Professional Documents

Culture Documents

A Report, 1970

A Report, 1970

Uploaded by

Alberto ChambelaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Report, 1970

A Report, 1970

Uploaded by

Alberto ChambelaCopyright:

Available Formats

A Report: Committee on Classification of

Particle Size in Feedstuffs

A procedure entitled, Proposed Method for

Determining and Expressing Fineness of Feed U.S. a Tyler

Materials by Sieving has been given careful con- Sieve Sieve Opening

sideration and approval by the Board of Direc- (No.) (~)

tors of the American Dairy Science Association.

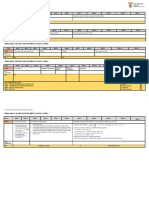

4 4 4,760

Publication of the procedure in the JOUR~rAL OF

6 6 3,360

DAIRY SCIENCE was approved at the annual

8 8 2,380

meeting of the Board of Directors, June, 1969. 12 10 1,680

An ad hoc intersociety committee has been

16 14 1,190

formed to encourage approval of this procedure

20 20 840

among related societies.

30 28 590

The proposed procedure is limited in use

40 35 420

to feed particles of spherical and cubical shape,

50 48 297

such as concentrates. Hopefully, additional

70 65 210

methods will be developed to classify elongated

100 100 149

particles such as flaked grains and ground rough-

140 150 105

ages.--W. L. Ensor, H. H. Olson, and V. F.

200 200 74

Colenbrander, Chairman. 270 270 53

Pan

Proposed Method of Determining

and Expressing Fineness of Feed !Katerials " United States Bureau of Standards.

by Sieving

PURPOSE 2) A suitable sieve shaker, such as a Ro-tap.®

3) A balance having an accuracy of at least

The purpose of this standard is to define a ± one-tenth gram.

test procedure to determine the fineness of feed 4) Sieve agitators such as leather rings, a

ingredients and a method of expressing the par- few kernels of corn, or small rubber bails

ticle size of the material. may be required to break up agghmmrates

on finer sieves, usually those smaller than

SCOPE 50-mesh.

This standard shall be used to determine the 5) A dispersion agent I should be available

fineness of feed ingredients where the reduction to facilitate sieving of high fat or simi-

process yields particles essentially spherical or lar materals.

cubical. It is not adequate to define the particle 6) A stiff-bristle sieve cleaning brush, or com-

size of materials such as steamed and rolled pressed air, is useful for cleaning sieves

grains, which are a flaked product, or products clogged with feed particles. Sieves must

such as chopped hay, where a substantial frac- be cleaned of oil at periodic intervals.

tion consists of elongated particles. This may be done by washing with a deter-

gent and water and drying. Ttmy should

TEST EQUIPMENT be washed whenever plugginff of the sieves

1) A set of wire-mesh sieves having a diam- indicates there are insufficient openings to

eter of eight inches shall be used. (With provide normal sieving.

the most common shaking equipment,

sieves having a height of one inch are METHOD OF SIEVING

most suitable to avoid the necessity of re- ]) Sample size. A sample of 100 g should

sieving the finer fraction.) The standard be used, although smaller samples may be

set of sieves shall consist of the following used if extra care is taken to recover all

sizes : material from the sieves.

2 ) The sample is placed on the top sieve of

1 Dispersion agents include: Cab-O-Sil MS avail- the set of sieves and shaken until the

able from the Cabot Corp., Boston; Ziolex 23A weight of material, on the sieve with the

and Zeofree 80 available from the J. M. Huber smallest openings which contains any ma-

Corp., New York ; and Flo-Gard available from the terial, reaches equilibrium. Equilibrium

Pittsburgh Plate Glass Co., St. Louis. shall be determined by inspecting and

689

690 JOURNAL OF DAIRY SCIENCE

weighing at five-nfinute intervals after = [di X di+l] 1/2

an original sieving time of ten minuses. Sg~ = geometric standard deviation

I f the weight on the smallest sieve con- W t = weight fraction on i th sieve

taining any material changes by 0.2 g or (Material passing the 270-

less during a five-minute period the siev- mesh sieve shall be considered

ing shall be considered complete at the to have a mean diameter of

onset of the previous period. 44 /z.)

