Professional Documents

Culture Documents

KST 279 Rev 0 Titanium

KST 279 Rev 0 Titanium

Uploaded by

Balaram GopalakrishnanCopyright:

Available Formats

You might also like

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (6)

- Draft WPS For Carbon Steel PipeDocument2 pagesDraft WPS For Carbon Steel Pipeabet_singkong893025% (4)

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- The Technology of Mounting and Joining Elements in Case of Metallic Structures Beijing National Stadium (Bird's Nest)Document12 pagesThe Technology of Mounting and Joining Elements in Case of Metallic Structures Beijing National Stadium (Bird's Nest)Matei SilviuNo ratings yet

- Pwps-Gtaw FcawDocument2 pagesPwps-Gtaw FcawAhmed ElsharkawNo ratings yet

- Reliance Engineering Associates (P) Limited Welding Procedure SpecificationDocument1 pageReliance Engineering Associates (P) Limited Welding Procedure SpecificationdeepakNo ratings yet

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- Welding Procedure SpecificationDocument4 pagesWelding Procedure SpecificationBhargav BbvsNo ratings yet

- DS-01 - LR BendsDocument1 pageDS-01 - LR BendsMecon LtdNo ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- HRP Ii WPS STR 225Document4 pagesHRP Ii WPS STR 225RohiNo ratings yet

- WPS 684 CS 012Document3 pagesWPS 684 CS 012siva8000100% (1)

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- DS-02 - LR BendsDocument1 pageDS-02 - LR BendsMecon LtdNo ratings yet

- Request For Welding Procedure ApprovalDocument13 pagesRequest For Welding Procedure ApprovalecsuperalNo ratings yet

- Ultrasonic Testing Report (Structural) (Completed Weld Tubular / Non Tubular)Document3 pagesUltrasonic Testing Report (Structural) (Completed Weld Tubular / Non Tubular)Anna PariniNo ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Fcaw Wps-001a PDFDocument3 pagesFcaw Wps-001a PDFirfan bari100% (1)

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Isw-16b (50SS Finian RD)Document1 pageIsw-16b (50SS Finian RD)Am ENo ratings yet

- Isw-16b (Goldsmith DR - DN50SS)Document1 pageIsw-16b (Goldsmith DR - DN50SS)Am ENo ratings yet

- HRP Ii WPS STR 209aDocument4 pagesHRP Ii WPS STR 209aRohiNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

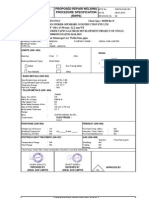

- Rev 2 - Proposed Repair WPSDocument2 pagesRev 2 - Proposed Repair WPSRakesh Patel75% (4)

- HRP Ii WPS STR 299aDocument4 pagesHRP Ii WPS STR 299aRohiNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (2)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Smash Enterprises, Pune SME/PQR/51/20-21/GSU SME/WPS/51/20-21Document3 pagesSmash Enterprises, Pune SME/PQR/51/20-21/GSU SME/WPS/51/20-21Meghan GhoneNo ratings yet

- Revised PWPS 001Document2 pagesRevised PWPS 001stdshopNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Welding Procedure Specification: PQR 2" Dia-5.54mm THKDocument2 pagesWelding Procedure Specification: PQR 2" Dia-5.54mm THKNil BorichaNo ratings yet

- WPS PQR XLSXDocument4 pagesWPS PQR XLSXMd Sahabul IslamNo ratings yet

- Prathna Alloys WC6 Page-2Document1 pagePrathna Alloys WC6 Page-2Kishan ChauhanNo ratings yet

- Request For Welding Procedure ApprovalDocument18 pagesRequest For Welding Procedure Approvalecsuperal100% (1)

- Ce0034-Wps PQR02 E7.62 P01 01 PDFDocument1 pageCe0034-Wps PQR02 E7.62 P01 01 PDFKhaled BouhlelNo ratings yet

- HRP Ii WPS LGP 316Document4 pagesHRP Ii WPS LGP 316RohiNo ratings yet

- IRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Document4 pagesIRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Mostafizur RahmanNo ratings yet

- Welding Procedure Specification: (As Per Asme Sec Ix)Document1 pageWelding Procedure Specification: (As Per Asme Sec Ix)Himanshu SinghNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Abdulmecit YetisNo ratings yet

- 2024 1 U11 Ta24 Pip 064 4 P11806 Ad1 PP UttmDocument3 pages2024 1 U11 Ta24 Pip 064 4 P11806 Ad1 PP Uttminjoker fxNo ratings yet

