Professional Documents

Culture Documents

IMG - 0144 PSME Code 2012 144

IMG - 0144 PSME Code 2012 144

Uploaded by

Bugoy20230 ratings0% found this document useful (0 votes)

3 views1 page1. This document provides requirements for vent connectors used with gas appliances, including that vent connectors must slope upward to the vent or chimney, be as short as practical, and have minimum clearances from combustible materials.

2. When two or more appliances are connected to a single vent, the smaller connector must enter at the highest level possible. Vent connectors serving Category I appliances cannot connect to mechanical draft systems for Category III or IV appliances.

3. Vent connectors must be supported to maintain clearances and prevent damage, and enter chimneys above the bottom to avoid stoppage. The entire length must be accessible for inspection and cleaning.

Original Description:

PSME

Original Title

IMG_0144 PSME Code 2012 144

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. This document provides requirements for vent connectors used with gas appliances, including that vent connectors must slope upward to the vent or chimney, be as short as practical, and have minimum clearances from combustible materials.

2. When two or more appliances are connected to a single vent, the smaller connector must enter at the highest level possible. Vent connectors serving Category I appliances cannot connect to mechanical draft systems for Category III or IV appliances.

3. Vent connectors must be supported to maintain clearances and prevent damage, and enter chimneys above the bottom to avoid stoppage. The entire length must be accessible for inspection and cleaning.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

3 views1 pageIMG - 0144 PSME Code 2012 144

IMG - 0144 PSME Code 2012 144

Uploaded by

Bugoy20231. This document provides requirements for vent connectors used with gas appliances, including that vent connectors must slope upward to the vent or chimney, be as short as practical, and have minimum clearances from combustible materials.

2. When two or more appliances are connected to a single vent, the smaller connector must enter at the highest level possible. Vent connectors serving Category I appliances cannot connect to mechanical draft systems for Category III or IV appliances.

3. Vent connectors must be supported to maintain clearances and prevent damage, and enter chimneys above the bottom to avoid stoppage. The entire length must be accessible for inspection and cleaning.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

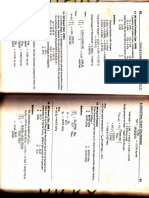

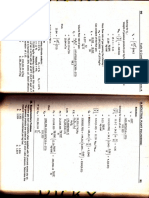

methods.

As an alternate method applicable slope upward toward the vent or chimney at

only where there are two draft hood- least 1/4 in.lft. (20 mm/m).

equipped appliances, the effective area of Exception: Vent connectors attached to a

the common vent connector or vent mechanical draft system installed in accor-

manifoid and all junction fittings shall be not dance with the manufacturers' instructions.

less than the atea of the larger vent

connector plus 50 percent of the areas of 802.10.9 Length of Vent Connector.

smaller flue collar outlets.

802.10.9.1 A vent connector shall be as

802.10.3.4 Where the size of a vent short as practical, and the gas utilization

connector is increased to overcome equipment located as close as practical to

installation limitations and obtain connector the chimney or vent.

capacity equal to the equipment input, the

size increase shall be made at the 802.10.9.2 The maximum horizontal length

equipment draft hood outlet. of a single-wall connector shall be 75

percent of the height of the chimney or vent

802.10.4 Two or More Appliances Gonnected except for engineered systems. The

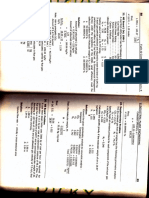

to a Single Vent. maximum length of an individual connector

for a chimney or vent system serving

802.10.4.1 Where two or more vent multiple appliances, from the appliance

connectors enter a common gas vent, outlet to the junction with the common vent

chimney flue, or single-wall metal pipe, the or another connector, shall be 100 percent

smaller connector shall enter 6t the highest of the height of the chimney or vent. [NFPA

