Professional Documents

Culture Documents

Analisa Cold Forming For Overlay Plate

Analisa Cold Forming For Overlay Plate

Uploaded by

ary jordanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analisa Cold Forming For Overlay Plate

Analisa Cold Forming For Overlay Plate

Uploaded by

ary jordanCopyright:

Available Formats

PANALLOY METAL ENGINEERING

Expert in Metal Repairing and Problem Solving of Industrial Equipments

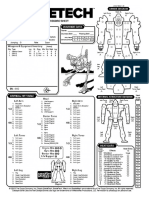

COLD FORMING PRE_ANALYSIS

ON MATERIAL OVERLAY PLATE WITH HARDNESS 58-62 HRC

and PLATE THICKNESS 10+9 MM

FOR BUCKET LOADER

PT.KOMATSU INDONESIA

Prepared By:

Hadi Sarono

Ary Jordan

Ir.Iwan Pandji Purnama

Bekasi, September 23TH 2022

PT.PANALLOY METAL ENGINEERING

Head Office : Perum Gramapuri Taman Sari Blok B1 No 19,Desa Wanasari, Cibitung Bekasi

HP. 08111870894, 082111867152

Workshop: Bandung, Purwakarta, Subang.

September 07, 2022

PANALLOY METAL ENGINEERING

Expert in Metal Repairing and Problem Solving of Industrial Equipments

This guide provides practical information on how to

cut, form and fabricate wear resistant overlay

plates. Unless otherwise indicated, the procedures

described apply to standard compositional grades

of overlay with structural carbon steel

substrates. Special instructions for overlay plate

with, for example, high strength or stainless alloy

substrates are provided where applicable.

Overlay Plate Ranges

The overlay plate range has been developed to

combat abrasion, erosion and impact at either

ambient or elevated temperatures. The range

comprises different hardfacing chromium carbide

alloys deposited on to a carbon steel or alloy

substrate.

The recommended method of cutting overlay plate

is by plasma-arc, as the high chromium and carbon

contents of the hardfacing overlay preclude the use

of oxy-fuel and most mechanical means. The

special properties of the very hard overlay alloy and

a ductile substrate allows these materials to be

formed and fabricated into complex shapes,

including concave or convex curves.

Wear resistant liners may be installed into

structures using a variety of methods including plug

welding. Fabrications can be produced by

conventional welding of the carbon steel substrate.

PT.PANALLOY METAL ENGINEERING

Head Office : Perum Gramapuri Taman Sari Blok B1 No 19,Desa Wanasari, Cibitung Bekasi

HP. 08111870894, 082111867152

Workshop: Bandung, Purwakarta, Subang.

PANALLOY METAL ENGINEERING

Expert in Metal Repairing and Problem Solving of Industrial Equipments

COLD FORMING

Hardfacing

Figure 1

Wherever possible roll in the direction

of the overlay beads

Convex forming has the effect of increasing

Figure 2 Hardfacing and/or widening the stress relief cracks

within the alloy facing. Experience shows

convex that this should not present problems if the

minimum recommended radius is not

exceeded. Above this figure there is an

increasing chance of spalling and crack

propagation into the carbide steel/substrate.

Hardfacing

Concave forming puts the alloy facing into

concave compression and the substrate into tension

and has the effect on closing the stress relief

cracks within the the alloy facing. The high

compressive strength of the overlay

combined with the ductility of the substrate

allows far small diameters to be formed.

Direction of Rolling

Wherever possible, plates should be formed with the weld beads aligned in the direction of

rolling. (See figure 1).

Minimum Diameters

The minimum recommended diameter to which overlay plate can be formed will depend on

the thickness of the plate, the type of substrate and whether the bend is concave (alloy

facing on the inside) or convex (alloy facing on the outside). See figure 2.

PT.PANALLOY METAL ENGINEERING

Head Office : Perum Gramapuri Taman Sari Blok B1 No 19,Desa Wanasari, Cibitung Bekasi

HP. 08111870894, 082111867152

Workshop: Bandung, Purwakarta, Subang.