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit Ghosh100% (1)

- Megha Engineering & Infrastructures Limited. Greenko Ap01 Irep Private LimitedDocument2 pagesMegha Engineering & Infrastructures Limited. Greenko Ap01 Irep Private LimitedABINASH SINGHNo ratings yet

- BH SO 1475630 - General Arrangement Drawing - Rev 03Document9 pagesBH SO 1475630 - General Arrangement Drawing - Rev 03Yasser HamaadNo ratings yet

- KSB MIL Control Valves Specification V0998-SPECDocument36 pagesKSB MIL Control Valves Specification V0998-SPECNutan PowerNo ratings yet

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- Equipment Data Sheet: Type: Doc No: Mds-Pv-01Document3 pagesEquipment Data Sheet: Type: Doc No: Mds-Pv-01Waqas WaqasNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- 45 KL Oil Storage Tank V-102: Mechanical Data Sheet For VesselDocument4 pages45 KL Oil Storage Tank V-102: Mechanical Data Sheet For VesselKrunalNo ratings yet

- WPS - Pre-Insulated PipesDocument4 pagesWPS - Pre-Insulated Pipesharis bhuttoNo ratings yet

- 4 2WPSDocument2 pages4 2WPSsaravanans18910% (1)

- HRP Ii WPS LGP 50aDocument2 pagesHRP Ii WPS LGP 50aRohiNo ratings yet

- Welding Procedure Specification: JOINT (QW-402)Document10 pagesWelding Procedure Specification: JOINT (QW-402)Lipika GayenNo ratings yet

- PIPING WPS and PQRDocument5 pagesPIPING WPS and PQRshibaprasad0115No ratings yet

- VISUALDocument57 pagesVISUALQuang Duan Nguyen100% (4)

- Fit-Up Weld MaterialsDocument42 pagesFit-Up Weld MaterialsEvan Jared L. GalvezNo ratings yet

- Poros Root Cause AnalysisDocument1 pagePoros Root Cause AnalysisMuhamad YusupNo ratings yet

- Acceptance Criteria Level B-B+Document2 pagesAcceptance Criteria Level B-B+Alin TomozeiNo ratings yet

- Welding Procedure Specification: WPS For Repair of Corrod Area (SMAW)Document1 pageWelding Procedure Specification: WPS For Repair of Corrod Area (SMAW)Lipika GayenNo ratings yet

- Fmea Sfe47.005 WeldingDocument8 pagesFmea Sfe47.005 Weldingkumaraswamy.kNo ratings yet

- Precios Dogo Labor Rapifix - 14fDocument111 pagesPrecios Dogo Labor Rapifix - 14fgustavoNo ratings yet

- WPS002 312Document2 pagesWPS002 312proxywarNo ratings yet

- Objective: Metallurgy & Materials Engineering Department University of IndonesiaDocument48 pagesObjective: Metallurgy & Materials Engineering Department University of IndonesiaAulia HafidzNo ratings yet

- Welding Procedure Specification According To EN ISO 15609, 2004Document2 pagesWelding Procedure Specification According To EN ISO 15609, 2004Dimitris NikouNo ratings yet

- F4-WPS PQR Stud WeldingDocument1 pageF4-WPS PQR Stud WeldingBernardo LeorNo ratings yet

- Technical Large RoofTopsDocument48 pagesTechnical Large RoofTopsnairam2003No ratings yet

- ETAK1700FEOJR PT enDocument6 pagesETAK1700FEOJR PT enVasile Ciprian DavidNo ratings yet

- WPS ISO 15614-1 WeldNote MetricDocument1 pageWPS ISO 15614-1 WeldNote MetricVirgil SorcaruNo ratings yet

- Thesis On Welding TechnologyDocument7 pagesThesis On Welding Technologyfjn3d3mc100% (3)

- Welding Equipment Calibration Record 15085-2Document4 pagesWelding Equipment Calibration Record 15085-2AMIT SHAHNo ratings yet

- New Microsoft Excel WorksheetDocument6 pagesNew Microsoft Excel Worksheetravi00098No ratings yet

- ROTORV5No1 2012 FSWAnggerMahrosMarjiDocument13 pagesROTORV5No1 2012 FSWAnggerMahrosMarjiMuhammad Whisnu NugrahaNo ratings yet

- Evers and Sons Inc.: Welding Procedure Specification (WpsDocument3 pagesEvers and Sons Inc.: Welding Procedure Specification (WpsRaja HoneNo ratings yet

