Professional Documents

Culture Documents

Accomplishment Instructions of CFM56 - 7B - SB - REV - 72-0636

Accomplishment Instructions of CFM56 - 7B - SB - REV - 72-0636

Uploaded by

aliCopyright:

Available Formats

You might also like

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- BOP TL Operation and Maintenance ManualDocument22 pagesBOP TL Operation and Maintenance Manualadvantage02580% (5)

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Operations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0Document18 pagesOperations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0dowel hernandezNo ratings yet

- Speed Tape Airbus - Descent & ArrivalDocument4 pagesSpeed Tape Airbus - Descent & Arrivalapi-3805097100% (29)

- Unit Injector - Install: Disassembly and AssemblyDocument13 pagesUnit Injector - Install: Disassembly and AssemblyAnung Nugroho100% (1)

- Mechanical Interview Jgc-KjoDocument6 pagesMechanical Interview Jgc-Kjonaveed7861100% (1)

- Boeing 777 Amm Refrences 2Document7 pagesBoeing 777 Amm Refrences 2tauqir73100% (1)

- SEBF 8164 гизьзы 3500Document19 pagesSEBF 8164 гизьзы 3500Aminadav100% (1)

- 2020 AMC ProgramDocument247 pages2020 AMC ProgramaliNo ratings yet

- A320 Automation PDFDocument1 pageA320 Automation PDFaliNo ratings yet

- Engine Yearbook 2017Document5 pagesEngine Yearbook 2017ali100% (1)

- Achivment Cwcs - cfm56Document16 pagesAchivment Cwcs - cfm56aliNo ratings yet

- Combustor Cwcs - cfm56Document21 pagesCombustor Cwcs - cfm56ali100% (3)

- 7B - MyCFMportal - CFM Symposium 2017Document14 pages7B - MyCFMportal - CFM Symposium 2017aliNo ratings yet

- Chapter 6 Work, Energy and PowerDocument12 pagesChapter 6 Work, Energy and PowerZhu Jiankun100% (1)

- Accomplishment of SB 72-1074Document7 pagesAccomplishment of SB 72-1074aliNo ratings yet

- Scanned by CamscannerDocument10 pagesScanned by CamscannerChandrashekhar KalyankarNo ratings yet

- Q400.amm (76) .Amm72 00 00 290 805Document30 pagesQ400.amm (76) .Amm72 00 00 290 805sasivannanNo ratings yet

- ASB 412-09-137A Page 1 of 10 Approved For Public ReleaseDocument10 pagesASB 412-09-137A Page 1 of 10 Approved For Public Releasesebastian eduardoNo ratings yet

- Aw119mkii, Ata 64-11Document10 pagesAw119mkii, Ata 64-11Christian Hennigs GoldbergNo ratings yet

- CFM56 7B SB Rev 72-0986 TSN.03 R 20181030Document15 pagesCFM56 7B SB Rev 72-0986 TSN.03 R 20181030aliNo ratings yet

- TASK 72-00-00-200-802, Borescope InspectionDocument34 pagesTASK 72-00-00-200-802, Borescope InspectionNestor LucianiNo ratings yet

- Ejemplo de Boletin de ServicioDocument11 pagesEjemplo de Boletin de ServicioCarlos AnguianoNo ratings yet

- TC 38 - Rev02 (1) SIDE BUFFER GREASEDocument11 pagesTC 38 - Rev02 (1) SIDE BUFFER GREASEnasirzeal990No ratings yet

- ASB 429-19-50 Page 1 of 9 Approved For Public ReleaseDocument9 pagesASB 429-19-50 Page 1 of 9 Approved For Public Releaserio tanoneNo ratings yet

- CFM56 5B SB Rev 72-1092 TSN.00 N 20201210Document20 pagesCFM56 5B SB Rev 72-1092 TSN.00 N 20201210Irfan05No ratings yet

- Manual For 1215 Kva Rig AlternatorDocument18 pagesManual For 1215 Kva Rig Alternatorprem080910No ratings yet

- MODEL 150 SERIES (1969 - 1976) : Supplemental Inspection Number: 57-11-01 1. TitleDocument2 pagesMODEL 150 SERIES (1969 - 1976) : Supplemental Inspection Number: 57-11-01 1. TitleRebeca SerranoNo ratings yet

- Ceb A 72-6048Document11 pagesCeb A 72-6048turboshaftNo ratings yet

- FAA 2017 0667 0006 - Attachment - 1Document5 pagesFAA 2017 0667 0006 - Attachment - 1pilot digitalNo ratings yet

- Schaku Coupler Rdso Spec No. 61-B-36-R - 1 - 68-1Document7 pagesSchaku Coupler Rdso Spec No. 61-B-36-R - 1 - 68-1Sumit Shyamal100% (1)

- FAA 2018 1039 0003 - Attachment - 1Document40 pagesFAA 2018 1039 0003 - Attachment - 1Luisbatista WachinNo ratings yet

- 06c AppendixB3 (750HP) 1582535947271Document79 pages06c AppendixB3 (750HP) 1582535947271Harsh TiwariNo ratings yet

- T 53-41-00-620-802-Renewal of The Temporary Protection of The WingDocument4 pagesT 53-41-00-620-802-Renewal of The Temporary Protection of The WingAldo Gibran Esquivel CarmonaNo ratings yet

- SHROUDDocument7 pagesSHROUD尹兴旺No ratings yet

- SB1200 Tomahawk Hard LandingDocument8 pagesSB1200 Tomahawk Hard LandingfelipeNo ratings yet