3) Material on all sieves shall be weighed c) Graphical solutions for geometric mean

and recorded. diameter and log-normal geometric

4) I f a dispersing agent is required, it should standard deviation may be obtained by

be added at a level of 0.5% and its effect plotting results on logarithmic proba-

on particle size need not be recorded. bility graph paper. Figure 1 shows an

5) If 20% or m o r e o f the material by weight example where

passes the smallest sieve, the fine material dgw ----dso ----particle diameter at 50%

shall be subjected to a nonsieving p a r - probability and

ticle size analysis, such as microscopic ds4 dso

Sgw -- -- particle size at 84%

measurement oz" sedimentation testing, and

dso d16

such analysis shall be reported separately. probability/dg w = dgw/particle diam-

eter at 16% probability. Or,

DATA ANALYSIS

dgw = 350 tL

Analyses of weight distribution data of all and

ground feeds and feed ingredients are based 640 350

on the assumption that these distributions are Sgw -- -- -- 1.83.

logarithmically normally distributed. 350 191

1) Calculation of particle size.

a) The size of particles shall be reported

99 /

99.9

in terms of geometric mean diameter

and geometric standard deviation by

weight.

b) Calculated values are obtained as fol- 95

lows : ~90

¢-

log d|) ..,80

d,.,v = log 1 / . x ( w i r-

" XW

l_ 50

S g w : log_l I ~ V , (l()~--~W ] ° g d g w ) 2 1 I / 2

> 2o

/ i

0 • | I

Where : -5 10

E 5

d i = diameter of screen openings of 0

the i TM sieve 1

dl4 = diameter of screen next larger

than i th screen (just above in 0.1 /i|| l a ! J I llll I i i I i I

a set) 50

100 500 1000 5000

Particle size,d; microns

dgw ~ geometric mean diameter

d i = geometric diameter of parti- Lognormol distribution for sorghum

cles on i n~ sieve grain ground .through 1/8" screen.

JOURNAl, OF D A I R Y SCIENCE VOL. 53, NO. 5

You might also like

- Huanyang VFD Spindle Control: Setting Up The VFDDocument5 pagesHuanyang VFD Spindle Control: Setting Up The VFDSandro Alcantara100% (1)

- Sieve Analysis ReportDocument15 pagesSieve Analysis ReportTjia Tjie100% (1)

- A Method For Determining and Expressing The Size of Feed Particles by SievingDocument5 pagesA Method For Determining and Expressing The Size of Feed Particles by SievingG_ASantosNo ratings yet

- Mechanical Analysis of Extracted Aggregate: Standard Method of Test ForDocument2 pagesMechanical Analysis of Extracted Aggregate: Standard Method of Test ForEvert RiveraNo ratings yet

- CMTC136REPORTG3Document5 pagesCMTC136REPORTG3himura kenshinNo ratings yet

- SievingDocument5 pagesSievingBor OtNo ratings yet

- Mechanical Analysis of Extracted Aggregate: Standard Method of Test ForDocument6 pagesMechanical Analysis of Extracted Aggregate: Standard Method of Test Forclint silNo ratings yet

- Sieve Analysis of Coarse and Fine AggregateDocument16 pagesSieve Analysis of Coarse and Fine AggregateKendra Joy SendicoNo ratings yet

- 1297074578570-Standard Test Procedure of Blanket Material (Irs Ge-3) PDFDocument6 pages1297074578570-Standard Test Procedure of Blanket Material (Irs Ge-3) PDFPrasanta Kumar ParidaNo ratings yet

- LAB 3 - PSD - DRY SIEVING (Level 1)Document9 pagesLAB 3 - PSD - DRY SIEVING (Level 1)Doris AsmaniNo ratings yet

- Is 15868 1-6 2008Document13 pagesIs 15868 1-6 2008veenau 1No ratings yet

- Dry Sieve ReportDocument11 pagesDry Sieve ReportNoor Shahirah Md Ruba'i93% (15)

- 2 - 9 - 38 PSD SieveDocument3 pages2 - 9 - 38 PSD Sievebebo94100% (2)

- Abdalrhman Ali: Engineering Technical Baghdad Department of Building and ConstructionDocument4 pagesAbdalrhman Ali: Engineering Technical Baghdad Department of Building and ConstructionAbdurrahman AliNo ratings yet