level consistent with the available headroom 54:12.11.9.21

or clearance to combustible material-

802.10.9.3 The maximum horizontal length

802.10.4.2 Vent connectors serving of a Type B double wall connector shall be

Category I appliances shall not be 100 percent of the height of the chimney or

connected to any portion of a mechanical vent, except for engineered systems. The

draft system operating under positive static maximum length of an individual connector

pressure, such as those serving Category lll for a chimney or vent system serving

or Category lV appliances. multiple appliances, from the appliance

outlet to the junction with the common vent

802.10.5 -Clearance. Minimum clearances from or another connector, shall be 100 percent

vent connectors to combustible material shall be of the height of the chimney or vent. [NFPA

in accordance with 54: 12.11.9.31

Exception: The clearance between a vent

connector and combustible material shall be 802.10.10 Support. A vent connector shall be

permitted to be reduced where the supported for the design and weight of the

combustible material is protected as material employed to maintain clearances and

specified for vent connectors in Table 5-3. prevent physical damage and separation of

joints.

802.10.6 Avoid Unnecessary Bends. A vent

connector shall be installed so as to avoid turns 802.10.11 Chimney Connection. lruneie

or other construction features that create entering a flue in a masonry or metal chimney,

excessive resistance to flow of vent gases. the vent connector shall be installed above the

extreme bottom to avoid stoppage. Where a

802.10.7 Joints. Joints between sections of thimble or slip joint is used to facilitate removal

connector piping and connections to flue collars of the connector, the connector shall be firmly

or draft hood outlets shall be fastened in attached to or inserted into the thimble or slip

accordance with one of the following methods: joint to prevent the connector from falling out.

(1) By sheet metal screws. I Means shall be employed to prevent the

(2) Vent connectors of listed vent material shall connector from entering so far as to restrict the

be assembled and connected to flue collars space between its end and the opposite wall of

or draft hood outlets in accordance with the the chimney flue.

manufactu rers' instructions.

(3) Other approved means. 802.10.12 lnspection. The entire length of a

vent connector shall be readily accessible for

802.10.8 Slope. A vent connector shall be inspection, cleaning, and replacement.

installed without any dips or sags and shall

144 2012 PHILIPPINE MECHANICAL ENGINEERING CODE

You might also like

- BSBSUS511 Project PortfolioDocument37 pagesBSBSUS511 Project PortfolioWalter Bravo100% (2)

- Revised National Plumbing Code: of The PhilippinesDocument49 pagesRevised National Plumbing Code: of The PhilippinesAlskduiNo ratings yet

- Specification For Phenolic Duct Works SystemsDocument2 pagesSpecification For Phenolic Duct Works Systemspsn_kylm100% (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Duct SystemsDocument32 pagesDuct SystemsJherson GravidesNo ratings yet

- Odour Control Unit PDFDocument4 pagesOdour Control Unit PDFjuncNo ratings yet

- Service DuctsDocument25 pagesService DuctsRiddhi Patel100% (1)

- IMG - 0142 PSME Code 2012 141Document1 pageIMG - 0142 PSME Code 2012 141Bugoy2023No ratings yet

- Steam 1Document4 pagesSteam 1NaNo ratings yet

- Revised National Plumbing Code of The Philippines 101-225Document125 pagesRevised National Plumbing Code of The Philippines 101-225Kenneth D. PacadaNo ratings yet

- 52331HVACDucts 000Document4 pages52331HVACDucts 000carlos ruizNo ratings yet

- HVAC Ductwork SpecificationDocument4 pagesHVAC Ductwork SpecificationhvacwallyNo ratings yet

- Research No 5Document11 pagesResearch No 5Hanie GraceNo ratings yet

- Crown Home Consultants: Cleopatra Plaza Tower (Nasr City) Specifications 15861/1 Rev.0 March.2012Document3 pagesCrown Home Consultants: Cleopatra Plaza Tower (Nasr City) Specifications 15861/1 Rev.0 March.2012Waleed Abd El-HamiedNo ratings yet

