Professional Documents

Culture Documents

MTT-I-DS-001 013 - C - Instrument Datasheet - Compressed

MTT-I-DS-001 013 - C - Instrument Datasheet - Compressed

Uploaded by

dandi zlkCopyright:

Available Formats

You might also like

- Ralph L. Webb, Nae-Hyun Kim - Principles of Enhanced Heat Transfer-CRC Press (2005)Document816 pagesRalph L. Webb, Nae-Hyun Kim - Principles of Enhanced Heat Transfer-CRC Press (2005)arif aktaş100% (1)

- Piping and Instrumentation Diagram DevelopmentFrom EverandPiping and Instrumentation Diagram DevelopmentRating: 3.5 out of 5 stars3.5/5 (3)

- Mi Swaco Screen Catalog-1Document1 pageMi Swaco Screen Catalog-1dandi zlk0% (1)

- MANUAL DezumidificatorDocument98 pagesMANUAL DezumidificatorcivodulNo ratings yet

- Oil Water Separator CalcDocument6 pagesOil Water Separator Calczamijaka100% (1)

- Flexural - Torsional Buckling Analysis of Thin Walled Columns Using The Fourier Series MethodDocument7 pagesFlexural - Torsional Buckling Analysis of Thin Walled Columns Using The Fourier Series MethodIJAERS JOURNALNo ratings yet

- Hanshin Hs 2519vdDocument2 pagesHanshin Hs 2519vdnotaden1849No ratings yet

- PPD - Module IDocument9 pagesPPD - Module IJohn Babe CapiliNo ratings yet

- IBL-I-DS-001 - 017 - C - Instrument Datasheet Signed AGa 20201230 - CompressedDocument49 pagesIBL-I-DS-001 - 017 - C - Instrument Datasheet Signed AGa 20201230 - Compresseddandi zlk100% (1)

- DS Pressure Gauge Rev.0 (Additional Scope)Document4 pagesDS Pressure Gauge Rev.0 (Additional Scope)Irwansyah CahyaNo ratings yet

- Ds-pp-0006 - Data Sheet For Sampling Jars (Rev.0) - 24!10!2023Document3 pagesDs-pp-0006 - Data Sheet For Sampling Jars (Rev.0) - 24!10!2023Panisa BanimaNo ratings yet

- 315020-DOC-7015 - (Instrument Datasheet - Pressure Regulator Valve) - RevADocument3 pages315020-DOC-7015 - (Instrument Datasheet - Pressure Regulator Valve) - RevAanwar sadatNo ratings yet

- DS - Pressure GaugeDocument5 pagesDS - Pressure GaugeNawfel ArafathNo ratings yet

- OSP078 IC DAS 8009 Rev.0 Pressure Differential Indicator DatasheetDocument4 pagesOSP078 IC DAS 8009 Rev.0 Pressure Differential Indicator DatasheetAhmedNo ratings yet

- DPT Level TransmitterDocument4 pagesDPT Level TransmitterkamarajkanNo ratings yet

- Datasheet For Pressure Controller - IfbDocument17 pagesDatasheet For Pressure Controller - Ifbfathan fathullahNo ratings yet

- Ip Pressure Transmitter Data SheetDocument4 pagesIp Pressure Transmitter Data SheetMohammad BabazadehNo ratings yet

- DS Pressure Gauge Rev.0 (Additional Scope) Part 3Document1 pageDS Pressure Gauge Rev.0 (Additional Scope) Part 3Irwansyah CahyaNo ratings yet

- Pmal-435-Hd-K-025-1 ObsDocument5 pagesPmal-435-Hd-K-025-1 ObsDavid BarrenecheaNo ratings yet

- Float Level Switch Specification - AFC-1 (ALL)Document8 pagesFloat Level Switch Specification - AFC-1 (ALL)Phạm Tấn PhướcNo ratings yet

- Self Acting Pressure Control ValveDocument7 pagesSelf Acting Pressure Control ValveSreejesh Sundaresan100% (1)

- EHK-IKPP-IS-DTS-004 Datasheet For Pressure & DP Indicator Rev 1Document7 pagesEHK-IKPP-IS-DTS-004 Datasheet For Pressure & DP Indicator Rev 1Ahmad RezaNo ratings yet

- 01 Datasheet Pressure Diff GaugesDocument2 pages01 Datasheet Pressure Diff GaugesFadlila MuhammadNo ratings yet

- V-2158-103-A-851 - 4 ITP For PumpDocument4 pagesV-2158-103-A-851 - 4 ITP For PumpMessaoud GoutasNo ratings yet

- DS - DP Type Flow IndicatorsDocument5 pagesDS - DP Type Flow IndicatorsNawfel ArafathNo ratings yet

- DS - Flow Element (Orifice)Document5 pagesDS - Flow Element (Orifice)Nawfel ArafathNo ratings yet

- 04 Datasheet Control ValveDocument8 pages04 Datasheet Control ValveFadlila MuhammadNo ratings yet

- EHK-PET-MS-INS-DTS-004 Data Sheet For Temperature Indicator Rev. 1-IFA - OKDocument5 pagesEHK-PET-MS-INS-DTS-004 Data Sheet For Temperature Indicator Rev. 1-IFA - OKSehargo JunizarNo ratings yet

- 000 in DTS 401Document6 pages000 in DTS 401zsmithNo ratings yet

- 09 Datasheet ATGDocument11 pages09 Datasheet ATGFadlila MuhammadNo ratings yet

- VF003 - Level Gauge (ALL) PDFDocument21 pagesVF003 - Level Gauge (ALL) PDFPhạm Tấn PhướcNo ratings yet

- Flexible HoseDocument1 pageFlexible HoseKhánh TrầnNo ratings yet

- Datasheet For On/Off Valve (Xv-001) Datasheet For On/Off Valve (Xv-001)Document2 pagesDatasheet For On/Off Valve (Xv-001) Datasheet For On/Off Valve (Xv-001)usama666No ratings yet

- 315020-DOC-7003 - (Instrument Datasheets - Magnetic Level Gauge) - RevADocument3 pages315020-DOC-7003 - (Instrument Datasheets - Magnetic Level Gauge) - RevAanwar sadatNo ratings yet

- Ds-pp-0106 - Mechanical Data Sheet For Hose Assemblies (Rev.e) - 30!10!2023Document5 pagesDs-pp-0106 - Mechanical Data Sheet For Hose Assemblies (Rev.e) - 30!10!2023Panisa BanimaNo ratings yet

- PSV Datasheet - Rev1Document64 pagesPSV Datasheet - Rev1sswahyudiNo ratings yet

- Safety Shower / Eye Wash: @T @S @D @B @C @PDDocument2 pagesSafety Shower / Eye Wash: @T @S @D @B @C @PDyskushwah16No ratings yet

- 0P16-I-IN-DTS-01-007 Datasheet For Temperature Gauge - Rev2Document6 pages0P16-I-IN-DTS-01-007 Datasheet For Temperature Gauge - Rev2fathan fathullahNo ratings yet

- Ds-pp-0107 - Mechanical Data Sheet For Swivel Joints (Rev.0)Document3 pagesDs-pp-0107 - Mechanical Data Sheet For Swivel Joints (Rev.0)Panisa BanimaNo ratings yet

- DS For Level SwitchDocument7 pagesDS For Level SwitchnathaNo ratings yet

- 02 Datasheet Pressure TransmitterDocument2 pages02 Datasheet Pressure TransmitterFadlila MuhammadNo ratings yet

- Shutdown Valve Data Sheets: Customer Name: Cpe Job #: Project TitleDocument2 pagesShutdown Valve Data Sheets: Customer Name: Cpe Job #: Project TitleImmanuelNo ratings yet

- Pressure Indicating TransmitterDocument8 pagesPressure Indicating TransmitterOktavianusHeruNo ratings yet

- TIPL-ES-CL-001 - P&ID ChecklistDocument7 pagesTIPL-ES-CL-001 - P&ID ChecklistAshwin PathakNo ratings yet

- Hose ConnectionDocument1 pageHose ConnectionKhánh TrầnNo ratings yet

- Ds-pp-0107 - Mechanical Data Sheet For Swivel Joints (Rev.b)Document3 pagesDs-pp-0107 - Mechanical Data Sheet For Swivel Joints (Rev.b)Panisa BanimaNo ratings yet

- Ds-pp-0012 - Data Sheet For Flow Glass (Rev.c)Document3 pagesDs-pp-0012 - Data Sheet For Flow Glass (Rev.c)Panisa BanimaNo ratings yet

- Discipline: Rev. No.: Size: Document No.: Unit / Area NameDocument5 pagesDiscipline: Rev. No.: Size: Document No.: Unit / Area NameRishabh VermaNo ratings yet

- SHELL - Flowmeter PDFDocument2 pagesSHELL - Flowmeter PDFgalih santosoNo ratings yet

- Datasheet For Level Gauge - IfbDocument51 pagesDatasheet For Level Gauge - Ifbfathan fathullahNo ratings yet

- Pressure Transmitter Spec Form 403 - KWDocument1 pagePressure Transmitter Spec Form 403 - KWsurendharNo ratings yet

- 3 - Pen Chart RecorderDocument1 page3 - Pen Chart RecorderHamza HashimNo ratings yet

- Datasheet Pressure & DP Transmitter For Teluk LamongDocument3 pagesDatasheet Pressure & DP Transmitter For Teluk LamongsswahyudiNo ratings yet

- Datasheet For Pressure Gauge - Process DataDocument8 pagesDatasheet For Pressure Gauge - Process DataLai HuynhNo ratings yet

- Ds-pp-0108 - Data Sheet For Underwing Nozzle Connector (Rev.0)Document2 pagesDs-pp-0108 - Data Sheet For Underwing Nozzle Connector (Rev.0)Panisa BanimaNo ratings yet

- (6648-0200-5-PS-DS-0026) 200-C-51 - Rev.FDocument15 pages(6648-0200-5-PS-DS-0026) 200-C-51 - Rev.FMohamed OuichaouiNo ratings yet

- Perú Corp. S.A.: Indicadores de PresiónDocument5 pagesPerú Corp. S.A.: Indicadores de PresiónDavid BarrenecheaNo ratings yet

- Datasheet For Level Controller - IfbDocument27 pagesDatasheet For Level Controller - Ifbfathan fathullahNo ratings yet

- Tech 1469 ManDocument25 pagesTech 1469 ManRiski KurniawanNo ratings yet

- Data Sheet For Magnetic Type Level GaugeDocument5 pagesData Sheet For Magnetic Type Level GaugeJaya RamNo ratings yet

- Pengadaan Semarang Gas Distribution Pipe Line (Cp-16) : Datasheet Contract NoDocument4 pagesPengadaan Semarang Gas Distribution Pipe Line (Cp-16) : Datasheet Contract Nobagus handokoNo ratings yet

- Ds-pp-0108 - Data Sheet For Underwing Nozzle Connector (Rev.c)Document2 pagesDs-pp-0108 - Data Sheet For Underwing Nozzle Connector (Rev.c)Panisa BanimaNo ratings yet

- Gambat South Gas Processing Facility (Gpf-Iii) : Client ContractorDocument1 pageGambat South Gas Processing Facility (Gpf-Iii) : Client ContractorMusab ShabbirNo ratings yet

- Illustrated Parts List: Not For ReproductionDocument8 pagesIllustrated Parts List: Not For ReproductionCorey EasleyNo ratings yet

- 00000-JDS-014 (Pressure Safety Valve) Rev 0Document4 pages00000-JDS-014 (Pressure Safety Valve) Rev 0sithulibra100% (1)

- Fluidic Components and Equipment 1968–9: Pergamon Electronics Data SeriesFrom EverandFluidic Components and Equipment 1968–9: Pergamon Electronics Data SeriesNo ratings yet

- Gambar Acuan FAN VSDDocument1 pageGambar Acuan FAN VSDdandi zlkNo ratings yet

- Drawing Choke Manifold From MedcoDocument1 pageDrawing Choke Manifold From Medcodandi zlkNo ratings yet

