Professional Documents

Culture Documents

Anup SS304L TC 1

Anup SS304L TC 1

Uploaded by

B.M Industrial WorksCopyright:

Available Formats

You might also like

- Material TCDocument1 pageMaterial TCgmbakshiNo ratings yet

- TubacexDocument1 pageTubacexMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- 90mm 316l Peeled and PolishedDocument1 page90mm 316l Peeled and PolishedB.M Industrial WorksNo ratings yet

- 90mm 316l Peeled and PolishedDocument1 page90mm 316l Peeled and PolishedB.M Industrial WorksNo ratings yet

- Test Certificate: (BS EN 10204 Type 3.1)Document1 pageTest Certificate: (BS EN 10204 Type 3.1)Sachin NambiarNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOMANIMARAN QC100% (1)

- Mill'S Test Certificate ACC. TO EN 10204 / 3.1Document2 pagesMill'S Test Certificate ACC. TO EN 10204 / 3.1Durulsan MakinaNo ratings yet

- 1.20mm T.C - Mehta SteelsDocument1 page1.20mm T.C - Mehta SteelsRonak FireNo ratings yet

- 16 MM MS Plate 355 JR - India-MTCDocument1 page16 MM MS Plate 355 JR - India-MTCQc QatarNo ratings yet

- 694Document1 page694Mauricio Ramirez100% (1)

- Cert ACERO INOX 316L PDFDocument1 pageCert ACERO INOX 316L PDFCarlos RomeroNo ratings yet

- Test Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811Document1 pageTest Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811akash_smhs0% (1)

- Espectrofotómetro de Absorción Atómica AA-7000Document28 pagesEspectrofotómetro de Absorción Atómica AA-7000Gustavo RuizNo ratings yet

- D72307 TC2 PDFDocument2 pagesD72307 TC2 PDFshivdas bichukaleNo ratings yet

- MTC PipeDocument1 pageMTC PipeMathavan ABMNo ratings yet

- Img 0001Document1 pageImg 0001Harish RanaNo ratings yet

- Certificado Tubo 1.1-2 AC SC SCH 80 X 5.8-1Document1 pageCertificado Tubo 1.1-2 AC SC SCH 80 X 5.8-1Raul Esteban Jaimes GalvisNo ratings yet

- Inspection Certificate 3.1 - ,: According EN 10204: 2005Document1 pageInspection Certificate 3.1 - ,: According EN 10204: 2005B.M Industrial Works100% (1)

- MFF Spect. Blind 6 CL 150Document1 pageMFF Spect. Blind 6 CL 150Mohamed RaafatNo ratings yet

- Ribo TC 324 (00000003)Document1 pageRibo TC 324 (00000003)Vinay YadavNo ratings yet

- T.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateDocument3 pagesT.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- Mittal Corp Limited Test Certificate FinalDocument1 pageMittal Corp Limited Test Certificate FinalMehmet SoysalNo ratings yet

- Global Aluminium Private Limited: M/S. Wonjin Autoparts India PVT LTD, ChennaiDocument1 pageGlobal Aluminium Private Limited: M/S. Wonjin Autoparts India PVT LTD, ChennaiSonu Singh100% (1)

- Test Certificate: CM/L-NO:5530357Document10 pagesTest Certificate: CM/L-NO:5530357TARUNKUMARNo ratings yet

- Page 1 of 1: Test Certificate No. 0000141878Document1 pagePage 1 of 1: Test Certificate No. 0000141878Vishwanathan NagarajanNo ratings yet

- Bishweshwar Lal Steels: Hot Rolled Steel Strip For Welded Tubes and Pipes As Per Is: 10748 - 2004Document1 pageBishweshwar Lal Steels: Hot Rolled Steel Strip For Welded Tubes and Pipes As Per Is: 10748 - 2004ravigurajapuNo ratings yet

- 2.5 MM 1250....Document1 page2.5 MM 1250....Balaji Defence100% (1)

- SS420, 12mm-RamDocument1 pageSS420, 12mm-RamganeshNo ratings yet

- Test Certificate: CM/L-NO:5200036277Document10 pagesTest Certificate: CM/L-NO:5200036277TARUNKUMARNo ratings yet

- MTC 4500528257 Iii - 210209Document3 pagesMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNo ratings yet