- Dung Quat Refinery Project: Welder & Welding Operator Qualification Test CertificateDocument2 pagesDung Quat Refinery Project: Welder & Welding Operator Qualification Test CertificateminhnnNo ratings yet

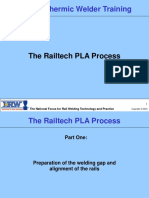

- Gap Preparation and AlignmentDocument16 pagesGap Preparation and AlignmentRadoi OlteanuNo ratings yet

- Front Side Member (Cut-P) : With The Radiator Side Support RemovedDocument5 pagesFront Side Member (Cut-P) : With The Radiator Side Support RemovedThiện NguyênNo ratings yet

- Technology Vocational Livelihood: Shielded Metal Arc WeldingDocument9 pagesTechnology Vocational Livelihood: Shielded Metal Arc WeldingjonquintanoNo ratings yet

- Smaw Module 2ndQ 1stDocument6 pagesSmaw Module 2ndQ 1stAdoracion Sales HugoNo ratings yet

- Welder WQTDocument85 pagesWelder WQTKy100% (1)

- Oil Purification Plants VOP 100 LT/H - 20 000 LT/HDocument6 pagesOil Purification Plants VOP 100 LT/H - 20 000 LT/Hjunaidi.036No ratings yet

- Consumables For Welding Aluminium Alloys.: (Approved in Accordance With Section 9)Document7 pagesConsumables For Welding Aluminium Alloys.: (Approved in Accordance With Section 9)ads_mechNo ratings yet

- Atelier CollectionDocument39 pagesAtelier Collectioncristi_stoiciucNo ratings yet

KST 279 Rev 0 Titanium

KST 279 Rev 0 Titanium

Uploaded by

Balaram GopalakrishnanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KST 279 Rev 0 Titanium

KST 279 Rev 0 Titanium

Uploaded by

Balaram GopalakrishnanCopyright:

Available Formats

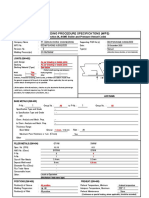

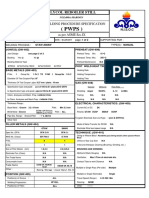

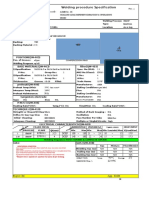

KEPPEL SHIPYARD 1 of 2

WELDING PROCEDURE SPECIFICATION

WPS No: KST 279 Rev. 0 SUPPORTING PQR No: KSTR 279-1, KSTR 279-2

VESSEL: GIMI FLNG PROCESS(ES) : GTAW

CODE/SPECIFICATION (S) : ASME IX :2017 PROCESS TYPE : Manual

MATERIAL DESIGNATIONS: Base Material Qualified: P. NO: 51 to P. NO: 51

ASTM B861 Grade 2 To ASTM B861 Grade 2 Thickness Range Qualified for groove weld: 1.5 mm To 7.82 mm

P. NO: 51 to P. NO: 51 Deposition Range Qualified for GTAW: NA

POSITION: (QW-405) Thickness Range Qualified for fillet : Unlimited.

Position Qualified for Groove Weld : All Dia. Range Qualified : All

Welding Progression : Vertical Uphill

Position(s) of Fillet : All

FILLER MATERIAL CLASSIFICATION SPECIFICATION A.No F.No DIA. (mm) BRAND NAME

TACKING: ** NA NA NA NA NA NA

ROOT/HOT: ERTi-2 AWS A5.16 NA 51 1.6 Revolloy Revofil Ti-2

FILL/CAP: ERTi-2 AWS A5.16 NA 51 1.6 Revolloy Revofil Ti-2

Shielding: ARGON (≥ 99.9%) FLOW RATE (Lts/min): 10~13 NOX

Trailing: ARGON (≥ 99.9%) FLOW RATE (Lts/min): 10~13 NOX

Purging: ARGON (≥ 99.9%) FLOW RATE (Lts/min): 20 NOX

Back Purging Shall be maintained until completion of CAP welding.

Note ** : No Tacking shall be used, Clamps only.

PREHEAT METHOD: NA

MEASURING: Tempilstik or Handheld Thermometer.

EDGE PREPARATION: Machining and Grinding (Iron Free Disc).

INTERUN CLEANING: Cleaning With Acetone(Best Chemical), Wire brushing (Stainless Steel) and Grinding (Iron Free Disc).

