accounting CycleDocument2 pages8 Steps in Accounting CycleMarko Zero FourNo ratings yet

- Project Management Environment - Questions (07012020)Document4 pagesProject Management Environment - Questions (07012020)Nadia Rahmeita PrasantiNo ratings yet

- One Warehouse Multiretailer System With Centralized Stock InformationDocument13 pagesOne Warehouse Multiretailer System With Centralized Stock InformationdeevaNo ratings yet

- Case Study Tren Engine ComponentsDocument2 pagesCase Study Tren Engine ComponentsUmar KhattakNo ratings yet

- QOS Improvement in MANET Routing by Route Optimization Through Convergence of Mobile AgentDocument6 pagesQOS Improvement in MANET Routing by Route Optimization Through Convergence of Mobile AgentNader JalalNo ratings yet

- Stages of Digital Transformation in Competency Management - TejaDocument6 pagesStages of Digital Transformation in Competency Management - TejaImmanuel Teja HarjayaNo ratings yet

- Black ScholesDocument3 pagesBlack ScholesAditiNo ratings yet

- Disbursement Voucher (New Orence)Document4 pagesDisbursement Voucher (New Orence)user computerNo ratings yet

- Lanka Bangla FinanceDocument31 pagesLanka Bangla FinanceJacobHauheng0% (1)