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romero100% (1)

- 4140 Material For TubeDocument2 pages4140 Material For Tubesharafudheen_sNo ratings yet

- 300 C SailDocument2 pages300 C Sailchandrabhushan kushwahaNo ratings yet

- PSP TCDocument7 pagesPSP TCPSP kanpurdehatNo ratings yet

- JSW Steel MTCDocument5 pagesJSW Steel MTCNelson 2428No ratings yet

- 1802 Brida Ac WN 6 X 150 SCH STD SWDocument1 page1802 Brida Ac WN 6 X 150 SCH STD SWAlejandro L MagnusNo ratings yet

- MTC 17 4PH Al20201127a174Document1 pageMTC 17 4PH Al20201127a174Ajeng PratiwiNo ratings yet

- Sample MTCDocument1 pageSample MTCheavens indiaNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- BF20112602 English MTC PDFDocument2 pagesBF20112602 English MTC PDFSvetlana VujovićNo ratings yet

- MOE Simplex - 24.06.2016 PDFDocument4 pagesMOE Simplex - 24.06.2016 PDFSabyasachi BangalNo ratings yet

- Rajendra Ferromet Pvt. LTD.: Material Test Certificate According To en 10204:2004 / 3.1Document1 pageRajendra Ferromet Pvt. LTD.: Material Test Certificate According To en 10204:2004 / 3.1qualityNo ratings yet

- 041101Document1 page041101Carolina MolfinoNo ratings yet

- E985F8E88F069BF1BB6F005056AC67B7Document1 pageE985F8E88F069BF1BB6F005056AC67B7Jose ReynosoNo ratings yet

- Sample MTC: Material Test CertificateDocument2 pagesSample MTC: Material Test CertificateSameer KmNo ratings yet

- Heat C090 SK3RQ1.5X1Document1 pageHeat C090 SK3RQ1.5X1Keshia Murillo PinnockNo ratings yet

- Varilla 1 1 - 4 A193 B7Document1 pageVarilla 1 1 - 4 A193 B7CarlosEduardoMorenoManceraNo ratings yet

- Material Test Report: Cse. Chiang Sung Enterprise Co., LTDDocument3 pagesMaterial Test Report: Cse. Chiang Sung Enterprise Co., LTDChethan Nagaraju KumbarNo ratings yet

- 1jsl Ltd. TPI 3 (31803) MMDocument2 pages1jsl Ltd. TPI 3 (31803) MMPratik KarekarNo ratings yet

- Test CertificateDocument2 pagesTest CertificatePRITESH100% (2)

- Fittings ThrededDocument2 pagesFittings ThrededreniNo ratings yet

- Vedanta Limited Cairn Oil & Gas: Integrated Field Plan Execution Services in Satellite Fields in Rj-On 90/1 BLOCKDocument23 pagesVedanta Limited Cairn Oil & Gas: Integrated Field Plan Execution Services in Satellite Fields in Rj-On 90/1 BLOCKPRAKASH PANDEYNo ratings yet

- Ispat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsDocument4 pagesIspat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsAbhi Sheoran100% (2)

- Mill Test Certificate: Din 125 Washer Electro Zinc PlatedDocument1 pageMill Test Certificate: Din 125 Washer Electro Zinc PlatedFodor ZoltanNo ratings yet

- MTC 410-317-304 - FastenerDocument2 pagesMTC 410-317-304 - Fastenermiguel contrerasNo ratings yet

- TC 1419 McnallyDocument2 pagesTC 1419 McnallymtlhwhNo ratings yet

- MTC Elbow 6inDocument1 pageMTC Elbow 6inhenryNo ratings yet

- MTC Annexure (6 Inch)Document16 pagesMTC Annexure (6 Inch)maheshNo ratings yet

- MTC 4500528257 Iii - 210209Document3 pagesMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNo ratings yet

- DB-En 19 R-2-829 PDFDocument4 pagesDB-En 19 R-2-829 PDFashokNo ratings yet

- Inc 800 MTC - FlangeDocument1 pageInc 800 MTC - Flangeranjith_007100% (1)

- SS 310 Mill TC - 16,18,20,22,40Document1 pageSS 310 Mill TC - 16,18,20,22,40rajiv.raskarNo ratings yet

