Professional Documents

Culture Documents

Air 2A

Air 2A

Uploaded by

Moriyasu NguyenCopyright:

Available Formats

You might also like

- Besa Guide To Good Practice For The Installation of Fire and Smoke Dampers (Sample)Document7 pagesBesa Guide To Good Practice For The Installation of Fire and Smoke Dampers (Sample)Moriyasu Nguyen33% (3)

- Solar-1 0Document4 pagesSolar-1 0Moriyasu NguyenNo ratings yet

- Solar 1Document4 pagesSolar 1api-221502147No ratings yet

- Informacion Valvula DesaireadoraDocument4 pagesInformacion Valvula DesaireadoraCesar GraterolNo ratings yet

- 2854164 - Air Release Valve Data Sheet and DimensionalDocument4 pages2854164 - Air Release Valve Data Sheet and DimensionalAdriana GonzálezNo ratings yet

- Air Release Valve Cla-ValDocument4 pagesAir Release Valve Cla-Valventas2.fireproofcolNo ratings yet

- Vortech® & 4900 Series Air SeparatorsDocument4 pagesVortech® & 4900 Series Air SeparatorsMagda Luz Marusich CastroNo ratings yet

- Onshore and Offshore: Echnical PresentationDocument66 pagesOnshore and Offshore: Echnical PresentationAnonymous 4MwmDaNbNo ratings yet

- SKRDocument8 pagesSKRNamrah FatimaNo ratings yet

- PyroPure Pure Steam GeneratorsDocument6 pagesPyroPure Pure Steam GeneratorsOdunlamiNo ratings yet

- Side Channel BlowersDocument8 pagesSide Channel BlowersGraham BarrNo ratings yet

- Valvula DesaireadoraDocument4 pagesValvula DesaireadoracccNo ratings yet

- Series 34: Fire Protection System Air Release ValveDocument4 pagesSeries 34: Fire Protection System Air Release ValvecccNo ratings yet

- 711-Copes Vulcan Vo II DesuperheaterDocument8 pages711-Copes Vulcan Vo II DesuperheaterWADENo ratings yet

- Automatic Air Release Valve For Low PressureDocument2 pagesAutomatic Air Release Valve For Low PressuresijilNo ratings yet

- Hydroseal Series 3500 Pilot Operated Relief ValvesDocument8 pagesHydroseal Series 3500 Pilot Operated Relief Valvesprihartono_diasNo ratings yet

- VSRT Bro 2017-1227Document6 pagesVSRT Bro 2017-1227Eduardo Camacho [Clayton de México]No ratings yet

- Sullair - Air Treatment BrochureDocument19 pagesSullair - Air Treatment BrochureJosi ElizeteNo ratings yet

- Direct Steam Injection Humidifiers PDFDocument8 pagesDirect Steam Injection Humidifiers PDFMohamed Osama El GendiNo ratings yet

- SpiraxSarco-B11-Steam TrappingDocument122 pagesSpiraxSarco-B11-Steam Trappingdanenic100% (4)

- Vertical Spiral Rib Tubeless Steam BoilersDocument6 pagesVertical Spiral Rib Tubeless Steam BoilersbenNo ratings yet

- A Review of Onshore Flare Systems PLVDocument9 pagesA Review of Onshore Flare Systems PLVPhilippe LAVOISIERNo ratings yet

- Yawmc-0406-Us (2) Valvulas YarwayDocument8 pagesYawmc-0406-Us (2) Valvulas YarwayLuis Manuel VazquezNo ratings yet

- Automatic Air Vents: For Hot and Cold Water SystemsDocument4 pagesAutomatic Air Vents: For Hot and Cold Water SystemsrameshNo ratings yet

- Quick ExhaustDocument2 pagesQuick Exhaustsatheez3251No ratings yet

- Air DryerDocument55 pagesAir Dryerriajul100% (1)

- Total Elegance and Safety: Ceraplus Electronic MixersDocument8 pagesTotal Elegance and Safety: Ceraplus Electronic MixersMohamed AzabNo ratings yet

- Multi-Stage Steam Turbines: Proven Reliability and EfficiencyDocument8 pagesMulti-Stage Steam Turbines: Proven Reliability and EfficiencyAlfredo Velasquez100% (1)

- Best Practices For Steam Control Valve InstallationDocument4 pagesBest Practices For Steam Control Valve InstallationYasmin.Shunmugam4188No ratings yet

- Energy-Saving Free Float Steam Trap: FeaturesDocument2 pagesEnergy-Saving Free Float Steam Trap: FeaturesSebastian AcevedoNo ratings yet

- Specification CL-1016-2016Document2 pagesSpecification CL-1016-2016Docente 361 UMECITNo ratings yet

- Two Three Way Ball ValvesDocument6 pagesTwo Three Way Ball ValvesUzair AnsariNo ratings yet

- Condensadora Vertical Lennox 13acx de 1.5 A 5 Ton R410a 13 Seer MonofasicaDocument36 pagesCondensadora Vertical Lennox 13acx de 1.5 A 5 Ton R410a 13 Seer MonofasicaJorgee RossaNo ratings yet