PANALLOY METAL ENGINEERING

Expert in Metal Repairing and Problem Solving of Industrial Equipments

The table below shows typical minimum diameters for cold forming* Overlay Plate.

Nominal Subtrate Minimum Diameter Minimum Diameter

Overlay Plate

Thicknesse Concave Convex

Single Layer

Overlays from (3.2- 9.5mm (3/8”) 400mm (16”) 250mm (10”)

6.3mm) 1/8”-2/8”

Double Layer

Overlays from (8.0- 12.5mm (1/2”) 450mm (18”) 400mm (16”)

12.5mm) 5/16”-3/8”

When using pyramid or pinch rolls, it is recommended that the top roll is protected with a sleeve

to prevent damage to the hardfacing. This should be fabricated from 12 mm (1/2") thick carbon

steel and sized approximately 50 mm (2") larger than the roll diameter to facilitate installation and

removal and to prevent binding.

When using a brake press from small diameter pipe, cones and square to round transitions, it is

recommended that a hydraulic press is employed for the best results. Forming can be carried out

with a male and female die, using a radiused top tool (min. 38cm/ 11/2") over a 'V' block.

FABRICATION

Flat profiles and formed sections can be fabricated into larger items or finished structures using

conventional welding procedures. Liners may be fixed to existing structures by bolting or by

various welding techniques.

Figure 3

3 mm (1/16”) min

Incorrect Correct

Ensure that the fillet does not overlap the hardfacing by stopping it above 3mm (1/16") below the interface.

PT.PANALLOY METAL ENGINEERING

Head Office : Perum Gramapuri Taman Sari Blok B1 No 19,Desa Wanasari, Cibitung Bekasi

HP. 08111870894, 082111867152

Workshop: Bandung, Purwakarta, Subang.

PANALLOY METAL ENGINEERING

Expert in Metal Repairing and Problem Solving of Industrial Equipments

Methods of attachment – Fillet Welding

The easiest method for attaching overlay plate to an existing structure is by a fillet weld. Care

should be taken to ensure that the weld is applied to the substrate only and does not overlay the

hardfacing or it's penetration, as this can lead to carbon contamination and embrittlement of the

weld. This is best achieved by stopping the fillet approximately 3mm (1/8") below the alloy/base

plate interface which should be clearly visible on a ground edge.

Any common welding process may be used including:

Shielded metal arc welding (US - SMAW) / Manual metal arc welding (UK - MMA)

Gas metal arc welding (GMAW) using solid wire.

Flux cored arc welding (FCAW) using gas shielded or open arc wires.

Selection of welding rods/wires

Where the overlaid plate has a standard carbon steel substrate and the structure onto which the

plate is to be attacked also comprises carbon steel or a steel which does not require preheat, the

following types of consumables may be used:

Coated rods: AWS A5.1 - E7016 EN499 E424 B12HS or E7018 EN499 E463 B32HS

Solid Wire for CO2 welding: AWS A5.18 - ER70S-3 EN440 G/W 2Si or ER70S-6 EN440

G3 Si1

Flux cored wires: AWS A5.20 - E70T-1 EN758 T460 RC3H10 or E71T-1 EN758 T463

PM1HS

If the structural member requires preheat, either because of it's chemical composition, yield

strength or thickness, a grade of welding rod or wire should be selected compatible with normal

practice for that base material:

For example: AWS A5.5 - E8018B2 (EN 1599 ECr.Mo1 B32HS)

If the Red Dog overlay has a stainless or alloy steel substrate and the structure to which it is to

be welding is a high alloy manganese steel, through-hardened steel or a type AISI-410 or 304

stainless alloy, then a suitable dissimilar metal alloy suck as a AWS A5.4 - E309 (EN1600 E23.12

LR21) stainless type rod (electrode) or wire should be used.