WELDING TECHNIQUE: Multi Pass, Maximum single pass layer width 7 mm (GTAW)

GTAW

Electrode Stickout Length : Max 8mm Gas Shroud Diamter: Approx 9mm

Tungsten Electrode Size and Type : 2.4 mm and 2% Thoriated

NOMINAL WALL THICKNESS PREHEAT TEMPERATURE MAX.INTERPASS TEMPERATURE

1.5 to 7.82 mm To Remove Moisture If Required 95°C

TRAVEL

NUMBER DIAMETER AMPERE VOLTAGE. HEAT INPUT

PROCESS POLARITY SPD. BRAND NAME

OF PASS (mm) (A) (V) (kJ/mm)

(mm/min)

Position - ALL

ROOT GTAW DCSP 1.6 56 ~ 62 9 ~ 10 44 ~ 48 0.62 ~ 0.85 Revolloy Revofil Ti-2

HOT GTAW DCSP 1.6 63 ~ 70 9 ~ 10 50 ~ 55 0.62 ~ 0.84 Revolloy Revofil Ti-2

CAP GTAW DCSP 1.6 69 ~ 77 10 ~ 11 56 ~ 62 0.67 ~ 0.91 Revolloy Revofil Ti-2

KSL REPRESENTATIVE CLIENT REPRESENTATIVE REGULATORY REPRESENTATIVE

NAME :_____________________ NAME :_____________________ NAME :_____________________

Witnessed ✔ Reviewed

And found to comply with:

ASME-IX 2017 Edition.

DATE: _____________________ DATE: _____________________ DATE: _____________________

02 July 2022

SIGNATURE: ________________

06.07.2022 Date: 2/7/2022

SIGNATURE: ________________ SIGNATURE: ________________

Sign: KAPR

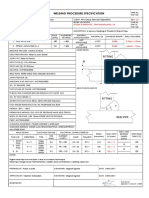

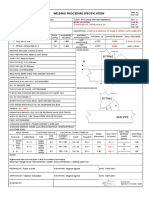

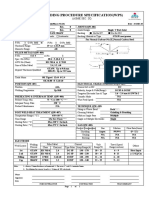

KEPPEL SHIPYARD 2 of 2

WELDING PROCEDURE SPECIFICATION

WPS No: KST 279 Rev. 0 SUPPORTING PQR No: KSTR 279-1, KSTR 279-2

SKETCH OF TYPICAL PREPARATION WELD METAL DEPOSITION SEQUENCE

70°± 2°

Root Face : 1.5 ±0.8mm

Root Gap : 2.0 ~ 4.0mm

S - Fillet Leg size as per fabrication drawing

(Multiple Pass - GTAW)

KSL REPRESENTATIVE CLIENT REPRESENTATIVE REGULATORY REPRESENTATIVE

NAME :_____________________ NAME :_____________________ NAME :_____________________

Witnessed ✔ Reviewed

And found to comply with:

ASME-IX 2017 Edition.

DATE: _____________________ DATE: _____________________ DATE: _____________________

02 July 2022

Date: 2/7/2022

SIGNATURE: ________________ 06.07.2022

SIGNATURE: ________________ SIGNATURE: ________________

Sign: KAPR

You might also like

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (6)

- Draft WPS For Carbon Steel PipeDocument2 pagesDraft WPS For Carbon Steel Pipeabet_singkong893025% (4)

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- The Technology of Mounting and Joining Elements in Case of Metallic Structures Beijing National Stadium (Bird's Nest)Document12 pagesThe Technology of Mounting and Joining Elements in Case of Metallic Structures Beijing National Stadium (Bird's Nest)Matei SilviuNo ratings yet

- Pwps-Gtaw FcawDocument2 pagesPwps-Gtaw FcawAhmed ElsharkawNo ratings yet

- Reliance Engineering Associates (P) Limited Welding Procedure SpecificationDocument1 pageReliance Engineering Associates (P) Limited Welding Procedure SpecificationdeepakNo ratings yet

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- Welding Procedure SpecificationDocument4 pagesWelding Procedure SpecificationBhargav BbvsNo ratings yet

- DS-01 - LR BendsDocument1 pageDS-01 - LR BendsMecon LtdNo ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- HRP Ii WPS STR 225Document4 pagesHRP Ii WPS STR 225RohiNo ratings yet

- WPS 684 CS 012Document3 pagesWPS 684 CS 012siva8000100% (1)