- Back FlushDocument4 pagesBack Flushfaiz firdausiNo ratings yet

- Spray Rinse & Steam HandlingDocument8 pagesSpray Rinse & Steam Handlingkresimir.mikoc9765No ratings yet

- TW HeatlssDocument12 pagesTW Heatlssherysyam1980No ratings yet

- Twintower, Heatless, Regenerative Compressed Air Dryers - 8-75 CFM Models (PDF, 913KB)Document4 pagesTwintower, Heatless, Regenerative Compressed Air Dryers - 8-75 CFM Models (PDF, 913KB)Sudar MyshaNo ratings yet

- Air SeperatorDocument4 pagesAir SeperatorMECH CUDCENo ratings yet

- Air SystemDocument58 pagesAir SystemmasdikaNo ratings yet

- About Control ValvesDocument17 pagesAbout Control ValvesSaurabh BarangeNo ratings yet

- LIT Sullair Single-Stage SAPSS200350 en 0Document8 pagesLIT Sullair Single-Stage SAPSS200350 en 0Pierre-André MarcouxNo ratings yet

- Butterfly Valve CATALOGDocument36 pagesButterfly Valve CATALOGGloriaNo ratings yet

- NRV EnglischDocument16 pagesNRV EnglischRodrigo GonçalvesNo ratings yet

- Gfps Us 1334 Datasheet Type 244 Data Sheet enDocument6 pagesGfps Us 1334 Datasheet Type 244 Data Sheet enOmar GuillenNo ratings yet

- Double-Seat-Valves DSV-Complete Sudmo BrochureDocument16 pagesDouble-Seat-Valves DSV-Complete Sudmo BrochureHector Serrano MagañaNo ratings yet

- Dunham Bush Package UnitsDocument8 pagesDunham Bush Package UnitsStephanie StewartNo ratings yet

- Manual BOOK AR SERIESDocument4 pagesManual BOOK AR SERIESchandra atmaNo ratings yet

- Sks Topic 6 Dust ControlDocument25 pagesSks Topic 6 Dust Controlrigoberto otinianoNo ratings yet

- COMPANY PRESENTATION Dec 2016Document30 pagesCOMPANY PRESENTATION Dec 2016mbohramurtazaNo ratings yet

- Conditioning of Steam & Air NotesDocument22 pagesConditioning of Steam & Air Notesbonginkosi mathunjwaNo ratings yet

- 5439 5440 Air Actuated 3-Way Stainless Ball Valves: FeaturesDocument6 pages5439 5440 Air Actuated 3-Way Stainless Ball Valves: FeaturesRADHAKRISHNANNo ratings yet

- Kadant - Thermocompressor Operation and MaintenanceDocument2 pagesKadant - Thermocompressor Operation and MaintenanceGarnazNo ratings yet

- Venturi Nozzle Systems Questions and AnswersDocument1 pageVenturi Nozzle Systems Questions and Answersbalaji12031988No ratings yet

- Turbine Bypass ValveDocument12 pagesTurbine Bypass ValveRam MohanNo ratings yet

- 1500 Series Level SwitchesDocument16 pages1500 Series Level SwitchesSmith CBNo ratings yet

- Air Release Valve: Jeevan Bhar Ka Saath..Document2 pagesAir Release Valve: Jeevan Bhar Ka Saath..arjun 11No ratings yet

- NUVE OT 300 430 570 710 - Horizontal Steam Sterilizer BrochureDocument6 pagesNUVE OT 300 430 570 710 - Horizontal Steam Sterilizer BrochureIvan CvasniucNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersFrom EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersRating: 4.5 out of 5 stars4.5/5 (2)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Kruger Vietnam - Presentation of General Fan - R3 - 09 Oct 2021Document80 pagesKruger Vietnam - Presentation of General Fan - R3 - 09 Oct 2021Moriyasu NguyenNo ratings yet

- Noiseandplanning Guidance Jun22Document53 pagesNoiseandplanning Guidance Jun22Moriyasu NguyenNo ratings yet

- Catalogo Incendio Rev500 ENGDocument63 pagesCatalogo Incendio Rev500 ENGMoriyasu NguyenNo ratings yet

- Solar-1 0Document4 pagesSolar-1 0Moriyasu NguyenNo ratings yet

- SPS 2Document9 pagesSPS 2Moriyasu NguyenNo ratings yet

- NVL - TPC ID Concept - Public RestroomDocument17 pagesNVL - TPC ID Concept - Public RestroomMoriyasu NguyenNo ratings yet

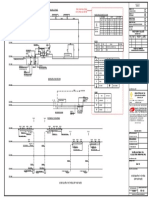

- Cấp ĐiệnDocument8 pagesCấp ĐiệnMoriyasu NguyenNo ratings yet

- Australian/New Zealand Standard: Hot-Dip Galvanized (Zinc) Coatings On Fabricated Ferrous ArticlesDocument7 pagesAustralian/New Zealand Standard: Hot-Dip Galvanized (Zinc) Coatings On Fabricated Ferrous ArticlesMoriyasu NguyenNo ratings yet