PT.PANALLOY METAL ENGINEERING

Head Office : Perum Gramapuri Taman Sari Blok B1 No 19,Desa Wanasari, Cibitung Bekasi

HP. 08111870894, 082111867152

Workshop: Bandung, Purwakarta, Subang.

PANALLOY METAL ENGINEERING

Expert in Metal Repairing and Problem Solving of Industrial Equipments

Methods of attachment - Plug Welding

Figure 4

Overlay plate can be attached to another plate or structure by plug welding through a series of

holes. Each hole should have a minimum 25mm (1 inch diameter, typically set at between 300mm

- 600mm (12-24") spacing.

Fixing holes should be cut by either carbon-arc gouging or plasma-arc cutting from the substrate

side where possible to prevent chromium and carbon contaminating the carbon steel. When

gouging plates thicker than 9.5mm (3/8") it is recommended that a hole is first drilled into the

substrate to stop just short of the alloy interface before gouging is started.

All slag should be removed from the fixing holes by grinding or chipping/hammering.

The plate is then attached to the structure by welding the outside diameter of the hole through

360 degrees and then filing the remaining space using the pattern shown in figure 4.

The thickness of the weld should be determined using the same criteria as for fillet welding and

should stop 3mm (1/8") short of the overlay alloy layer. When the weld has been filled to the

desired level, it can be protected from abrasion by 'capping' with a suitable wear resistant alloy

using Red Dog Armolloy tubular hardfacing rods (electrodes).

STRUCTURAL WELDING

Overlay plate can be fabricated by welding the mild steel substrate using standard mild steel or

low hydrogen electrodes. The following details are a general guide to welding Overlay plate.

Care must be taken to ensure that all structural welds stop short of the hardfacing alloy layer. The

only welding carried out on the hardfaced side of the plate will involve the capping of joints, for

wear protection, with a compatible hardfacing electrode.

PT.PANALLOY METAL ENGINEERING

Head Office : Perum Gramapuri Taman Sari Blok B1 No 19,Desa Wanasari, Cibitung Bekasi

HP. 08111870894, 082111867152

Workshop: Bandung, Purwakarta, Subang.

PANALLOY METAL ENGINEERING

Expert in Metal Repairing and Problem Solving of Industrial Equipments

Fillet welds

Grind the edge of the plate to remove any slag and scale left from cutting. Care should be taken

to ensure that the weld is applied to the substrate only and does not overlap the hardfacing or it's

penetration zone, as this can lead to carbon contamination and embrittlement of the weld and the

adjacent area. This is best achieved by stopping the fillet approximately 3mm (1/8") below the

overlay/base plate interface which should be clearly visible on a ground edge. (See figure 3).

Butt Welds

Partial penetration butt welds involve cutting

3mm (1/16”) a bevel into the carbon steel base by

gouging or flame cutting (see figure 5).

Figure 5

A 2mm to 3mm (1/16-1/8") 'land' should be

2 mm (1/16”) - 3mm (1/8”) left to prevent burn-through to the hardfaced

layer when welding (see figure 6). Fit and

tack sections, then weld using the same

Figure 6 technique as conventional joining.

Full penetration butt welds require the

6 mm (1/4”) min

hardfacing (including alloy penetration zone

see figure 8) to be completely removed from

the joint area by grinding/gouging back to at

least 6mm (1/4") past the weld joint area. Fit

and tack the bevelled sections, then using

Figure 7 the same technique as conventional joining.

PT.PANALLOY METAL ENGINEERING

Head Office : Perum Gramapuri Taman Sari Blok B1 No 19,Desa Wanasari, Cibitung Bekasi

HP. 08111870894, 082111867152

Workshop: Bandung, Purwakarta, Subang.

PANALLOY METAL ENGINEERING

Expert in Metal Repairing and Problem Solving of Industrial Equipments

Welding Technique and Consumable Selection

The root pass must not melt through the 'land' into the hardfacing as this will lead to carbon

contamination and embrittlement of the weld.