- Flow SeriesDocument14 pagesFlow Seriesdandi zlkNo ratings yet

- Oteco Pressure Gauge Product BrochureDocument12 pagesOteco Pressure Gauge Product Brochuredandi zlkNo ratings yet

- BJC-6432 MSDSDocument3 pagesBJC-6432 MSDSdandi zlkNo ratings yet

- (PDF) Hydril Ram Annular Good Diagrams BOP ProductsDocument1 page(PDF) Hydril Ram Annular Good Diagrams BOP Productsdandi zlkNo ratings yet

- IBL-I-DS-001 - 017 - C - Instrument Datasheet Signed AGa 20201230 - CompressedDocument49 pagesIBL-I-DS-001 - 017 - C - Instrument Datasheet Signed AGa 20201230 - Compresseddandi zlk100% (1)

- 1 - MNL - Dreco Rig - Crown Block-1Document1 page1 - MNL - Dreco Rig - Crown Block-1dandi zlkNo ratings yet

- PML BG15999 CompressedDocument3 pagesPML BG15999 Compresseddandi zlkNo ratings yet

- Model G Tubing Spider Manual Rev 1 (1) - 2-14Document13 pagesModel G Tubing Spider Manual Rev 1 (1) - 2-14dandi zlkNo ratings yet

- DatasheetDocument11 pagesDatasheetdandi zlkNo ratings yet

- Flow Meter Oval Flowpet EG PDF 12Document1 pageFlow Meter Oval Flowpet EG PDF 12dandi zlkNo ratings yet

- P5 CPLG NPTDocument2 pagesP5 CPLG NPTdandi zlkNo ratings yet

- Alco Certificate of Conformance and OriginDocument1 pageAlco Certificate of Conformance and Origindandi zlkNo ratings yet

- 3M Red CPLG SWDocument2 pages3M Red CPLG SWdandi zlkNo ratings yet

- LBK 25-05-2021 Bit Sub - GabunganDocument4 pagesLBK 25-05-2021 Bit Sub - Gabungandandi zlkNo ratings yet

- Catshaft & Output Shaft Assembly EMSCO-2Document1 pageCatshaft & Output Shaft Assembly EMSCO-2dandi zlkNo ratings yet

- DUZDocument1 pageDUZdandi zlkNo ratings yet

- P-7 Red CPLG NPTDocument4 pagesP-7 Red CPLG NPTdandi zlkNo ratings yet

- P6-Red CPLG SWDocument4 pagesP6-Red CPLG SWdandi zlkNo ratings yet

- Bull CA71 EDocument4 pagesBull CA71 Edandi zlkNo ratings yet

- Flow Meter Oval Flowpet EG PDF 1Document1 pageFlow Meter Oval Flowpet EG PDF 1dandi zlkNo ratings yet

- 42MT New Starter - Product Details - Delco RemyDocument2 pages42MT New Starter - Product Details - Delco Remydandi zlkNo ratings yet

- Zulfaqar: Journal of Defence Management, Social Science & HumanitiesDocument11 pagesZulfaqar: Journal of Defence Management, Social Science & Humanitiesazani yahyaNo ratings yet

- Cpqra Errata SheetDocument2 pagesCpqra Errata SheetNasrulhudaNo ratings yet

- Get Back To Balance: Unbalanced Rotors Can Damage More Than Just BearingsDocument2 pagesGet Back To Balance: Unbalanced Rotors Can Damage More Than Just BearingsAnonymous PVXBGg9TNo ratings yet

- Multiple Fracture Propagation Model For A Three-Dimensional Hydraulic Fracturing SimulatorDocument12 pagesMultiple Fracture Propagation Model For A Three-Dimensional Hydraulic Fracturing SimulatorErick Barroso MartinezNo ratings yet

- Analysis of Design Methodologies of Subsea Structure FoundationsDocument19 pagesAnalysis of Design Methodologies of Subsea Structure FoundationsMariusz MilewskiNo ratings yet

- 1 s2.0 S0272884220326407 MainDocument9 pages1 s2.0 S0272884220326407 MainNguyen Trung HuyNo ratings yet

- Chap 6 Suspension and Emulsion PolymerizationsDocument40 pagesChap 6 Suspension and Emulsion PolymerizationsSyuan CNo ratings yet

- NDT Technician: Visual Testing of Pipe ThreadsDocument12 pagesNDT Technician: Visual Testing of Pipe ThreadsPablo Gonzalez100% (1)

- P.E.S. College of Engineering, Mandya - 571 401Document2 pagesP.E.S. College of Engineering, Mandya - 571 401Vikas D NayakNo ratings yet

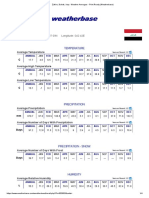

- Zakho, Iraq Travel Weather Averages (Weatherbase)Document4 pagesZakho, Iraq Travel Weather Averages (Weatherbase)gazi shaikhNo ratings yet

- EDX Supplies Maintenance PartsDocument9 pagesEDX Supplies Maintenance Partsprocessos.prosperNo ratings yet

- Cambridge IGCSE: Physics 0625/22Document16 pagesCambridge IGCSE: Physics 0625/22jad obaidNo ratings yet

- S 1611018 Chapter2Document36 pagesS 1611018 Chapter2Adji SetiaNo ratings yet

- HVAC CourseDocument86 pagesHVAC CourseIbrahim Mostafa100% (5)

- Genial Universal FlowDocument16 pagesGenial Universal FlowCharissa ArdhinaNo ratings yet

- Sri Vidya College of Engineering & Technology Course Material (Lecture Notes)Document47 pagesSri Vidya College of Engineering & Technology Course Material (Lecture Notes)Kumar RockyNo ratings yet

- Fundamentals of Mechanical Engineering - Mechatronics KME101TDocument1 pageFundamentals of Mechanical Engineering - Mechatronics KME101TmanishNo ratings yet

- Trivia 2Document3 pagesTrivia 2PJ GealoneNo ratings yet

- 930R e 930T Power TrainDocument34 pages930R e 930T Power TrainGilson RodriguesNo ratings yet

- Physics Investigatory Project. AbishekDocument5 pagesPhysics Investigatory Project. Abishekarchchihan archchihanNo ratings yet

- Dale Ewen, Neill Schurter, Erik Gundersen - Applied Physics, 11th Edition-Prentice Hall - Pearce (2016) - 327-334Document8 pagesDale Ewen, Neill Schurter, Erik Gundersen - Applied Physics, 11th Edition-Prentice Hall - Pearce (2016) - 327-334yusufapid3323No ratings yet

- E2 411 Materials Science and Engineering Finals Assignment 1Document6 pagesE2 411 Materials Science and Engineering Finals Assignment 1dewardNo ratings yet

- BookDocument26 pagesBookcoolsatishNo ratings yet

- Self Compacting ConcreteDocument33 pagesSelf Compacting Concreteapi-252700561100% (1)

MTT-I-DS-001 013 - C - Instrument Datasheet - Compressed

MTT-I-DS-001 013 - C - Instrument Datasheet - Compressed

Uploaded by

dandi zlkOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MTT-I-DS-001 013 - C - Instrument Datasheet - Compressed

MTT-I-DS-001 013 - C - Instrument Datasheet - Compressed

Uploaded by

dandi zlkCopyright:

Available Formats

SOUTH SUMATRA BLOCK

Rev. C

INSTRUMENT DATASHEET

Doc. No. MTT-I-DS-001 ~ 013

COMPANY : MEDCO E&P INDONESIA

PROJECT TITLE : MATRA FACILITIES OPTIMIZATION PROJECT

LOCATION : MATRA STATION, SSB EASTERN

C 18-Dec-20 Issued for Construction SYW/ PRD DEK AMW AGA IDG

B 27-Oct-20 Issued for Approval SYW/ PRD DEK AMW AGA -

A 1-Oct-20 Issued for Review SYW/ PRD DEK - - -

ENG. LEAD PRJ. LEAD ENG. MGR SR. MGR

REV. NO. DATE DESCRIPTION PREPARED

CHECKED APPROVED

MATRA FACILITIES OPTIMIZATION

PT. MEDCO E & P INDONESIA Doc. Title : DATA SHEET

INDEX

Doc. No. : MTT-I-DS-001 ~ 013 Rev. C

DATASHEET INDEX

Document No. Revision Description

MTT-I-DS-001 C Instrument Datasheet for Pressure Gauge

MTT-I-DS-002 C Instrument Datasheet for Pressure Transmitter

MTT-I-DS-003 C Instrument Datasheet for Pressure Safety Valve

MTT-I-DS-004 C Instrument Datasheet for Pressure Control Valve

MTT-I-DS-005 C Instrument Datasheet for Pressure Regulating Valve

MTT-I-DS-006 C Instrument Datasheet for Solenoid (On/ Off) Valve

MTT-I-DS-007 C Instrument Datasheet for Flow Element (Orifice)

MTT-I-DS-008 C Instrument Datasheet for Flow Recorder

MTT-I-DS-009 C Instrument Datasheet for Liquid Flowmeter

MTT-I-DS-010 C Instrument Datasheet for Level Control Valve

MTT-I-DS-011 C Instrument Datasheet for Level Gauge

MTT-I-DS-012 C Instrument Datasheet for Level Transmitter

MTT-I-DS-013 C Instrument Datasheet for Pressure Differential Indicator

1 Tag Number See List

2 Service See List

GENERAL

3 P&ID No. See List

4 Line No. Equipment No. See List See List

5 Fluid Type Fluid State See List See List

o

6 Temperature Design See List F

o o

PROCESS 7 Design Temperature Operating Temperature See List F See List F

CONDITIONS 8 Design Pressure Operating Pressure See List psig See List psig

9

10

11 Type Direct

12 Mounting Local

13 Dial Size 4.5"

14 Case Material Phenolic or Equal

15 Ring Type Screwed

16 Blowout Protection Yes

17 Lens Material Shatterproof Glass

18 Liquid Filling See List

19 Accuracy +/- 0.5%

ELEMENT 20 Allowable Overrange 130%

AND GAUGE 21 Dial / Background Colour Black / White

22 Pressure Element Type Bourdon Tube

23 Element Material 316SS

24 Socket Material 316SS

25 Movement Material 316SS

26 Connection Location Bottom

27 Process Connection 1/2" NPT(M)

28 Instrument Range Min Max SEE LIST SEE LIST

29 Zero Adjustment Yes

30 Ingrees Protection IP 65

31 PG Coupling Yes for Pressure Gauge

32 Overload Protection SEE LIST

33 2-Way Manifold N/A

ACCESSORIES 34 5-Way Manifold N/A

35 Diaphragm Seal N/A

36 Syphon N/A

37 Others N/A

38 Manufacturer Note 2

39 Model VTA

PURCHASE 40 Serial No. VTA

41 Requisition Number -

42 Purchase Order No. -

Notes :