- 191210-01 CommentsDocument7 pages191210-01 CommentsMoriyasu NguyenNo ratings yet

- 01-26-05 ENL - CoolingTowerDocument106 pages01-26-05 ENL - CoolingTowerMoriyasu NguyenNo ratings yet

- Twin City Fan & Blower Guide Specification Plenum Fans: Model MPQS, Direct DriveDocument7 pagesTwin City Fan & Blower Guide Specification Plenum Fans: Model MPQS, Direct DriveMoriyasu NguyenNo ratings yet

- Hpac Pools Article2Document6 pagesHpac Pools Article2Moriyasu NguyenNo ratings yet

- 3246es en PDFDocument2 pages3246es en PDFMoriyasu NguyenNo ratings yet

- Aritech Ceiling Mount Sensor Ds PDFDocument2 pagesAritech Ceiling Mount Sensor Ds PDFMoriyasu NguyenNo ratings yet

- Alastair Brockett PresentationDocument65 pagesAlastair Brockett PresentationMoriyasu NguyenNo ratings yet

- Installation Operation MaintenanceDocument64 pagesInstallation Operation MaintenanceMoriyasu NguyenNo ratings yet

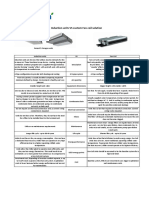

- Swegon Inductioin Units Vs Fan Coil UnitsDocument1 pageSwegon Inductioin Units Vs Fan Coil UnitsMoriyasu NguyenNo ratings yet

- Revise Code 10 7 2015Document335 pagesRevise Code 10 7 2015Moriyasu NguyenNo ratings yet

- Upvc Sewer Drainage Systems Product Brochure PDFDocument32 pagesUpvc Sewer Drainage Systems Product Brochure PDFMoriyasu NguyenNo ratings yet

- SG: trình bày: ở bản vẽ ký hiệu và viết tắtDocument1 pageSG: trình bày: ở bản vẽ ký hiệu và viết tắtMoriyasu NguyenNo ratings yet

- 13 - NucleiDocument17 pages13 - Nucleigauthamdoc321No ratings yet

- Assessing Uncertainties of Well-To-Tank GreenhouseDocument27 pagesAssessing Uncertainties of Well-To-Tank GreenhousejoelNo ratings yet

- Laws of Motion NCERT MCQDocument20 pagesLaws of Motion NCERT MCQwixirepNo ratings yet

- Mechanics 2024Document85 pagesMechanics 2024Mawande WandarhNo ratings yet

- TOPICS IN ENERGY, WATER AND EnvironmentDocument21 pagesTOPICS IN ENERGY, WATER AND EnvironmentAhmed KingNo ratings yet

- High Precision PSR Constant Current LED Driver Description FeaturesDocument2 pagesHigh Precision PSR Constant Current LED Driver Description FeaturesVictorUrbinaNo ratings yet

- CRU21035a Esb Networks Standard Prices For Generator Connections 2021Document41 pagesCRU21035a Esb Networks Standard Prices For Generator Connections 2021Muhammad Ashraf Ali AwanNo ratings yet

- AS5590 Dynamic Soaring: Ranjith M., AE, Ranjith.m@iitm - Ac.inDocument18 pagesAS5590 Dynamic Soaring: Ranjith M., AE, Ranjith.m@iitm - Ac.inranjith_mohanNo ratings yet

- T Tad532geDocument8 pagesT Tad532geAhmed AlabsiNo ratings yet

- RT-85 ICU With New Drain Pipe Arrangement (Issue 2, 17-12-2010)Document3 pagesRT-85 ICU With New Drain Pipe Arrangement (Issue 2, 17-12-2010)maxwell333No ratings yet

- Ojt Report Class 11Document19 pagesOjt Report Class 11Lochan SahNo ratings yet

- 01 TurboExpCompAMBDocument40 pages01 TurboExpCompAMBMohamed GamilNo ratings yet

- On-Site Hypochlorite Generating SystemsDocument8 pagesOn-Site Hypochlorite Generating SystemsNguyễn NgọcNo ratings yet

- Lehe20208 00Document3 pagesLehe20208 00practicante crcNo ratings yet

- A1 Key To Component: Diagram, Piping & Instrumentation Ac Nirvana of Hot Discharge-HocDocument2 pagesA1 Key To Component: Diagram, Piping & Instrumentation Ac Nirvana of Hot Discharge-Hocsachin JoshiNo ratings yet

- Solar Quotation ComparisonDocument1 pageSolar Quotation ComparisonTamilselvan BalasubramaniNo ratings yet

- LEC 3-Introduction-to-Building-ServicesDocument10 pagesLEC 3-Introduction-to-Building-Servicesmdnitollamastem12hNo ratings yet