Welding consumables commonly used for structural welding of C-Mn steels should be employed

and conventional welding procedures/techniques should be used.

For example:

AWS 5.1 E7018 (SMAW)

AWS A5.18 E703-6 (GMAW) with75% Argon 25% CO²

AWS A5.20 E70T-1 (FCAW)

Note: Where the fabrication proves difficult to align with sufficient accuracy to ensure that no

contamination by the hardfacing is likely during welding, it is recommended that a 309 type

stainless steel welding rod (electrode) be used.

TRITEN™ ENGINEERING GUIDE

SUMMARY OF PROCEDURES

Always use a radiused top tool when forming a press brake.

Ensure that no hardfacing can contaminate the welds. If in doubt, use a AWS A5.4 -

E309 Stainless steel consumable during fabrication.

Use conventional welding consumables and procedures for fabrication to match the

substrate requirements.

Cap joints on the facing side with a matching hardfacing electrode by recommendation.

PT.PANALLOY METAL ENGINEERING

Head Office : Perum Gramapuri Taman Sari Blok B1 No 19,Desa Wanasari, Cibitung Bekasi

HP. 08111870894, 082111867152

Workshop: Bandung, Purwakarta, Subang.

You might also like

- PSC NotesDocument87 pagesPSC Notessarath156No ratings yet

- A Comprehensive Review On Pre and Post-Forming Evaluation of Aluminum To Steel BlanksDocument22 pagesA Comprehensive Review On Pre and Post-Forming Evaluation of Aluminum To Steel Blanksjose ramirez cruzNo ratings yet

- Reinforcing Steel in Slabs On Grade - tcm45-346883Document3 pagesReinforcing Steel in Slabs On Grade - tcm45-346883gurpreets_807665No ratings yet

- TB29 - Deckform Sept 02Document2 pagesTB29 - Deckform Sept 02Ravinesh SinghNo ratings yet

- Composite Alloy Wear Parts For Use in The Mining IndustryDocument7 pagesComposite Alloy Wear Parts For Use in The Mining IndustryDon_GostavitoNo ratings yet

- Sandwich Panels 2006 Special1Document4 pagesSandwich Panels 2006 Special1haidardiwantara83No ratings yet

- Cavitation Erosion Resistance ofDocument5 pagesCavitation Erosion Resistance ofSalem GarrabNo ratings yet

- Rust Mill Scale and Other Surface Contaminants - ETN-M-5-14Document8 pagesRust Mill Scale and Other Surface Contaminants - ETN-M-5-14ali tahaNo ratings yet

- Field Guide For Rust On Reinforcing BarsDocument4 pagesField Guide For Rust On Reinforcing Barsragunas tatyaNo ratings yet

- MES Die Castings Design and Specification Guide: Delivery Engineered SolutionsDocument12 pagesMES Die Castings Design and Specification Guide: Delivery Engineered SolutionsRafał Lesiczka100% (1)

- pp69-72 MSI10Document4 pagespp69-72 MSI10imetallurgyNo ratings yet

- Introduction and Perspectives: Why Carburize Case-Harden?Document10 pagesIntroduction and Perspectives: Why Carburize Case-Harden?Denis Yasmin AlineNo ratings yet

- VijayaKumar2014 Article IdentificationOfSuitableProcesDocument11 pagesVijayaKumar2014 Article IdentificationOfSuitableProcesCyril Joseph DanielNo ratings yet

- G Mohan 2021 Eng. Res. Express 3 025023Document13 pagesG Mohan 2021 Eng. Res. Express 3 025023DilipSinghNo ratings yet

- Crsi Technical Rebar GuideDocument4 pagesCrsi Technical Rebar Guideحسن كاظم ريسان B-4No ratings yet

- Engineered Casting Solutions 2006 CastinDocument6 pagesEngineered Casting Solutions 2006 CastinMandeep SinghNo ratings yet

