Professional Documents

Culture Documents

Technique of A Feasibility Study For The Use of A Variable Frequency Drive in Pumping Units

Technique of A Feasibility Study For The Use of A Variable Frequency Drive in Pumping Units

Uploaded by

Makhsum BozorovOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technique of A Feasibility Study For The Use of A Variable Frequency Drive in Pumping Units

Technique of A Feasibility Study For The Use of A Variable Frequency Drive in Pumping Units

Uploaded by

Makhsum BozorovCopyright:

Available Formats

Volume 12| November, 2022 ISSN: 2795-7640

Technique of A Feasibility Study for

the Use of a Variable Frequency

Drive in Pumping Units

Khafizov Islom Ikramovich Ph.D., docent

Bukhara Engineering-Technological Institute

Hafizov Xudoyor Islomovich Master Student

Bukhara Engineering-Technological Institute

Ahmadov Elmurod Kamol Master Student

o'g'li Bukhara Engineering-Technological Institute

The article presents the methodology of a feasibility study for the use of variable

frequency drives in pump units. The calculation methodology of the application of the

variable frequency drive in pump units is presented and it is proved that its application

ABSTRACT

makes it possible to use large pump units in low-flow mode and, therefore, to reduce

their total number. The problem of determining the technical and economic parameters

of D-series pumps is also considered and it is shown that the linear dimensions of pump

units grow much slower than their capacity and flow rate. An expression for

determining the relative linear dimensions of the units being compared is given.

Keywords: Units, pump units, D-series

I. Introduction It is shown in [2] that the linear

Given the obvious advantages, the dimensions of pumping units grow much

frequency-controlled electric drive is becoming slower than their power and supply. As is

quite widespread in pumping installations. At known, the volumes (dimensions) of machines

present, conditions have developed that make (electric motors, pumps, etc.) are proportional

it possible to use it everywhere. Semiconductor to the nominal values of their torque:

technology development made it possible to V = kM (1)

create reliable and relatively inexpensive where M − is torque;and k − is the

frequency-controlled electric drives based on coefficient of proportionality.

static converters. As a result, work on research, If we express the moment in terms of the

development, and creation of pumping units operating parameters of the pumping unit and

equipped with an automated frequency- extract the cubic root from both parts of the

controlled electric drive has expanded. equation (1), we get the dependence of the

linear dimensions of the unit on its main

II.Material and Methods parameters:

The use of a frequency-controlled electric QH

drive-in pumping units makes it possible to use L = 3 kM = 3 k * 3 , (2)

large pumping units in the low-flow mode and,

n

consequently, reduce their total number. Here where Q − t ed; − is the pump unit

it is appropriate to say that more powerful head;; n − is the pump unit rotation speed and

units have higher technical indicators, ;; − is the unit efficiency.

including higher efficiency.

Eurasian Journal of Engineering and Technology www.geniusjournals.org

P a g e | 24

Volume 12| November, 2022 ISSN: 2795-7640

Thus, the use of a frequency-controlled

III.Results electric drive under certain conditions not only

We believe that the head values of the does not increase the capital investment but

compared units are approximately the same for also reduces it somewhat (by a certain amount

the specific installation under consideration. of DK).

We take the parameters of the smallest of the Calculations have shown that the use of a

compared aggregates as the basic ones. For frequency-controlled electric drive in

these conditions, after some transformations, combination with the enlargement of the unit

we obtain an expression for determining the power, depending on the purpose of the station

relative linear dimensions of the compared and other specific conditions, can reduce the

aggregates specified costs by 20-50 % [2].

Q / n The feasibility study of the use of a

L* = 3 l l l , (3) frequency-controlled electric drive in pumping

Qb / b nb

units is carried out in the following sequence.

where Ql , l , nl − are the nominal 1. Make up hydraulic and electric

parameters of the larger unit; Qb , b , nb circuit diagrams to compare the pumping

systems.