- CTRBDocument98 pagesCTRBAlok AmanNo ratings yet

- Work Instruction: General Overhauling of Centrifugal Pump OSCS-IMS-WI - 020Document8 pagesWork Instruction: General Overhauling of Centrifugal Pump OSCS-IMS-WI - 020MahmoudNo ratings yet

- 212 Asb 08 130Document7 pages212 Asb 08 130Walberto PachecoNo ratings yet

- Bell 212Document9 pagesBell 212Juan Pablo AriasNo ratings yet

- Nozzle: 1. GeneralDocument4 pagesNozzle: 1. GeneralSergio LópezNo ratings yet

- 06d AppendixB4 (550HP) 1582536012902Document94 pages06d AppendixB4 (550HP) 1582536012902Harsh TiwariNo ratings yet

- 407ASB407ASB22128Document10 pages407ASB407ASB22128camiloguayazanNo ratings yet

- Well Control Exercises PDFDocument69 pagesWell Control Exercises PDFal7assany88% (17)

- CFM SB 72-1033Document30 pagesCFM SB 72-1033Mohammad Akhter100% (1)

- ASB255A: TitleDocument14 pagesASB255A: TitleoscarNo ratings yet

- Asb - 212 10 140Document12 pagesAsb - 212 10 140smartasss100% (1)

- Cylinder Head - Inspect: Shutdown SIS Previous ScreenDocument3 pagesCylinder Head - Inspect: Shutdown SIS Previous ScreenbejoythomasNo ratings yet

- Mccauley Propeller Systems Owner Operator Information ManualDocument6 pagesMccauley Propeller Systems Owner Operator Information ManualElLoko MartinesNo ratings yet

- Installation and Rigging ProceduresDocument15 pagesInstallation and Rigging ProceduresRene QueirozNo ratings yet

- Mainenace Guidelines For LHB Cocahes.Document7 pagesMainenace Guidelines For LHB Cocahes.Parthaprotim Nath0% (1)

- Air Cruisers Service Bulletin 737 103-25-50Document18 pagesAir Cruisers Service Bulletin 737 103-25-50moliveroNo ratings yet

- Continental Aileron Cable Rigging Event Criteria: Page 1Document11 pagesContinental Aileron Cable Rigging Event Criteria: Page 1Jose Miguel Atehortua ArenasNo ratings yet

- Qa-Lhb-Draft Gear & CouplingDocument4 pagesQa-Lhb-Draft Gear & CouplingSriram SubramanianNo ratings yet

- 73 10 01 PDFDocument6 pages73 10 01 PDFAnonymous 298xlo3uUNo ratings yet

- PS NotesDocument6 pagesPS NotesnidhisasidharanNo ratings yet

- SUCKER ROD PUMP Fact SheetDocument9 pagesSUCKER ROD PUMP Fact Sheetsufiyan siddiquiNo ratings yet

- Annexure 3486Document8 pagesAnnexure 3486Kamal RajuNo ratings yet

- Lembar Inspeksi Bell 412 600 FH 12 MonthDocument6 pagesLembar Inspeksi Bell 412 600 FH 12 MonthReza Setyo PermadiNo ratings yet

- CFM56 5B SB Rev 72-0921 TSN.03 N 20181030Document15 pagesCFM56 5B SB Rev 72-0921 TSN.03 N 20181030Yasin çetinNo ratings yet

- 72 50 02Document6 pages72 50 02alvaro lemosNo ratings yet

- Program Winch Teardown - 21-9-15Document11 pagesProgram Winch Teardown - 21-9-15Anonymous 1qAH6CKCNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- Dozova NAD+ Vitamin Supplement Supports Healthy Aging, Energy - Sehetna-EgDocument4 pagesDozova NAD+ Vitamin Supplement Supports Healthy Aging, Energy - Sehetna-EgaliNo ratings yet

- Course Title: Stud. Qualif.: Instructors:: Thematic PlanDocument1 pageCourse Title: Stud. Qualif.: Instructors:: Thematic PlanaliNo ratings yet

- CFM56 7B SB Rev 72-0986 TSN.03 R 20181030Document15 pagesCFM56 7B SB Rev 72-0986 TSN.03 R 20181030aliNo ratings yet

- Hydraulic Systems No. 1 or No. 2 - Fill With Hydraulic FluidDocument12 pagesHydraulic Systems No. 1 or No. 2 - Fill With Hydraulic FluidaliNo ratings yet

- Engine FailureDocument2 pagesEngine Failuresaudia686100% (18)

- Accomplishment of SB 72-1074Document7 pagesAccomplishment of SB 72-1074aliNo ratings yet

- Type-Certificate Data Sheet: An Agency of The European UnionDocument28 pagesType-Certificate Data Sheet: An Agency of The European UnionaliNo ratings yet

- A320 NEO Vs CEO Comparison StudyDocument15 pagesA320 NEO Vs CEO Comparison StudyArpit Saraswat100% (4)

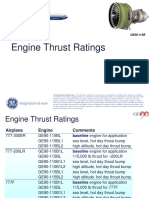

- Thrust Rating Summary 11-6-2009Document2 pagesThrust Rating Summary 11-6-2009aliNo ratings yet

- Ecu Software - cfm56Document9 pagesEcu Software - cfm56aliNo ratings yet

- Type-Certificate Data Sheet: An Agency of The European UnionDocument24 pagesType-Certificate Data Sheet: An Agency of The European UnionaliNo ratings yet

- Fuel cfm56Document12 pagesFuel cfm56aliNo ratings yet

- Nacelle cfm56Document13 pagesNacelle cfm56aliNo ratings yet

- Https Cwcs - cfm56 HPT BladeDocument8 pagesHttps Cwcs - cfm56 HPT Bladeali100% (1)