- Alu SQ Rod 80X80Document1 pageAlu SQ Rod 80X80B.M Industrial WorksNo ratings yet

- Inspection Certificate 3.1 - ,: According EN 10204: 2005Document1 pageInspection Certificate 3.1 - ,: According EN 10204: 2005B.M Industrial Works100% (1)

- CK45 VSP TCDocument1 pageCK45 VSP TCB.M Industrial WorksNo ratings yet

- 15 Saptember Ut Report - 2022Document1 page15 Saptember Ut Report - 2022B.M Industrial WorksNo ratings yet

- Hydraulic Failure AnalysisDocument93 pagesHydraulic Failure AnalysisJoseph Jose86% (7)

- Lesson 3 Sieve AnalysisDocument20 pagesLesson 3 Sieve AnalysisjrNo ratings yet

- To Study The Analysis, Design and Behavior of Corrugated Steel SiloDocument7 pagesTo Study The Analysis, Design and Behavior of Corrugated Steel SiloMohammed AlnasharNo ratings yet

- DehydrationDocument4 pagesDehydrationAlexandra CatalinaNo ratings yet

- Dried Java Plum Tantoyparedesvillaneva 1Document8 pagesDried Java Plum Tantoyparedesvillaneva 1yournicole T.No ratings yet

- 11kv Disc Insulator GTP and SpecificationDocument10 pages11kv Disc Insulator GTP and SpecificationSatyaNo ratings yet

- Chemistry Project Class 12Document13 pagesChemistry Project Class 12Shlok Sah50% (2)

- Effects of Temperature On Enzyme ActivityDocument6 pagesEffects of Temperature On Enzyme Activityapi-340424437No ratings yet

- Atex Directive in A NutshellDocument4 pagesAtex Directive in A NutshellAnonymous 96SYLheENo ratings yet

- Edexcel GCE Biology Unit-4 (R) June 2013 Question PaperDocument20 pagesEdexcel GCE Biology Unit-4 (R) June 2013 Question PaperAvrinox100% (1)

- Fisa Tehnica Robineti Sertar R55Document2 pagesFisa Tehnica Robineti Sertar R55Petrisor FilipNo ratings yet

- Nicrofer 3220 3220h eDocument15 pagesNicrofer 3220 3220h eKevinCollinNo ratings yet

- Chapter 7 Case Study: Engineering Ethics and PrinciplesDocument14 pagesChapter 7 Case Study: Engineering Ethics and PrinciplesInna IgnacioNo ratings yet

- Verification of Johnson-Cook Material Model Constants of Aa2024-T3 For Use in Finite Element Simulation of Friction Stir Welding and Its Utilization in Severe Plastic DeformationDocument5 pagesVerification of Johnson-Cook Material Model Constants of Aa2024-T3 For Use in Finite Element Simulation of Friction Stir Welding and Its Utilization in Severe Plastic DeformationInternational Journal of Research in Engineering and TechnologyNo ratings yet

- 104 - Vacuum DryingDocument2 pages104 - Vacuum DryingJeisson PerezNo ratings yet

- Pregelatinised StarchDocument4 pagesPregelatinised StarchHani AlhelwaniNo ratings yet

- D 6003 - 96Document8 pagesD 6003 - 96othmanNo ratings yet

- MolarityDocument2 pagesMolarityUdayan RoyNo ratings yet

- Statistical Thermodynamics - An Engineering ApproachDocument284 pagesStatistical Thermodynamics - An Engineering Approachhgutierrezcable0% (1)

- Unit - 3 Solar Photovoltaic SystemDocument15 pagesUnit - 3 Solar Photovoltaic SystemSudhir MallampatiNo ratings yet

- Concentration of Solution: (Molarity)Document8 pagesConcentration of Solution: (Molarity)Ethylaine ApilanNo ratings yet

- Site Visit ReportDocument3 pagesSite Visit ReportSolomon BalemeziNo ratings yet

- SVKM J.V. Parekh International School 2018-2019 Cycle Test 2 Portion Class: IXDocument3 pagesSVKM J.V. Parekh International School 2018-2019 Cycle Test 2 Portion Class: IXNyonikaNo ratings yet

- 2160607-Elementary Structural Design 09012017 040945AMDocument16 pages2160607-Elementary Structural Design 09012017 040945AMAydinAkhtarpour100% (1)