−are the nominal parameters of the base unit;

2. Determine the composition of the

From expression (3), it follows that the

main equipment of the compared pumping

linear dimensions of the enlarged unit in

units: pumping units, valves, valves, check

comparison with the basic unit increase to a

valves, cells of switchgear, and control devices

lesser extent than its feed increases. This

(frequency converters, etc.).

pattern has been tested on common domestic

3. They assemble the main

pumping units of the D series. Based on the

equipment of the compared pumping units.

actual dimensions of the D-series units taken

4. Determine the capital costs for

from the catalog [2], the relative linear

the basic and new options for electrical

dimensions of six standard sizes of pumps in

equipment Кel, pumping equipment Кpum,

this series are calculated using the equation

hydro-mechanical equipment Кhm, and

lbh construction part Кcon. The price lists of

L*actual = 3 l l l , (4)

lbbb hb companies and equipment manufacturers

where ll , bl , hl — dimensions (length, determine the cost of electrical and hydro-

mechanical equipment. For a preliminary

width, height) of the larger unit; lb , bb , hb — estimate of the cost of a frequency-controlled

dimensions (length, width, height) of the base electric drive and additional capital costs

unit. associated with the use of a frequency-

Since the linear dimensions of pumping controlled electric drive, the graphs shown in

units increase more slowly than their supply fig. 1. and 2. can be used. The cost of the

increases, increasing the unit capacity of the construction part can be determined by the

units allows you to reduce their total number aggregated specific indicators of the cost of

and reduce the size of buildings, simplify the construction of pumping stations, contained,

hydraulic scheme of the station, reduce the for example, in [3], taking into account the

number of pipe fittings and the number of cells current inflationary coefficients of the cost of

in the electrical switchgear, etc. construction.

By equipping the pump units with a 5. Determine the depreciation

variable frequency drive, reducing the number deductions A from the cost:

of units at the pumping stations does not electrical equipment

reduce the operating capacity to change their Ael = Arel .un K el ;

operating modes caused by changes in water pumping equipment

consumption. Apum = Arel .un K pum ;

Eurasian Journal of Engineering and Technology www.geniusjournals.org

P a g e | 25

Volume 12| November, 2022 ISSN: 2795-7640

hydro-mechanical equipment the construction part of the pumping

station Acon = Arel .un K con ;

Ahm = Arel .un K hm ;

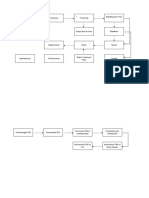

Fig.1. Specific cost of converters and control devices of various types of adjustable electric drive:

1 — low-voltage frequency converters; 2 — high-voltage frequency converters with dual voltage;

3 — high-voltage frequency converters; 4 — high-voltage transformer-free converters according to the

valve motor system; 5 — hydraulic variator “Twin-Disk”.

Fig.2. Additional costs associated with the use of converters and various types of controlled

electric drive control devices: 1—5 — the same as in fig. 1

Approximate values of depreciation rates for various types of equipment are given in table 1.

Table 1

Depreciation rates by type of main equipment

Serial Equipment types Depreciation rate

А, % Arel .un

1 Pump equipment

19 0,19

2 Gate valves, gates,

21,3 0,213

valves

3 Electrical equipment 8,3 0,083

4 Construction part 2,6 0,026

6. Determine the energy consumption Wreg in use frequency-controlled drive (FCD) in the automatic

control system of the pumping unit, kWh,

Eurasian Journal of Engineering and Technology www.geniusjournals.org

P a g e | 26

Volume 12| November, 2022 ISSN: 2795-7640

NbTcal (1 + )

Wreg = 0.25 (1 + H b*. p ) + 2 (1 − H b*. p )

7. Determine the energy savings, obtained as a result of a decrease in overpressure when using the

FCD in the ACS of the pumping unit.

8. Determine the energy savings W obtained as a result of the use of large capacity pumping units

with higher efficiency big , in comparison with the units of the basic version b , kWh,

W = Wreg 1 − b

big

where big b

9. Determine the energy consumption Wn.reg , kWh, of the pumping unit when the units are

operating according to the basic version, without a frequency-controlled electric drive:

Wn.reg = Wreg + Wrec + W .

10. Determine the amount of water lost due to non-productive costs when operating in the basic

mode. This volume of water corresponds to the volume of water saved when using a variable frequency

drive in the ACS of the pumping unit Vsav. year .

11. Determine the decrease in the volume of non-productive water consumption, dumped into

the sewer, when operating in the basic mode.

Vdec.dum. year = ( 0,80 0,85 ) Vsav. year

12. Determine the electricity costs for the base case.

Cel .b = Wn.reg Pel

Where electricity tariff.