- CSC-246 Cross Section Cfm56-5C PDFDocument1 pageCSC-246 Cross Section Cfm56-5C PDFaliNo ratings yet

- Cross Section Inf Cfm56-7B PDFDocument1 pageCross Section Inf Cfm56-7B PDFaliNo ratings yet

- 7B - Line Maintenance - EGT - CFM Symposium 2017Document7 pages7B - Line Maintenance - EGT - CFM Symposium 2017aliNo ratings yet

- ASA Aft Sump Leak - Customer Exp - 2017 WTTDocument9 pagesASA Aft Sump Leak - Customer Exp - 2017 WTTaliNo ratings yet

- 7B - Line Maintenance - Tailpipe Fires - CFM Symposium 2017Document10 pages7B - Line Maintenance - Tailpipe Fires - CFM Symposium 2017aliNo ratings yet

- CFM56 FH Feb 2016 PDFDocument35 pagesCFM56 FH Feb 2016 PDFaliNo ratings yet

- 21.0. 7B - Line Maintenance - MCD - CFM Symposium 2017Document15 pages21.0. 7B - Line Maintenance - MCD - CFM Symposium 2017aliNo ratings yet

- Therapeutic Diet Manual: DIRECTIVE #4311Document27 pagesTherapeutic Diet Manual: DIRECTIVE #4311DuNo ratings yet

- Koch - Control ChartsDocument40 pagesKoch - Control ChartsAkash MarathakamNo ratings yet

- Absolute Priority Based Cell ReselectionDocument11 pagesAbsolute Priority Based Cell ReselectionNeoRa Ndivo RamsNo ratings yet

- AAB2000C1Document11 pagesAAB2000C1marcos morillo0% (1)

- CWAG Rectangular CoordinatesDocument52 pagesCWAG Rectangular CoordinatesRolando MerleNo ratings yet

- Free Download All Aeronautical Engg Books: AERO 3-1 BOOKSDocument11 pagesFree Download All Aeronautical Engg Books: AERO 3-1 BOOKSMacen SnoodleNo ratings yet

- The Fruit Garden CAL: Columbine & AcanthusDocument7 pagesThe Fruit Garden CAL: Columbine & AcanthusMiraNo ratings yet

- Comm - Name Comm - Code Comm - WT Index20122013 I Primary Articles (A) - Food ArticlesDocument48 pagesComm - Name Comm - Code Comm - WT Index20122013 I Primary Articles (A) - Food ArticlesNavin SanjeevNo ratings yet

- W8 Module08 Meaning and Relevance of History Presentation 1Document22 pagesW8 Module08 Meaning and Relevance of History Presentation 1Jessa UdtohanNo ratings yet

- BDA 542 V3 - powerCON TRUE 1 TOP - NAC3MX-W-TOPDocument2 pagesBDA 542 V3 - powerCON TRUE 1 TOP - NAC3MX-W-TOPluis manuelNo ratings yet

- Production of Biodegradable Plastics AsDocument6 pagesProduction of Biodegradable Plastics AsEbenezer EffisahNo ratings yet

- Everlast INTERVAL TRAINING ROUND TIMER PDFDocument1 pageEverlast INTERVAL TRAINING ROUND TIMER PDFanniaanniaNo ratings yet

- Fetomaternal Hemorrhage (FMH), An Update Review of LiteratureDocument35 pagesFetomaternal Hemorrhage (FMH), An Update Review of LiteratureEugenia Jeniffer JNo ratings yet

- Unit-6 Patterns of Industrialisation PDFDocument12 pagesUnit-6 Patterns of Industrialisation PDFNavdeep SinghNo ratings yet

- Advanced Landscape DesignDocument10 pagesAdvanced Landscape DesignSomhita DasNo ratings yet

- KONAN Emmanuel Sales Technical Engineer 16 Juin 23Document1 pageKONAN Emmanuel Sales Technical Engineer 16 Juin 23EMMANUEL KONANNo ratings yet

- Brochure Keor S GBDocument8 pagesBrochure Keor S GBFernando CespedesNo ratings yet

- Md. Rizwanur Rahman - CVDocument4 pagesMd. Rizwanur Rahman - CVHimelNo ratings yet

- ToR For Fiberglass Biogas Plants Installation - EOI PDFDocument4 pagesToR For Fiberglass Biogas Plants Installation - EOI PDFmy09No ratings yet

- Snag SummmariesDocument171 pagesSnag Summmarieslaltu adgiriNo ratings yet

- UntitledDocument14 pagesUntitlednaresh kumarNo ratings yet

- COMPRE - MODULE 4 (Pharmacology and Toxicology) : Attempt ReviewDocument40 pagesCOMPRE - MODULE 4 (Pharmacology and Toxicology) : Attempt ReviewLance RafaelNo ratings yet

- Regulator InfoDocument6 pagesRegulator InfoAguilar AlexNo ratings yet

- Sewing Skills Checklist PDFDocument44 pagesSewing Skills Checklist PDFyemkem100% (1)

- 3B Reactions of Alcohols and ThiolsDocument27 pages3B Reactions of Alcohols and ThiolsAnloraine GonzalesNo ratings yet

- HT Billing System - May'2022Document2 pagesHT Billing System - May'2022V.Sampath RaoNo ratings yet

- Palliative Ultrasound-Guided Endoscopic Diode Laser Ablation of Transitional Cell Carcinomas of The Lower Urinary Tract in Dogs.Document10 pagesPalliative Ultrasound-Guided Endoscopic Diode Laser Ablation of Transitional Cell Carcinomas of The Lower Urinary Tract in Dogs.Dante Nathaniel FajardoNo ratings yet