- Kenny's Solid Bench FileDocument24 pagesKenny's Solid Bench Fileotaken6No ratings yet

- Full Report - Exp 1Document29 pagesFull Report - Exp 1Chiu FongNo ratings yet

- Particle Size Fact Sheet Stark 2016Document4 pagesParticle Size Fact Sheet Stark 2016Tanka KhanalNo ratings yet

- Experiment C Particle Size DistributionDocument9 pagesExperiment C Particle Size DistributionCahayaKebahagiaanNo ratings yet

- Is 14579-1998 DIN 53932 Determination of Water Absorption of Textile FabricsDocument7 pagesIs 14579-1998 DIN 53932 Determination of Water Absorption of Textile Fabricsmatersci_ebayNo ratings yet

- 05 Psd-Sieve Analysis (Level 0)Document8 pages05 Psd-Sieve Analysis (Level 0)Taylor GreysonNo ratings yet

- Pravin B. Awate (M.Pharm, Pharmaceutics) Assistant Professor Rdcop, BhorDocument15 pagesPravin B. Awate (M.Pharm, Pharmaceutics) Assistant Professor Rdcop, BhorPravin AwateNo ratings yet

- Measuring The Physical Quality of Pellets: DurabilityDocument6 pagesMeasuring The Physical Quality of Pellets: Durabilityree alexa suertoNo ratings yet

- LEVEL 0 - Week 3 - Sedimentation TestDocument4 pagesLEVEL 0 - Week 3 - Sedimentation TestNoradila RoslanNo ratings yet

- Evaluating Particle Size of Feedstuffs: DefinitionsDocument4 pagesEvaluating Particle Size of Feedstuffs: DefinitionsMaamar AmamraNo ratings yet

- Standard Method of Test For: 1. ScopeDocument4 pagesStandard Method of Test For: 1. ScopeSalma AlzwayNo ratings yet

- Final Mat Oel RPTDocument14 pagesFinal Mat Oel RPTl236729No ratings yet

- Sieve AnalysisDocument3 pagesSieve AnalysisMostafa FawzyNo ratings yet

- Soil Ex2Document7 pagesSoil Ex2Azeezan AlessaNo ratings yet

- Department of Transportation: California Test 202 November 2011Document20 pagesDepartment of Transportation: California Test 202 November 2011Patrick Sucre MumoNo ratings yet

- Rubber Content of Crumb Rubber Modified Bitumen: Soxhlet MethodDocument8 pagesRubber Content of Crumb Rubber Modified Bitumen: Soxhlet MethodLa FoliakNo ratings yet

- Sieve Analysis of Fine and Coarse Aggregate: Test Procedure ForDocument5 pagesSieve Analysis of Fine and Coarse Aggregate: Test Procedure Forzulaffan zairifliNo ratings yet

- Advantages and Disadvantages of Particle Size Reduction Techniques PDFDocument23 pagesAdvantages and Disadvantages of Particle Size Reduction Techniques PDFarturomarquezmaya5475No ratings yet

- Method Statement Lab - BSA (Soil) - 032718Document9 pagesMethod Statement Lab - BSA (Soil) - 032718Puteri NursyuhadaNo ratings yet

- Dry Sieve AnalysisDocument3 pagesDry Sieve AnalysisHuda Fauzi0% (1)

- Distribucion Granulometrica (1) - 9-16Document11 pagesDistribucion Granulometrica (1) - 9-16Santos Rodrigo Yaricahua UgarteNo ratings yet

- Department of Building Technology: College of Architecture and PlanningDocument11 pagesDepartment of Building Technology: College of Architecture and PlanningZach EffahNo ratings yet

- Test Method For The Grain-Size Analysis of Granular Soil MaterialsDocument19 pagesTest Method For The Grain-Size Analysis of Granular Soil Materialsdhan singhNo ratings yet

- AASHTO T 27 - Sieve Analysis of Fine and Coarse AggregatesDocument4 pagesAASHTO T 27 - Sieve Analysis of Fine and Coarse AggregatesBambang DwihargonoNo ratings yet

- E 276 - 98 - Rti3ni05oaDocument4 pagesE 276 - 98 - Rti3ni05oaMd Ahtesham DanishNo ratings yet