13. Determine the electricity costs for the new option (with the use of aggregates of

enlarged capacity and FCD in the automatic control system of the pumping unit)

Cel .n = Wreg Pel

14. Determine the costs of covering the non-productive flow of clean water during the

operation of the pumping unit without FCD.

CQ = PQ Psav. year ,

where PQ — the cost of 1m3 of clean water.

15. Determine the costs of processing and transporting wastewater in the

wastewater system (sewers).

Cq = Pq Pdec.dum. year ,

where Pq — the cost of pumping and processing of wastewater.

16. Determine the number of capital costs for the basic K b and new K n options for electrical,

hydraulic, and construction parts

K b = K el .b + K pum.b + K hm.b + K con.b

K n = K el .n + K pum.n + K hm.n + K con.n

17. Determine the amount of depreciation for the base AΣb and new AΣn options

Ab = Ael .b + Apum.b + Ahm.b + Acon.b

An = Ael .n + Apum.n + Ahm.n + Acon.n

18. Determine the number of operating costs for both options Cb and Cn , taking into

account energy consumption, saving clean water, reducing the discharge of effluents into the sewage

system, and depreciation deductions

Eurasian Journal of Engineering and Technology www.geniusjournals.org

P a g e | 27

Volume 12| November, 2022 ISSN: 2795-7640

Cb = Cel .b + CQ + Cq − Ab ;

Cn = Cel .n − An

19. Determine the reduced costs for both options

Зb = Cb + EK b ;

Зn = Cn + EK n ;

where E—is the coefficient of efficiency of capital investments, depending on the adopted payback

period for additional capital investments:

E = 1/ Tpb

Payback period Тpb, year. 2 3 4 5 6

0,16

Coefficient Е. 0,5 0,33 0,25

0,2

6

20. The reduction of the reduced costs,%, is calculated according to the new variant Зn in

comparison with the basic variant Зb ,%

Зb − Зn

З = 100.

Зb

The payback period of ACS equipped with a variable speed drive, taking into account the net

water savings, reduction of wastewater discharge into the sewerage, and increase in the unit capacity

of pump units is determined by the following expression

K − dK

Tpb =

Cel + Cn.w + Cw.w − Ael K + Ac dK '

where K = K fcd + K acs —additional capital costs associated with the creation of an energy-

saving ACS based on FCD; dK = K b + K n —reduction of capital costs due to the enlargement of the

unit capacity of pumping units and a decrease in their number;

Cel = Cel .b − Cel .n — reduction in operating costs due to the use of a variable frequency drive in

the ACS of a pumping unit and an increase in the efficiency of pumping units due to the enlargement of

their unit capacity;

Cn.w = CQ — reduction in operating costs due to a decrease in excess pressure in the

network and a reduction in non-productive water consumption due to the use of a variable frequency

drive in the ACS of a pumping unit;

Cw.w = Cq — reduction in operating costs due to a decrease in excess pressure in the

network and a reduction in wastewater discharge into the sewage system due to the use of a

frequency-controlled electric drive in the ACS of the pumping unit;

Ael = 0, 083 — depreciation rate for electrical equipment;

Ac = 0, 026 — depreciation rate for the construction part.

IV.Discussion the number of units at the pumping stations

For the D-series pump units, the does not reduce the operating possibilities of

regularity is established that the linear changing the modes of their operation caused

dimensions of the enlarged unit increase less by the change in the water flow rate.

than the linear dimensions of the base unit. The Thus, the application of a frequency-

results of calculating the relative parameters of controlled electric drive under certain

the pumps of the D series, a pump unit conditions not only does not increase capital

equipped with a D320-70 pump are presented. investments but also reduces them to some

Due to equipping the pump units with the extent.

frequency-controlled drive, the reduction of

Eurasian Journal of Engineering and Technology www.geniusjournals.org

P a g e | 28

Volume 12| November, 2022 ISSN: 2795-7640

Calculations have shown that the the solar cells, MODERN SCIENCE

application of a variable frequency drive in International scientific journal №02,

combination with an increase in unit capacity, 2017, Founder and publisher: “Strategic

depending on the purpose of the plant and Studies Institute” LLC., Moscow, 2017,

other specific conditions, allows for reducing P.43-46

the reduced costs by 20-50%. 4. Khafizov I.I., Gafforov K.K. Application,

The sequence of feasibility study of

and prospects of variable frequency

variable frequency drive application in

means in electric drives of pumping

pumping units is given.