- Kerr EffectDocument5 pagesKerr EffectJose GalvanNo ratings yet

- Al55 66 Technical Manual v11 EngDocument60 pagesAl55 66 Technical Manual v11 EngProblem VelikiNo ratings yet

Accomplishment Instructions of CFM56 - 7B - SB - REV - 72-0636

Accomplishment Instructions of CFM56 - 7B - SB - REV - 72-0636

Uploaded by

aliOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Accomplishment Instructions of CFM56 - 7B - SB - REV - 72-0636

Accomplishment Instructions of CFM56 - 7B - SB - REV - 72-0636

Uploaded by

aliCopyright:

Available Formats

ENGINE - HP Compressor and HP Turbine Blades (72-31-01 and 72-52-01) - Inspection for

Engine Hardware Distress Due to Continuous Sand, Dust and Dirt Ingestion in the Middle

East and North Africa

(3) Consumables:

None.

B. Industry Support Information

None.

C. Configuration Chart

None.

D. Parts Disposition

None.

E. Tooling - Price and Availability

(1) Fixtures, tools, test and support equipment (use specified tools or equivalent):

Tool Description

Number

856A1322 Borescope - Lightsource Set

856A1321 Fiberscope Set

856A1323 Monitor, Resolution - Borescope

NOTE: Flexible borescope probe must be 0.157 inch (4.0 mm) or smaller in

diameter in order to insert through HPC stage 4 vane sector bleed slots.

3. ACCOMPLISHMENT INSTRUCTIONS B737-800-E.O-35

A. General

(1) Do the following inspection on engines operating for more than 80 percent of

their departures within Afghanistan, Algeria, Bahrain, Chad, Egypt, Ethiopia,

Iran, Iraq, Israel, Jordan, Kuwait, Lebanon, Libya, Mali, Mauritania, Niger,

Oman, Pakistan, Qatar, Saudi Arabia, Somalia, Sudan, Syria, United Arab

Emirates, or Yemen, as follows:

(a) Do a borescope inspection of the HPC airfoils and look for erosion of the

airfoil corners and chord. Refer to the Boeing 737-600/-700/-800/-900

AMM, TASK 72-00-00-200-804-F00.

1 If the HPC airfoils show no sign of erosion and have square corners,

repeat the inspection in 4,800 cycles.

2 If the HPC airfoils show rounded corners less than the manual limit,

repeat the inspection in 1,600 cycles.

May 24, 2007 CFM56-7B S/B 72-0636

Revision 08, October 08, 2019 PAGE 6

CFM Designated: - CONFIDENTIAL Subject to the restrictions on the media

ENGINE - HP Compressor and HP Turbine Blades (72-31-01 and 72-52-01) - Inspection for

Engine Hardware Distress Due to Continuous Sand, Dust and Dirt Ingestion in the Middle

East and North Africa

(b) Do a borescope inspection of the LE of the HPT blades and look

for oxidation, through wall holes, and cracking. Refer to the Boeing

737-600/-700/-800/-900 AMM, TASK 72-00-00-200-807-F00.

NOTE: Deleted

1 Do this task again at intervals of 800 subsequent cycles thereafter.

2 Refer to the Boeing 737-600/-700/-800/-900 AMM for serviceability

requirements.

3 Deleted.

(c) Do a borescope inspection of the HPC stage 4 vane sectors as follows:

1 Remove the upper left side LPT air cooling tube, refer to Figure 1

and do as follows:

a Remove retaining strap (35-700, 72-00-02) and bolts (35-690)

from LPT air cooling tube (35-750) and bracket (01-820,

72-41-00).

b Remove retaining strap (35-680) and bolts (35-670) from LPT air

cooling tube (35-750) and bracket (35-810) at the 10:30 o'clock

position of flange R.

c Remove retaining strap (35-720) and bolts (35-710) from LPT air

cooling tube (35-750) and bracket (35-840) at the 11:00 o'clock

position of flange P.

d Remove LPT air cooling tube (35-750), seal ring (35-760) and

bolts (35-730) from combustion case at the 11:00 o'clock position.

e For pre-CFM56-7B S/B 72-0117, remove LPT air cooling tube

(35-750), gasket (35-770), metering plate (35-780), seal ring

(35-790) and bolts (35-740) from HPC front stator at the 10:30

o'clock position.

f For post-CFM56-7B S/B 72-0117, remove LPT air cooling tube

(35-750), seal ring (35-790) and bolts (35-740) from HPC front

stator at the 10:30 o'clock position.

2 Do a special flexible borescope inspection as follows:

a Inspect the HPC stage 4 vane sector trailing edges for erosion

as follows:

May 24, 2007 CFM56-7B S/B 72-0636

Revision 08, October 08, 2019 PAGE 7

CFM Designated: - CONFIDENTIAL Subject to the restrictions on the media

ENGINE - HP Compressor and HP Turbine Blades (72-31-01 and 72-52-01) - Inspection for

Engine Hardware Distress Due to Continuous Sand, Dust and Dirt Ingestion in the Middle

East and North Africa

1) Use the resolution-borescope monitor to make sure the

fiberscope set is serviceable.

2) Connect the fiber light cable.

3) Insert the flexible borescope probe in the LPT bleed port on

the HPC front stator 10:30 o'clock position.

4) Insert the flexible borescope probe through the HPC stage

4 vane sector bleed slot.

NOTE: Approximately five or six vane sector bleed slots

will be visible though the LPT bleed port. It is

recommended to inspect in at least two or three

positions to obtain the best viewing angle of the

vane sector trailing edge.