- Grain Size Dostribution of Sieve AnalysisDocument9 pagesGrain Size Dostribution of Sieve AnalysisPranavNo ratings yet

- Ce 162 Lab #5 Engineering Classification of SoilsDocument16 pagesCe 162 Lab #5 Engineering Classification of SoilsAngel Umali Gacutan100% (2)

- Transportation of Coarse Coal in A Fine MediumDocument7 pagesTransportation of Coarse Coal in A Fine Mediumaaa aaaaaNo ratings yet

- FilterationDocument22 pagesFilterationMohit SharmaNo ratings yet

- Laboratory Experiments Compilation: College of Engineering EducationDocument21 pagesLaboratory Experiments Compilation: College of Engineering EducationhachimanNo ratings yet

- Experiment No - 4 Sieve Analysis of Aggregates: ObjectDocument2 pagesExperiment No - 4 Sieve Analysis of Aggregates: ObjectSasi ShashNo ratings yet

- Properties of Fine Aggregate:: Gradation and TextureDocument12 pagesProperties of Fine Aggregate:: Gradation and Texturesalil dubeyNo ratings yet

- Asae+s269 (2) 4+dec96 PDFDocument3 pagesAsae+s269 (2) 4+dec96 PDFMuhammad RochimNo ratings yet

- SPE-111286 Advances in Measuring Porosity and Permeability From Drill CuttingsDocument9 pagesSPE-111286 Advances in Measuring Porosity and Permeability From Drill CuttingsBruceNo ratings yet

- E 1757 - 01 (2015)Document4 pagesE 1757 - 01 (2015)Eric GozzerNo ratings yet

- Fakulti Kejuruteraan Awam Universiti Teknologi Mara Pasir Gudang Laboratory ManualDocument5 pagesFakulti Kejuruteraan Awam Universiti Teknologi Mara Pasir Gudang Laboratory ManualZaffira RahmanNo ratings yet

- Micromeritics 3Document27 pagesMicromeritics 3novi_lingga100% (1)

- 2a6a - Lab 8 - Group 1 (2a6a) - Ecg428 - Mac24Document10 pages2a6a - Lab 8 - Group 1 (2a6a) - Ecg428 - Mac24Izzah AfiqahNo ratings yet

- Nobre Opq 2005Document2 pagesNobre Opq 2005LawNo ratings yet

- A Model For Predicting The Size Distribution of Product From A Granulating DrumDocument9 pagesA Model For Predicting The Size Distribution of Product From A Granulating DrumJaenni KimNo ratings yet

- ASTM D 6940 - 03Document5 pagesASTM D 6940 - 03Jordan RiveraNo ratings yet

- Experimental Study On Stabilization of Clay Soil Using Coir FiberDocument18 pagesExperimental Study On Stabilization of Clay Soil Using Coir Fiber153-B RAKSHITHANo ratings yet

- Pharmacutical Engineering, Practical, Lab Mannual..kTDocument111 pagesPharmacutical Engineering, Practical, Lab Mannual..kTMANTHANNo ratings yet

- J ANIM SCI-1986-Cochran-1469-75Document8 pagesJ ANIM SCI-1986-Cochran-1469-75Alberto ChambelaNo ratings yet

- J ANIM SCI-1985-Estell-1061-71Document12 pagesJ ANIM SCI-1985-Estell-1061-71Alberto ChambelaNo ratings yet

- J ANIM SCI-1979-Hartnell-381-92Document13 pagesJ ANIM SCI-1979-Hartnell-381-92Alberto ChambelaNo ratings yet

- Aldrich Et Al, 1993Document15 pagesAldrich Et Al, 1993Alberto ChambelaNo ratings yet

- J ANIM SCI-1939-Hale-389-93Document6 pagesJ ANIM SCI-1939-Hale-389-93Alberto ChambelaNo ratings yet

- Albright - 1993Document14 pagesAlbright - 1993Alberto ChambelaNo ratings yet

- Phys2 Ch2 Heat Temp Law0Document56 pagesPhys2 Ch2 Heat Temp Law0Trung Trần100% (1)