It is proved that the creation of energy- units, Международный научно-

saving ACS in a pumping station based on the практический электронный журнал

use of a variable frequency drive pays off in a «МОЯ ПРОФЕССИОНАЛЬНАЯ

sufficiently acceptable time even without КАРЬЕРА» (ISSN 2658-7998, догоров с

taking into account water savings Elibrary №284-07/2019), 15.11.2020

5. Khafizov I.I., Xafizov X.I. Modeling the

VI. Conclusions introduction of ions into single-crystal

Depending on the calculated payback GaAs (001) to create p-n junctions to

period of the ACS equipped with a variable increase the efficiency of solar cells,

frequency drive, a decision on the expediency МОЛОДЕЖНЫЙ

of its use in the pumping station is made. At

ИССЛЕДОВАТЕЛЬСКИЙ ПОТЕНЦИАЛ,

present, an acceptable payback period is

Сборник статей II Международного

considered to be 2-3 years. In any case, the

payback period should not exceed the service научно-исследовательского

life of the ACS equipment and the variable конкурса, состоявшегося 11 января

frequency drive, i.e. 10-11 years. 2021 г. в г. Петрозаводске, ст.105-111

6. Н.Н.Садуллаев., А.Х.Шобоев.,

References М.Б.Бозоров., А.Т.Паноев. Система

1. Khafizov I.I., Komil Gafforov, Bakhodir мониторинга электропотребления

Oblokulov, Aziz Azimov Elimination of предприятия на основе

energy losses in pumping installations коэффициента эффективности

by means variable frequency drive, системы электроснабжения.

International Engineering Journal For Europaische Fachhochschule. Volume:

Research & Development, Vol.5, Issue 3, 08 / 2016. P.40-43. URL:

April 2020, E-ISSN NO:-2349-0721,

https://www.elibrary.ru/item.asp?id=2

Impact factor: 6.03.P.83-89,

7542999 e- ISSN: 2195-2183

http://iejrd.com/index.php/%20/articl

e/view/17/5 7. Н.Н.Садуллаев., А.Х.Шобоев.,

2. Khafizov I.I., Komil Gafforov, М.Б.Бозоров., А.Т.Паноев. Oценка

Muxammedov Sh., Jurakulov A Energy эффективности системы

saving when using a variable frequency электроснабжения методом

drive in pump installations, Journal of многокритериального анализа.

Critical Reviews, ISSN- 2394-5125 Vol 7, Europaische Fachhochschule. Volume:

Issue 12, 2020, P.99-102, 08 / 2016. P.36-39. URL:

http://dx.doi.org/10.31838/jcr.07.12.1 https://www.elibrary.ru/item.asp?id=2

6 7542998 e- ISSN: 2195-2183

3. Khafizov I.I.,Khaitov B.B. The 8. Н.Н.Садуллаев., М.Б.Бозоров., Ш.Н.

investigation of ions implantation Нематов. Kонтроль эффективности

processes into a single-crystal функционирования промышленной

GaAs(001) to increase the efficiency of сети по обобщенному показателю

Eurasian Journal of Engineering and Technology www.geniusjournals.org

P a g e | 29

Volume 12| November, 2022 ISSN: 2795-7640

эффективности системы

электроснабжения. Проблемы

информатики и энергетики. Volume:

03 / 2018. P.57-62. URL:

https://assets.uzsci.uz/edition/file/5e4

3dd733cce7.pdf#page=57

9. M.B. BOZOROV., I.I. XAFIZOV., J.M.

ZOIROV., F.R. KAYIMOV., B.S.

XAMDAMOV., D.А. ORIPOV., SHARIPOV

А.SH. Forecasting electricity

consumption of industrial enterprises

using excel program. JournalNX- A

Multidisciplinary Peer Reviewed

Journal. Volume: 07 ISSUE 2 / 2021.

P.346-350. URL:

https://media.neliti.com/media/publica

tions/342773-forecasting-electricity-

consumption-of-i-ab0342bf.pdf e-

ISSN: 2581-4230

10. Х.И.Хафизов., М.Б.Бозоров. Разработка

метода комплексного исследования

энергоэффективности системы

электроснабжения промышленных

предприятий. Сборник статей

Международного научно-

исследовательского конкурса.

Петразаводск, Россия (2021). P.10-19.

