Professional Documents

Culture Documents

Pressure Sensor

Pressure Sensor

Uploaded by

Asad AhmedCopyright:

Available Formats

You might also like

- BS60080 2020 Technical Note - Flame DetectionDocument7 pagesBS60080 2020 Technical Note - Flame DetectionmaheshNo ratings yet

- A Guide to Electronic Maintenance and RepairsFrom EverandA Guide to Electronic Maintenance and RepairsRating: 4.5 out of 5 stars4.5/5 (7)

- Bosch Plena Amplifier DatasheetDocument3 pagesBosch Plena Amplifier DatasheetcboueidNo ratings yet

- Eng DS 1210 B6Document6 pagesEng DS 1210 B6Asad AhmedNo ratings yet

- Pressure Transducer: SpecificationsDocument9 pagesPressure Transducer: SpecificationsWILLIAM AGUDELONo ratings yet

- SCXL004DN: Precision Compensated, Low Pressure SensorsDocument3 pagesSCXL004DN: Precision Compensated, Low Pressure Sensorsloza_2912004No ratings yet

- Eds 300 ShippingDocument2 pagesEds 300 ShippingARINo ratings yet

- XDB102 2 (A)Document3 pagesXDB102 2 (A)Young WuNo ratings yet

- 24PC Pressure SensorsDocument4 pages24PC Pressure SensorsrngNo ratings yet

- SMT2001Document10 pagesSMT2001Lavanya ReddyNo ratings yet

- XDB102 4Document4 pagesXDB102 4Young WuNo ratings yet

- XDB102 6Document4 pagesXDB102 6Young WuNo ratings yet

- XDB102 3Document3 pagesXDB102 3Young WuNo ratings yet

- M3200 DatasheetDocument22 pagesM3200 DatasheetWilliams RobinsonNo ratings yet

- MBS3300Document8 pagesMBS3300บัณฑิตย์ จันทร์ทาNo ratings yet

- Pressure Sensor HoneywellDocument6 pagesPressure Sensor Honeywellamol_aradwadNo ratings yet

- Pressure Transmitter: Description: Technical DataDocument2 pagesPressure Transmitter: Description: Technical DataCristianNo ratings yet

- Pressure Transducer: Special FeaturesDocument4 pagesPressure Transducer: Special FeaturesIMP PROYECTONo ratings yet

- MS763Document4 pagesMS763Biosens BioNo ratings yet

- Sensor de PresionDocument4 pagesSensor de PresionjoseNo ratings yet

- Pressure Transmitter For Air and Water Applications: Type MBS 1900Document4 pagesPressure Transmitter For Air and Water Applications: Type MBS 1900chandras20No ratings yet

- Pt303 Pt308 (Ashcroft)Document4 pagesPt303 Pt308 (Ashcroft)Serge LapointeNo ratings yet

- 2 Inch D1dip-Mv Flu Diferencial de PresionDocument6 pages2 Inch D1dip-Mv Flu Diferencial de PresionFernando CharryNo ratings yet

- Pressure Switch: Up To 2 Switching Outputs Analogue OutputDocument4 pagesPressure Switch: Up To 2 Switching Outputs Analogue OutputОстап ФеренсовичNo ratings yet

- 40PC Series: Fully Signal Conditioned Pressure TransducerDocument8 pages40PC Series: Fully Signal Conditioned Pressure TransducerAbdel HassibNo ratings yet

- En18321 3 02 18 - As1000Document2 pagesEn18321 3 02 18 - As1000witriusNo ratings yet

- GF DS SFM3019 D1Document18 pagesGF DS SFM3019 D1Vahan KirakosyanNo ratings yet

- Danfoss MBS 3000 and MBS3050Document8 pagesDanfoss MBS 3000 and MBS3050zhenyupanNo ratings yet

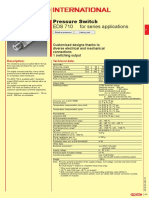

- EDS 410 For Series Applications: Pressure SwitchDocument2 pagesEDS 410 For Series Applications: Pressure SwitchDaniel GómezNo ratings yet

- D O S O: Ifferential Utput Ilicon ScillatorDocument8 pagesD O S O: Ifferential Utput Ilicon ScillatorkynixNo ratings yet

- Pressure Transmitter: Description: Technical DataDocument2 pagesPressure Transmitter: Description: Technical Dataendangfarid hidayatNo ratings yet