- Kinetic Theory of GassesDocument8 pagesKinetic Theory of GassesAziz Khan SultanNo ratings yet

- zOSV2R3 - MVS Program Management - User's Guide and Reference - IBM - 2017Document258 pageszOSV2R3 - MVS Program Management - User's Guide and Reference - IBM - 2017Nicholas VanHaiVuNo ratings yet

- Wittkower Architectural Principles in The Age of HumanismDocument6 pagesWittkower Architectural Principles in The Age of HumanismSunday Heavycloth Jr.33% (3)

- Application Note AN6016: LCD Backlight Inverter Drive IC (FAN7311)Document18 pagesApplication Note AN6016: LCD Backlight Inverter Drive IC (FAN7311)Osama YaseenNo ratings yet

- ESF Parts Sheet With Standards Filled 2019 (1) - 1Document1 pageESF Parts Sheet With Standards Filled 2019 (1) - 1GiridharNo ratings yet

- Installation Instructions Models Xtri-S / Xtri-D / Xtri-R: Building Technologies DivisionDocument8 pagesInstallation Instructions Models Xtri-S / Xtri-D / Xtri-R: Building Technologies DivisionPrabu KhayanganNo ratings yet

- Aps Nonlinear Logic With Safety Matrix en PDFDocument30 pagesAps Nonlinear Logic With Safety Matrix en PDFVinom1No ratings yet

- Daily Report Project ReportDocument24 pagesDaily Report Project ReportAyush jainNo ratings yet

- Napco XP-600Document28 pagesNapco XP-600Felipe Cesar Gonzales HuaracaNo ratings yet

- Experiment 2 - Aditya Kumar (17EC03)Document3 pagesExperiment 2 - Aditya Kumar (17EC03)AdityaNo ratings yet

- Self Test CH - 2 SolutionDocument3 pagesSelf Test CH - 2 SolutionsolomonNo ratings yet

- Design and Implementation of PFC CUK Converter-Based PMBLDCM DriveDocument5 pagesDesign and Implementation of PFC CUK Converter-Based PMBLDCM Drivesarav03No ratings yet

- DIP Lecture 9Document34 pagesDIP Lecture 9Sukanti PalNo ratings yet

- Various Arithmetic Functions and Their ApplicationsDocument402 pagesVarious Arithmetic Functions and Their ApplicationsFlorentin SmarandacheNo ratings yet

- 6 Hydrogeochemical Facies Investigation of Surface and GroundwaterDocument13 pages6 Hydrogeochemical Facies Investigation of Surface and GroundwaterMervatNo ratings yet

- Final Demo DLPDocument7 pagesFinal Demo DLPAljohaila GulamNo ratings yet

- Casting & ForgingDocument42 pagesCasting & ForgingMrinal100% (1)

- OAB TechnicalDocument2 pagesOAB Technicalvanitha_kundaramNo ratings yet

- Aeroprakt A32-080-POHDocument60 pagesAeroprakt A32-080-POHRafael ShNo ratings yet

- 09 Flight Techniques 747 400 v10Document18 pages09 Flight Techniques 747 400 v10flightstudent100% (1)

- Open Ended LabDocument11 pagesOpen Ended LabM. TahmanNo ratings yet

- 5020-250-S12-P04-0027 - TOFD-20113 - Rev.1Document53 pages5020-250-S12-P04-0027 - TOFD-20113 - Rev.1ahmed elezabyNo ratings yet

- Social Jet Lag: Sleep-Corrected Formula: Chronobiology InternationalDocument6 pagesSocial Jet Lag: Sleep-Corrected Formula: Chronobiology InternationalEtaursaeNo ratings yet

- EZR ManualDocument40 pagesEZR Manualdancuk99No ratings yet

- 1.590 ATP 2023-24 GR 11 Maths Final PDFDocument5 pages1.590 ATP 2023-24 GR 11 Maths Final PDFMac Mawasha100% (1)

- Which Is The Scale That Contains Absolute or True Zero Which Implies The Absence of Any Trait?Document6 pagesWhich Is The Scale That Contains Absolute or True Zero Which Implies The Absence of Any Trait?Nakul SabooNo ratings yet

- 102 196 1 SMDocument7 pages102 196 1 SMlaminar sibaraniNo ratings yet