- Surat Penawaran MembershipDocument5 pagesSurat Penawaran MembershipAhmad JauhariNo ratings yet

- FE PresentationOrder-ModDocument8 pagesFE PresentationOrder-ModHrishabhJainNo ratings yet

- CSIR 2021 Circular Economy As Development OpportunityDocument80 pagesCSIR 2021 Circular Economy As Development OpportunitysarikahoosenNo ratings yet

- Mush Winding2Document18 pagesMush Winding2MebreNo ratings yet

- TOTAL WALTHER CI-Technology: Technical ManualDocument140 pagesTOTAL WALTHER CI-Technology: Technical ManualJORDAN LOPEZNo ratings yet

- Low Oil Pressure in A Diesel EngineDocument4 pagesLow Oil Pressure in A Diesel EngineYosephBerhanuNo ratings yet

- ECU MS 4 Sport: Bosch Motorsport ManualDocument23 pagesECU MS 4 Sport: Bosch Motorsport ManualServicios y Repuestos Jeremy Azhael 2320 C.ANo ratings yet

- 4) Arc Welding EquipmentsDocument6 pages4) Arc Welding EquipmentsKrako TramNo ratings yet

- Product Catalogue 2021/22: Your Solution Partner 1978Document12 pagesProduct Catalogue 2021/22: Your Solution Partner 1978BaselNo ratings yet

- Wjr2525t-4025t-13yh3f01 2014Document74 pagesWjr2525t-4025t-13yh3f01 2014Eduardo Álvarez Juárez100% (1)

- BIO UNIT 10.1 (Study Guide)Document22 pagesBIO UNIT 10.1 (Study Guide)Izzy Dynielle SolamilloNo ratings yet

- Class 10 Social Science MCQs Chapter 1 DevelopmentDocument11 pagesClass 10 Social Science MCQs Chapter 1 DevelopmentParveen KumarNo ratings yet

- Phy 10 MergedDocument22 pagesPhy 10 MergedPranav GurjarNo ratings yet

Air 2A

Air 2A

Uploaded by

Moriyasu NguyenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air 2A

Air 2A

Uploaded by

Moriyasu NguyenCopyright:

Available Formats

SPIROVENT AIR

AIR ELIMINATORS

STANDARD VELOCITY

THE ULTIMATE IN DISTRIBUTION EFFICIENCY

PERMANENTLY AIR-FREE SYSTEM WATER

AIR IN SYSTEM WATER THE KEY DIFFERENCE

CAUSES MANY PROBLEMS. The Spirovent’s unique construction allows not

Noisy pipes, valves and other air-related only for the removal of entrained air, but also

system noises are often accepted as the signs for the countless microbubbles. Consisting of

of a functioning system. Excessive pump a woven copper wire configuration soldered to

noise, cavitation and cascading water in a copper tube, the patented Spirotube® creates

terminal units are considered normal. a low velocity area in the Spirovent that scrubs

the bubbles from the water. The air bubbles rise

But....serious problems can occur. and collect in the air chamber before they are

Air in system water can cause corrosion, vented from the system via an integral

reduced efficiency, poorly heated or automatic valve. Air problems

inadequately cooled rooms, accelerated become a thing of the past!

component wear, and ongoing complaints.

Result:

Unnecessary maintenance costs and a

dissatisfied owner.

There is a solution!

A system without air-related problems is

possible! There is a device that will keep

your system free of air, permanently. Less

maintenance, quiet operation, fewer costs!

The name:

SPIROVENT AIR

2” Threaded

4” Flanged

THE ULTIMATE IN DISTRIBUTION EFFICIENCY

Spirotop

ADVANTAGES TO THE

INSTALLER AND THE END-USER

Baseboard

● Greatly reduced initial fill and start-up time

Circulator

● No venting required

Spirovent

● Optimum heat transfer Air Eliminator

● Increased component life Circulator

● Reduced oxygen-based corrosion and pump cavitation

● Quiet operation Boiler

Recommended

location for

THE SPIROTUBE MAKES THE DIFFERENCE Acceptable location circulator and

expansion tank

for circulator and

It allows the Spirovent to scrub out 100% of the free air, expansion tank

100% of the entrained air, and up to 99.6% of the dissolved

air in the system. Even the smallest microbubbles coalesce INSTALL THE SPIROVENT

and rise. Air is eliminated, component life and heat transfer

FOR OPTIMUM PERFORMANCE

abilities are increased; oxygen-based corrosion and pump

cavitation are reduced; and annoying gurgling, cascading, Ideal placement of the Spirovent is based on microbubble

and other air-related system noises are eliminated. separation and Henry’s Law. Simply put, Henry’s Law states

that air is released from water as the temperature increases

or the pressure decreases*. For this reason, the Spirovent

is typically installed in the hottest point of the system.

For a heating installation, this is in the supply from the boiler.

In a chilled water circuit, the warmest point is in the return

to the chiller.