- Vent SystemDocument8 pagesVent SystemzebidiansNo ratings yet

- Duct For Corrosive Fumes ExhaustDocument8 pagesDuct For Corrosive Fumes ExhaustTS WongNo ratings yet

- Section - 15910 Ductwork AccessoriesDocument3 pagesSection - 15910 Ductwork AccessoriesalbrgmailNo ratings yet

- Lightnin Otection SystemDocument6 pagesLightnin Otection Systemsajeevi piumikaNo ratings yet

- The Akatherm Akavent System: Design GuidelinesDocument16 pagesThe Akatherm Akavent System: Design Guidelinesdaud heruNo ratings yet

- DuctHeaters CatalogDocument12 pagesDuctHeaters Catalogjohnking5555No ratings yet

- Plumb Ling VentingDocument30 pagesPlumb Ling VentingNatthasart MuangsuankwanNo ratings yet

- Bipcui 02#120216Document3 pagesBipcui 02#120216Marlon CayabyabNo ratings yet

- Assignment 1Document7 pagesAssignment 1Jon Lester CabanesNo ratings yet

- Code of Practice On Sanitary Plumbing and Drainage System 15 28Document14 pagesCode of Practice On Sanitary Plumbing and Drainage System 15 28KyawtNo ratings yet

- 3%!, #,!33 3ealing 2equirements !pplicable 3tatic 0ressure #Onstruction #LassDocument2 pages3%!, #,!33 3ealing 2equirements !pplicable 3tatic 0ressure #Onstruction #LassShiyun SeNo ratings yet

- Chapter 9 - VentsDocument8 pagesChapter 9 - VentsVivek ShettyNo ratings yet

- GeminiDocument5 pagesGeminiSoy ChandaraNo ratings yet

- 4.2.1.1 Outside Air Intakes Shall: (See Section 6.3 For Smoke Damper Operation To Restrict The Intake of Smoke.)Document7 pages4.2.1.1 Outside Air Intakes Shall: (See Section 6.3 For Smoke Damper Operation To Restrict The Intake of Smoke.)Sujit DungaNo ratings yet

- Pre Insulated Duct SpecificationDocument6 pagesPre Insulated Duct SpecificationGlishna Peushan Widanapathirana0% (1)

- Vents For Plumbing System PDFDocument47 pagesVents For Plumbing System PDFIrfanshah2013No ratings yet

- Ac Units Technical Specifications Annex ADocument44 pagesAc Units Technical Specifications Annex Aengr.genaNo ratings yet

- Chapter 7 (ACMV)Document140 pagesChapter 7 (ACMV)engkankwNo ratings yet

- Vent Size & Max. Distance From Fixture PDFDocument1 pageVent Size & Max. Distance From Fixture PDFbilal almelegyNo ratings yet

- Rowan University Design Guide 2013Document3 pagesRowan University Design Guide 2013zeliteNo ratings yet

- Gas Piping Building Services 1Document21 pagesGas Piping Building Services 1abinayaNo ratings yet

- LKS Dust Opacity Analyzer D10 2Document19 pagesLKS Dust Opacity Analyzer D10 2KC WangNo ratings yet

- Hager Guide To 17th Edition Consumer UnitsDocument26 pagesHager Guide To 17th Edition Consumer UnitsGabetsos KaraflidisNo ratings yet

- AppendixDocument24 pagesAppendixSecret SecretNo ratings yet

- Chapter 38 Instrument Installation and Commissioning 2010 Instrumentation Reference Book Fourth EditionDocument6 pagesChapter 38 Instrument Installation and Commissioning 2010 Instrumentation Reference Book Fourth EditionMotasim_mNo ratings yet

- Protection of Petroleum or Gas TanksDocument4 pagesProtection of Petroleum or Gas TanksvidalNo ratings yet

- Abstract of IE RulesDocument6 pagesAbstract of IE RulesNavneet SinghNo ratings yet

- VBA 7.03 Mechanical Services Condensate Drainage Utilising Self-Sealing DevicesDocument4 pagesVBA 7.03 Mechanical Services Condensate Drainage Utilising Self-Sealing DevicesstevenNo ratings yet