5) Articulate the scope to focus on the vane sector trailing

edge.

6) Look for erosion on the vane sector trailing edge, especially

near the outer platform.

7) Re-inspection intervals depend on the amount of

serviceable distress found.

a) If no erosion is found, then re-inspect before 4,800

cycles.

b) If trailing edge is eroded but not axially past the start

of the bleed slot (Figure 2), then re-inspect before

1,600 cycles.

c) If trailing edge is eroded axially past the start of the

bleed slot (Figure 2), then remove engine before 100

cycles.

8) Slowly pull the flex scope back out of the port after

inspection is completed.

3 Install the upper LPT air cooling tube on the left side of the engine,

refer to Figure 1 and do as follows:

a Install LPT air cooling tube (35-750, 72-00-02), seal ring (35-760)

and bolts (35-730) on combustion case at the 11 o'clock position.

Torque the bolts to 62-68 lb in. (7.0-7.7 N·m).

b For pre-CFM56-7B S/B 72-0117, install LPT air cooling tube

(35-750), gasket (35-770), metering plate (35-780), seal ring

(35-790) and bolts (35-740) on HPC front stator at the 10:30

o'clock position. Torque the bolts to 62-68 lb in. (7.0-7.7 N·m).

May 24, 2007 CFM56-7B S/B 72-0636

Revision 08, October 08, 2019 PAGE 8

CFM Designated: - CONFIDENTIAL Subject to the restrictions on the media

ENGINE - HP Compressor and HP Turbine Blades (72-31-01 and 72-52-01) - Inspection for

Engine Hardware Distress Due to Continuous Sand, Dust and Dirt Ingestion in the Middle

East and North Africa

c For post-CFM56-7B S/B 72-0117, install LPT air cooling tube

(35-750), seal ring (35-790) and bolts (35-740) on HPC front

stator at the 10:30 o'clock position. Torque the bolts to 62-68 lb

in. (7.0-7.7 N·m).

d Install retaining strap (35-720) and bolts (35-710) on LPT air

cooling tube (35-750) and bracket (35-840) at the 11 o'clock

position of flange P. Torque bolts to 62-68 lb in. (7.0-7.7 N·m).

e Install retaining strap (35-680) and bolts (35-670) on LPT air

cooling tube (35-750) and bracket (35-810) at the 10:30 o'clock

position of flange R. Torque bolts to 62-68 lb in. (7.0-7.7 N·m).

f Install retaining strap (35-700) and bolts (35-690) on LPT air

cooling tube (35-750) and bracket (01-820, 72-41-00). Torque

bolts to 62-68 lb in. (7.0-7.7 N·m).

(d) When the engine is routed for shop visit, do as follows:

1 If the HPT blades have accumulated more than 5,000 CSN of

operation, when routed for repair request inspection of the leading

edge internal rib for evaluation of crack initiation and repair

acceptability as specified in RD 150-1551. To make sure that the

repair facility knows that the inspection is necessary, request the

inspection in RD 150-1551 to be done on your repair request

documentation. The HPT blades that pass CFM56-7B ESM,

72-52-01, INSPECTION 001 serviceability inspections and the

inspections specified in RD 150-1551 will be identified by an X

marked after the cycle count identification. For these HPT blades,

when returned to operation, use the on-wing borescope inspection

interval as defined below.

a Do this task every 800 subsequent cycles thereafter.

May 24, 2007 CFM56-7B S/B 72-0636

Revision 08, October 08, 2019 PAGE 9

CFM Designated: - CONFIDENTIAL Subject to the restrictions on the media

ENGINE - HP Compressor and HP Turbine Blades (72-31-01 and 72-52-01) - Inspection for

Engine Hardware Distress Due to Continuous Sand, Dust and Dirt Ingestion in the Middle

East and North Africa

Left Side LPT Cooling Tubes

Figure 1, ( Sheet 1 of 3 )

May 24, 2007 CFM56-7B S/B 72-0636

Revision 08, October 08, 2019 PAGE 10

CFM Designated: - CONFIDENTIAL Subject to the restrictions on the media

ENGINE - HP Compressor and HP Turbine Blades (72-31-01 and 72-52-01) - Inspection for

Engine Hardware Distress Due to Continuous Sand, Dust and Dirt Ingestion in the Middle

East and North Africa

Left Side LPT Cooling Tubes

Figure 1, ( Sheet 2 )

May 24, 2007 CFM56-7B S/B 72-0636

Revision 08, October 08, 2019 PAGE 11

CFM Designated: - CONFIDENTIAL Subject to the restrictions on the media

ENGINE - HP Compressor and HP Turbine Blades (72-31-01 and 72-52-01) - Inspection for

Engine Hardware Distress Due to Continuous Sand, Dust and Dirt Ingestion in the Middle

East and North Africa

Left Side LPT Cooling Tubes

Figure 1, ( Sheet 3 )

May 24, 2007 CFM56-7B S/B 72-0636

Revision 08, October 08, 2019 PAGE 12

CFM Designated: - CONFIDENTIAL Subject to the restrictions on the media

ENGINE - HP Compressor and HP Turbine Blades (72-31-01 and 72-52-01) - Inspection for

Engine Hardware Distress Due to Continuous Sand, Dust and Dirt Ingestion in the Middle

East and North Africa

HPC Stage 4 Vane Sector Trailing Edge Inspection

Figure 2

May 24, 2007 CFM56-7B S/B 72-0636

Revision 08, October 08, 2019 PAGE 13

CFM Designated: - CONFIDENTIAL Subject to the restrictions on the media

You might also like

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- BOP TL Operation and Maintenance ManualDocument22 pagesBOP TL Operation and Maintenance Manualadvantage02580% (5)