URL:

http://is.nkzu.kz/publishings/%7BC1D

6204A-6585-4F17-B6AD-

E67180342C1C%7D.pdf#page=12

11. М.Б. Бозоров., И.И. Хафизов., А.Т.

Паноев., Ж.М. Зоиров., Ш.К. Ергашев.,

Ф.Р. Кайимов., Б.С. Хамдамов., Д.А.

Орипов., А.Ш. Шарипов. Разработка

метода оценки эффективности

системы электроснабжения

промышленных предприятий.

Сборник научных статей по итогам

международной научной

конференции. Казань (2021). P.42-45.

URL:

https://www.elibrary.ru/item.asp?id=4

4776698

Eurasian Journal of Engineering and Technology www.geniusjournals.org

P a g e | 30

You might also like

- Didacta - Catalogue 2016Document74 pagesDidacta - Catalogue 2016Riccardo VianelloNo ratings yet

- Control NarrativeDocument19 pagesControl NarrativeVilla VallejosNo ratings yet

- Malah Et Al. - 2020 - Backstepping Controllers Design For A Grid Connected Wind-Photovoltaic Hybrid Power System-AnnotatedDocument6 pagesMalah Et Al. - 2020 - Backstepping Controllers Design For A Grid Connected Wind-Photovoltaic Hybrid Power System-AnnotatedMohamed Riyad BoudallaaNo ratings yet

- Back-To-Back Converter Design and Control For Synchronous Generator-Based Wind TurbinesDocument8 pagesBack-To-Back Converter Design and Control For Synchronous Generator-Based Wind TurbinesBinh NgoNo ratings yet

- Matecconf Bultrans2017 08002Document4 pagesMatecconf Bultrans2017 08002ihsanulhaqNo ratings yet

- Performance Comparison of Active Rectifier Control Schemes in More Electric Aircraft ApplicationsDocument10 pagesPerformance Comparison of Active Rectifier Control Schemes in More Electric Aircraft ApplicationsBadal PatnaikNo ratings yet

- Unit CommDocument56 pagesUnit CommkgurumoorthiNo ratings yet

- Simplified Modeling of Hydraulic Governor-Turbine For Stable Operation Under Operating ConditionsDocument5 pagesSimplified Modeling of Hydraulic Governor-Turbine For Stable Operation Under Operating ConditionsShrestha SanjayNo ratings yet

- The Usage of Supercapacitors For Energy Storage Systems in The DC-Link of Machine ToolsDocument6 pagesThe Usage of Supercapacitors For Energy Storage Systems in The DC-Link of Machine ToolsEdu Daryl MacerenNo ratings yet

- Buck Boost ConverterDocument8 pagesBuck Boost ConverterJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Modeling Wind Farms For Power System LoadDocument8 pagesModeling Wind Farms For Power System LoadArmando MaloneNo ratings yet

- EE4455Document7 pagesEE4455Ravi ChandranNo ratings yet

- Modeling and Analysis of Canal Type Small Hydro PoDocument10 pagesModeling and Analysis of Canal Type Small Hydro PoJavier Conesa OutedaNo ratings yet

- Nonlinear Control of Variable Speed Wind TurbinesDocument7 pagesNonlinear Control of Variable Speed Wind TurbinesSoumya RanjanNo ratings yet

- Bombeamento SolarDocument11 pagesBombeamento Solarmarcos_tavares_22No ratings yet

- Topologies and Control Strategies of Cascaded Bridgeless Multilevel RectifiersDocument13 pagesTopologies and Control Strategies of Cascaded Bridgeless Multilevel RectifierschetangwNo ratings yet

- Ullah 2009Document12 pagesUllah 2009t64008No ratings yet

- Control of Three-Phase Inverter For AC Motor Drive With Small DC-Link Capacitor Fed by Single-Phase AC SourceDocument8 pagesControl of Three-Phase Inverter For AC Motor Drive With Small DC-Link Capacitor Fed by Single-Phase AC SourceAnand KumarNo ratings yet

- Axial FlowDocument13 pagesAxial FlowArivanandan Get GoingNo ratings yet

- The International Journal of Engineering & ScienceDocument6 pagesThe International Journal of Engineering & SciencetheijesNo ratings yet

- Diaf RevisedDocument37 pagesDiaf RevisedAkaruii BowoNo ratings yet

- Modelling, Operation and Control of HVDC Connected Oshore Wind FarmsDocument26 pagesModelling, Operation and Control of HVDC Connected Oshore Wind FarmsMohammed Shareef ShaikhNo ratings yet