- ETN-M-5-14 Rust, Mill Scale, and Other Surface Contaminants On Steel Reinforcing BarsDocument8 pagesETN-M-5-14 Rust, Mill Scale, and Other Surface Contaminants On Steel Reinforcing BarsOmarMageedNo ratings yet

- 1 s2.0 S2214860420310617 MainDocument18 pages1 s2.0 S2214860420310617 Main戴海龙No ratings yet

- Improvements To Portal Frame Design Using Stressed Skin Action of Sandwich PanelsDocument13 pagesImprovements To Portal Frame Design Using Stressed Skin Action of Sandwich Panelsmehdi_hoseineeNo ratings yet

- Wall-Colmonoy Wallex-12 ENG January2021Document3 pagesWall-Colmonoy Wallex-12 ENG January2021pranav kariaNo ratings yet

- Seminor On Prestressed ConcreteDocument43 pagesSeminor On Prestressed ConcreteNatarajan SaravananNo ratings yet

- Various Types of Jacketing in Construction. - CivilwalaDocument15 pagesVarious Types of Jacketing in Construction. - CivilwalaJhon shonNo ratings yet

- Design of Prestressed Concrete Pressure PipeDocument14 pagesDesign of Prestressed Concrete Pressure Pipeunix0123No ratings yet

- Clad Construction TiFabDocument6 pagesClad Construction TiFabJaison JoseNo ratings yet

- Journal Article - Comparison RCC - CompositeDocument6 pagesJournal Article - Comparison RCC - CompositeSri KayNo ratings yet

- MasterBond EpoxiesDocument4 pagesMasterBond EpoxiesPinakin PatelNo ratings yet

- Shearwall BE Debonding 990108Document11 pagesShearwall BE Debonding 990108Saeed TariverdiloNo ratings yet

- Preloaded Bolting: (Image Courtesy of Mabey Bridge LTD.)Document9 pagesPreloaded Bolting: (Image Courtesy of Mabey Bridge LTD.)Benjamin IndrawanNo ratings yet

- 3 Other Design RequirementDocument2 pages3 Other Design RequirementRajan_2010No ratings yet

- 10.1515 - JMBM 2022 0006Document12 pages10.1515 - JMBM 2022 0006jiji wangNo ratings yet

- GSS 008-2020 - WHY CHROME (CR) SHOULD BE BELOW 0.30%Document3 pagesGSS 008-2020 - WHY CHROME (CR) SHOULD BE BELOW 0.30%SANJAY AGARWALNo ratings yet

- 05catpg358 PDFDocument1 page05catpg358 PDFBanksyNo ratings yet

- 19 Framework Design and Metal Selection For Metal-Ceramic RestorationsmicDocument27 pages19 Framework Design and Metal Selection For Metal-Ceramic RestorationsmicCarlissyaNo ratings yet

- Nagesh KulkarniferrocementDocument9 pagesNagesh KulkarniferrocementFreddie KooNo ratings yet

- TQIWPJS0ON 9 Aluminium ExtrusionDocument3 pagesTQIWPJS0ON 9 Aluminium Extrusionlamia97No ratings yet

- Cladding in Heat Exchanger - BaherDocument3 pagesCladding in Heat Exchanger - BaherWael MansourNo ratings yet

- Corrosive Protective CoatingsDocument6 pagesCorrosive Protective CoatingsMarcelo MinaNo ratings yet

- (2019) QuyenDocument3 pages(2019) QuyenJMarce16No ratings yet

- Pubs 91518021Document16 pagesPubs 91518021Yogi173No ratings yet

- Ni HardMaterialDataandApplications 11017 PDFDocument28 pagesNi HardMaterialDataandApplications 11017 PDFhesamalaNo ratings yet

- Strength of Concrete Structure Partial Replacement of Sand by Copper SlagDocument6 pagesStrength of Concrete Structure Partial Replacement of Sand by Copper SlagEditor IJTSRDNo ratings yet