The patented Spirotube, Spirotop

the core of the Spirovent

Air Handler

The automatic air vent is guaranteed not to leak and

Spirovent

can only be closed by the installer for a pressure test. Air Eliminator

Lifting eyes make installation easy. Circulator

The air chamber has been designed so that dirt Chiller

cannot reach the valve.

Welded steel construction guarantees long life. Expansion

Tank

Valve for releasing large amounts of air during filling

and for skimming off floating dirt.

*For more detailed technical information,

The unique Spirotube is the core of the Spirovent. ask about our Spirotism booklet .

Designed to trap the smallest microbubble, yet it

offers little resistance to flow.

Threaded or flanged connections available.

Threaded 3⁄4”-4”; Flanged 2” and up.

Drain plug. Also suitable for connecting a valve

or temperature sensor.

THE ULTIMATE IN DISTRIBUTION EFFICIENCY

SPIROVENT® AIR

PRESSURE DROP

1.4 12”

Pressure Drop (Feet of Head)

1 10”

0.8 8”

0.6

6”

0.4 5”

0.3 4”

0.2 3”

2.5”

0.14

2”

0.1

0.08

0.06

0.04

1 2 3 4 5 6

Water Velocity at Inlet Nozzle (Feet/sec)

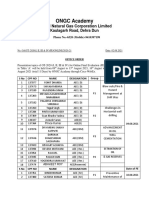

TECHNICAL SPECIFICATIONS

SPIROVENT AIR

Part Number VSR200 VSR250 VSR300 VSR400 VSR500 VSR600 VSR800 VSR1000 VSR1200

Pipe Size Inch 2 2.5 3 4 5 6 8 10 12

O.D. Inch 2.375 3.0 3.5 4.5 5.5 6.625 8.625 10.75 12.75

Thread NPT 2 2.5 3 4 — — — — —

D Inch 6.3 6.3 8.6 8.6 12.8 12.8 16.0 20.0 24.0

H1

OD

H1 Inch 19.0 19.0 23.7 23.7 30.6 30.6 38.4 47.8 56.3

h1 Inch 5.0 5.4 6.4 6.8 8.6 9.2 10.8 13.0 15.2

PS

L (Threaded) Inch 10.2 10.2 14.6 14.6 — — — — —

h1

LF (Flanged) Inch 15.2 15.7 20.2 20.6 27.7 27.7 33.6 37.5 42.5

e

e Inch 1 1 1 1 1 1 1 1 1

D

Volume Gal. 1.3 1.3 4.5 4.5 13.2 13.2 27.7 55.5 92.5 L

Weight LF

Threaded Lbs. 23 28 45 47 — — — — —

Flanged Lbs. 48 59 95 107 186 200 360 564 1050

Recom. Flow* GPM 60 90 140 240 370 540 940 1470 2090

*Approximately 6 ft. per second inlet velocity

All Spirovents fabricated and stamped in accordance with ASME Section VIII, Division 1 for unfired pressure vessels.

Standard rating is 150 psi at 270°F. Consult local sales office for special requirements.

Custom dimensions available for space limitations.

Refer to High Velocity models for higher flows and web site Submittal Data for models up to 36”.

Spirotherm, Inc. Tel.: 630-307-2662

25 N. Brandon Drive Fax: 630-307-3773

A SPIRO ENTERPRISES COMPANY Glendale Heights, IL 60139 www.spirotherm.com

E-mail: info@spirotherm.com

©2014 Spirotherm, Inc. Air-2A

You might also like

- Besa Guide To Good Practice For The Installation of Fire and Smoke Dampers (Sample)Document7 pagesBesa Guide To Good Practice For The Installation of Fire and Smoke Dampers (Sample)Moriyasu Nguyen33% (3)

- Solar-1 0Document4 pagesSolar-1 0Moriyasu NguyenNo ratings yet

- Solar 1Document4 pagesSolar 1api-221502147No ratings yet

- Informacion Valvula DesaireadoraDocument4 pagesInformacion Valvula DesaireadoraCesar GraterolNo ratings yet

- 2854164 - Air Release Valve Data Sheet and DimensionalDocument4 pages2854164 - Air Release Valve Data Sheet and DimensionalAdriana GonzálezNo ratings yet

- Air Release Valve Cla-ValDocument4 pagesAir Release Valve Cla-Valventas2.fireproofcolNo ratings yet

- Vortech® & 4900 Series Air SeparatorsDocument4 pagesVortech® & 4900 Series Air SeparatorsMagda Luz Marusich CastroNo ratings yet

- Onshore and Offshore: Echnical PresentationDocument66 pagesOnshore and Offshore: Echnical PresentationAnonymous 4MwmDaNbNo ratings yet

- SKRDocument8 pagesSKRNamrah FatimaNo ratings yet

- PyroPure Pure Steam GeneratorsDocument6 pagesPyroPure Pure Steam GeneratorsOdunlamiNo ratings yet

- Side Channel BlowersDocument8 pagesSide Channel BlowersGraham BarrNo ratings yet