1 VTA : Vendor to Advice

2 Refer to Medco PML

3 Required function/ simulation test during FAT

4 Material certificate, COO and COC is required during inspection

C 18-Dec-20 Issued for Construction SYW / PRD DEK / AMW AGA / IDG

B 27-Oct-20 Issued for Approval SYW / PRD DEK / AMW AGA

A 1-Oct-20 Issued for Review SYW / PRD DEK -

REV. DATE DESCRIPTION PREP CHKD APPD

MATRA FACILITIES OPTIMIZATION

PT. MEDCO E & P INDONESIA Doc. Title : DATA SHEET

PRESSURE GAUGE

Doc. No. : MTT-I-DS-001 Rev : C

Sheet 1 of 2

Operating Design Range

No. Tag No. Service Description P&ID Temp Press Temp Press (psig) Accessories

(oF) (psig) (oF) (psig) Min Max

1 PI - 102B Liquid Outlet Test Separator (MTT-MBD-102) MTT-R-PI- 003 100 50 145 250 0 100 I

2 PI - 104 Purge Gas Line MTT-R-PI- 003 100 40 145 250 0 50 I

3 PI - 105 Purge Gas Line MTT-R-PI- 004 100 40 145 250 0 50 I

4 PI - 331A Discharge CTP MTT-R-PI- 006 100 300 200 600 0 600 I, J

5 PI - 332A Discharge CTP MTT-R-PI- 006 100 300 200 343 0 600 I, J

6 PI - 334A Discharge CTP MTT-R-PI- 006 100 300 200 600 0 600 I, J

7 PI - 504 Purge Gas Line MTT-R-PI- 010 100 40 145 250 0 50 I

8 PI - 103 Production Separator (MTT-MBD-103) MTT-R-PI- 026 100 50 200 250 0 100 I

9 PI - 502A Pneumatic Supply for KO Drum Pump MTT-R-PI- 027 80 140 90 200 0 200 I

10 PI - 502B Pneumatic Supply for KO Drum Pump MTT-R-PI- 027 80 140 90 200 0 200 I

11 PI - 502C Discharge Flare KOD Pump MTT-R-PI- 027 100 60 145 250 0 100 I

12 PI - 502D Discharge Flare KOD Pump MTT-R-PI- 027 100 60 145 250 0 100 I

13 PI - 503 Pneumatic Supply for Pit Pump MTT-R-PI- 027 80 140 90 200 0 200 I

14 PI - 101A KO Drum (MTT-MBD-502) MTT-R-PI- 027 100 10 145 250 0 50 I

15 PI - 341A Scale Inhibitor - Utility air MTT-R-PI- 028 80 140 90 200 0 200 I

16 PI - 342A Scale Inhibitor - Utility air MTT-R-PI- 028 80 140 90 200 0 200 I

17 PI - 341B Scale Inhibitor - Discharge Line MTT-R-PI- 028 100 100 200 195 0 200 I

18 PI - 342B Scale Inhibitor - Discharge Line MTT-R-PI- 028 100 100 200 195 0 200 I

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

Accessories:

A : Syphon

B : Snubber

C : Diaphragm Seal

D : Pulsation Dampener

E : Overload Protection (Pointer Overload Stop)

F : Gauge Saver

G : 2-Way Manifold

H : 5-Way Manifold

I : PG Coupling

J : Glycerin filled

C 18-Dec-20 Issued for Construction SYW / PRD DEK / AMW AGA / IDG

B 27-Oct-20 Issued for Approval SYW / PRD DEK / AMW AGA

A 1-Oct-20 Issued for Review SYW / PRD DEK -

REV. DATE DESCRIPTION PREP CHKD APPD

MATRA FACILITIES OPTIMIZATION

PT. MEDCO E & P INDONESIA Doc. Title : DATA SHEET

PRESSURE GAUGE

Doc. No. : MTT-I-DS-001 Rev : C

Sheet 2 of 2

1 Tag Number

2 Service

GENERAL

3 P&ID No.

4 Line No. Equipment No.

5 Fluid Type Fluid State

6 Units (Note 1) Minimum Normal Maximum

PROCESS 7 Pressure psig

CONDITIONS 8 Temperature o

F

9 Design Pressure psig See List

10 Design Temperature Fo See List

11 Service Gauge Pressure

12 Type Diaphragm

13 Material 316SS

ELEMENT

14 Range Adjustment Set at YES FACTORY

15 Instrument Range Min Max psig psig

16 Calibration Range Min Max psig psig

17 Accuracy +/- 0.04 % of span or better

18 Repeatability +/- 0.1 % of span or better

19 Transmitter Output Comm. Protocol 4-20 mA SMART-HART

20 Material Body Low Copper Cast Aluminium Alloy

21 Wetted Parts & Manifold 316SS

22 Indicator Digital LCD Type

TRANSMITTER 23 Case Color & Painting Mfr. Std

24 Mounting 2" Pipe Stanchion

25 Enclosure Type Hazardous Protection Class 1 Div 2

26 Weather Protection Class NEMA 4X

27 Electrical Power Supply 24 VDC

28 Electrical Connection 1/2" NPTF

29 Process Connection 1/2" NPTF

30 Diaphragm Sealed N/A

31 Manufacturer Type N/A N/A

32 Construction N/A

33 Material Wetted Parts Other Parts N/A N/A

34 Fill Fluid N/A

35 Capilary Material Length N/A N/A

36 Process Connection N/A

OPTIONS

37 Extended Diaphragm Length N/A

38 Calibration Ring Yes

39 Mounting Bracket Yes

40 Valve Manifold 2-Way Manifold

41 Lightning Arrestor Required

42 SS Name Plate Yes

43 SIL Rating N/A

44 Manufacturer Note 2

45 Model Serial No. VTA VTA

PURCHASE

46 Requisition Number -

47 Purchase Order No. -

Notes :

1 VTA : Vendor to Advice

2 Refer to Medco PML

3 Required function/ simulation test during FAT

4 Material certificate, COO and COC is required during inspection

C 18-Dec-20 Issued for Construction SYW / PRD DEK / AMW AGA / IDG

B 27-Oct-20 Issued for Approval SYW / PRD DEK / AMW AGA

A 1-Oct-20 Issued for Review SYW / PRD DEK -

REV. DATE DESCRIPTION PREP CHKD APPD

MATRA FACILITIES OPTIMIZATION

PT. MEDCO E & P INDONESIA Doc. Title : DATA SHEET

PRESSURE TRANSMITTER

Doc. No. : MTT-I-DS-002 Rev : C

Sheet 1 of 2

Pressure (psig) Temperature (F) Instrument Calibrated

Fluid Type/ P&ID No.

No. Tag No Range Range

State Min. Normal Design Min. Normal Design (psig) (psig)

1 PIT - 101 HC Liquid - 50 250 - 100 145 0 - 200 0 - 200 001

2 PIT - 102 HC Liquid - 50 250 - 100 200 0 - 200 0 - 200 001

3 PZT - 102A HC Gas - 50 250 - 100 145 0 - 200 0 - 200 003

4 PZT - 102B HC Gas - 50 250 - 100 145 0 - 200 0 - 200 003

5 PZT - 331 HC Liquid 200 300 600 - 100 200 0 - 800 0 - 600 006

6 PZT - 332 HC Liquid 200 300 343 - 100 200 0 - 800 0 - 600 006

7 PZT - 334 HC Liquid 200 300 600 - 100 200 0 - 800 0 - 600 006

8 PZT - 331A HC Liquid - ATM 250 - 100 200 0 - 10 0 - 10 006

9 PZT - 332A HC Liquid - ATM 250 - 100 200 0 - 10 0 - 10 006

10 PZT - 334A HC Liquid - ATM 250 - 100 200 0 - 10 0 - 10 006

11 PZT - 103A HC Gas - 50 250 - 100 200 0 - 200 0 - 200 026

12 PZT - 103B HC Gas - 50 250 - 100 200 0 - 200 0 - 200 026

C 18-Dec-20 Issued for Construction SYW / PRD DEK / AMW AGA / IDG

B 27-Oct-20 Issued for Approval SYW / PRD DEK / AMW AGA

A 1-Oct-20 Issued for Review SYW / PRD DEK -

REV. DATE DESCRIPTION PREP CHKD APPD

MATRA FACILITIES OPTIMIZATION

PT. MEDCO E & P INDONESIA Doc. Title : DATA SHEET

PRESSURE TRANSMITTER

Doc. No. : MTT-I-DS-002 Rev : C

Sheet 2 of 2

1 Tag Number See List

2 Service See List

3 Line No. Vessel No. See List See List

4 Pipe Class Inlet Pipe Class Outlet See List See List

GENERAL

5 Design Safety, Relief, Safety-Relief Safety

6 Type Conventional, Bellow, Pilot Operated Conventional

7 Bonnet Type Nozzle (Full, Semi) Closed Full

8 P&ID See List

9 Fluid State See List See List

10 Required Capacity See List

o

11 Design Pressure Design Temperature See List psig See List F

12 Oper. Pressure Set Pressure See List psig See List psig

o o

13 Oper. Temperature Relieving Temperature See List F See List F

14 Constant (Note 1) psig

15 Back Pressure Variable (Note 1) psig

16 Total See List psig

PROCESS 17 Molecular Weight See List

CONDITIONS 18 % Allowable Overpressure See List

19 Compressibility Factor See List

20 Ratio of Specific Heats See List

21

22

23

24

25

26

27 Design Code API RP 520, API STD 526, ASME SEC VIII

28 Sizing Basis See List

29 Valve Style Safety

BASIS

30 Calculated Area VTA in2

AND

SELECTION 31 Selected Area VTA in2

32 Orifice Designation VTA

33 Noise Level VTA

34

35 Size Inlet Outlet See List in See List in

CONNECTIONS

36 Flange Rating & Facing Inlet Outlet See List RF See List RF

37 Body & Bonnet Carbon Steel

38 Seat & Discs 316 SS

39 Resilient Seat Seal VTA

40 Guide and Rings 316 SS

MATERIALS

41 Spring 316 SS

42 Nozzle VTA

43 Bellows VTA

44

45 Cap : Screwed or Bolted Screwed

46 Lever : Plain or Packed N/A

OPTIONS 47 Test Gage No

48 Hydrotest Fire Safe Test Required Required

49 Weight VTA

50 Manufacturer Model VTA VTA

51 Item Number VTA

PURCHASE

52 Requisition Number -

53 Serial Number VTA

Notes :

1 Vendor to provide PSV Calculation during engineering stage for Company Approval

C 18-Dec-20 Issued for Construction SYW / PRD DEK / AMW AGA / IDG

B 27-Oct-20 Issued for Approval SYW / PRD DEK / AMW AGA

A 1-Oct-20 Issued for Review SYW / PRD DEK -

REV. DATE DESCRIPTION PREP CHKD APPD

MATRA FACILITIES OPTIMIZATION

PT. MEDCO E & P INDONESIA Doc. Title : DATA SHEET

PRESSURE SAFETY VALVE

Doc. No. : MTT-I-DS-003 Rev : C

Sheet 1 of 2

Tag No. PSV-102 PSV-103A PSV-331 PSV-332 PSV-334 PRV-341 PRV-342

P&ID No. MTT-R-PI-003 MTT-R-PI-026 MTT-R-PI-006 MTT-R-PI-006 MTT-R-PI-006 MTT-R-PI-028 MTT-R-PI-028

Fluid Type/ State HC Gas HC Gas HC Liquid HC Liquid HC Liquid Scale Inh./ Liquid Scale Inh./ Liquid

Line/ Vessel No. MTT-MBD-102 MTT-MBD-103 MTT-PAX-331 MTT-PAX-332 MTT-PAX-334 MTT-PZZ-341 MTT-PZZ-342

Design Type/ Sizing Basis Blocked Discharge Blocked Discharge Blocked Discharge Blocked Discharge Blocked Discharge Blocked Discharge Blocked Discharge

(Note 3) (Note 3)

Required Capacity (lb/h) 5733 5733 136200 132900 136200 4.5 4,5

Design Pressure (psig) 250 250 600 343 600 195 195

Design Temperature (F) 145 200 200 200 200 200 200

Operating Pressure (psig) 50 50 300 240 300 60 60

Operating Temperature (F) 100 100 100 100 100 100 100

Set Pressure (psig) 250 250 540 300 540 195 195

Relieving Temp (F) 100 100 100 100 100 100 100

Total Backpressure (psig) 15 15 10 10 10 10 10

Molecular Weight 25.15 25.15 23.16 23.16 23.16 N/A N/A

% Allowable overpressure 10 10 10 10 10 10 10

Compressibility factor 0.9805 0.9805 - - - - -

Ratio of specific heats (Cp/Cv) 1.223 1.223 - - - - -

Specific Gravity 0.87 0.87 0.9375 0.9375 0.9375 1.1 - 1.3 1.1 - 1.3

Viscosity (cP) 0.01147 0.01147 43.14 43.14 43.14 <60 <60

Calculated Area (Note 1) 0.458 0.458 0.505 0.679 0.505 VTA VTA

2"-150# x 2"-150# x 1/2"-NPT x 1/2"-NPT x

PSV Size & Rating 2"-600# x 3"-150# 2"-600# x 3"-150# 2"-600# x 3"-150#

3"-150# 3"-150# 1/2"-NPT 1/2"-NPT

Selected Area & Orifice Des. VTA VTA VTA VTA VTA VTA VTA

Noise Level VTA VTA VTA VTA VTA VTA VTA

Notes:

1. Vendor to verify PSV calculation

2. Vendor to advice

3. Sizing for small PSV based on manufacture data curve (non API)

C 18-Dec-20 Issued for Construction SYW / PRD DEK / AMW AGA / IDG

B 27-Oct-20 Issued for Approval SYW / PRD DEK / AMW AGA

A 1-Oct-20 Issued for Review SYW / PRD DEK -

REV. DATE DESCRIPTION PREP CHKD APPD

MATRA FACILITIES OPTIMIZATION

PT. MEDCO E & P INDONESIA Doc. Title : DATA SHEET

PRESSURE SAFETY VALVE

Doc. No. : MTT-I-DS-003 Rev : C

Sheet 2 of 2

1 Tag No. PCV-341A/B

2 Service P&ID Utility air for Chemical Pump MTT-R-PI-028

3 Line No. Piping Class 1/2"-UA-9116/9117-1A 1A

GENERAL

4 Pipe Material Pipe Insulation Carbon Steel No

5 Area Classification Area Certification Zone 2, IIA

6 Line Size & Schedule Inlet Outlet 1/2 inch 1/2 inch

o o

7 Ambient Temperature Min. Max 70 F 100 F

8 Available Air Supply Pressure Min. Max 90 Psig 140 Psig

9 Corrosive Erosive Toxic

10 Fluid Name Fluid Phase Hydrocarbon Gas

11 Shut Off D.P psi

12 Units Minimum Flow Normal Flow Maximum Flow

13 Flow Rate SCFM 2.00 4.00 8.0

14 Inlet Pressure psig 90.00 110.00 140.0

15 Pressure Drop psi 30.00 30.00 40.0

16 Inlet Temperature o

F 90 90 90

17 Specific Gravity (SG) 1 1 1

PROCESS

18 Density lb/ft3 7.19E-02 7.19E-02 7.19E-02

19 Molecular Weight - 28.85 28.85 28.85

20 Compressibility Factor - 1.00E+00 1.00E+00 1.00E+00

21 Viscosity cP 1.92E-02 1.92E-02 1.92E-02

22 Specific Heat Ratio (Cp/Cv) - 1.40E+00 1.40E+00 1.40E+00

23 Vapour Pressure psig

24 Critical Pressure psig

25 %Flashing %

26 Pressure Opt Design psig 110 175

27 Temperature Opt Design o

F 90 200

28 Flow Coefficient Cv Calculated Selected - (Note 1) (Note 1) (Note 1)

CALC

29 Travel %

30 Sound Pressure Level @ 3 ft. dBA max. 85 dBA

31 Manufacturer (Note 1) 62 Manufacturer (Note 1)

32 Model Air Supply Regulator (Note 1) 63 Model (Note 1)

33 Body Type Pressure Reducing Regulator 64 Actuator Type Diaphragm/ Spring

PRESSURE RANGE

34 ANSI Class End Conn. 150# RF 65 Actuator Size (Note 1)

ACTUATOR &

35 Body Size 1/2 in 66 Valve Failed Position Closed

36 Face to Face Dimension FNPT 67 Travel Indicator No

37 Guiding (Note 1) 68 Inlet Pressure Range Min Max 0 psig 250 psig

38 Flow Direction (Up/Down) Up 69 Outlet Pressure RangeMin Max 0 psig 150 psig

39 Bonnet Type (Note 1) 70 Handwheel -

40 Body Material / Bonnet 316 SS 71 Bench Set -

VALVE BODY & TRIM

41 Soft Seat Material Nitrile / Fluorocarbon 72 Actuator Force Design Pressure (Note 1)

42 Charateristic (Note 1) 73 Manufacturer -

43 Trim Type (Note 1) 74 Model -

POSITIONER

44 Trim Size (Note 1) 75 Positioner Type -

45 Trim Construction (Note 1) 76 IP Transducer IP Tag Number - -

46 Calculated Cv Max Nor (Note 1) 77 Enclosure Class -

47 Rated Cv (Note 1) 78 Signal Input -

48 Balanced / Unbalanced - 79 Gauge Range - -

49 Trim Material - Disc Plug 316SS 80 Connection -

50 Trim Material - Seat 316SS 81 Air Set Yes

51 Trim Material - Shaft 316SS 82 Filter / Gauge Yes

ACCESSORIES

PNEUMATIC

52 Shutoff Class Class V 83 Material Aluminium

53 Max SPL Allowable (dBA) 85 @ 3 ft 84 Tube Material 316SS

54 Painting Mfr. Std 85 Fitting Type SS compression fittings

55 Name Plate Yes, 316SS 86 Size & Connection (Note 1)

56 Hydrotest (Note 1) 87

CERTIFICATION

57 Material Certification Required 88 Manufacturer (Note 3)

PURCHASE

TEST /

58 Hazardous Area Certification N/A 89 Model (Note 1)

59 Dimension Required 90 Requsition No. -

60 91 Item No. -

61 92 Serial No. -

Notes :

1 Vendor to Advice

2 Vendor shall perform sizing calculations and submit to COMPANY for approval at bid stage

3 Refer to Medco PML

C 18-Dec-20 Issued for Construction SYW / PRD DEK / AMW AGA / IDG

B 27-Oct-20 Issued for Approval SYW / PRD DEK / AMW AGA

A 1-Oct-20 Issued for Review SYW / PRD DEK -

REV. DATE DESCRIPTION PREP CHKD APPD

MATRA FACILITIES OPTIMIZATION

PT. MEDCO E & P INDONESIA Doc. Title : DATA SHEET

PRESSURE CONTROL VALVE

Doc. No. : MTT-I-DS-004 Rev : C

Sheet 1 of 1

1 Tag No. PRV-504

2 Service P&ID Purge Gas Line MTT-R-PI-010

3 Line No. Piping Class - ANSI 150#

GENERAL

4 Pipe Material Pipe Insulation Carbon Steel No

5 Area Classification Area Certification Zone 2, IIA

6 Line Size & Schedule Inlet Outlet 1 inch 1 inch

o o

7 Ambient Temperature Min. Max 70 F 100 F

8 Available Air Supply Pressure Min. Max - Psig - Psig

9 Corrosive Erosive Toxic No No No

10 Fluid Name Fluid Phase Hydrocarbon Gas

11 Shut Off D.P psi

12 Units Minimum Flow Normal Flow Maximum Flow

13 Flow Rate MMSCFD 0.0006 0.0021 0.0140

14 Inlet Pressure psig 50.00 50.00 50.0

15 Pressure Drop psi 22.00 22.00 22.0

16 Inlet Temperature o

F 100.00 100.00 100.0

17 Specific Gravity (SG) 0.80 0.80 0.8

PROCESS

18 Density lb/ft3 1.68 1.68 1.7

19 Molecular Weight - 22.94 22.94 22.9

20 Compressibility Factor - 0.90 0.90 0.9

21 Viscosity cP 0.0122 0.01 0.0

22 Specific Heat Ratio (Cp/Cv) - 1.339 1.34 1.3

23 Vapour Pressure psig 2680.00 2680.00 2680.0

24 Critical Pressure psig 1618.00 1618.00 1618.0

25 %Flashing %

26 Pressure Opt Design psig 50 250

27 Temperature Opt Design o

F 100 200

28 Flow Coefficient Cv Calculated Selected - (Note 1) (Note 1) (Note 1)

CALC

29 Travel %

30 Sound Pressure Level @ 3 ft. dBA max. 85 dBA

31 Manufacturer (Note 1) 62 Manufacturer (Note 1)

32 Model (Note 1) 63 Model (Note 1)

33 Body Type Pressure Reducing Regulator 64 Actuator Type Diaphragm

34 ANSI Class End Conn. 150# RF 65 Actuator Size (Note 1)

ACTUATOR

35 Body Size 1 in 66 Valve Failed Position Open

36 Face to Face Dimension ANSI/ASME B16.10 67 Travel Indicator No

37 Guiding (Note 1) 68 Air Supply Min Max - psig - psig

38 Flow Direction (Up/Down) Up 69 Actuator Orientation -

39 Bonnet Type (Note 1) 70 Handwheel -

40 Body Material / Bonnet Carbon Steel 71 Bench Set -

VALVE BODY & TRIM

41 Packing Material PTFE 72 Actuator Force Design Pressure -

42 Charateristic (Note 1) 73 Manufacturer -

43 Trim Type (Note 1) 74 Model -

POSITIONER

44 Trim Size (Note 1) 75 Positioner Type -

45 Trim Construction (Note 1) 76 IP Transducer IP Tag Number - -

46 Calculated Cv Max Nor (Note 1) 77 Enclosure Class -

47 Rated Cv (Note 1) 78 Signal Input -

48 Balanced / Unbalanced Balanced / Unbalanced 79 Gauge Range - -

49 Trim Material - Disc Plug 316SS 80 Connection -

50 Trim Material - Seat 316SS 81 Air Set -

51 Trim Material - Shaft 316SS 82 Filter / Gauge -

ACCESSORIES

PNEUMATIC

52 Shutoff Class Class V 83 Material -

53 Max SPL Allowable (dBA) 85 @ 3 ft 84 Tube Material -

54 Painting Mfr. Std 85 Fitting Type -

55 Name Plate Yes, 316SS 86 Size & Connection -

56 Hydrotest Required 87

CERTIFICATION

57 Material Certification Yes 88 Manufacturer (Note 3)

PURCHASE

TEST /

58 Hazardous Area Certification N/A 89 Model (Note 1)

59 Dimension Required 90 Requsition No. -

60 91 Item No. -

61 92 Serial No. -

Notes :