- Casting Steel Alloys PDFDocument6 pagesCasting Steel Alloys PDFIAmaeyNo ratings yet

- Welding - SteelConstructionDocument19 pagesWelding - SteelConstructionsiroliver39No ratings yet

- SRIA TN42-2 Welding of ReinforcementDocument2 pagesSRIA TN42-2 Welding of ReinforcementMoh IsmailNo ratings yet

- 129 - Download - Application of Corrosion Protection TechniqueDocument4 pages129 - Download - Application of Corrosion Protection TechniqueAli BahraniNo ratings yet

- Dependence of Overload Performance Spot 2008Document6 pagesDependence of Overload Performance Spot 2008Vipin MishraNo ratings yet

- Galvanizing For Corrosion Protection (AGA)Document18 pagesGalvanizing For Corrosion Protection (AGA)Abrianto AkuanNo ratings yet

- Dimension Stone Cladding Design - Dowel Anchorage Design: Conference PaperDocument15 pagesDimension Stone Cladding Design - Dowel Anchorage Design: Conference PaperYusuf TrunkwalaNo ratings yet

- Effect of Case Depth On Fatigue Performance of AISI 8620 Carburized SteelDocument7 pagesEffect of Case Depth On Fatigue Performance of AISI 8620 Carburized SteelthisisjineshNo ratings yet

- Strength Properties of Steel Slag in Concrete IJERTV6IS110046 PDFDocument5 pagesStrength Properties of Steel Slag in Concrete IJERTV6IS110046 PDFMâjñù MâjñúNo ratings yet

- 1 s2.0 S2352012421004422 MainDocument12 pages1 s2.0 S2352012421004422 Mainshashank chandraNo ratings yet

- LPFW Huffman KaserDocument4 pagesLPFW Huffman KaserAndrey Gyrych100% (1)

- Analysis and Design of Residential Using EtabsDocument2 pagesAnalysis and Design of Residential Using Etabsinnovative technologiesNo ratings yet

- 2023 Solid-State Welding of Aluminum To Magnesium Alloys A ReviewDocument23 pages2023 Solid-State Welding of Aluminum To Magnesium Alloys A Reviewguravshubham7777No ratings yet

- HH 1Document2 pagesHH 1mirzakamranbaig.mkNo ratings yet

- 1 s2.0 S0257897221006563 MainDocument8 pages1 s2.0 S0257897221006563 Maintaufikrosly5750No ratings yet

- Austempering, A Heat Treating Process Ideal For Many High-Wear Applications, Is Not Just For Ductile IronDocument4 pagesAustempering, A Heat Treating Process Ideal For Many High-Wear Applications, Is Not Just For Ductile IronLizbeth Huerta LarumbeNo ratings yet

- Effect of Orientation, Thickness, and Composition On Properties of Ductile Iron CastingsDocument12 pagesEffect of Orientation, Thickness, and Composition On Properties of Ductile Iron CastingsHemal JalavadiaNo ratings yet

- Irjet V3i523Document4 pagesIrjet V3i523anon_294850851No ratings yet

- B.Sc. in CBZDocument97 pagesB.Sc. in CBZShravani SalunkheNo ratings yet

- Carbide GradesDocument51 pagesCarbide GradesRicardo BravoNo ratings yet

- Radio Propagation and Network PlanningDocument46 pagesRadio Propagation and Network Planningمحمد فاضلNo ratings yet

- What Is The Commutation ProcessDocument3 pagesWhat Is The Commutation Processكرار قاسم صبيح ابنيانNo ratings yet

- The Formation of Heavier Elements During Star Formation and EvolutionDocument8 pagesThe Formation of Heavier Elements During Star Formation and EvolutionJohn Nerlo DequiñaNo ratings yet

- Department of M Echanical and Industrial Engineering M I 205: Fluid M Echanics Tutorial 5Document1 pageDepartment of M Echanical and Industrial Engineering M I 205: Fluid M Echanics Tutorial 5Ashutosh SinghNo ratings yet