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- DS-02 - LR BendsDocument1 pageDS-02 - LR BendsMecon LtdNo ratings yet

- Request For Welding Procedure ApprovalDocument13 pagesRequest For Welding Procedure ApprovalecsuperalNo ratings yet

- Ultrasonic Testing Report (Structural) (Completed Weld Tubular / Non Tubular)Document3 pagesUltrasonic Testing Report (Structural) (Completed Weld Tubular / Non Tubular)Anna PariniNo ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Fcaw Wps-001a PDFDocument3 pagesFcaw Wps-001a PDFirfan bari100% (1)

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Isw-16b (50SS Finian RD)Document1 pageIsw-16b (50SS Finian RD)Am ENo ratings yet

- Isw-16b (Goldsmith DR - DN50SS)Document1 pageIsw-16b (Goldsmith DR - DN50SS)Am ENo ratings yet

- HRP Ii WPS STR 209aDocument4 pagesHRP Ii WPS STR 209aRohiNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Rev 2 - Proposed Repair WPSDocument2 pagesRev 2 - Proposed Repair WPSRakesh Patel75% (4)

- HRP Ii WPS STR 299aDocument4 pagesHRP Ii WPS STR 299aRohiNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (2)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Smash Enterprises, Pune SME/PQR/51/20-21/GSU SME/WPS/51/20-21Document3 pagesSmash Enterprises, Pune SME/PQR/51/20-21/GSU SME/WPS/51/20-21Meghan GhoneNo ratings yet

- Revised PWPS 001Document2 pagesRevised PWPS 001stdshopNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Welding Procedure Specification: PQR 2" Dia-5.54mm THKDocument2 pagesWelding Procedure Specification: PQR 2" Dia-5.54mm THKNil BorichaNo ratings yet

- WPS PQR XLSXDocument4 pagesWPS PQR XLSXMd Sahabul IslamNo ratings yet

- Prathna Alloys WC6 Page-2Document1 pagePrathna Alloys WC6 Page-2Kishan ChauhanNo ratings yet

- Request For Welding Procedure ApprovalDocument18 pagesRequest For Welding Procedure Approvalecsuperal100% (1)

- Ce0034-Wps PQR02 E7.62 P01 01 PDFDocument1 pageCe0034-Wps PQR02 E7.62 P01 01 PDFKhaled BouhlelNo ratings yet

- HRP Ii WPS LGP 316Document4 pagesHRP Ii WPS LGP 316RohiNo ratings yet

- IRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Document4 pagesIRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Mostafizur RahmanNo ratings yet

- Welding Procedure Specification: (As Per Asme Sec Ix)Document1 pageWelding Procedure Specification: (As Per Asme Sec Ix)Himanshu SinghNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Abdulmecit YetisNo ratings yet

- 2024 1 U11 Ta24 Pip 064 4 P11806 Ad1 PP UttmDocument3 pages2024 1 U11 Ta24 Pip 064 4 P11806 Ad1 PP Uttminjoker fxNo ratings yet

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit Ghosh100% (1)

- Megha Engineering & Infrastructures Limited. Greenko Ap01 Irep Private LimitedDocument2 pagesMegha Engineering & Infrastructures Limited. Greenko Ap01 Irep Private LimitedABINASH SINGHNo ratings yet

- BH SO 1475630 - General Arrangement Drawing - Rev 03Document9 pagesBH SO 1475630 - General Arrangement Drawing - Rev 03Yasser HamaadNo ratings yet

- KSB MIL Control Valves Specification V0998-SPECDocument36 pagesKSB MIL Control Valves Specification V0998-SPECNutan PowerNo ratings yet

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- Equipment Data Sheet: Type: Doc No: Mds-Pv-01Document3 pagesEquipment Data Sheet: Type: Doc No: Mds-Pv-01Waqas WaqasNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- 45 KL Oil Storage Tank V-102: Mechanical Data Sheet For VesselDocument4 pages45 KL Oil Storage Tank V-102: Mechanical Data Sheet For VesselKrunalNo ratings yet

- WPS - Pre-Insulated PipesDocument4 pagesWPS - Pre-Insulated Pipesharis bhuttoNo ratings yet

- 4 2WPSDocument2 pages4 2WPSsaravanans18910% (1)

- HRP Ii WPS LGP 50aDocument2 pagesHRP Ii WPS LGP 50aRohiNo ratings yet

- Welding Procedure Specification: JOINT (QW-402)Document10 pagesWelding Procedure Specification: JOINT (QW-402)Lipika GayenNo ratings yet