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Operations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0Document18 pagesOperations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0dowel hernandezNo ratings yet

- Speed Tape Airbus - Descent & ArrivalDocument4 pagesSpeed Tape Airbus - Descent & Arrivalapi-3805097100% (29)

- Unit Injector - Install: Disassembly and AssemblyDocument13 pagesUnit Injector - Install: Disassembly and AssemblyAnung Nugroho100% (1)

- Mechanical Interview Jgc-KjoDocument6 pagesMechanical Interview Jgc-Kjonaveed7861100% (1)

- Boeing 777 Amm Refrences 2Document7 pagesBoeing 777 Amm Refrences 2tauqir73100% (1)

- SEBF 8164 гизьзы 3500Document19 pagesSEBF 8164 гизьзы 3500Aminadav100% (1)

- 2020 AMC ProgramDocument247 pages2020 AMC ProgramaliNo ratings yet

- A320 Automation PDFDocument1 pageA320 Automation PDFaliNo ratings yet

- Engine Yearbook 2017Document5 pagesEngine Yearbook 2017ali100% (1)

- Achivment Cwcs - cfm56Document16 pagesAchivment Cwcs - cfm56aliNo ratings yet

- Combustor Cwcs - cfm56Document21 pagesCombustor Cwcs - cfm56ali100% (3)

- 7B - MyCFMportal - CFM Symposium 2017Document14 pages7B - MyCFMportal - CFM Symposium 2017aliNo ratings yet

- Chapter 6 Work, Energy and PowerDocument12 pagesChapter 6 Work, Energy and PowerZhu Jiankun100% (1)

- Accomplishment of SB 72-1074Document7 pagesAccomplishment of SB 72-1074aliNo ratings yet

- Scanned by CamscannerDocument10 pagesScanned by CamscannerChandrashekhar KalyankarNo ratings yet

- Q400.amm (76) .Amm72 00 00 290 805Document30 pagesQ400.amm (76) .Amm72 00 00 290 805sasivannanNo ratings yet

- ASB 412-09-137A Page 1 of 10 Approved For Public ReleaseDocument10 pagesASB 412-09-137A Page 1 of 10 Approved For Public Releasesebastian eduardoNo ratings yet

- Aw119mkii, Ata 64-11Document10 pagesAw119mkii, Ata 64-11Christian Hennigs GoldbergNo ratings yet

- CFM56 7B SB Rev 72-0986 TSN.03 R 20181030Document15 pagesCFM56 7B SB Rev 72-0986 TSN.03 R 20181030aliNo ratings yet

- TASK 72-00-00-200-802, Borescope InspectionDocument34 pagesTASK 72-00-00-200-802, Borescope InspectionNestor LucianiNo ratings yet

- Ejemplo de Boletin de ServicioDocument11 pagesEjemplo de Boletin de ServicioCarlos AnguianoNo ratings yet

- TC 38 - Rev02 (1) SIDE BUFFER GREASEDocument11 pagesTC 38 - Rev02 (1) SIDE BUFFER GREASEnasirzeal990No ratings yet

- ASB 429-19-50 Page 1 of 9 Approved For Public ReleaseDocument9 pagesASB 429-19-50 Page 1 of 9 Approved For Public Releaserio tanoneNo ratings yet

- CFM56 5B SB Rev 72-1092 TSN.00 N 20201210Document20 pagesCFM56 5B SB Rev 72-1092 TSN.00 N 20201210Irfan05No ratings yet

- Manual For 1215 Kva Rig AlternatorDocument18 pagesManual For 1215 Kva Rig Alternatorprem080910No ratings yet

- MODEL 150 SERIES (1969 - 1976) : Supplemental Inspection Number: 57-11-01 1. TitleDocument2 pagesMODEL 150 SERIES (1969 - 1976) : Supplemental Inspection Number: 57-11-01 1. TitleRebeca SerranoNo ratings yet

- Ceb A 72-6048Document11 pagesCeb A 72-6048turboshaftNo ratings yet

- FAA 2017 0667 0006 - Attachment - 1Document5 pagesFAA 2017 0667 0006 - Attachment - 1pilot digitalNo ratings yet

- Schaku Coupler Rdso Spec No. 61-B-36-R - 1 - 68-1Document7 pagesSchaku Coupler Rdso Spec No. 61-B-36-R - 1 - 68-1Sumit Shyamal100% (1)

- FAA 2018 1039 0003 - Attachment - 1Document40 pagesFAA 2018 1039 0003 - Attachment - 1Luisbatista WachinNo ratings yet

- 06c AppendixB3 (750HP) 1582535947271Document79 pages06c AppendixB3 (750HP) 1582535947271Harsh TiwariNo ratings yet

- T 53-41-00-620-802-Renewal of The Temporary Protection of The WingDocument4 pagesT 53-41-00-620-802-Renewal of The Temporary Protection of The WingAldo Gibran Esquivel CarmonaNo ratings yet

- SHROUDDocument7 pagesSHROUD尹兴旺No ratings yet

- SB1200 Tomahawk Hard LandingDocument8 pagesSB1200 Tomahawk Hard LandingfelipeNo ratings yet

- CTRBDocument98 pagesCTRBAlok AmanNo ratings yet

- Work Instruction: General Overhauling of Centrifugal Pump OSCS-IMS-WI - 020Document8 pagesWork Instruction: General Overhauling of Centrifugal Pump OSCS-IMS-WI - 020MahmoudNo ratings yet