1 Vendor to Advice

2 Vendor shall perform sizing calculations and submit to COMPANY for approval at bid stage

3 Refer to Medco PML

C 18-Dec-20 Issued for Construction SYW / PRD DEK / AMW AGA / IDG

B 27-Oct-20 Issued for Approval SYW / PRD DEK / AMW AGA

A 1-Oct-20 Issued for Review SYW / PRD DEK -

REV. DATE DESCRIPTION PREP CHKD APPD

MATRA FACILITIES OPTIMIZATION

PT. MEDCO E & P INDONESIA Doc. Title : DATA SHEET

PRESSURE REGULATING VALVE

Doc. No. : MTT-I-DS-005 Rev : C

Sheet 1 of 3

1 Tag No. PRV-502A/B

2 Service P&ID Utility Air to KO Drum Pump MTT-R-PI-027

3 Line No. Piping Class -

GENERAL

4 Pipe Material Pipe Insulation Stainless Steel No

5 Area Classification Area Certification Zone 2, IIA

6 Line Size & Schedule Inlet Outlet 1/2 inch - 1/2 inch -

o o

7 Ambient Temperature Min. Max 70 F 100 F

8 Available Air Supply Pressure Min. Max 90 Psig 140 Psig

9 Corrosive Erosive Toxic Yes No No

10 Fluid Name Fluid Phase Air Gas

11 Shut Off D.P psi 140

12 Units Minimum Flow Normal Flow Maximum Flow

13 Flow Rate SCFM 15.00 20.00 50.0

14 Inlet Pressure psig 90 110 140

15 Pressure Drop psi 30 40 70

16 Inlet Temperature o

F 90 90 90

17 Specific Gravity (SG) 1 1 1

PROCESS

18 Density lb/ft3 7.19E-02 7.19E-02 7.19E-02

19 Molecular Weight - 28.85 28.85 28.85

20 Compressibility Factor - 1.00E+00 1.00E+00 1.00E+00

21 Viscosity cP 1.92E-02 1.92E-02 1.92E-02

22 Specific Heat Ratio (Cp/Cv) - 1.40E+00 1.40E+00 1.40E+00

23 Vapour Pressure psig

24 Critical Pressure psig

25 %Flashing %

26 Pressure Opt Design psig 110 175

27 Temperature Opt Design o

F 90 200

28 Flow Coefficient Cv Calculated Selected - (Note 1) (Note 1) (Note 1)

CALC

29 Travel %

30 Sound Pressure Level @ 3 ft. dBA max. 85 dBA

31 Manufacturer (Note 1) 62 Manufacturer (Note 1)

32 Model Air Supply Regulator (Note 1) 63 Model (Note 1)

33 Body Type Pressure Reducing Regulator 64 Actuator Type Diaphragm/ Spring

PRESSURE RANGE

34 ANSI Class End Conn. 150# RF 65 Actuator Size (Note 1)

ACTUATOR &

35 Body Size 1/2 in 66 Valve Failed Position Closed

36 Face to Face Dimension FNPT 67 Travel Indicator No

37 Guiding (Note 1) 68 Inlet Pressure Range Min Max 0 psig 250 psig

38 Flow Direction (Up/Down) Up 69 Outlet Pressure RangeMin Max 0 psig 150 psig

39 Bonnet Type (Note 1) 70 Handwheel -

40 Body Material / Bonnet 316 SS 71 Bench Set -

VALVE BODY & TRIM

41 Soft Seat Material Nitrile / Fluorocarbon 72 Actuator Force Design Pressure (Note 1)

42 Charateristic (Note 1) 73 Manufacturer -

43 Trim Type (Note 1) 74 Model -

POSITIONER

44 Trim Size (Note 1) 75 Positioner Type -

45 Trim Construction (Note 1) 76 IP Transducer IP Tag Number - -

46 Calculated Cv Max Nor (Note 1) 77 Enclosure Class -

47 Rated Cv (Note 1) 78 Signal Input -

48 Balanced / Unbalanced - 79 Gauge Range - -

49 Trim Material - Disc Plug 316SS 80 Connection -

50 Trim Material - Seat 316SS 81 Air Set Yes

51 Trim Material - Shaft 316SS 82 Filter / Gauge Yes

ACCESSORIES

PNEUMATIC

52 Shutoff Class Class V 83 Material Aluminium

53 Max SPL Allowable (dBA) 85 @ 3 ft 84 Tube Material 316SS

54 Painting Mfr. Std 85 Fitting Type SS compression fittings

55 Name Plate Yes, 316SS 86 Size & Connection (Note 1)

56 Hydrotest (Note 1) 87

CERTIFICATION

57 Material Certification Required 88 Manufacturer (Note 3)

PURCHASE

TEST /

58 Hazardous Area Certification N/A 89 Model (Note 1)

59 Dimension Required 90 Requsition No. -

60 91 Item No. -

61 92 Serial No. -

Notes :

1 Vendor to Advice

2 Vendor shall perform sizing calculations and submit to COMPANY for approval at bid stage

3 Refer to Medco PML

C 18-Dec-20 Issued for Construction SYW / PRD DEK / AMW AGA / IDG

B 27-Oct-20 Issued for Approval SYW / PRD DEK / AMW AGA

A 1-Oct-20 Issued for Review SYW / PRD DEK -

REV. DATE DESCRIPTION PREP CHKD APPD

MATRA FACILITIES OPTIMIZATION

PT. MEDCO E & P INDONESIA Doc. Title : DATA SHEET

PRESSURE REGULATING VALVE

Doc. No. : MTT-I-DS-005 Rev : C

Sheet 2 of 3

1 Tag No. PRV-503

2 Service P&ID Utility Air to Pit Pump MTT-R-PI-027

3 Line No. Piping Class -

GENERAL

4 Pipe Material Pipe Insulation Stainless Steel No

5 Area Classification Area Certification Zone 2, IIA

6 Line Size & Schedule Inlet Outlet 1/2 inch - 1/2 inch -

o o

7 Ambient Temperature Min. Max 70 F 100 F

8 Available Air Supply Pressure Min. Max 90 Psig 140 Psig

9 Corrosive Erosive Toxic Yes No No

10 Fluid Name Fluid Phase Air Gas

11 Shut Off D.P psi 140

12 Units Minimum Flow Normal Flow Maximum Flow

13 Flow Rate SCFM 4.00 8.00 12.0

14 Inlet Pressure psig 90 110 140

15 Pressure Drop psi 40 60 90

16 Inlet Temperature o

F 90 90 90

17 Specific Gravity (SG) 1 1 1

PROCESS

18 Density lb/ft3 7.19E-02 7.19E-02 7.19E-02

19 Molecular Weight - 28.85 28.85 28.85

20 Compressibility Factor - 1.00E+00 1.00E+00 1.00E+00

21 Viscosity cP 1.92E-02 1.92E-02 1.92E-02

22 Specific Heat Ratio (Cp/Cv) - 1.40E+00 1.40E+00 1.40E+00

23 Vapour Pressure psig

24 Critical Pressure psig

25 %Flashing %

26 Pressure Opt Design psig 110 175

27 Temperature Opt Design o

F 90 200

28 Flow Coefficient Cv Calculated Selected - (Note 1) (Note 1) (Note 1)

CALC

29 Travel %

30 Sound Pressure Level @ 3 ft. dBA max. 85 dBA

31 Manufacturer (Note 1) 62 Manufacturer (Note 1)

32 Model Air Supply Regulator (Note 1) 63 Model (Note 1)

33 Body Type Pressure Reducing Regulator 64 Actuator Type Diaphragm/ Spring

PRESSURE RANGE

34 ANSI Class End Conn. 150# RF 65 Actuator Size (Note 1)

ACTUATOR &

35 Body Size 1/2 in 66 Valve Failed Position Closed

36 Face to Face Dimension FNPT 67 Travel Indicator No

37 Guiding (Note 1) 68 Inlet Pressure Range Min Max 0 psig 250 psig

38 Flow Direction (Up/Down) Up 69 Outlet Pressure RangeMin Max 0 psig 150 psig

39 Bonnet Type (Note 1) 70 Handwheel -

40 Body Material / Bonnet 316 SS 71 Bench Set -

VALVE BODY & TRIM

41 Soft Seat Material Nitrile / Fluorocarbon 72 Actuator Force Design Pressure (Note 1)

42 Charateristic (Note 1) 73 Manufacturer -

43 Trim Type (Note 1) 74 Model -

POSITIONER

44 Trim Size (Note 1) 75 Positioner Type -

45 Trim Construction (Note 1) 76 IP Transducer IP Tag Number - -

46 Calculated Cv Max Nor (Note 1) 77 Enclosure Class -

47 Rated Cv (Note 1) 78 Signal Input -

48 Balanced / Unbalanced - 79 Gauge Range - -

49 Trim Material - Disc Plug 316SS 80 Connection -

50 Trim Material - Seat 316SS 81 Air Set Yes

51 Trim Material - Shaft 316SS 82 Filter / Gauge Yes

ACCESSORIES

PNEUMATIC

52 Shutoff Class Class V 83 Material Aluminium

53 Max SPL Allowable (dBA) 85 @ 3 ft 84 Tube Material 316SS

54 Painting Mfr. Std 85 Fitting Type SS compression fittings

55 Name Plate Yes, 316SS 86 Size & Connection (Note 1)

56 Hydrotest (Note 1) 87

CERTIFICATION

57 Material Certification Required 88 Manufacturer (Note 3)

PURCHASE

TEST /

58 Hazardous Area Certification N/A 89 Model (Note 1)

59 Dimension Required 90 Requsition No. -

60 91 Item No. -

61 92 Serial No. -

Notes :

1 Vendor to Advice

2 Vendor shall perform sizing calculations and submit to COMPANY for approval at bid stage

3 Refer to Medco PML

C 18-Dec-20 Issued for Construction SYW / PRD DEK / AMW AGA / IDG

B 27-Oct-20 Issued for Approval SYW / PRD DEK / AMW AGA

A 1-Oct-20 Issued for Review SYW / PRD DEK -

REV. DATE DESCRIPTION PREP CHKD APPD

MATRA FACILITIES OPTIMIZATION

PT. MEDCO E & P INDONESIA Doc. Title : DATA SHEET

PRESSURE REGULATING VALVE

Doc. No. : MTT-I-DS-005 Rev : C

Sheet 3 of 3

1 Tag No. XV-331/ 334 50 Manufacturer Refer to Medco PML

2 Service 51 Model (Note 1)

Shutoff Valve for Fuel Gas Line CTP

52 Actuator Type Cylinder with Spring Return Piston

3 P&ID MTT-R-PI-006 53 Double or Single Acting Single acting

GENERAL

4 Line No. - 54 Spring Return Required

5 Line Size Line Schedule 1" 55 Actuator Mechanism Scotch yoke

6 Piping Class Piping Insulation 1B No 56 Air Failure Position Fail Close

7 Atm. Condition Humidity - 70 - 100 % 57 Filter & Regulator c/w Pressure Gauge Required 316 SS

o

8 Ambient Temperature Min & Max 70 - 100 F 58 Lubricator & Pneumatic Conn. (Note 1) 1/2" NPTF

9 59 Max Degree or Rotation 90 Degree

10 Process Fluid Hydrocarbon 60 Orientation Parallel to line

11 Fluid State Gas 61 Mechanical Position Indicator Red Closed /Green Opened

12 Operating Pressure 28 - 50 psig 62 Limit Stop Required

ACTUATOR

13 Design Pressure 250 psig 63 Overload Protection Required

PROCESS

o

14 Operating Temperature 100 F 64 Break & Run Torqe (Open/Close) (Note 1) (Note 1)

15 Blowdown Temperature Min & Max - o

F - o

F 65 End Torqe (Open/Close) (Note 1) (Note 1)

o

16 Design Temperature 200 F 66 Opening/Closing Time 3 sec 4 sec

17 Toxic & Corrosive No 67 Adjustable Stroking Time (Note 1)

18 Shut Off DP 250 psi 68 Valve DP for Sizing Yes

19 69 Actuator Test Pressure (Note 1)

20 70 Manual Override / Handwheel No

21 Manufacturer Refer to Medco PML 71 Valve Control Station Set Required

22 Model (Note 1) 72 Fire Safe No

23 Body Type & Size Ball 1 inch 73 Painting & Finish Color (Note 4) Red

24 Flange Type Size & Rating RF ANSI 800# 74 Air Consumption & Weight (Note 1) (Note 1)

25 Valve Type Ball Valve 75 Air Supply Min/Max 90 psig 140 psig

26 Valve Configuration Floating 76 Control Scheme Type Yes

27 Port Size Reduced bore 77 Identification Plate Yes

28 Max Degree of Rotation 90 degree 78 Tag No. Open Position ZSO-334

29 Fire Safe Req. Design Code Yes API-6FA LIMIT SWITCHES 79 Tag No. Close Position ZSC-334

30 Material Body Carbon Steel 80 Switch Type Proximity

31 Ball/ Disc 316 SS 316 SS 81 Rating 24VDC, 2A

32 Body seat PTFE 82 Electrical Connection 1/2" NPTF

33 Stem 316 SS 83 Enclosure Cass IP 65 Eex'd

34 Stem O-ring Viton 84 Tag No. 1 XY-331/ 334

VALVE

35 Bolts/ Nuts (Note 1) 85 Tag No. 2 -

36 Packing Graphite 86 Tag No. 3 -

37 Bonnet Type Standard 87 Switch Rating 24 VDC

38 Body Assembly Split body, (Note 2) 88 Ingress Protection IP 65 Eex'd

39 Seat Tightness Refer to API 598 89 Explosion Proof Yes

40 TSO Direction Bi-directional 90 Coil Insulation -

41 Fluid Parameter Non Toxic / Non Corrosive 91 Manual Override / Reset -

42 92 Electrical Connection 1/2" NPTF

43 93 Manufacture Model -

PILOT VALVE

44 94 Type 3-Way

45 95 Material 316 SS

46 96 Pneumatic Connection 1/4 in NPT

47 97 Manual Override / Reset Yes

48 98 Partial Stroke Facility No

49 99 SIL Rating No

Notes :