- (GE) P161 - 3F Gauge Pressure Sensor DieDocument2 pages(GE) P161 - 3F Gauge Pressure Sensor Died5969660No ratings yet

- En18351 3 02 18 - Eds710 - OemDocument2 pagesEn18351 3 02 18 - Eds710 - Oemвиктор колесниковNo ratings yet

- Screw-In Transmitter: Stainless Steel SensorDocument4 pagesScrew-In Transmitter: Stainless Steel SensorjOAONo ratings yet

- 8.press SensorDocument10 pages8.press SensorGaurav MaithilNo ratings yet

- A2 Pressure Transmitter: Data SheetDocument4 pagesA2 Pressure Transmitter: Data SheetpatrickNo ratings yet

- Series PD-33 X: Piezoresistive Differential Pressure Transmitters With Excellent AccuracyDocument7 pagesSeries PD-33 X: Piezoresistive Differential Pressure Transmitters With Excellent AccuracymuhammetnaberNo ratings yet

- Interactive Catalog Replaces Catalog PagesDocument3 pagesInteractive Catalog Replaces Catalog Pagesmohamad_mozaNo ratings yet

- Wika Ac1Document4 pagesWika Ac1DOUBENo ratings yet

- AI244586497020en 001201Document9 pagesAI244586497020en 001201Aditya ShankarNo ratings yet

- DB LMP307 eDocument5 pagesDB LMP307 egilad.leizerNo ratings yet

- Melt Pressure Transmitters MN Series: Voltage OutputDocument4 pagesMelt Pressure Transmitters MN Series: Voltage OutputNilesh WableNo ratings yet

- DTS MN 07-2017 Eng PDFDocument4 pagesDTS MN 07-2017 Eng PDFvipul patelNo ratings yet

- Electronic Pressure Transmitter: (Minimum Order Quantity 500 Units)Document2 pagesElectronic Pressure Transmitter: (Minimum Order Quantity 500 Units)Felipe RodriguesNo ratings yet

- Melt Pressure Transmitters MN Series: Voltage OutputDocument4 pagesMelt Pressure Transmitters MN Series: Voltage OutputGopal HegdeNo ratings yet

- Technical - Data - Sheet Awiflex en 10 Rev10 03Document4 pagesTechnical - Data - Sheet Awiflex en 10 Rev10 03romulus berdeiNo ratings yet

- CRI P 340 - EngDocument4 pagesCRI P 340 - EngJerNo ratings yet

- DB DMP331 eDocument6 pagesDB DMP331 etouili majdiNo ratings yet

- Voltage Transducer LV 25-P I 10 Ma V 10 .. 500 VDocument2 pagesVoltage Transducer LV 25-P I 10 Ma V 10 .. 500 VFilipe PereiraNo ratings yet

- Pressure Transmitter: Increased Functional SafetyDocument2 pagesPressure Transmitter: Increased Functional SafetyMeleștean MihaiNo ratings yet

- Honeywell Sensing Airflow Sensors Awm700 Series Datasheet 32301627 B en PDFDocument7 pagesHoneywell Sensing Airflow Sensors Awm700 Series Datasheet 32301627 B en PDFAlejandro Palomino AmaroNo ratings yet

- Pressure Switches: Up To 2 Switch Outputs Analogue OutputDocument6 pagesPressure Switches: Up To 2 Switch Outputs Analogue OutputНикола СтефановићNo ratings yet

- DTS Ks-Sil2 01-2019 Eng PDFDocument8 pagesDTS Ks-Sil2 01-2019 Eng PDFMiguel Ángel CenamorNo ratings yet

- MPM281 Pressure SensorDocument4 pagesMPM281 Pressure SensorPetr -No ratings yet

- AI309145930291en 000301Document6 pagesAI309145930291en 000301Aicky IkrackNo ratings yet

- 2-Wire, RH+T Transmitters: 2 X 4 20 Ma Outputs Ip65/Ip66 Dual LCD Display Flameproof SC805, SC806, SC807Document6 pages2-Wire, RH+T Transmitters: 2 X 4 20 Ma Outputs Ip65/Ip66 Dual LCD Display Flameproof SC805, SC806, SC807Ravi Kant GuptaNo ratings yet

- DB DMP331 eDocument5 pagesDB DMP331 egilad.leizerNo ratings yet

- 2SMPB 02eDocument30 pages2SMPB 02edexkezzNo ratings yet

- Intelimains NTC Basebox DatasheetDocument4 pagesIntelimains NTC Basebox DatasheetEnny ClocielNo ratings yet