- Wang 2017Document13 pagesWang 2017gerson gomesNo ratings yet

- Energies: Small Wind Turbine Emulator Based On Lambda-Cp Curves Obtained Under Real Operating ConditionsDocument17 pagesEnergies: Small Wind Turbine Emulator Based On Lambda-Cp Curves Obtained Under Real Operating ConditionsAnant MilanNo ratings yet

- An Integrated Control Algorithm For A Single-Stage PV Pumping System Using An Open-End Winding Induction MotorDocument10 pagesAn Integrated Control Algorithm For A Single-Stage PV Pumping System Using An Open-End Winding Induction MotorHashim KhanNo ratings yet

- Improvement of Identification Procedure Using Hybrid Cuckoo Search Algorithm For Turbine-Governor and Excitation SystemDocument8 pagesImprovement of Identification Procedure Using Hybrid Cuckoo Search Algorithm For Turbine-Governor and Excitation SystemTeo TeoNo ratings yet

- Bueno Usar Figurasanalysis - of - Battery - Lifetime - Extension - in - A - Small-Scale - Wind-Energy - System - Using - SupercapacitorsDocument10 pagesBueno Usar Figurasanalysis - of - Battery - Lifetime - Extension - in - A - Small-Scale - Wind-Energy - System - Using - SupercapacitorsJonathan Muñoz TaboraNo ratings yet

- Design and Performance Analysis of A Photovoltaic WaterDocument8 pagesDesign and Performance Analysis of A Photovoltaic WaterPrakash Kumar RayNo ratings yet

- The Low Cost Voltage and Current Measurement Device Design For Power ConvertersDocument7 pagesThe Low Cost Voltage and Current Measurement Device Design For Power ConvertersΧρηστος ΠεχλιβανηςNo ratings yet

- Modeling of WPP For Short Circuit AnalysisDocument7 pagesModeling of WPP For Short Circuit AnalysisbalajisugunaNo ratings yet

- Load Flow AnalysisDocument8 pagesLoad Flow AnalysisKamalNo ratings yet

- Grid Connection Quasi Z-Source Inverter Based On Model Predictive Control With Less Sensors CountDocument7 pagesGrid Connection Quasi Z-Source Inverter Based On Model Predictive Control With Less Sensors CountckrimyouNo ratings yet

- Dynamic Modeling of Wind Power Generation: H Ector A. Pulgar-Painemal and Peter W. SauerDocument6 pagesDynamic Modeling of Wind Power Generation: H Ector A. Pulgar-Painemal and Peter W. SauerkfaliNo ratings yet

- SPL: 25447 Simplified Computer-Aided Analysis of Electrical Current in Motors Used For Beam Pumping SystemsDocument14 pagesSPL: 25447 Simplified Computer-Aided Analysis of Electrical Current in Motors Used For Beam Pumping SystemsJosé TimanáNo ratings yet

- Hybrid Energy Management System Design With Renewable Energy Sources (Fuel Cells, PV Cells and Wind Energy) A ReviewDocument4 pagesHybrid Energy Management System Design With Renewable Energy Sources (Fuel Cells, PV Cells and Wind Energy) A ReviewYogesh OjhaNo ratings yet

- Energy Evaluation For DC Railway Systems With Inverting SubstationsDocument7 pagesEnergy Evaluation For DC Railway Systems With Inverting SubstationsEdwin HuamanNo ratings yet

- Multivariable Optimal Control of An Industrial Nonlinear Boiler Turbine UnitDocument17 pagesMultivariable Optimal Control of An Industrial Nonlinear Boiler Turbine UnitAliAlMisbahNo ratings yet

- Optimal PDFDocument6 pagesOptimal PDFjalilemadiNo ratings yet

- Review of Optimal Selection of Turbines For Hydroelectric ProjectsDocument7 pagesReview of Optimal Selection of Turbines For Hydroelectric ProjectsephremNo ratings yet

- HVAC Transmission System For Offshore Wind Power Plants Including Mid-Cable Reactive Power Compensation Optimal Design and CompariDocument11 pagesHVAC Transmission System For Offshore Wind Power Plants Including Mid-Cable Reactive Power Compensation Optimal Design and ComparikhandhediaashokNo ratings yet