- Relay S-3PH From 30A To 40A: Power ControllerDocument4 pagesRelay S-3PH From 30A To 40A: Power ControllerPrecila CanobidaNo ratings yet

- Elevator Control Valves: EN ISO 9001Document6 pagesElevator Control Valves: EN ISO 9001Jibjab7No ratings yet

- Electrical Layout Design in BuildingDocument15 pagesElectrical Layout Design in BuildingIlam ShresthaNo ratings yet

- PumpDocument25 pagesPumpIbrahim AhmedNo ratings yet

- Long Answer Questions - CHP 'Sound'Document4 pagesLong Answer Questions - CHP 'Sound'SaachiNo ratings yet

- Module 1-18EE53-NotesDocument20 pagesModule 1-18EE53-NotesAshwiniNo ratings yet

- PolyflameDocument2 pagesPolyflameumn_mlkNo ratings yet

- 0 Solid Liquid Gas Synthetic: The Periodic Table of ElementsDocument1 page0 Solid Liquid Gas Synthetic: The Periodic Table of ElementsDragos AndrianaNo ratings yet

- Annexure-1 Grid Transformer Recommendation - DelCEN 2500 HVDocument2 pagesAnnexure-1 Grid Transformer Recommendation - DelCEN 2500 HVSAEL SOLARNo ratings yet

- Experiment No. 01: Single Phase Half Wave Rectification With Inductive Load Psychomotor Skill Level: P4 Name: Roll NoDocument8 pagesExperiment No. 01: Single Phase Half Wave Rectification With Inductive Load Psychomotor Skill Level: P4 Name: Roll NoRana EhsanNo ratings yet

- Putnam 2019Document1 pagePutnam 2019Andrew CourtneyNo ratings yet

- LEDW UL2 UL1R 3AR Eng Rev22Document143 pagesLEDW UL2 UL1R 3AR Eng Rev22david1210712No ratings yet

- Radiographic-Testing-Level-2-Non-Destructive-Testing-And-Evaluation (Set 2)Document12 pagesRadiographic-Testing-Level-2-Non-Destructive-Testing-And-Evaluation (Set 2)thakurlaboratoriesNo ratings yet

- Cbse - Maths - Pre - Final - Iii (Standard) - Set - 2 - KeyDocument18 pagesCbse - Maths - Pre - Final - Iii (Standard) - Set - 2 - Keybdsouza899No ratings yet

- MinorDocument4 pagesMinorSarrahNo ratings yet

- BMEN 301 F2021 Module 3-The Mechanics of Soft TissueDocument18 pagesBMEN 301 F2021 Module 3-The Mechanics of Soft TissueAyesha ANo ratings yet

- Machine Model GENPWTwoAxisDocument1 pageMachine Model GENPWTwoAxisManuelNo ratings yet

- HECPS Generator Circuit-Breakers: Unique Solution For Pumped Storage Power PlantsDocument13 pagesHECPS Generator Circuit-Breakers: Unique Solution For Pumped Storage Power Plantshamza shahzadNo ratings yet

- Rish Split Current TransformerDocument6 pagesRish Split Current TransformerluisNo ratings yet

- Basic Mechanical Engineering MCQs PartDocument11 pagesBasic Mechanical Engineering MCQs PartTrbman exaNo ratings yet

- TGD Part EDocument88 pagesTGD Part EOlivia SaferNo ratings yet

- Time Domain AnalysisDocument14 pagesTime Domain AnalysisAbdullah MdNo ratings yet

- Locust LCT-1SDocument1 pageLocust LCT-1StehMaevNo ratings yet

- Infrared Target-Flare Discrimination Using A ZISC Hardware Neural NetworkDocument67 pagesInfrared Target-Flare Discrimination Using A ZISC Hardware Neural NetworkBlaze123xNo ratings yet