- XGZP161 Pressure Sensor-V2Document8 pagesXGZP161 Pressure Sensor-V2samsularief03No ratings yet

- Invoice 03Document1 pageInvoice 03Asad AhmedNo ratings yet

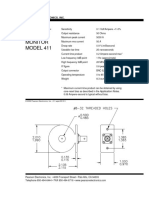

- Pearson Current Monitor MODEL 411Document1 pagePearson Current Monitor MODEL 411Asad AhmedNo ratings yet

- A Comprehensive Guide On WhatApp Customer SupportDocument55 pagesA Comprehensive Guide On WhatApp Customer SupportAsad AhmedNo ratings yet

- TicketDocument2 pagesTicketAsad AhmedNo ratings yet

- AD824Document16 pagesAD824Asad AhmedNo ratings yet

- 0bfac16f-3bd2-4759-bbe9-0daa6cdd1956Document2 pages0bfac16f-3bd2-4759-bbe9-0daa6cdd1956Asad AhmedNo ratings yet

- 108Document1 page108Asad AhmedNo ratings yet

- Microchip Arm926ej S Microcontroller 64 KB 10 Bit TfbgaDocument50 pagesMicrochip Arm926ej S Microcontroller 64 KB 10 Bit TfbgaAsad AhmedNo ratings yet

- 07 31 2020 15.02.26Document1 page07 31 2020 15.02.26Asad AhmedNo ratings yet

- SN54LV4053A, SN74LV4053A Triple 2-Channel Analog Multiplexers/DemultiplexersDocument33 pagesSN54LV4053A, SN74LV4053A Triple 2-Channel Analog Multiplexers/DemultiplexersAsad AhmedNo ratings yet

- Silo - Tips - Cardiostart Defibrillator MonitorDocument92 pagesSilo - Tips - Cardiostart Defibrillator MonitorAsad AhmedNo ratings yet

- Atmel 6438 32 Bit ARM926 Embedded Microprocessor S-2585389Document1,227 pagesAtmel 6438 32 Bit ARM926 Embedded Microprocessor S-2585389Asad AhmedNo ratings yet

- ContinueDocument2 pagesContinueAsad AhmedNo ratings yet

- Vishay Sfernice: FeaturesDocument5 pagesVishay Sfernice: FeaturesAsad AhmedNo ratings yet

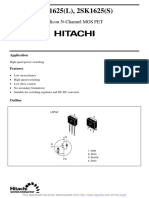

- 740 3 005230 2SK1625Document6 pages740 3 005230 2SK1625Asad AhmedNo ratings yet

- Lab 9101aDocument2 pagesLab 9101aAsad AhmedNo ratings yet

- Ecx 10 N 20Document4 pagesEcx 10 N 20Asad AhmedNo ratings yet

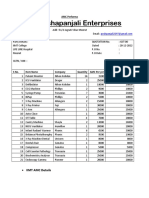

- IIMT AMC QutationDocument1 pageIIMT AMC QutationAsad AhmedNo ratings yet

- 1987 Samsung SFET Data BookDocument446 pages1987 Samsung SFET Data BookAsad AhmedNo ratings yet

- Noninvasive Blood Pressure (NIBP) Measurement by Oscillometric PrincipleDocument6 pagesNoninvasive Blood Pressure (NIBP) Measurement by Oscillometric PrincipleAsad AhmedNo ratings yet

- DC-DC Converter YD12 Series Technical Specification V1.0Document6 pagesDC-DC Converter YD12 Series Technical Specification V1.0Asad AhmedNo ratings yet

- DSA00164356Document14 pagesDSA00164356Asad AhmedNo ratings yet

- Red Light Violation Detection SystemDocument2 pagesRed Light Violation Detection SystemAsad AhmedNo ratings yet

- DatasheetDocument12 pagesDatasheetAsad AhmedNo ratings yet

- Infineon IHW30N120R5 DataSheet v02 - 03 ENDocument15 pagesInfineon IHW30N120R5 DataSheet v02 - 03 ENAsad AhmedNo ratings yet

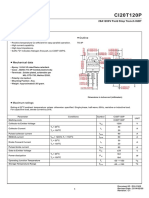

- CI20T120P: Features OutlineDocument4 pagesCI20T120P: Features OutlineAsad AhmedNo ratings yet