- Valvula DesaireadoraDocument4 pagesValvula DesaireadoracccNo ratings yet

- Series 34: Fire Protection System Air Release ValveDocument4 pagesSeries 34: Fire Protection System Air Release ValvecccNo ratings yet

- 711-Copes Vulcan Vo II DesuperheaterDocument8 pages711-Copes Vulcan Vo II DesuperheaterWADENo ratings yet

- Automatic Air Release Valve For Low PressureDocument2 pagesAutomatic Air Release Valve For Low PressuresijilNo ratings yet

- Hydroseal Series 3500 Pilot Operated Relief ValvesDocument8 pagesHydroseal Series 3500 Pilot Operated Relief Valvesprihartono_diasNo ratings yet

- VSRT Bro 2017-1227Document6 pagesVSRT Bro 2017-1227Eduardo Camacho [Clayton de México]No ratings yet

- Sullair - Air Treatment BrochureDocument19 pagesSullair - Air Treatment BrochureJosi ElizeteNo ratings yet

- Direct Steam Injection Humidifiers PDFDocument8 pagesDirect Steam Injection Humidifiers PDFMohamed Osama El GendiNo ratings yet

- SpiraxSarco-B11-Steam TrappingDocument122 pagesSpiraxSarco-B11-Steam Trappingdanenic100% (4)

- Vertical Spiral Rib Tubeless Steam BoilersDocument6 pagesVertical Spiral Rib Tubeless Steam BoilersbenNo ratings yet

- A Review of Onshore Flare Systems PLVDocument9 pagesA Review of Onshore Flare Systems PLVPhilippe LAVOISIERNo ratings yet

- Yawmc-0406-Us (2) Valvulas YarwayDocument8 pagesYawmc-0406-Us (2) Valvulas YarwayLuis Manuel VazquezNo ratings yet

- Automatic Air Vents: For Hot and Cold Water SystemsDocument4 pagesAutomatic Air Vents: For Hot and Cold Water SystemsrameshNo ratings yet

- Quick ExhaustDocument2 pagesQuick Exhaustsatheez3251No ratings yet

- Air DryerDocument55 pagesAir Dryerriajul100% (1)

- Total Elegance and Safety: Ceraplus Electronic MixersDocument8 pagesTotal Elegance and Safety: Ceraplus Electronic MixersMohamed AzabNo ratings yet

- Multi-Stage Steam Turbines: Proven Reliability and EfficiencyDocument8 pagesMulti-Stage Steam Turbines: Proven Reliability and EfficiencyAlfredo Velasquez100% (1)

- Best Practices For Steam Control Valve InstallationDocument4 pagesBest Practices For Steam Control Valve InstallationYasmin.Shunmugam4188No ratings yet

- Energy-Saving Free Float Steam Trap: FeaturesDocument2 pagesEnergy-Saving Free Float Steam Trap: FeaturesSebastian AcevedoNo ratings yet

- Specification CL-1016-2016Document2 pagesSpecification CL-1016-2016Docente 361 UMECITNo ratings yet

- Two Three Way Ball ValvesDocument6 pagesTwo Three Way Ball ValvesUzair AnsariNo ratings yet

- Condensadora Vertical Lennox 13acx de 1.5 A 5 Ton R410a 13 Seer MonofasicaDocument36 pagesCondensadora Vertical Lennox 13acx de 1.5 A 5 Ton R410a 13 Seer MonofasicaJorgee RossaNo ratings yet

- Back FlushDocument4 pagesBack Flushfaiz firdausiNo ratings yet

- Spray Rinse & Steam HandlingDocument8 pagesSpray Rinse & Steam Handlingkresimir.mikoc9765No ratings yet

- TW HeatlssDocument12 pagesTW Heatlssherysyam1980No ratings yet

- Twintower, Heatless, Regenerative Compressed Air Dryers - 8-75 CFM Models (PDF, 913KB)Document4 pagesTwintower, Heatless, Regenerative Compressed Air Dryers - 8-75 CFM Models (PDF, 913KB)Sudar MyshaNo ratings yet

- Air SeperatorDocument4 pagesAir SeperatorMECH CUDCENo ratings yet

- Air SystemDocument58 pagesAir SystemmasdikaNo ratings yet

- About Control ValvesDocument17 pagesAbout Control ValvesSaurabh BarangeNo ratings yet

- LIT Sullair Single-Stage SAPSS200350 en 0Document8 pagesLIT Sullair Single-Stage SAPSS200350 en 0Pierre-André MarcouxNo ratings yet

- Butterfly Valve CATALOGDocument36 pagesButterfly Valve CATALOGGloriaNo ratings yet

- NRV EnglischDocument16 pagesNRV EnglischRodrigo GonçalvesNo ratings yet

- Gfps Us 1334 Datasheet Type 244 Data Sheet enDocument6 pagesGfps Us 1334 Datasheet Type 244 Data Sheet enOmar GuillenNo ratings yet