1 Vendor to Advice

2 Stem & Body sealant injection port and self relieving seats shall be provided

3 Stem O-Ring shall be Anti Explosive Decompression (AED) type

4 Painting shall refer to doc. "Surface Preparation, Painting and Galvanizing Specification"

5 Valve shall be completed with vent and drain plug (anti blow)

C 18-Dec-20 Issued for Construction SYW / PRD DEK / AMW AGA / IDG

B 27-Oct-20 Issued for Approval SYW / PRD DEK / AMW AGA

A 1-Oct-20 Issued for Review SYW / PRD DEK -

REV. DATE DESCRIPTION PREP CHKD APPD

MATRA FACILITIES OPTIMIZATION

PT. MEDCO E & P INDONESIA Doc. Title : DATA SHEET

SOLENOID (ON/ OFF) VALVE

Doc. No. : MTT-I-DS-006 Rev : C

Sheet 1 of 2

1 Tag No. XV-502A/B 50 Manufacturer -

2 Service 51 Model -

Utility Air for KO Drum Pump

52 Actuator Type -

3 P&ID MTT-R-PI-027 53 Double or Single Acting -

GENERAL

4 Line No. - 54 Spring Return -

5 Line Size Line Schedule 1/2" 55 Actuator Mechanism -

6 Piping Class Piping Insulation - No 56 Air Failure Position -

7 Atm. Condition Humidity - 70 - 100 % 57 Filter & Regulator c/w Pressure Gauge - -

o

8 Ambient Temperature Min & Max 70 - 100 F 58 Lubricator & Pneumatic Conn. - -

9 59 Max Degree or Rotation -

10 Process Fluid Utility Air 60 Orientation -

11 Fluid State Gas 61 Mechanical Position Indicator -

12 Operating Pressure 110 psig 62 Limit Stop -

ACTUATOR

13 Design Pressure 200 psig 63 Overload Protection -

PROCESS

o

14 Operating Temperature 100 F 64 Break & Run Torqe (Open/Close) - -

15 Blowdown Temperature Min & Max - o

F - o

F 65 End Torqe (Open/Close) - -

o

16 Design Temperature 200 F 66 Opening/Closing Time - -

17 Toxic & Corrosive No 67 Adjustable Stroking Time -

18 Shut Off DP 200 psi 68 Valve DP for Sizing -

19 69 Actuator Test Pressure -

20 70 Manual Override / Handwheel -

21 Manufacturer Refer to Medco PML 71 Valve Control Station Set -

22 Model (Note 1) 72 Fire Safe -

23 Body Type & Size Solenoid Valve 3/8" inch 73 Painting & Finish Color - -

24 Flange Type Size & Rating NPT - 74 Air Consumption & Weight - -

25 Valve Type Solenoid Valve 75 Air Supply Min/Max - -

26 Valve Configuration (Note 1) 76 Control Scheme Type -

27 Port Size (Note 1) 77 Identification Plate -

28 Max Degree of Rotation (Note 1) 78 Tag No. Open Position -

29 Fire Safe Req. Design Code - - LIMIT SWITCHES 79 Tag No. Close Position -

30 Material Body 316 SS 80 Switch Type -

31 Ball/ Disc 316 SS 316 SS 81 Rating -

32 Body seat (Note 1) 82 Electrical Connection -

33 Stem (Note 1) 83 Enclosure Cass -

34 Stem O-ring (Note 1) 84 Tag No. 1 XY-502A/B

VALVE

35 Bolts/ Nuts (Note 1) 85 Tag No. 2 -

36 Packing (Note 1) 86 Tag No. 3 -

37 Bonnet Type Standard 87 Switch Rating 24 VDC

38 Body Assembly (Note 1) 88 Ingress Protection IP 65 Eex'd

39 Seat Tightness Refer to API 598 89 Explosion Proof Yes

40 TSO Direction Bi-directional 90 Coil Insulation -

41 Fluid Parameter Non Toxic / Non Corrosive 91 Manual Override / Reset -

42 92 Electrical Connection 1/2" NPTF

43 93 Manufacture Model -

PILOT VALVE

44 94 Type 3-Way

45 95 Material 316 SS

46 96 Pneumatic Connection 1/4 in NPT

47 97 Manual Override / Reset Yes

48 98 Partial Stroke Facility No

49 99 SIL Rating No

Notes :

1 Vendor to Advice

C 18-Dec-20 Issued for Construction SYW / PRD DEK / AMW AGA / IDG

B 27-Oct-20 Issued for Approval SYW / PRD DEK / AMW AGA

A 1-Oct-20 Issued for Review SYW / PRD DEK -

REV. DATE DESCRIPTION PREP CHKD APPD

MATRA FACILITIES OPTIMIZATION

PT. MEDCO E & P INDONESIA Doc. Title : DATA SHEET

SOLENOID (ON/ OFF) VALVE

Doc. No. : MTT-I-DS-006 Rev : C

Sheet 1 of 2

SERVICE: TAG No: FE - 102 FE - 103

1 Service description: Gas Outlet from Test Separator Gas Outlet from Production Separator

(MTT-MBD-102) (MTT-MBD-103)

2 P&ID No: MTT-R-PI-003 MTT-R-PI-026

3 Line No: 6"-HG-3836-1B 4"-HG-3844-1B

4 Line Size / Rating: 6" ANSI 150# 4" ANSI 150#

5 Fluid type: Hydrocarbon Hydrocarbon

6 Fluid state: Gas Gas

7 Operating flow rate (Min/Norm/Max): MMSCFD 0.1545455 0.6 1.7 0.1545455 0.6 1.7

8 Upstream pressure (Min/Norm/Max): Psig 20 50 150 20 50 150

9 Design pressure (Min/Max): Psig - 250 - 250

10 Max allowable press. drop: inH2O 100 100

11 Oper. Temperature (Min/Norm/Max): ºF 80 100 120 80 100 120

12 Design temperature (Min/Max): ºF 145 200

13 Operating specific gravity: 0.83 0.83

14 Compressibility: Z 0.98 0.98

15 Molecular weight: 24.04 24.04

16 Specific heats ratio: Cp/Cv 1.23 1.23

17 Viscosity: cP 0.01 0.01

18 Density lb/ft3 0.26 0.26

19 Pipe Specification

ORIFICE PLATE & HOLDER

20 Plate Geometry: Concentric Concentric

21 Plate: Type Square Edge Square Edge

22 Plate: Material 316 SS 316 SS

23 Vent or Drain Hole: Yes/Top Yes/Top

24 Plate Holder: Type Senior Orifice Fitting Senior Orifice Fitting

25 Plate Holder: Material Carbon Steel (Note 4) Carbon Steel (Note 4)

26 Pipe Connection: RF Flange RF Flange

27 Flange Rating: ANSI 150# ANSI 150#

28 Flange Material Carbon Steel (Note 4) Carbon Steel (Note 4)

29 Gasket Material Mfr Std Mfr Std

30 Gasket Thickness Mfr Std Mfr Std

31 Upstream Run min.20 D min.20 D

32 Downstream Run min.10 D min.10 D

ORIFICE DETAIL

1 Line I.D: Size Nominal in 4.026 4 4.026 4

2 Orifice Bore diameter: in 2 2

3 Beta ratio d/D: max 0.75 max 0.75

4 Plate thickness: in min. 0.125 min. 0.125

5 Manufacturer: (Note 4) (Note 4)

6 Model No.: (Note 4) (Note 4)

Notes:

1 The plate handle shall be stamped with Tag, Bore, Line ID and "Upstream" in 10mm characters on the upstream side.

2 Vendor should provide Orifice Calculation for approval

3 Vendor to provide orifice holder complete with A193 B7 Bolt, Cadmium Plated and A194 2H Nut, Cadmium Plated.

4 Vendor to advise, Refer to Medco PML

C 18-Dec-20 Issued for Construction SYW / PRD DEK / AMW AGA / IDG

B 27-Oct-20 Issued for Approval SYW / PRD DEK / AMW AGA

A 1-Oct-20 Issued for Review SYW / PRD DEK -

REV. DATE DESCRIPTION PREPD CHKD APPD

MATRA FACILITIES OPTIMIZATION

PT. MEDCO E &P INDONESIA Document DATA SHEET

Title : FLOW ELEMENT (ORIFICE)

Document No. : MTT-I-DS-007 Rev : C

Sheet 1 of 2

SERVICE: TAG No: FE - 104 FE - 105

1 Service description:

Purge Gas Purge Gas

2 P&ID No: MTT-R-PI-003 MTT-R-PI-004

3 Line No: 1"-FG-9423-1B 1"-FG-9422-1B

4 Line Size / Rating: 1" ANSI 150# 1" ANSI 150#

5 Fluid type: Hydrocarbon Hydrocarbon

6 Fluid state: Gas Gas

7 Operating flow rate (Min/Norm/Max): MMSCFD 0.01 0.01 0.02 0.01 0.01 0.02

8 Upstream pressure (Min/Norm/Max): Psig 20 35 50 20 35 50

9 Design pressure (Min/Max): Psig - 250 - 250

10 Max allowable press. drop: inH2O 100 100

11 Oper. Temperature (Min/Norm/Max): ºF 80 100 120 80 100 120

12 Design temperature (Min/Max): ºF 145 145

13 Operating specific gravity: 0.83 0.83

14 Compressibility: Z 0.98 0.98

15 Molecular weight: 24.04 24.04

16 Specific heats ratio: Cp/Cv 1.23 1.23

17 Viscosity: cP 0.01 0.01

18 Density lb/ft3 0.26 0.26

19 Pipe Specification

METERING ELEMENT

19 Type Local Indicator Local Indicator

20 Flow Direction Horizontal Horizontal

21 Instrument Range (Min/ Max) MMSCFD 0 - 0.03 0 - 0.03

22 Accuracy + 1.5% Range + 1.5% Range

23 Material Tube Liner 316L SS N/A 316L SS N/A

24 Float Other Wetted Parts 316L SS 316L SS 316L SS 316L SS

25 Connection In Size Rating Type 1 in ANSI 150# RF 1 in ANSI 150# RF

26 Out Size Rating Type 1 in ANSI 150# RF 1 in ANSI 150# RF

ACCESSORIES

27 Dampener Not required Not required

28 Cooling Fin Not required Not required

29 Needle Valve Not required Not required

30 Remote Output Gauge Tag No. Not required Not required

31 Remote Output Gauge Range Min. Max. Not required Not required

32

PURGE METER

33 Single or Double N/A N/A

34 Filter Regulator N/A N/A

35 Purge Meter N/A N/A

36 Constant Differential Relay N/A N/A

37 Mouting Plate N/A N/A

38

PURCHASE

39 Manufacture Refer to Medco PML Refer to Medco PML

40 Model (Note 4) (Note 4)

41 Requisition Number - -

42

Notes:

1 The plate handle shall be stamped with Tag, Bore, Line ID and "Upstream" in 10mm characters on the upstream side.

2 Vendor should provide Orifice Calculation for approval

3 Vendor to provide orifice holder complete with A193 B7 Bolt, Cadmium Plated and A194 2H Nut, Cadmium Plated.

4 Vendor to advise

C 18-Dec-20 Issued for Construction SYW / PRD DEK / AMW AGA / IDG

B 27-Oct-20 Issued for Approval SYW / PRD DEK / AMW AGA

A 1-Oct-20 Issued for Review SYW / PRD DEK -

REV. DATE DESCRIPTION PREPD CHKD APPD

MATRA FACILITIES OPTIMIZATION

PT. MEDCO E &P INDONESIA Document DATA SHEET

Title : FLOW ELEMENT (ROTAMETER)