- 212 Asb 08 130Document7 pages212 Asb 08 130Walberto PachecoNo ratings yet

- Bell 212Document9 pagesBell 212Juan Pablo AriasNo ratings yet

- Nozzle: 1. GeneralDocument4 pagesNozzle: 1. GeneralSergio LópezNo ratings yet

- 06d AppendixB4 (550HP) 1582536012902Document94 pages06d AppendixB4 (550HP) 1582536012902Harsh TiwariNo ratings yet

- 407ASB407ASB22128Document10 pages407ASB407ASB22128camiloguayazanNo ratings yet

- Well Control Exercises PDFDocument69 pagesWell Control Exercises PDFal7assany88% (17)

- CFM SB 72-1033Document30 pagesCFM SB 72-1033Mohammad Akhter100% (1)

- ASB255A: TitleDocument14 pagesASB255A: TitleoscarNo ratings yet

- Asb - 212 10 140Document12 pagesAsb - 212 10 140smartasss100% (1)

- Cylinder Head - Inspect: Shutdown SIS Previous ScreenDocument3 pagesCylinder Head - Inspect: Shutdown SIS Previous ScreenbejoythomasNo ratings yet

- Mccauley Propeller Systems Owner Operator Information ManualDocument6 pagesMccauley Propeller Systems Owner Operator Information ManualElLoko MartinesNo ratings yet

- Installation and Rigging ProceduresDocument15 pagesInstallation and Rigging ProceduresRene QueirozNo ratings yet

- Mainenace Guidelines For LHB Cocahes.Document7 pagesMainenace Guidelines For LHB Cocahes.Parthaprotim Nath0% (1)

- Air Cruisers Service Bulletin 737 103-25-50Document18 pagesAir Cruisers Service Bulletin 737 103-25-50moliveroNo ratings yet

- Continental Aileron Cable Rigging Event Criteria: Page 1Document11 pagesContinental Aileron Cable Rigging Event Criteria: Page 1Jose Miguel Atehortua ArenasNo ratings yet

- Qa-Lhb-Draft Gear & CouplingDocument4 pagesQa-Lhb-Draft Gear & CouplingSriram SubramanianNo ratings yet

- 73 10 01 PDFDocument6 pages73 10 01 PDFAnonymous 298xlo3uUNo ratings yet

- PS NotesDocument6 pagesPS NotesnidhisasidharanNo ratings yet

- SUCKER ROD PUMP Fact SheetDocument9 pagesSUCKER ROD PUMP Fact Sheetsufiyan siddiquiNo ratings yet

- Annexure 3486Document8 pagesAnnexure 3486Kamal RajuNo ratings yet

- Lembar Inspeksi Bell 412 600 FH 12 MonthDocument6 pagesLembar Inspeksi Bell 412 600 FH 12 MonthReza Setyo PermadiNo ratings yet

- CFM56 5B SB Rev 72-0921 TSN.03 N 20181030Document15 pagesCFM56 5B SB Rev 72-0921 TSN.03 N 20181030Yasin çetinNo ratings yet

- 72 50 02Document6 pages72 50 02alvaro lemosNo ratings yet

- Program Winch Teardown - 21-9-15Document11 pagesProgram Winch Teardown - 21-9-15Anonymous 1qAH6CKCNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- Dozova NAD+ Vitamin Supplement Supports Healthy Aging, Energy - Sehetna-EgDocument4 pagesDozova NAD+ Vitamin Supplement Supports Healthy Aging, Energy - Sehetna-EgaliNo ratings yet

- Course Title: Stud. Qualif.: Instructors:: Thematic PlanDocument1 pageCourse Title: Stud. Qualif.: Instructors:: Thematic PlanaliNo ratings yet

- CFM56 7B SB Rev 72-0986 TSN.03 R 20181030Document15 pagesCFM56 7B SB Rev 72-0986 TSN.03 R 20181030aliNo ratings yet

- Hydraulic Systems No. 1 or No. 2 - Fill With Hydraulic FluidDocument12 pagesHydraulic Systems No. 1 or No. 2 - Fill With Hydraulic FluidaliNo ratings yet

- Engine FailureDocument2 pagesEngine Failuresaudia686100% (18)

- Accomplishment of SB 72-1074Document7 pagesAccomplishment of SB 72-1074aliNo ratings yet

- Type-Certificate Data Sheet: An Agency of The European UnionDocument28 pagesType-Certificate Data Sheet: An Agency of The European UnionaliNo ratings yet

- A320 NEO Vs CEO Comparison StudyDocument15 pagesA320 NEO Vs CEO Comparison StudyArpit Saraswat100% (4)

- Thrust Rating Summary 11-6-2009Document2 pagesThrust Rating Summary 11-6-2009aliNo ratings yet

- Ecu Software - cfm56Document9 pagesEcu Software - cfm56aliNo ratings yet

- Type-Certificate Data Sheet: An Agency of The European UnionDocument24 pagesType-Certificate Data Sheet: An Agency of The European UnionaliNo ratings yet

- Fuel cfm56Document12 pagesFuel cfm56aliNo ratings yet

- Nacelle cfm56Document13 pagesNacelle cfm56aliNo ratings yet

- Https Cwcs - cfm56 HPT BladeDocument8 pagesHttps Cwcs - cfm56 HPT Bladeali100% (1)

- CSC-246 Cross Section Cfm56-5C PDFDocument1 pageCSC-246 Cross Section Cfm56-5C PDFaliNo ratings yet

- Cross Section Inf Cfm56-7B PDFDocument1 pageCross Section Inf Cfm56-7B PDFaliNo ratings yet