- Double-Seat-Valves DSV-Complete Sudmo BrochureDocument16 pagesDouble-Seat-Valves DSV-Complete Sudmo BrochureHector Serrano MagañaNo ratings yet

- Dunham Bush Package UnitsDocument8 pagesDunham Bush Package UnitsStephanie StewartNo ratings yet

- Manual BOOK AR SERIESDocument4 pagesManual BOOK AR SERIESchandra atmaNo ratings yet

- Sks Topic 6 Dust ControlDocument25 pagesSks Topic 6 Dust Controlrigoberto otinianoNo ratings yet

- COMPANY PRESENTATION Dec 2016Document30 pagesCOMPANY PRESENTATION Dec 2016mbohramurtazaNo ratings yet

- Conditioning of Steam & Air NotesDocument22 pagesConditioning of Steam & Air Notesbonginkosi mathunjwaNo ratings yet

- 5439 5440 Air Actuated 3-Way Stainless Ball Valves: FeaturesDocument6 pages5439 5440 Air Actuated 3-Way Stainless Ball Valves: FeaturesRADHAKRISHNANNo ratings yet

- Kadant - Thermocompressor Operation and MaintenanceDocument2 pagesKadant - Thermocompressor Operation and MaintenanceGarnazNo ratings yet

- Venturi Nozzle Systems Questions and AnswersDocument1 pageVenturi Nozzle Systems Questions and Answersbalaji12031988No ratings yet

- Turbine Bypass ValveDocument12 pagesTurbine Bypass ValveRam MohanNo ratings yet

- 1500 Series Level SwitchesDocument16 pages1500 Series Level SwitchesSmith CBNo ratings yet

- Air Release Valve: Jeevan Bhar Ka Saath..Document2 pagesAir Release Valve: Jeevan Bhar Ka Saath..arjun 11No ratings yet

- NUVE OT 300 430 570 710 - Horizontal Steam Sterilizer BrochureDocument6 pagesNUVE OT 300 430 570 710 - Horizontal Steam Sterilizer BrochureIvan CvasniucNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersFrom EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersRating: 4.5 out of 5 stars4.5/5 (2)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Kruger Vietnam - Presentation of General Fan - R3 - 09 Oct 2021Document80 pagesKruger Vietnam - Presentation of General Fan - R3 - 09 Oct 2021Moriyasu NguyenNo ratings yet

- Noiseandplanning Guidance Jun22Document53 pagesNoiseandplanning Guidance Jun22Moriyasu NguyenNo ratings yet

- Catalogo Incendio Rev500 ENGDocument63 pagesCatalogo Incendio Rev500 ENGMoriyasu NguyenNo ratings yet

- Solar-1 0Document4 pagesSolar-1 0Moriyasu NguyenNo ratings yet

- SPS 2Document9 pagesSPS 2Moriyasu NguyenNo ratings yet

- NVL - TPC ID Concept - Public RestroomDocument17 pagesNVL - TPC ID Concept - Public RestroomMoriyasu NguyenNo ratings yet

- Cấp ĐiệnDocument8 pagesCấp ĐiệnMoriyasu NguyenNo ratings yet

- Australian/New Zealand Standard: Hot-Dip Galvanized (Zinc) Coatings On Fabricated Ferrous ArticlesDocument7 pagesAustralian/New Zealand Standard: Hot-Dip Galvanized (Zinc) Coatings On Fabricated Ferrous ArticlesMoriyasu NguyenNo ratings yet

- 191210-01 CommentsDocument7 pages191210-01 CommentsMoriyasu NguyenNo ratings yet

- 01-26-05 ENL - CoolingTowerDocument106 pages01-26-05 ENL - CoolingTowerMoriyasu NguyenNo ratings yet

- Twin City Fan & Blower Guide Specification Plenum Fans: Model MPQS, Direct DriveDocument7 pagesTwin City Fan & Blower Guide Specification Plenum Fans: Model MPQS, Direct DriveMoriyasu NguyenNo ratings yet

- Hpac Pools Article2Document6 pagesHpac Pools Article2Moriyasu NguyenNo ratings yet

- 3246es en PDFDocument2 pages3246es en PDFMoriyasu NguyenNo ratings yet

- Aritech Ceiling Mount Sensor Ds PDFDocument2 pagesAritech Ceiling Mount Sensor Ds PDFMoriyasu NguyenNo ratings yet

- Alastair Brockett PresentationDocument65 pagesAlastair Brockett PresentationMoriyasu NguyenNo ratings yet

- Installation Operation MaintenanceDocument64 pagesInstallation Operation MaintenanceMoriyasu NguyenNo ratings yet

- Swegon Inductioin Units Vs Fan Coil UnitsDocument1 pageSwegon Inductioin Units Vs Fan Coil UnitsMoriyasu NguyenNo ratings yet

- Revise Code 10 7 2015Document335 pagesRevise Code 10 7 2015Moriyasu NguyenNo ratings yet

- Upvc Sewer Drainage Systems Product Brochure PDFDocument32 pagesUpvc Sewer Drainage Systems Product Brochure PDFMoriyasu NguyenNo ratings yet