- Corrosion MonitoringDocument22 pagesCorrosion MonitoringJai Patel100% (2)

- Teachers Guidebook CCE Whole GuideDocument375 pagesTeachers Guidebook CCE Whole GuideJedy Tah0% (1)

- Synthesis of Soap DetergentDocument4 pagesSynthesis of Soap DetergentHarvey Mher RarangNo ratings yet

- Cuidados Electrodo Con LitioDocument2 pagesCuidados Electrodo Con LitioFelix MendozaNo ratings yet

- How To Read U Tube Manometer PDFDocument5 pagesHow To Read U Tube Manometer PDFAnonymous zdCUbW8Hf0% (1)

Anup SS304L TC 1

Anup SS304L TC 1

Uploaded by

B.M Industrial WorksOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anup SS304L TC 1

Anup SS304L TC 1

Uploaded by

B.M Industrial WorksCopyright:

Available Formats

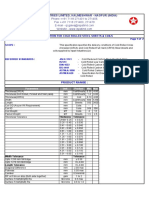

Inspection Certificate 3.

1 According To EN 10204 : 2005

CONSINGEE B.M. INDUSTRIAL WORKS Test Certificate No. : 172852

Date of Issue : 15.07.2021

P. O. No. & Date :

Invoice No. & Date :

Supply Process Length Stamp of

Product Grade Tolerance Weight (MT)

Condition Route (Meter) Engineer

Annealed,

Bright Round EIF-AOD - 0.560

SA240 TP304L Peeled & 3.60-6.65 k12/k10

Bars CCM 0.490

Polished

CHEMICAL COMPOSITION (%)

C Mn Si S P Cr NI MO Size Pcs

Min. - - - - - 18.00 8.00 -

Max. 0.030 2.00 0.75 0.030 0.045 20.00 10.50 -

Heat No.

20L1659 0.020 1.67 0.58 0.024 0.038 19.12 9.30 - 35 mm 32

20L1758 0.025 1.71 0.65 0.028 0.034 18.82 8.60 - 18 mm 30

MECHANICAL TEST RESULT - Test Condition : Annealed

Tensile Impact, Joules

Elongation Charpy - 2 mm V Notch,

Proof Strength, Strength, Hardness

% Reduction Direction - Longitudinal

Parameter N/MM2 ASTM EN ISO Test Method :- EN ISO 148-1,

GL = 50 of Area %

A370:17a 6506-1 HBW Test Temperature-

MM

0.2% (Rp 0.2) N/MM2 I II III Average

SPEC 205 MIN 515 MIN 40 MIN 45 MIN 95 Max - - - -

35 mm 367 654 51.80 55.00 87-90 - - - -

18 mm 349 627 54.10 51.00 90-93 - - - -

METALLURGICAL TEST RESULT

JOMINY HARDENABILITY NON METALLIC INCLUSION RATING GRAIN

IS 3848 ASTM E45 MACRO TEST

SIZE

PARAMETER ASTM

DISTANCE A B C D ASTM

MM /INCH

J1 J2 J3 J4 TYPE E 381

T H T H T H T H E 112

RESULT HRC - - - - RESULT - - - - - - - - 6-7 C2R2S2

Remarks:

Material is ultrasonically tested as per ASTM A388 & found satisfactory.

The material is free from Radioactive & Mercury contaminations.

Lead has not added during manufacturing.

Material confirms the requirements as per ASTM A479/ASME SA479: 2017 Cond. A

For Laxcon Steels Limited.

We here by certify that above material described herein has been

manufactured and tested with satisfactory results in accordance with

the Specification & requirements

Authorized Signatory (Q.C.)