- Microfast 0.75 Fast UnitDocument4 pagesMicrofast 0.75 Fast UnitJelena KalcNo ratings yet

- Section 15910 Ductwork AccessoriesDocument9 pagesSection 15910 Ductwork AccessorieskdpmansiNo ratings yet

- Compact PRC Exam ReviewerDocument34 pagesCompact PRC Exam ReviewerDaniel Fancis Amabran Barrientos100% (1)

- SECTION 15861 Air Filters Part 1 - General 1.1 Related DocumentsDocument3 pagesSECTION 15861 Air Filters Part 1 - General 1.1 Related DocumentsfatREVITNo ratings yet

- Venting For Plumbing SystemsDocument47 pagesVenting For Plumbing Systemscrawdoogie100% (1)

- Promat Self Supporting DuctsDocument9 pagesPromat Self Supporting DuctsBen CarrollNo ratings yet

- Steam Trap Installation Best Practices STLDocument2 pagesSteam Trap Installation Best Practices STLRosyad Broe CaporegimeNo ratings yet

- Fire Code 140Document21 pagesFire Code 140patitay036817No ratings yet

- 1210.0 Gas Piping InstallationDocument8 pages1210.0 Gas Piping InstallationHu Hin AngNo ratings yet

- Equator 1Document48 pagesEquator 1sajkhdjksahdkjNo ratings yet

- Design Guide For Customer-Owned Transformer VaultsDocument8 pagesDesign Guide For Customer-Owned Transformer VaultssauroNo ratings yet

- Specification For Phenolic Duct Works SystemsDocument2 pagesSpecification For Phenolic Duct Works Systemspsn_kylmNo ratings yet

- IMG - 0140 PSME Code 2012 139Document1 pageIMG - 0140 PSME Code 2012 139Bugoy2023No ratings yet

- 1.Chiều dài ống gió mềm-SMACNA 1995Document4 pages1.Chiều dài ống gió mềm-SMACNA 1995Long MaiNo ratings yet

- Refrig. InsulationDocument2 pagesRefrig. Insulationamechmar5935No ratings yet

- Trafo Installed IndoorDocument20 pagesTrafo Installed IndoorAtoelAcoNo ratings yet

- CVS3 HVAC Duct Metal Work Specifications FINALDocument8 pagesCVS3 HVAC Duct Metal Work Specifications FINALMohammed MohieNo ratings yet

- LKS Dust & Opacity Analyzer D10Document18 pagesLKS Dust & Opacity Analyzer D10KC WangNo ratings yet

- Air Condition GuidelinesDocument2 pagesAir Condition Guidelinesivan.infiniteedgeNo ratings yet

- IMG - 0044 ESAS 2001 Solved Problem Objectives 9-18Document1 pageIMG - 0044 ESAS 2001 Solved Problem Objectives 9-18Bugoy2023No ratings yet

- Img - 0046 MCQ For Power & Ipe 83Document1 pageImg - 0046 MCQ For Power & Ipe 83Bugoy2023No ratings yet

- Img - 0043 MCQ For Power & Ipe 77Document1 pageImg - 0043 MCQ For Power & Ipe 77Bugoy2023No ratings yet

- Img - 0045 MCQ For Power & Ipe 81Document1 pageImg - 0045 MCQ For Power & Ipe 81Bugoy2023No ratings yet

- Img - 0049 MCQ For Power & Ipe 89Document1 pageImg - 0049 MCQ For Power & Ipe 89Bugoy2023No ratings yet

- Img - 0047 MCQ For Power & Ipe 85Document1 pageImg - 0047 MCQ For Power & Ipe 85Bugoy2023No ratings yet

- Img - 0041 MCQ For Power & Ipe 73Document1 pageImg - 0041 MCQ For Power & Ipe 73Bugoy2023No ratings yet