- SG: trình bày: ở bản vẽ ký hiệu và viết tắtDocument1 pageSG: trình bày: ở bản vẽ ký hiệu và viết tắtMoriyasu NguyenNo ratings yet

- 13 - NucleiDocument17 pages13 - Nucleigauthamdoc321No ratings yet

- Assessing Uncertainties of Well-To-Tank GreenhouseDocument27 pagesAssessing Uncertainties of Well-To-Tank GreenhousejoelNo ratings yet

- Laws of Motion NCERT MCQDocument20 pagesLaws of Motion NCERT MCQwixirepNo ratings yet

- Mechanics 2024Document85 pagesMechanics 2024Mawande WandarhNo ratings yet

- TOPICS IN ENERGY, WATER AND EnvironmentDocument21 pagesTOPICS IN ENERGY, WATER AND EnvironmentAhmed KingNo ratings yet

- High Precision PSR Constant Current LED Driver Description FeaturesDocument2 pagesHigh Precision PSR Constant Current LED Driver Description FeaturesVictorUrbinaNo ratings yet

- CRU21035a Esb Networks Standard Prices For Generator Connections 2021Document41 pagesCRU21035a Esb Networks Standard Prices For Generator Connections 2021Muhammad Ashraf Ali AwanNo ratings yet

- AS5590 Dynamic Soaring: Ranjith M., AE, Ranjith.m@iitm - Ac.inDocument18 pagesAS5590 Dynamic Soaring: Ranjith M., AE, Ranjith.m@iitm - Ac.inranjith_mohanNo ratings yet

- T Tad532geDocument8 pagesT Tad532geAhmed AlabsiNo ratings yet

- RT-85 ICU With New Drain Pipe Arrangement (Issue 2, 17-12-2010)Document3 pagesRT-85 ICU With New Drain Pipe Arrangement (Issue 2, 17-12-2010)maxwell333No ratings yet

- Ojt Report Class 11Document19 pagesOjt Report Class 11Lochan SahNo ratings yet

- 01 TurboExpCompAMBDocument40 pages01 TurboExpCompAMBMohamed GamilNo ratings yet

- On-Site Hypochlorite Generating SystemsDocument8 pagesOn-Site Hypochlorite Generating SystemsNguyễn NgọcNo ratings yet

- Lehe20208 00Document3 pagesLehe20208 00practicante crcNo ratings yet

- A1 Key To Component: Diagram, Piping & Instrumentation Ac Nirvana of Hot Discharge-HocDocument2 pagesA1 Key To Component: Diagram, Piping & Instrumentation Ac Nirvana of Hot Discharge-Hocsachin JoshiNo ratings yet

- Solar Quotation ComparisonDocument1 pageSolar Quotation ComparisonTamilselvan BalasubramaniNo ratings yet

- LEC 3-Introduction-to-Building-ServicesDocument10 pagesLEC 3-Introduction-to-Building-Servicesmdnitollamastem12hNo ratings yet

- Surat Penawaran MembershipDocument5 pagesSurat Penawaran MembershipAhmad JauhariNo ratings yet

- FE PresentationOrder-ModDocument8 pagesFE PresentationOrder-ModHrishabhJainNo ratings yet

- CSIR 2021 Circular Economy As Development OpportunityDocument80 pagesCSIR 2021 Circular Economy As Development OpportunitysarikahoosenNo ratings yet

- Mush Winding2Document18 pagesMush Winding2MebreNo ratings yet

- TOTAL WALTHER CI-Technology: Technical ManualDocument140 pagesTOTAL WALTHER CI-Technology: Technical ManualJORDAN LOPEZNo ratings yet

- Low Oil Pressure in A Diesel EngineDocument4 pagesLow Oil Pressure in A Diesel EngineYosephBerhanuNo ratings yet

- ECU MS 4 Sport: Bosch Motorsport ManualDocument23 pagesECU MS 4 Sport: Bosch Motorsport ManualServicios y Repuestos Jeremy Azhael 2320 C.ANo ratings yet

- 4) Arc Welding EquipmentsDocument6 pages4) Arc Welding EquipmentsKrako TramNo ratings yet

- Product Catalogue 2021/22: Your Solution Partner 1978Document12 pagesProduct Catalogue 2021/22: Your Solution Partner 1978BaselNo ratings yet

- Wjr2525t-4025t-13yh3f01 2014Document74 pagesWjr2525t-4025t-13yh3f01 2014Eduardo Álvarez Juárez100% (1)

- BIO UNIT 10.1 (Study Guide)Document22 pagesBIO UNIT 10.1 (Study Guide)Izzy Dynielle SolamilloNo ratings yet

- Class 10 Social Science MCQs Chapter 1 DevelopmentDocument11 pagesClass 10 Social Science MCQs Chapter 1 DevelopmentParveen KumarNo ratings yet

- Phy 10 MergedDocument22 pagesPhy 10 MergedPranav GurjarNo ratings yet