Document No. : MTT-I-DS-007 Rev : C

Sheet 2 of 2

SERVICE: TAG No: FR/PR-102 FR/PR-103

1 Service description: Gas Outlet from Production

Gas Outlet from Test Separator

Separator

2 Line/Vessel No: 6"-HG-3836-1B 4"-HG-3844-1B

3 P & I D No: MTT-R-PI-003 MTT-R-PI-026

4 R.F.Q. No: P.O No. - -

5 Manufacturer: (Note 4) (Note 4)

6 Vendor: (Note 4) (Note 4)

7 Model No: (Note 4) (Note 4)

8 Serial No: (Note 4) (Note 4)

9 Electrical Area Classification: Class I Div 2 Class I Div 2

10 Electrical Certification: - -

PROCESS SERVICE CONDITION

11 Fluid Type/State Hydrocarbon / Gas Hydrocarbon / Gas

o

12 Temperature Oper / Design F 100/ 145 100/ 200

13 Pressure Oper / Design psig 50/ 250 50/ 250

14

CONSTRUCTION TRANSMITTER

15 Transmitter Type Multivariable Multivariable

16 Mounting: Stanchion Stanchion

17 Case Material (Note 4) (Note 4)

18 Material Body/Bolting Mfr.Std Mfr.Std Mfr.Std Mfr.Std

19 Static Press Calibrated Range psig 0 - 100 0 - 100

20 Diff. Pressure Element Type Diaphragm Diaphragm

21 Element Material 316SS 316SS

22 Over Pressure Protection/Rating Yes 150# Yes 150#

23 Range Unit in H2O in H2O

24 Flow Range Limit inH2O 0-200 0-200

25 Calibrated Range inH2O 0-100 0-100

26 Temperature Sensor N/A N/A

27 Calibrated Range F N/A N/A

28 Accuracy +/-% Span 0.1% 0.1%

29 Total Temp Effect at max Span +/-% (Note 4) (Note 4)

30 Stability (6 months) +/-% Range (Note 4) (Note 4)

31 Power Supply/Output Signal 24VDC 4-20 mA 24VDC 4-20 mA

32 Integral Meter/Meter Scale (Note 4) Yes (Note 4) Yes

33 Enclosure Type/IP Rating NEMA 4X 65 NEMA 4X 65

34 Cable Entry Size/Termination 1/2" NPT 1/2" NPT

35 Process Connection/Pneumatic 1/2" NPT-F 1/2" NPT-F

36 Connection Location (Note 4) (Note 4)

37 Display LCD LCD

38 Eng. Unit Display psig, inH2O psig, inH2O

FLOW TOTALIZER

39 Totalizer Flowrate + Totalizer Flowrate + Totalizer

40 Totalizer Eng. Unit Display MMSCFD MMSCFD

41 Model No: (Note 4) (Note 4)

INSTRUMENT OPTIONS

42 Valve Manifold/Mounting 5-way Mounted 5-way Mounted

43 Smart Electronic/Protocol Yes HART Yes HART

44 Mounting Bracket/Type Yes Mfr Std Yes Mfr Std

Notes:

1 316SS tags stamped with Tag No in 15mm characters shall be permanently attached using 316SS screws or wire

2 All permanent instrument fittings shall be stainless steel.

3 Instrument valve manifolds, where specified as a VENDOR supplied option shall be close coupled to the transmitter.

4 Vendor to Specify or Advise.

C 18-Dec-20 Issued for Construction SYW / PRD DEK / AMW AGA / IDG

B 27-Oct-20 Issued for Approval SYW / PRD DEK / AMW AGA

A 1-Oct-20 Issued for Review SYW / PRD DEK -

REV. DATE DESCRIPTION PREPD CHKD APPD

MATRA FACILITIES OPTIMIZATION

PT. MEDCO E &P INDONESIA Document DATA SHEET

Title : FLOW RECORDER

Document No. : MTT-I-DS-008 Rev : C

Sheet 1 of 1

SERVICE: TAG No: FQI-102

1 Service description: Test Separator

(MTT-MBD-102)

2 Line/Vessel No: -

3 P & I D No: MTT-R-PI-003

4 Fluid type : Hydrocarbon

5 Fluid state: Liquid

6 Fluid viscosity: cP 43.14

7 Specific gravity: 0.9375

8 Percent solids & type:

9 Maxm allowable DP: Psig 5 psig (VTA)

10 Temperature Minm/ Maxm: ºF 80 120

11 Pressure Op/ Design: Psig 50 250

12 Flow rate Minm/Max: BPD 900 7800

13 Velocity Minm/Max: ft/s 1.191451588 10.32591376

14 Line size/schedule: 4" 40

15 Amb temp Minm/Maxm: 70 100

METER SPECIFICATION

16 Type : Turbine Meter

17 Manufacturer / Model: (VTA)

18 Nominal flow range: (VTA)

19 Pressure drop at maxm flow: 5 psi at max rated flow

20 Body rating (pressure/temperature): ANSI 150#

21 Body material / Flange material: 316 SS 316 SS

22 End connections size/type: 2" RF - Flange

23 Shaft material / Support material: (VTA) (VTA)

24 Rotor material: (VTA)

25 Bearing type (sleeve/ball/floating): Sleeve

26 Bearing material Tungsteen Carbide

27 Maximum rated speed or frequency: (VTA)

28 Accuracy: % 0.5

29 Linearity: in + 0.5

30 K factor (cycles per vol unit): in (VTA)

31 Excitation (V/Hz -if modulating type): (VTA)

32 Pickup type (std/RF/expl. proof): in Class I Div 2 Gr. C/D

33 Enclosure certification & IP rating: NEMA 4X, 7

34 Cable entry: (VTA)

35 Strainer size & mesh: Required

36 Upstream and Downstream Run refer to API MPMS 5.3

FLOW TOTALIZER SPECIFICATION:

40 Totalizer: Flow rate + totalization

41 Logging data (non volatile memory) available

42 Transmitter output signal: Modbus (RS485)

43 Power supply: 24 VDC (Loop Powered)

44 Calibration: (Note 2)

45 Local indication: LCD

46 Mounting: Turbine mounted

47 Enclosure certification & IP rating: NEMA 4X, 7

48 Cable entry: 1/2" NPT

Notes:

1 316SS tags stamped with Tag No in 10mm characters shall be permanently attached using 316SS screws or wire

2 The unit is to be calibrated according to the above specification and ready for installation

3 VTA : Vendor To Advise

C 18-Dec-20 Issued for Construction SYW / PRD DEK / AMW AGA / IDG

B 27-Oct-20 Issued For Approval SYW / PRD DEK / AMW AGA

A 1-Oct-20 Issued For Review SYW / PRD DEK -

REV. DATE DESCRIPTION PREPD CHKD APPD

MATRA FACILITIES OPTIMIZATION

PT. MEDCO E &P INDONESIA Document Title DATA SHEET

: LIQUID FLOW METER

Document No. : MTT-I-DS-009 Rev : C

Sheet 1 of 1

1 Tag No. ILCV-103A

2 Service P&ID Interface Level Control Valve MTT-R-PI-026

3 Line No. Piping Class 4"-HL-3844-1B ANSI 150#

GENERAL

4 Pipe Material Pipe Insulation Carbon Steel No

5 Area Classification Area Certification Zone 2, IIA

6 Line Size & Schedule Inlet Outlet 4 inch 4 inch

o o

7 Ambient Temperature Min. Max 70 F 100 F

8 Available Air Supply Pressure Min. Max 90 Psig 140 Psig

9 Corrosive Erosive Toxic No No No

10 Fluid Name Fluid Phase Hydrocarbon Gas

11 Shut Off D.P psi 250

12 Units Minimum Flow Normal Flow Maximum Flow

13 Flow Rate BPD 3360 5600 6720

14 Inlet Pressure psig 50 50 50

15 Pressure Drop psi 40 40 40

16 Inlet Temperature o

F 100 100 100

17 Specific Gravity (SG) 0.94 0.94 0.94

PROCESS

18 Density lb/ft3 58.78 58.78 58.78

19 Molecular Weight - 23.16 23.16 23.16

20 Compressibility Factor - - - -

21 Viscosity cP 43.1400 43.14 43.1

22 Specific Heat Ratio (Cp/Cv) - - - -

23 True Vapour Pressure at 37.8 deg.C psig 49.88 49.88 49.88

24 Critical Pressure psig 2686.00 2686.00 2686.00

25 %Flashing %

26 Pressure Opt Design psig 50 250

27 Temperature Opt Design o

F 100 200

28 Flow Coefficient Cv Calculated Selected - (Note 1) (Note 1) (Note 1)

CALC

29 Travel %

30 Sound Pressure Level @ 3 ft. dBA max. 85 dBA

31 Manufacturer (Note 1) 62 Manufacturer (Note 1)

32 Model (Note 1) 63 Model (Note 1)

33 Body Type Globe 64 Actuator Type Diaphragm

34 ANSI Class End Conn. 150# RF 65 Actuator Size (Note 1)

ACTUATOR

35 Body Size 3 in 66 Valve Failed Position Open

36 Face to Face Dimension ANSI/ASME B16.10 67 Travel Indicator Yes

37 Guiding Post 68 Air Supply Min Max 0 psig 30 psig

38 Flow Direction (Up/Down) Up 69 Actuator Orientation (Note 1)

39 Bonnet Type Plain 70 Handwheel No

40 Body Material / Bonnet Carbon Steel 71 Bench Set 3 - 15 psig

VALVE BODY & TRIM

41 Packing Material PTFE 72 Actuator Force Design Pressure (Note 1)

42 Charateristic Linear 73 Manufacturer (Note 1)

43 Trim Type (Note 1) 74 Model (Note 1)

POSITIONER

44 Trim Size (Note 1) 75 Positioner Type Pneumatic

45 Trim Construction (Note 1) 76 IP Transducer IP Tag Number I to P LY-103A

46 Calculated Cv Max Nor (Note 1) 77 Enclosure Class IP 65 & Eex"d"

47 Rated Cv (Note 1) 78 Signal Input 4-20 mA

48 Balanced / Unbalanced Balanced / Unbalanced 79 Gauge Range Yes (Note 1)

49 Trim Material - Disc Plug 316SS 80 Connection (Note 1)

50 Trim Material - Seat 316SS 81 Air Set Yes

51 Trim Material - Shaft 316SS 82 Filter / Gauge Yes

ACCESSORIES

PNEUMATIC

52 Shutoff Class Class V 83 Material Aluminium

53 Max SPL Allowable (dBA) 85 @ 3 ft 84 Tube Material 316SS

54 Painting Mfr. Std 85 Fitting Type Compression tube fittings

55 Name Plate Yes, 316SS 86 Size & Connection (Note 1)

56 Hydrotest ISA S75.19 87

CERTIFICATION

57 Material Certification Yes 88 Manufacturer (Note 3)

PURCHASE

TEST /

58 Hazardous Area Certification Zone 2, IIA 89 Model (Note 1)

59 Dimension Required 90 Requsition No. -

60 91 Item No. -

61 92 Serial No. -

Notes :