- Renewable Hybrid SystemDocument6 pagesRenewable Hybrid SystemGhayas Ud-din DarNo ratings yet

- PM Brushless DC Motor Drive With A New Power-Converter TopologyDocument10 pagesPM Brushless DC Motor Drive With A New Power-Converter TopologyIshithaNo ratings yet

- Electric Propulsion System Characterization Through ExperimentsDocument9 pagesElectric Propulsion System Characterization Through Experiments呂文祺No ratings yet

- Reactive Power Limitation Due To Wind-Farm Collector NetworksDocument6 pagesReactive Power Limitation Due To Wind-Farm Collector NetworksJagath VallabhaiNo ratings yet

- DC Link Measurements Based Sensorless Induction Motor Variable-Speed DriveDocument14 pagesDC Link Measurements Based Sensorless Induction Motor Variable-Speed DriveNationalinstituteDsnrNo ratings yet

- IEEE Um Artigo ExDocument9 pagesIEEE Um Artigo Exrod8silvaNo ratings yet

- Design of A Brushless DC Permanent Magnet Generator For Use in Micro-Wind Turbine Applications - Preprint HALDocument11 pagesDesign of A Brushless DC Permanent Magnet Generator For Use in Micro-Wind Turbine Applications - Preprint HALGheorghe VasileNo ratings yet

- Optimal Design of Modern Transformerless PV Inverter TopologiesDocument11 pagesOptimal Design of Modern Transformerless PV Inverter TopologiesJesús MendozaNo ratings yet

- Optimal Cost Analysis of Wind-Solar Hybrid System Powered AC and DC Irrigation Pumps Using HOMERDocument5 pagesOptimal Cost Analysis of Wind-Solar Hybrid System Powered AC and DC Irrigation Pumps Using HOMERJhon Sebastian Arias ValenciaNo ratings yet

- Vector Controlled Induction Machines For Stand-Alone Wind Energy ApplicationsDocument8 pagesVector Controlled Induction Machines For Stand-Alone Wind Energy Applicationssatyam swarup dubeyNo ratings yet

- Assessment of Flicker Emission in A Grid Connected Wind FarmsDocument12 pagesAssessment of Flicker Emission in A Grid Connected Wind FarmspetraschukmNo ratings yet

- A Method For Constructing Reduced Order Transformer Models For System Studies From Detailed Lumped Parameter ModelsDocument7 pagesA Method For Constructing Reduced Order Transformer Models For System Studies From Detailed Lumped Parameter ModelsIlona Dr. SmunczNo ratings yet

- Analysis For Turbine Maintenance CostDocument3 pagesAnalysis For Turbine Maintenance CostFERNANDO GARZON VIZCAYONo ratings yet

- DFIG Equivalent Circuit and Mismatch AssDocument11 pagesDFIG Equivalent Circuit and Mismatch AssKavi PriyaNo ratings yet

- Simulation Model of Hydro Power PlantDocument7 pagesSimulation Model of Hydro Power Plantwoldemariam workuNo ratings yet

- Eleco47770 2019 8990621Document5 pagesEleco47770 2019 8990621rasoolNo ratings yet

- Engineering Journal Software Based Reconfiguration For The Cascaded H-Bridge Multilevel ConverterDocument8 pagesEngineering Journal Software Based Reconfiguration For The Cascaded H-Bridge Multilevel ConverterEngineering JournalNo ratings yet

- 2016 Zhang Et Al Pess VF 3lnpc PMSG BTB DMPC 2Document9 pages2016 Zhang Et Al Pess VF 3lnpc PMSG BTB DMPC 2nasbNo ratings yet

- Design of A Three-Phase Boost Type Vienna Rectifier For 1kW Wind Energy Conversion SystemDocument10 pagesDesign of A Three-Phase Boost Type Vienna Rectifier For 1kW Wind Energy Conversion SystemSreekanth IyerNo ratings yet

- Modeling and Control of PMSG Based Variable Speed Wind Turbine 2010 Electric Power Systems ResearchDocument7 pagesModeling and Control of PMSG Based Variable Speed Wind Turbine 2010 Electric Power Systems ResearchRAJESHNo ratings yet

- Potencia ReactivaDocument6 pagesPotencia ReactivamuNo ratings yet

- Valley Tank PricedDocument13 pagesValley Tank PricedMwesigwa DaniNo ratings yet