You might also like

- Material TCDocument1 pageMaterial TCgmbakshiNo ratings yet

- TubacexDocument1 pageTubacexMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- 90mm 316l Peeled and PolishedDocument1 page90mm 316l Peeled and PolishedB.M Industrial WorksNo ratings yet

- 90mm 316l Peeled and PolishedDocument1 page90mm 316l Peeled and PolishedB.M Industrial WorksNo ratings yet

- Test Certificate: (BS EN 10204 Type 3.1)Document1 pageTest Certificate: (BS EN 10204 Type 3.1)Sachin NambiarNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOMANIMARAN QC100% (1)

- Mill'S Test Certificate ACC. TO EN 10204 / 3.1Document2 pagesMill'S Test Certificate ACC. TO EN 10204 / 3.1Durulsan MakinaNo ratings yet

- 1.20mm T.C - Mehta SteelsDocument1 page1.20mm T.C - Mehta SteelsRonak FireNo ratings yet

- 16 MM MS Plate 355 JR - India-MTCDocument1 page16 MM MS Plate 355 JR - India-MTCQc QatarNo ratings yet

- 694Document1 page694Mauricio Ramirez100% (1)

- Cert ACERO INOX 316L PDFDocument1 pageCert ACERO INOX 316L PDFCarlos RomeroNo ratings yet

- Test Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811Document1 pageTest Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811akash_smhs0% (1)

- Espectrofotómetro de Absorción Atómica AA-7000Document28 pagesEspectrofotómetro de Absorción Atómica AA-7000Gustavo RuizNo ratings yet

- D72307 TC2 PDFDocument2 pagesD72307 TC2 PDFshivdas bichukaleNo ratings yet

- MTC PipeDocument1 pageMTC PipeMathavan ABMNo ratings yet

- Img 0001Document1 pageImg 0001Harish RanaNo ratings yet

- Certificado Tubo 1.1-2 AC SC SCH 80 X 5.8-1Document1 pageCertificado Tubo 1.1-2 AC SC SCH 80 X 5.8-1Raul Esteban Jaimes GalvisNo ratings yet

- Inspection Certificate 3.1 - ,: According EN 10204: 2005Document1 pageInspection Certificate 3.1 - ,: According EN 10204: 2005B.M Industrial Works100% (1)

- MFF Spect. Blind 6 CL 150Document1 pageMFF Spect. Blind 6 CL 150Mohamed RaafatNo ratings yet

- Ribo TC 324 (00000003)Document1 pageRibo TC 324 (00000003)Vinay YadavNo ratings yet

- T.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateDocument3 pagesT.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- Mittal Corp Limited Test Certificate FinalDocument1 pageMittal Corp Limited Test Certificate FinalMehmet SoysalNo ratings yet

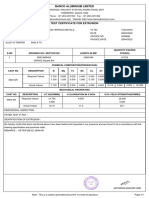

- Global Aluminium Private Limited: M/S. Wonjin Autoparts India PVT LTD, ChennaiDocument1 pageGlobal Aluminium Private Limited: M/S. Wonjin Autoparts India PVT LTD, ChennaiSonu Singh100% (1)

- Test Certificate: CM/L-NO:5530357Document10 pagesTest Certificate: CM/L-NO:5530357TARUNKUMARNo ratings yet

- Page 1 of 1: Test Certificate No. 0000141878Document1 pagePage 1 of 1: Test Certificate No. 0000141878Vishwanathan NagarajanNo ratings yet

- Bishweshwar Lal Steels: Hot Rolled Steel Strip For Welded Tubes and Pipes As Per Is: 10748 - 2004Document1 pageBishweshwar Lal Steels: Hot Rolled Steel Strip For Welded Tubes and Pipes As Per Is: 10748 - 2004ravigurajapuNo ratings yet

- 2.5 MM 1250....Document1 page2.5 MM 1250....Balaji Defence100% (1)

- SS420, 12mm-RamDocument1 pageSS420, 12mm-RamganeshNo ratings yet

- Test Certificate: CM/L-NO:5200036277Document10 pagesTest Certificate: CM/L-NO:5200036277TARUNKUMARNo ratings yet

- MTC 4500528257 Iii - 210209Document3 pagesMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNo ratings yet

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romero100% (1)

- 4140 Material For TubeDocument2 pages4140 Material For Tubesharafudheen_sNo ratings yet

- 300 C SailDocument2 pages300 C Sailchandrabhushan kushwahaNo ratings yet

- PSP TCDocument7 pagesPSP TCPSP kanpurdehatNo ratings yet

- JSW Steel MTCDocument5 pagesJSW Steel MTCNelson 2428No ratings yet

- 1802 Brida Ac WN 6 X 150 SCH STD SWDocument1 page1802 Brida Ac WN 6 X 150 SCH STD SWAlejandro L MagnusNo ratings yet