1 Vendor to Advice

2 Vendor shall perform sizing calculations and submit to COMPANY for approval at bid stage

3 Brand Control Valve : Fisher, Flowserve, Masoneillan, Valtek, Severn Glocorn

C 18-Dec-20 Issued for Construction SYW / PRD DEK / AMW AGA / IDG

B 27-Oct-20 Issued for Approval SYW / PRD DEK / AMW AGA

A 1-Oct-20 Issued for Review SYW / PRD DEK -

REV. DATE DESCRIPTION PREP CHKD APPD

MATRA FACILITIES OPTIMIZATION

PT. MEDCO E & P INDONESIA Doc. Title : DATA SHEET

LEVEL CONTROL VALVE

Doc. No. : MTT-I-DS-010 Rev : C

Sheet 1 of 2

1 Tag No. LCV-103B

2 Service P&ID Level Control Valve (Oil) MTT-R-PI-026

3 Line No. Piping Class - ANSI 150#

GENERAL

4 Pipe Material Pipe Insulation Carbon Steel No

5 Area Classification Area Certification Zone 2, IIA

6 Line Size & Schedule Inlet Outlet 3 inch 3 inch

o o

7 Ambient Temperature Min. Max 70 F 100 F

8 Available Air Supply Pressure Min. Max 90 Psig 140 Psig

9 Corrosive Erosive Toxic No No No

10 Fluid Name Fluid Phase Hydrocarbon Gas

11 Shut Off D.P psi 250

12 Units Minimum Flow Normal Flow Maximum Flow

13 Flow Rate BPD 2220 3700 4440

14 Inlet Pressure psig 50 50 50

15 Pressure Drop psi 40 40 40

16 Inlet Temperature o

F 100 100 100

17 Specific Gravity (SG) 0.94 0.94 0.94

PROCESS

18 Density lb/ft3 58.78 58.78 58.78

19 Molecular Weight - 23.16 23.16 23.16

20 Compressibility Factor - - - -

21 Viscosity cP 43.1400 43.14 43.1

22 Specific Heat Ratio (Cp/Cv) - - - -

23 Vapour Pressure psig 49.88 49.88 49.88

24 Critical Pressure psig 2686.00 2686.00 2686.00

25 %Flashing %

26 Pressure Opt Design psig 50 250

27 Temperature Opt Design o

F 100 200

28 Flow Coefficient Cv Calculated Selected - (Note 1) (Note 1) (Note 1)

CALC

29 Travel %

30 Sound Pressure Level @ 3 ft. dBA max. 85 dBA

31 Manufacturer (Note 1) 62 Manufacturer (Note 1)

32 Model (Note 1) 63 Model (Note 1)

33 Body Type Globe 64 Actuator Type Diaphragm

34 ANSI Class End Conn. 150# RF 65 Actuator Size (Note 1)

ACTUATOR

35 Body Size 3 in 66 Valve Failed Position Open

36 Face to Face Dimension ANSI/ASME B16.10 67 Travel Indicator Yes

37 Guiding Post 68 Air Supply Min Max 0 psig 30 psig

38 Flow Direction (Up/Down) Up 69 Actuator Orientation (Note 1)

39 Bonnet Type Plain 70 Handwheel No

40 Body Material / Bonnet Carbon Steel 71 Bench Set 3 - 15 psig

VALVE BODY & TRIM

41 Packing Material PTFE 72 Actuator Force Design Pressure (Note 1)

42 Charateristic Linear 73 Manufacturer (Note 1)

43 Trim Type (Note 1) 74 Model (Note 1)

POSITIONER

44 Trim Size (Note 1) 75 Positioner Type Pneumatic

45 Trim Construction (Note 1) 76 IP Transducer IP Tag Number I to P LY-103B

46 Calculated Cv Max Nor (Note 1) 77 Enclosure Class IP 65 & Eex"d"

47 Rated Cv (Note 1) 78 Signal Input 4-20 mA

48 Balanced / Unbalanced Balanced / Unbalanced 79 Gauge Range Yes (Note 1)

49 Trim Material - Disc Plug 316SS 80 Connection (Note 1)

50 Trim Material - Seat 316SS 81 Air Set Yes

51 Trim Material - Shaft 316SS 82 Filter / Gauge Yes

ACCESSORIES

PNEUMATIC

52 Shutoff Class Class V 83 Material Aluminium

53 Max SPL Allowable (dBA) 85 @ 3 ft 84 Tube Material 316SS

54 Painting Mfr. Std 85 Fitting Type Compression tube fittings

55 Name Plate Yes, 316SS 86 Size & Connection (Note 1)

56 Hydrotest ISA S75.19 87

CERTIFICATION

57 Material Certification Yes 88 Manufacturer (Note 3)

PURCHASE

TEST /

58 Hazardous Area Certification Zone 2, IIA 89 Model (Note 1)

59 Dimension Required 90 Requsition No. -

60 91 Item No. -

61 92 Serial No. -

Notes :

1 Vendor to Advice

2 Vendor shall perform sizing calculations and submit to COMPANY for approval at bid stage

3 Brand Control Valve : Fisher, Flowserve, Masoneillan, Valtek, Severn Glocorn

C 18-Dec-20 Issued for Construction SYW / PRD DEK / AMW AGA / IDG

B 27-Oct-20 Issued for Approval SYW / PRD DEK / AMW AGA

A 1-Oct-20 Issued for Review SYW / PRD DEK -

REV. DATE DESCRIPTION PREP CHKD APPD

MATRA FACILITIES OPTIMIZATION

PT. MEDCO E & P INDONESIA Doc. Title : DATA SHEET

LEVEL CONTROL VALVE

Doc. No. : MTT-I-DS-010 Rev : C

Sheet 2 of 2

1 Tag Number ILG-103

2 Service Production Separator

GENERAL

3 P&ID No. MTT-R-PI-026

4 Equipment No. MTT-MBD-103

5 Fluid Type Hydrocarbon Liquid

6 Design Pressure psig 250

PROCESS 7 Oper. Pressure psig 50

CONDITIONS 8 Design Temperature o

F 200

o

9 Oper. Temperature F 100

10 Operating Specific Gravity (SG) 0.9375

11 Supply / Assembly Gauge & Valve Assembly

12 Type of Gauge Transparant

13 Centre to Centre Visible Length 42 inch (Note 1) inch

14 Process Connection Type NPTM

15 Size Rating 3/4" & Class 800#

16 Coloumn Rating 800#

GAUGE GLASS 17 Section Required Unit Glass Length (Note 1) (Note 1)

18 Chamber Size, Schedule, Thickness Mfr. Std

19 Connection Location Type Top & Bottom NPT

20 End Finish NPTM

21 Enclosure Type (Note 1)

22 Hazardous Protection Class Certificate N/A

23 Weather Protection N/A

24 Type Bonnet Mfr Std. Std.

25 Connection

26 Vessel 3/4" NPTM

GAUGE COCK

27 Gauge 3/4' NPTF

28 Drain 1/2" NPTF

29 Vent 1/2" NPTF

30 Coloumn or Chamber Gauge Cover Carbon Steel Carbon Steel

31 Glass or Tubular Gasket & Cushion Borosilicate (Note 1)

32 Bolts Nuts (Note 1) (Note 1)

MATERIALS

33 Flange Screw Valve Body (Note 1) (Note 1)

34 Trim Ball Check 316 SS 316 SS

35 Packing Mfr. Std

36 Calibration Scale -

37 Non-Forst -

38 Illuminator -

OPTIONS 39 Mica Shield -

40 External Jacket -

41 Internal Tube -

42 Other -

43 Manufacturer Refer to Medco PML

44 Model Serial No. (Note 1) (Note 1)

PURCHASE

45 Requisition Number -

46 Purchase Order No. -

Notes :

1 VTA : Vendor to Advice

C 18-Dec-20 Issued for Construction SYW / PRD DEK / AMW AGA / IDG

B 27-Oct-20 Issued For Approval SYW / PRD DEK / AMW AGA

A 1-Oct-20 Issued For Review SYW / PRD DEK -

REV. DATE DESCRIPTION PREP CHKD APPD

MATRA FACILITIES OPTIMIZATION

PT. MEDCO E & P INDONESIA Document Title : DATA SHEET

LEVEL GAUGE

Document No. : MTT-I-DS-011 Rev : C

Sheet 1 of 4

1 Tag Number LG-103

2 Service Production Separator

GENERAL

3 P&ID No. MTT-R-PI-026

4 Equipment No. MTT-MBD-103

5 Fluid Type Hydrocarbon Liquid

6 Design Pressure psig 250

PROCESS 7 Oper. Pressure psig 50

CONDITIONS 8 Design Temperature o

F 200

o

9 Oper. Temperature F 100

10 Operating Specific Gravity (SG) 0.9375

11 Supply / Assembly Gauge & Valve Assembly

12 Type of Gauge Transparant

13 Centre to Centre Visible Length 42 inch (Note 1) inch

14 Process Connection Type NPTM

15 Size Rating 3/4" & Class 800#

16 Coloumn Rating 800#

GAUGE GLASS 17 Section Required Unit Glass Length (Note 1) (Note 1)

18 Chamber Size, Schedule, Thickness Mfr. Std

19 Connection Location Type Top & Bottom NPT

20 End Finish NPTM

21 Enclosure Type (Note 1)

22 Hazardous Protection Class Certificate N/A

23 Weather Protection N/A

24 Type Bonnet Mfr Std. Std.

25 Connection

26 Vessel 3/4" NPTM

GAUGE COCK

27 Gauge 3/4' NPTF

28 Drain 1/2" NPTF

29 Vent 1/2" NPTF

30 Coloumn or Chamber Gauge Cover Carbon Steel Carbon Steel

31 Glass or Tubular Gasket & Cushion Borosilicate (Note 1)

32 Bolts Nuts (Note 1) (Note 1)

MATERIALS

33 Flange Screw Valve Body (Note 1) (Note 1)

34 Trim Ball Check 316 SS 316 SS

35 Packing Mfr. Std

36 Calibration Scale -

37 Non-Forst -

38 Illuminator -

OPTIONS 39 Mica Shield -

40 External Jacket -

41 Internal Tube -

42 Other -

43 Manufacturer Refer to Medco PML

44 Model Serial No. VTA VTA

PURCHASE

45 Requisition Number -

46 Purchase Order No. -

Notes :

1 VTA : Vendor to Advice

C 18-Dec-20 Issued for Construction SYW / PRD DEK / AMW AGA / IDG

B 27-Oct-20 Issued For Approval SYW / PRD DEK / AMW AGA

A 1-Oct-20 Issued For Review SYW / PRD DEK -

REV. DATE DESCRIPTION PREP CHKD APPD

MATRA FACILITIES OPTIMIZATION

PT. MEDCO E & P INDONESIA Document Title : DATA SHEET

LEVEL GAUGE

Document No. : MTT-I-DS-011 Rev : C

Sheet 2 of 4

1 Tag Number LG-502

2 Service KO Drum

GENERAL

3 P&ID No. MTT-R-PI-027

4 Equipment No. MTT-MBD-502

5 Fluid Type Hydrocarbon Liquid

6 Design Pressure psig 250

PROCESS 7 Oper. Pressure psig 10

CONDITIONS 8 Design Temperature o

F 145

o

9 Oper. Temperature F 100

10 Operating Specific Gravity (SG) 0.8371

11 Supply / Assembly Gauge & Valve Assembly

12 Type of Gauge Transparant

13 Centre to Centre Visible Length 30 inch (Note 1) inch

14 Process Connection Type NPTM

15 Size Rating 3/4" & Class 800#

16 Coloumn Rating 800#

GAUGE GLASS 17 Section Required Unit Glass Length (Note 1) (Note 1)

18 Chamber Size, Schedule, Thickness Mfr. Std

19 Connection Location Type Top & Bottom NPT

20 End Finish NPTM

21 Enclosure Type (Note 1)

22 Hazardous Protection Class Certificate N/A

23 Weather Protection N/A

24 Type Bonnet Mfr Std. Std.

25 Connection

26 Vessel 3/4" NPTM

GAUGE COCK

27 Gauge 3/4' NPTF

28 Drain 1/2" NPTF

29 Vent 1/2" NPTF

30 Coloumn or Chamber Gauge Cover Carbon Steel Carbon Steel

31 Glass or Tubular Gasket & Cushion Borosilicate (Note 1)

32 Bolts Nuts (Note 1) (Note 1)

MATERIALS

33 Flange Screw Valve Body (Note 1) (Note 1)

34 Trim Ball Check 316 SS 316 SS

35 Packing Mfr. Std

36 Calibration Scale -

37 Non-Forst -

38 Illuminator -

OPTIONS 39 Mica Shield -

40 External Jacket -

41 Internal Tube -

42 Other -

43 Manufacturer Refer to Medco PML

44 Model Serial No. VTA VTA

PURCHASE

45 Requisition Number -

46 Purchase Order No. -

Notes :

1 VTA : Vendor to Advice

C 18-Dec-20 Issued for Construction SYW / PRD DEK / AMW AGA / IDG

B 27-Oct-20 Issued For Approval SYW / PRD DEK / AMW AGA

A 1-Oct-20 Issued For Review SYW / PRD DEK -

REV. DATE DESCRIPTION PREP CHKD APPD

MATRA FACILITIES OPTIMIZATION

PT. MEDCO E & P INDONESIA Document Title : DATA SHEET

LEVEL GAUGE

Document No. : MTT-I-DS-011 Rev : C

Sheet 3 of 4

1 Tag Number LG-341/ 342

2 Service Calibration Gauge for Chemical Injection System

GENERAL

3 P&ID No. MTT-R-PI-028

4 Equipment No. -

5 Fluid Type Chemical Injection

6 Design Pressure psig ATM

PROCESS 7 Oper. Pressure psig ATM

CONDITIONS 8 Design Temperature o

F 100

o

9 Oper. Temperature F ATM

10 Operating Specific Gravity (SG) 1.1