- Order Details PDFDocument3 pagesOrder Details PDFAsad AhmedNo ratings yet

- Projecttronics Robotics FinalDocument4 pagesProjecttronics Robotics FinalRushikesh MoonNo ratings yet

- CS438 Midterm SolDocument6 pagesCS438 Midterm SolDavide SlanziNo ratings yet

- E2 14 03 04Document6 pagesE2 14 03 04dinakaran2020No ratings yet

- FY21xxS User's Manual - V2.2Document7 pagesFY21xxS User's Manual - V2.2xoltrialNo ratings yet

- Unit 3: Step 3 - Understand Technology CommercializationDocument15 pagesUnit 3: Step 3 - Understand Technology CommercializationCAROL CASTRONo ratings yet

- Project Report: Project Topic: Role of Prime Bank LTD On Encouraging EntrepreneursDocument2 pagesProject Report: Project Topic: Role of Prime Bank LTD On Encouraging EntrepreneursZahid Bin Islam100% (1)

- E Learning in Timor-Leste, Paper by Sara Moreira On e Learning at The National University of Timor Loro Sa'eDocument3 pagesE Learning in Timor-Leste, Paper by Sara Moreira On e Learning at The National University of Timor Loro Sa'ePapers and Powerpoints from UNTL-VU Joint Conferenes in DiliNo ratings yet

- Saving Reading UploadingDownloading Mechanism of CSV File and Text File Using Csharp AspnetDocument4 pagesSaving Reading UploadingDownloading Mechanism of CSV File and Text File Using Csharp AspnetLajapathy ArunNo ratings yet

- Inspection Report 865 Reese Creek RDDocument48 pagesInspection Report 865 Reese Creek RDAlice LemaNo ratings yet

- Simulation Projects (Ece) Digital Signal Processing (Adsp & Texas) Image ProcessingDocument2 pagesSimulation Projects (Ece) Digital Signal Processing (Adsp & Texas) Image Processingpradeepkumar1826No ratings yet

- Annotated Bibliography FinalDocument6 pagesAnnotated Bibliography Finalapi-355201975No ratings yet

- Technical Data Sheet For Ep 7-12 (12V 7ah) Vrla BatteryDocument3 pagesTechnical Data Sheet For Ep 7-12 (12V 7ah) Vrla BatteryJegadeshwaran RNo ratings yet

- 4 Study of Small Scale LNG CarrierDocument25 pages4 Study of Small Scale LNG CarrierSangeethRoshan100% (1)

- Diameter Protocol Introduction - Base & DCCA - 20131128Document32 pagesDiameter Protocol Introduction - Base & DCCA - 20131128Tsai Chunyeh100% (2)

- Energy Audit in Textile Industry-A Study With Ring Frame MotorDocument5 pagesEnergy Audit in Textile Industry-A Study With Ring Frame MotorNarender Mehra SethNo ratings yet

- Penske Shock ManualDocument32 pagesPenske Shock ManualUfix FabricationNo ratings yet

- Chimney CalculationsDocument3 pagesChimney CalculationsSteve WanNo ratings yet

- Radio Path SurveyDocument12 pagesRadio Path SurveyJon Snow-StarkNo ratings yet

- ImgDocument1 pageImgWann PutraNo ratings yet

- Construction Check Sheet Tank B-0004A: MechanicalDocument1 pageConstruction Check Sheet Tank B-0004A: MechanicalhrimklimNo ratings yet

- SIMCA 13 Multivariate Batch Process ModelingDocument2 pagesSIMCA 13 Multivariate Batch Process ModelingJbel PiNo ratings yet

- ECG Abstract PDFDocument2 pagesECG Abstract PDFgangadhara0% (1)

- PTS Thermal InsulationDocument44 pagesPTS Thermal InsulationJustin LowNo ratings yet

- List of Manufacturer UG&OHTL For MaterialDocument8 pagesList of Manufacturer UG&OHTL For MaterialHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Yamaha MU100R SoundlistDocument134 pagesYamaha MU100R SoundlistAntuan Anartista MultidisciplinarNo ratings yet

- PETRONAS Hydraulic Series v2. 23-05-2016Document4 pagesPETRONAS Hydraulic Series v2. 23-05-2016Roter DiamNo ratings yet

- ABB Technical Data Sheet Electrical Machines: No. Data Unit RemarksDocument8 pagesABB Technical Data Sheet Electrical Machines: No. Data Unit RemarksIngenieria DyconNo ratings yet