- MTC 17 4PH Al20201127a174Document1 pageMTC 17 4PH Al20201127a174Ajeng PratiwiNo ratings yet

- Sample MTCDocument1 pageSample MTCheavens indiaNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- BF20112602 English MTC PDFDocument2 pagesBF20112602 English MTC PDFSvetlana VujovićNo ratings yet

- MOE Simplex - 24.06.2016 PDFDocument4 pagesMOE Simplex - 24.06.2016 PDFSabyasachi BangalNo ratings yet

- Rajendra Ferromet Pvt. LTD.: Material Test Certificate According To en 10204:2004 / 3.1Document1 pageRajendra Ferromet Pvt. LTD.: Material Test Certificate According To en 10204:2004 / 3.1qualityNo ratings yet

- 041101Document1 page041101Carolina MolfinoNo ratings yet

- E985F8E88F069BF1BB6F005056AC67B7Document1 pageE985F8E88F069BF1BB6F005056AC67B7Jose ReynosoNo ratings yet

- Sample MTC: Material Test CertificateDocument2 pagesSample MTC: Material Test CertificateSameer KmNo ratings yet

- Heat C090 SK3RQ1.5X1Document1 pageHeat C090 SK3RQ1.5X1Keshia Murillo PinnockNo ratings yet

- Varilla 1 1 - 4 A193 B7Document1 pageVarilla 1 1 - 4 A193 B7CarlosEduardoMorenoManceraNo ratings yet

- Material Test Report: Cse. Chiang Sung Enterprise Co., LTDDocument3 pagesMaterial Test Report: Cse. Chiang Sung Enterprise Co., LTDChethan Nagaraju KumbarNo ratings yet

- 1jsl Ltd. TPI 3 (31803) MMDocument2 pages1jsl Ltd. TPI 3 (31803) MMPratik KarekarNo ratings yet

- Test CertificateDocument2 pagesTest CertificatePRITESH100% (2)

- Fittings ThrededDocument2 pagesFittings ThrededreniNo ratings yet

- Vedanta Limited Cairn Oil & Gas: Integrated Field Plan Execution Services in Satellite Fields in Rj-On 90/1 BLOCKDocument23 pagesVedanta Limited Cairn Oil & Gas: Integrated Field Plan Execution Services in Satellite Fields in Rj-On 90/1 BLOCKPRAKASH PANDEYNo ratings yet

- Ispat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsDocument4 pagesIspat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsAbhi Sheoran100% (2)

- Mill Test Certificate: Din 125 Washer Electro Zinc PlatedDocument1 pageMill Test Certificate: Din 125 Washer Electro Zinc PlatedFodor ZoltanNo ratings yet

- MTC 410-317-304 - FastenerDocument2 pagesMTC 410-317-304 - Fastenermiguel contrerasNo ratings yet

- TC 1419 McnallyDocument2 pagesTC 1419 McnallymtlhwhNo ratings yet

- MTC Elbow 6inDocument1 pageMTC Elbow 6inhenryNo ratings yet

- MTC Annexure (6 Inch)Document16 pagesMTC Annexure (6 Inch)maheshNo ratings yet

- MTC 4500528257 Iii - 210209Document3 pagesMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNo ratings yet

- DB-En 19 R-2-829 PDFDocument4 pagesDB-En 19 R-2-829 PDFashokNo ratings yet

- Inc 800 MTC - FlangeDocument1 pageInc 800 MTC - Flangeranjith_007100% (1)

- SS 310 Mill TC - 16,18,20,22,40Document1 pageSS 310 Mill TC - 16,18,20,22,40rajiv.raskarNo ratings yet

- Alu SQ Rod 80X80Document1 pageAlu SQ Rod 80X80B.M Industrial WorksNo ratings yet

- Inspection Certificate 3.1 - ,: According EN 10204: 2005Document1 pageInspection Certificate 3.1 - ,: According EN 10204: 2005B.M Industrial Works100% (1)

- CK45 VSP TCDocument1 pageCK45 VSP TCB.M Industrial WorksNo ratings yet

- 15 Saptember Ut Report - 2022Document1 page15 Saptember Ut Report - 2022B.M Industrial WorksNo ratings yet

- Hydraulic Failure AnalysisDocument93 pagesHydraulic Failure AnalysisJoseph Jose86% (7)