- PIPING WPS and PQRDocument5 pagesPIPING WPS and PQRshibaprasad0115No ratings yet

- VISUALDocument57 pagesVISUALQuang Duan Nguyen100% (4)

- Fit-Up Weld MaterialsDocument42 pagesFit-Up Weld MaterialsEvan Jared L. GalvezNo ratings yet

- Poros Root Cause AnalysisDocument1 pagePoros Root Cause AnalysisMuhamad YusupNo ratings yet

- Acceptance Criteria Level B-B+Document2 pagesAcceptance Criteria Level B-B+Alin TomozeiNo ratings yet

- Welding Procedure Specification: WPS For Repair of Corrod Area (SMAW)Document1 pageWelding Procedure Specification: WPS For Repair of Corrod Area (SMAW)Lipika GayenNo ratings yet

- Fmea Sfe47.005 WeldingDocument8 pagesFmea Sfe47.005 Weldingkumaraswamy.kNo ratings yet

- Precios Dogo Labor Rapifix - 14fDocument111 pagesPrecios Dogo Labor Rapifix - 14fgustavoNo ratings yet

- WPS002 312Document2 pagesWPS002 312proxywarNo ratings yet

- Objective: Metallurgy & Materials Engineering Department University of IndonesiaDocument48 pagesObjective: Metallurgy & Materials Engineering Department University of IndonesiaAulia HafidzNo ratings yet

- Welding Procedure Specification According To EN ISO 15609, 2004Document2 pagesWelding Procedure Specification According To EN ISO 15609, 2004Dimitris NikouNo ratings yet

- F4-WPS PQR Stud WeldingDocument1 pageF4-WPS PQR Stud WeldingBernardo LeorNo ratings yet

- Technical Large RoofTopsDocument48 pagesTechnical Large RoofTopsnairam2003No ratings yet

- ETAK1700FEOJR PT enDocument6 pagesETAK1700FEOJR PT enVasile Ciprian DavidNo ratings yet

- WPS ISO 15614-1 WeldNote MetricDocument1 pageWPS ISO 15614-1 WeldNote MetricVirgil SorcaruNo ratings yet

- Thesis On Welding TechnologyDocument7 pagesThesis On Welding Technologyfjn3d3mc100% (3)

- Welding Equipment Calibration Record 15085-2Document4 pagesWelding Equipment Calibration Record 15085-2AMIT SHAHNo ratings yet

- New Microsoft Excel WorksheetDocument6 pagesNew Microsoft Excel Worksheetravi00098No ratings yet

- ROTORV5No1 2012 FSWAnggerMahrosMarjiDocument13 pagesROTORV5No1 2012 FSWAnggerMahrosMarjiMuhammad Whisnu NugrahaNo ratings yet

- Evers and Sons Inc.: Welding Procedure Specification (WpsDocument3 pagesEvers and Sons Inc.: Welding Procedure Specification (WpsRaja HoneNo ratings yet

- Dung Quat Refinery Project: Welder & Welding Operator Qualification Test CertificateDocument2 pagesDung Quat Refinery Project: Welder & Welding Operator Qualification Test CertificateminhnnNo ratings yet

- Gap Preparation and AlignmentDocument16 pagesGap Preparation and AlignmentRadoi OlteanuNo ratings yet

- Front Side Member (Cut-P) : With The Radiator Side Support RemovedDocument5 pagesFront Side Member (Cut-P) : With The Radiator Side Support RemovedThiện NguyênNo ratings yet

- Technology Vocational Livelihood: Shielded Metal Arc WeldingDocument9 pagesTechnology Vocational Livelihood: Shielded Metal Arc WeldingjonquintanoNo ratings yet

- Smaw Module 2ndQ 1stDocument6 pagesSmaw Module 2ndQ 1stAdoracion Sales HugoNo ratings yet

- Welder WQTDocument85 pagesWelder WQTKy100% (1)

- Oil Purification Plants VOP 100 LT/H - 20 000 LT/HDocument6 pagesOil Purification Plants VOP 100 LT/H - 20 000 LT/Hjunaidi.036No ratings yet

- Consumables For Welding Aluminium Alloys.: (Approved in Accordance With Section 9)Document7 pagesConsumables For Welding Aluminium Alloys.: (Approved in Accordance With Section 9)ads_mechNo ratings yet

- Atelier CollectionDocument39 pagesAtelier Collectioncristi_stoiciucNo ratings yet