- Img - 0048 MCQ For Power & Ipe 87Document1 pageImg - 0048 MCQ For Power & Ipe 87Bugoy2023No ratings yet

- Img - 0042 MCQ For Power & Ipe 75Document1 pageImg - 0042 MCQ For Power & Ipe 75Bugoy2023No ratings yet

- Img - 0050 MCQ For Power & Ipe 91Document1 pageImg - 0050 MCQ For Power & Ipe 91Bugoy2023No ratings yet

- Img - 0044 MCQ For Power & Ipe 79Document1 pageImg - 0044 MCQ For Power & Ipe 79Bugoy2023No ratings yet

- Img - 0091 MCQ Ece Board Exam 169Document1 pageImg - 0091 MCQ Ece Board Exam 169Bugoy2023No ratings yet

- IMG - 0094 PSME Code 2012 92Document1 pageIMG - 0094 PSME Code 2012 92Bugoy2023No ratings yet

- IMG - 0126 PSME Code 2008 117Document1 pageIMG - 0126 PSME Code 2008 117Bugoy2023No ratings yet

- IMG - 0121 PSME Code 2008 112Document1 pageIMG - 0121 PSME Code 2008 112Bugoy2023No ratings yet

- IMG - 0130 PSME Code 2008 121Document1 pageIMG - 0130 PSME Code 2008 121Bugoy2023No ratings yet

- IMG - 0124 PSME Code 2008 115Document1 pageIMG - 0124 PSME Code 2008 115Bugoy2023No ratings yet

- IMG - 0098 PSME Code 2012 96Document1 pageIMG - 0098 PSME Code 2012 96Bugoy2023No ratings yet

- IMG - 0128 PSME Code 2008 119Document1 pageIMG - 0128 PSME Code 2008 119Bugoy2023No ratings yet

- IMG - 0130 ESAS 2001 Solved Problem Objectives 23-15Document1 pageIMG - 0130 ESAS 2001 Solved Problem Objectives 23-15Bugoy2023No ratings yet

- Img - 0098 MCQ Ece Board Exam 183Document1 pageImg - 0098 MCQ Ece Board Exam 183Bugoy2023No ratings yet

- IMG - 0100 PSME Code 2012 98Document1 pageIMG - 0100 PSME Code 2012 98Bugoy2023No ratings yet

- IMG - 0096 PSME Code 2012 94Document1 pageIMG - 0096 PSME Code 2012 94Bugoy2023No ratings yet

- Img - 0097 MCQ Ece Board Exam 181Document1 pageImg - 0097 MCQ Ece Board Exam 181Bugoy2023No ratings yet

- IMG - 0092 PSME Code 2012 90Document1 pageIMG - 0092 PSME Code 2012 90Bugoy2023No ratings yet

- Img - 0099 MCQ Ece Board Exam 185Document1 pageImg - 0099 MCQ Ece Board Exam 185Bugoy2023No ratings yet

- Img - 0093 MCQ Ece Board Exam 173Document1 pageImg - 0093 MCQ Ece Board Exam 173Bugoy2023No ratings yet

- Img - 0095 MCQ Ece Board Exam 177Document1 pageImg - 0095 MCQ Ece Board Exam 177Bugoy2023No ratings yet

- Img - 0092 MCQ Ece Board Exam 171Document1 pageImg - 0092 MCQ Ece Board Exam 171Bugoy2023No ratings yet

- Img - 0096 MCQ Ece Board Exam 179Document1 pageImg - 0096 MCQ Ece Board Exam 179Bugoy2023No ratings yet

- Service and Repair Manual: GS - 3384 GS - 3390 GS - 4390 GS - 5390Document213 pagesService and Repair Manual: GS - 3384 GS - 3390 GS - 4390 GS - 5390Juan CortezNo ratings yet

- Research Title Defense 2Document5 pagesResearch Title Defense 2Matsuri VirusNo ratings yet

- Marine Compression Ignition 2000 PresentDocument2,618 pagesMarine Compression Ignition 2000 Presentahmed hasanNo ratings yet