- 7B - Line Maintenance - EGT - CFM Symposium 2017Document7 pages7B - Line Maintenance - EGT - CFM Symposium 2017aliNo ratings yet

- ASA Aft Sump Leak - Customer Exp - 2017 WTTDocument9 pagesASA Aft Sump Leak - Customer Exp - 2017 WTTaliNo ratings yet

- 7B - Line Maintenance - Tailpipe Fires - CFM Symposium 2017Document10 pages7B - Line Maintenance - Tailpipe Fires - CFM Symposium 2017aliNo ratings yet

- CFM56 FH Feb 2016 PDFDocument35 pagesCFM56 FH Feb 2016 PDFaliNo ratings yet

- 21.0. 7B - Line Maintenance - MCD - CFM Symposium 2017Document15 pages21.0. 7B - Line Maintenance - MCD - CFM Symposium 2017aliNo ratings yet

- Therapeutic Diet Manual: DIRECTIVE #4311Document27 pagesTherapeutic Diet Manual: DIRECTIVE #4311DuNo ratings yet

- Koch - Control ChartsDocument40 pagesKoch - Control ChartsAkash MarathakamNo ratings yet

- Absolute Priority Based Cell ReselectionDocument11 pagesAbsolute Priority Based Cell ReselectionNeoRa Ndivo RamsNo ratings yet

- AAB2000C1Document11 pagesAAB2000C1marcos morillo0% (1)

- CWAG Rectangular CoordinatesDocument52 pagesCWAG Rectangular CoordinatesRolando MerleNo ratings yet

- Free Download All Aeronautical Engg Books: AERO 3-1 BOOKSDocument11 pagesFree Download All Aeronautical Engg Books: AERO 3-1 BOOKSMacen SnoodleNo ratings yet

- The Fruit Garden CAL: Columbine & AcanthusDocument7 pagesThe Fruit Garden CAL: Columbine & AcanthusMiraNo ratings yet

- Comm - Name Comm - Code Comm - WT Index20122013 I Primary Articles (A) - Food ArticlesDocument48 pagesComm - Name Comm - Code Comm - WT Index20122013 I Primary Articles (A) - Food ArticlesNavin SanjeevNo ratings yet

- W8 Module08 Meaning and Relevance of History Presentation 1Document22 pagesW8 Module08 Meaning and Relevance of History Presentation 1Jessa UdtohanNo ratings yet

- BDA 542 V3 - powerCON TRUE 1 TOP - NAC3MX-W-TOPDocument2 pagesBDA 542 V3 - powerCON TRUE 1 TOP - NAC3MX-W-TOPluis manuelNo ratings yet

- Production of Biodegradable Plastics AsDocument6 pagesProduction of Biodegradable Plastics AsEbenezer EffisahNo ratings yet

- Everlast INTERVAL TRAINING ROUND TIMER PDFDocument1 pageEverlast INTERVAL TRAINING ROUND TIMER PDFanniaanniaNo ratings yet

- Fetomaternal Hemorrhage (FMH), An Update Review of LiteratureDocument35 pagesFetomaternal Hemorrhage (FMH), An Update Review of LiteratureEugenia Jeniffer JNo ratings yet

- Unit-6 Patterns of Industrialisation PDFDocument12 pagesUnit-6 Patterns of Industrialisation PDFNavdeep SinghNo ratings yet

- Advanced Landscape DesignDocument10 pagesAdvanced Landscape DesignSomhita DasNo ratings yet

- KONAN Emmanuel Sales Technical Engineer 16 Juin 23Document1 pageKONAN Emmanuel Sales Technical Engineer 16 Juin 23EMMANUEL KONANNo ratings yet

- Brochure Keor S GBDocument8 pagesBrochure Keor S GBFernando CespedesNo ratings yet

- Md. Rizwanur Rahman - CVDocument4 pagesMd. Rizwanur Rahman - CVHimelNo ratings yet

- ToR For Fiberglass Biogas Plants Installation - EOI PDFDocument4 pagesToR For Fiberglass Biogas Plants Installation - EOI PDFmy09No ratings yet

- Snag SummmariesDocument171 pagesSnag Summmarieslaltu adgiriNo ratings yet

- UntitledDocument14 pagesUntitlednaresh kumarNo ratings yet

- COMPRE - MODULE 4 (Pharmacology and Toxicology) : Attempt ReviewDocument40 pagesCOMPRE - MODULE 4 (Pharmacology and Toxicology) : Attempt ReviewLance RafaelNo ratings yet

- Regulator InfoDocument6 pagesRegulator InfoAguilar AlexNo ratings yet

- Sewing Skills Checklist PDFDocument44 pagesSewing Skills Checklist PDFyemkem100% (1)

- 3B Reactions of Alcohols and ThiolsDocument27 pages3B Reactions of Alcohols and ThiolsAnloraine GonzalesNo ratings yet

- HT Billing System - May'2022Document2 pagesHT Billing System - May'2022V.Sampath RaoNo ratings yet

- Palliative Ultrasound-Guided Endoscopic Diode Laser Ablation of Transitional Cell Carcinomas of The Lower Urinary Tract in Dogs.Document10 pagesPalliative Ultrasound-Guided Endoscopic Diode Laser Ablation of Transitional Cell Carcinomas of The Lower Urinary Tract in Dogs.Dante Nathaniel FajardoNo ratings yet

- Kerr EffectDocument5 pagesKerr EffectJose GalvanNo ratings yet

- Al55 66 Technical Manual v11 EngDocument60 pagesAl55 66 Technical Manual v11 EngProblem VelikiNo ratings yet