- Lesson 3 Sieve AnalysisDocument20 pagesLesson 3 Sieve AnalysisjrNo ratings yet

- To Study The Analysis, Design and Behavior of Corrugated Steel SiloDocument7 pagesTo Study The Analysis, Design and Behavior of Corrugated Steel SiloMohammed AlnasharNo ratings yet

- DehydrationDocument4 pagesDehydrationAlexandra CatalinaNo ratings yet

- Dried Java Plum Tantoyparedesvillaneva 1Document8 pagesDried Java Plum Tantoyparedesvillaneva 1yournicole T.No ratings yet

- 11kv Disc Insulator GTP and SpecificationDocument10 pages11kv Disc Insulator GTP and SpecificationSatyaNo ratings yet

- Chemistry Project Class 12Document13 pagesChemistry Project Class 12Shlok Sah50% (2)

- Effects of Temperature On Enzyme ActivityDocument6 pagesEffects of Temperature On Enzyme Activityapi-340424437No ratings yet

- Atex Directive in A NutshellDocument4 pagesAtex Directive in A NutshellAnonymous 96SYLheENo ratings yet

- Edexcel GCE Biology Unit-4 (R) June 2013 Question PaperDocument20 pagesEdexcel GCE Biology Unit-4 (R) June 2013 Question PaperAvrinox100% (1)

- Fisa Tehnica Robineti Sertar R55Document2 pagesFisa Tehnica Robineti Sertar R55Petrisor FilipNo ratings yet

- Nicrofer 3220 3220h eDocument15 pagesNicrofer 3220 3220h eKevinCollinNo ratings yet

- Chapter 7 Case Study: Engineering Ethics and PrinciplesDocument14 pagesChapter 7 Case Study: Engineering Ethics and PrinciplesInna IgnacioNo ratings yet

- Verification of Johnson-Cook Material Model Constants of Aa2024-T3 For Use in Finite Element Simulation of Friction Stir Welding and Its Utilization in Severe Plastic DeformationDocument5 pagesVerification of Johnson-Cook Material Model Constants of Aa2024-T3 For Use in Finite Element Simulation of Friction Stir Welding and Its Utilization in Severe Plastic DeformationInternational Journal of Research in Engineering and TechnologyNo ratings yet

- 104 - Vacuum DryingDocument2 pages104 - Vacuum DryingJeisson PerezNo ratings yet

- Pregelatinised StarchDocument4 pagesPregelatinised StarchHani AlhelwaniNo ratings yet

- D 6003 - 96Document8 pagesD 6003 - 96othmanNo ratings yet

- MolarityDocument2 pagesMolarityUdayan RoyNo ratings yet

- Statistical Thermodynamics - An Engineering ApproachDocument284 pagesStatistical Thermodynamics - An Engineering Approachhgutierrezcable0% (1)

- Unit - 3 Solar Photovoltaic SystemDocument15 pagesUnit - 3 Solar Photovoltaic SystemSudhir MallampatiNo ratings yet

- Concentration of Solution: (Molarity)Document8 pagesConcentration of Solution: (Molarity)Ethylaine ApilanNo ratings yet

- Site Visit ReportDocument3 pagesSite Visit ReportSolomon BalemeziNo ratings yet

- SVKM J.V. Parekh International School 2018-2019 Cycle Test 2 Portion Class: IXDocument3 pagesSVKM J.V. Parekh International School 2018-2019 Cycle Test 2 Portion Class: IXNyonikaNo ratings yet

- 2160607-Elementary Structural Design 09012017 040945AMDocument16 pages2160607-Elementary Structural Design 09012017 040945AMAydinAkhtarpour100% (1)

- Corrosion MonitoringDocument22 pagesCorrosion MonitoringJai Patel100% (2)

- Teachers Guidebook CCE Whole GuideDocument375 pagesTeachers Guidebook CCE Whole GuideJedy Tah0% (1)

- Synthesis of Soap DetergentDocument4 pagesSynthesis of Soap DetergentHarvey Mher RarangNo ratings yet

- Cuidados Electrodo Con LitioDocument2 pagesCuidados Electrodo Con LitioFelix MendozaNo ratings yet

- How To Read U Tube Manometer PDFDocument5 pagesHow To Read U Tube Manometer PDFAnonymous zdCUbW8Hf0% (1)