- Test Report For Feeder Protection RelayDocument3 pagesTest Report For Feeder Protection RelayHari haranNo ratings yet

- Mechanical Seal Applications A Comprehensive ReportDocument2 pagesMechanical Seal Applications A Comprehensive Reportvarunzhao86No ratings yet

- Cement IntrooductionDocument4 pagesCement Introoductiondigvijay singhNo ratings yet

- Learning Module 1: Our Saviour'S Foundation, IncDocument8 pagesLearning Module 1: Our Saviour'S Foundation, IncSharmaine DiegoNo ratings yet

- (2D Simulation) Thermal Power Plant Upgrade Via A Rotating Detonation Combustor andDocument11 pages(2D Simulation) Thermal Power Plant Upgrade Via A Rotating Detonation Combustor andDylan HsiehNo ratings yet

- Products and solution-VFDDocument58 pagesProducts and solution-VFDAneka Teknik SolusindoNo ratings yet

- II Internals (1dt20ai028) ChemDocument20 pagesII Internals (1dt20ai028) Chem1DT20AI016-Deeksha RNo ratings yet

- CBSE Class 11 Chemistry-EquilibriumDocument71 pagesCBSE Class 11 Chemistry-EquilibriumkrkdjcjjddjNo ratings yet

- Continuous ReactorDocument36 pagesContinuous ReactorDehison Guerrero PurisNo ratings yet

- Geothermal-Energy-Day-1-Ma'am LadelynDocument4 pagesGeothermal-Energy-Day-1-Ma'am LadelynLadelyn BugarinNo ratings yet

- The Goal of A Separations Process Is To Purify SolutionsDocument10 pagesThe Goal of A Separations Process Is To Purify Solutionskiranpatil1014532No ratings yet

- Cognito - Physics QuizDocument1 pageCognito - Physics QuizYay YayayNo ratings yet

- Electrical Safety 3 Steps To Test Your RCCB PosterDocument1 pageElectrical Safety 3 Steps To Test Your RCCB PosterGoogool YNo ratings yet

- Part 7Document20 pagesPart 7Fitri Rizki AmaliaNo ratings yet

- Jac HFC4GB1Document70 pagesJac HFC4GB1Jeifred Espitia AraujoNo ratings yet

- Data Sheet Solenoid Valves Type EVR 2 40 NC / No: RD.3A.D2.02 1Document20 pagesData Sheet Solenoid Valves Type EVR 2 40 NC / No: RD.3A.D2.02 1GogaNo ratings yet

- NDT For High Temperature Hydrogen Attack (HTHA) - NdeDocument7 pagesNDT For High Temperature Hydrogen Attack (HTHA) - NdeMahbub ShojibNo ratings yet

- 3.1 # Diffusion and OsmosisDocument4 pages3.1 # Diffusion and OsmosisSara Nadeem KhanNo ratings yet

- ET Training ID Fan CBDDocument22 pagesET Training ID Fan CBDVishal HiremathNo ratings yet

- Engine Problems and TestsDocument42 pagesEngine Problems and TestsBiniyamNo ratings yet

- Bek3 Oem Genset Controller ManualDocument36 pagesBek3 Oem Genset Controller ManualNguyễn Tấn BạoNo ratings yet

- Side Stream FiltrationDocument8 pagesSide Stream FiltrationAhmed WagihNo ratings yet

- Oli Energol GR-XPDocument2 pagesOli Energol GR-XPakun leptopNo ratings yet

- ASME Pressure Vessel Design PDFDocument62 pagesASME Pressure Vessel Design PDFhilwan sultonNo ratings yet

- ICCT Annual Report 2020Document36 pagesICCT Annual Report 2020The International Council on Clean Transportation100% (1)

- Chapter 3 - Work Energy and PowerDocument15 pagesChapter 3 - Work Energy and PowerRITCHIE LOU CAGULADANo ratings yet