- Tough Wastewater Pumps For Pressurised Systems: Grundfos Seg Submersible Grinder PumpsDocument2 pagesTough Wastewater Pumps For Pressurised Systems: Grundfos Seg Submersible Grinder PumpsNug LarsoNo ratings yet

- Diagram Alir Orientasi PKSDocument7 pagesDiagram Alir Orientasi PKSYudha MaulanaNo ratings yet

- SIA Guidance Note 47Document11 pagesSIA Guidance Note 47Ali BiomyNo ratings yet

- Alegria Service Manual 7 2011-11Document121 pagesAlegria Service Manual 7 2011-11nbiolab6659100% (1)

- Rifox Product Overview 3.2010Document16 pagesRifox Product Overview 3.2010eyderortega1980No ratings yet

- N 50B 4KG1 PDFDocument2 pagesN 50B 4KG1 PDFdocrafiNo ratings yet

- Affinity Laws For Centrifugal PumpsDocument5 pagesAffinity Laws For Centrifugal PumpsSeto Tri LaksonoNo ratings yet

- Fill Fluid Slytherm Technical DatasheetDocument28 pagesFill Fluid Slytherm Technical Datasheetsooraj1234No ratings yet

- MSD 252 Safety Inspection FormDocument11 pagesMSD 252 Safety Inspection FormNitin GoyalNo ratings yet

- Sebp4195 76 01 Allcd - 003 PDFDocument965 pagesSebp4195 76 01 Allcd - 003 PDFFacturas hidrodieselNo ratings yet

- 2011 02 Huijben Spie Why Every Urea Plant Needs A Continuous NC Meter PDFDocument9 pages2011 02 Huijben Spie Why Every Urea Plant Needs A Continuous NC Meter PDFfawadintNo ratings yet

- 10 10h EksDocument2 pages10 10h EksandresNo ratings yet

- Customs Clearance Process For Import of Capital MachineryDocument43 pagesCustoms Clearance Process For Import of Capital Machinery2rmjNo ratings yet

- Woodward TG Actuators 04045Document44 pagesWoodward TG Actuators 04045Jose Luis Castro Aguilar100% (1)

- 00 - ZF - CPP00189 TVK NB 03Document154 pages00 - ZF - CPP00189 TVK NB 03Felipe OliveiraNo ratings yet

- Arranque Dificil Dd15Document8 pagesArranque Dificil Dd15nicix100% (1)

- MS 120 Major MaintenanceDocument100 pagesMS 120 Major MaintenanceCristi Florian NicolaeNo ratings yet

- Dynex Piston PumpDocument44 pagesDynex Piston PumpLUIS DELFINNo ratings yet

- F27980036 - 181108SV Revised 30042019Document21 pagesF27980036 - 181108SV Revised 30042019hhNo ratings yet

- Tuv Nel - Evaluation of Roxar MPFM2600 Multiphase Flowmeter PDFDocument23 pagesTuv Nel - Evaluation of Roxar MPFM2600 Multiphase Flowmeter PDFReza GhanavatiNo ratings yet

- Enercat Long Term Paraffin&Scale Prevention May 2021Document21 pagesEnercat Long Term Paraffin&Scale Prevention May 2021Cae Indru100% (1)

- PR-1076 - Isolation of Process Equipment ProcedureDocument41 pagesPR-1076 - Isolation of Process Equipment Procedurevaithy1990100% (4)

- 1.1 General: "Processes and Environmental Management" at SUEZ LTD, BWSSB, TK HalliDocument29 pages1.1 General: "Processes and Environmental Management" at SUEZ LTD, BWSSB, TK HalliYogeesh B ENo ratings yet

- Grundfos A Wide Range of Quality Pumps 60 HZDocument24 pagesGrundfos A Wide Range of Quality Pumps 60 HZAdan Serrano CaroNo ratings yet

- 4at Auto Trans PDFDocument60 pages4at Auto Trans PDFEduardo ValenzuelaNo ratings yet

- YLB Mobile Asphalt Mixing Plant: Henan Sinoroader Heavy Industry CorporationDocument14 pagesYLB Mobile Asphalt Mixing Plant: Henan Sinoroader Heavy Industry CorporationMohammad Daoud100% (1)

- Good Water Warehouse CatalogDocument184 pagesGood Water Warehouse CatalogNEFTALI VARGAS MANDUJANONo ratings yet