Pressure Sensor

Pressure Sensor

Uploaded by

Asad AhmedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Sensor

Pressure Sensor

Uploaded by

Asad AhmedCopyright:

Available Formats

1210 Sub psi

PC Board Mountable Pressure Sensor

40 mV Output Typical

Differential Pressures

Metal Tube and Ceramic Barbed Ports

Temperature Compensated

DESCRIPTION

The 1210 sub PSI is a temperature compensated, piezoresistive silicon pressure sensor packaged in a

dual-in-line configuration. It is intended for cost sensitive applications where excellent performance and long-

term stability are required.

Integral temperature compensation is provided over a range of 0-60ºC using laser-trimmed resistors. An

additional laser-trimmed resistor is included to normalize pressure sensitivity variations by programming the gain

of an external differential amplifier. This provides sensitivity interchangeability of ±1%. Differential pressure

ranges from 0-5 (12.5mB) to 0-10 (25mB) in H2O are available. Multiple leads, metal or ceramic barbed tubes

are available for specific applications.

Please refer to the 1210 1psi and standard datasheet for information on products with operating

pressures greater than 1psi.

FEATURES APPLICATIONS

Dual-in-Line Package Sleep Apnea

Ceramic Barbed Ports Option Respirators/Ventilators

3/32 in. ID Hosing [2.4mm] Air Duct Flow

±0.5% Non Linearity Medical Instrumentation

±1.0% Temperature Performance

1.0% Interchangeable Span

(provided by gain set resistor)

Solid State Reliability

STANDARD RANGES

Range in. H2O

0 to 5

0 to 10

1210 Sub psi www.meas-spec.com September 2010

1/4

1210 Sub psi

PERFORMANCE SPECIFICATIONS

Supply Current: 1.5 mA

Ambient Temperature: 25ºC (unless otherwise specified)

PARAMETERS MIN TYP MAX UNITS NOTES

Span 20 40 70 mV 1

Zero Pressure Output -2 2 mV

Pressure Non Linearity -0.5 ±0.3 0.5 % Span 2

Pressure Hysteresis -0.25 ±0.15 0.25 % Span

Input & Output Resistance 1000 3600 4500 Ω

Temperature Error – Span -1.0 1.0 % Span 3

Temperature Error – Zero -1.25 1.25 % Span 3

Thermal Hysteresis – Zero ±0.1 % Span 3

Supply Current 0.5 1.5 2.0 mA

Response Time (10% to 90%) 200 µS 4

Output Noise (10Hz to 1kHz) 1.0 µV p-p

Long Term Stability ±0.2 %Span 5

Pressure Overload 5 psi

Compensated Temperature 0 60 °C

Operating Temperature -25 +85 ºC

Storage Temperature -40 +125 ºC

Weight 3 grams

Media Non-Corrosive Dry Gases Compatible with Silicon, Pyrex,

RTV, Gold, Ceramic, Nickel, and Aluminum

Notes

1. Ratiometric to supply current.

2. Best fit straight line. Non linearity for 10inH2O is 0.75%

3. Maximum temperature error between 0°C and 60°C with respect to 25°C.Thermal error of offset for 5inH2O is 2.0%

4. For a zero-to-full scale pressure step change.

5. Long term stability over a one year period with constant current and temperature.

1210 Sub psi www.meas-spec.com September 2010

2/4

1210 Sub psi

DIMENSIONS

CONNECTIONS

1210 Sub psi www.meas-spec.com September 2010

3/4

1210 Sub psi

APPLICATION SCHEMATIC

ORDERING INFORMATION

1210 A - 10W D - 3 S

Pressure Tubes (L = Long, S = Short, N = None, and B = Barbed)

Lead Configuration (1,3 - See Dimensions Diagram)

Type (D = Differential)

Pressure

Grade

Model

NORTH AMERICA EUROPE ASIA

Measurement Specialties

Measurement Specialties (China), Ltd.

Measurement Specialties

(Europe), Ltd. No. 26 Langshan Road

45738 Northport Loop West

26 Rue des Dames Shenzhen High-Tech Park (North)

Fremont, CA 94538

78340 Les Clayes-sous-Bois, France Nanshan District, Shenzhen 518107

Tel: 1-800-767-1888

Tel: +33 (0) 130 79 33 00 China

Fax: 1-510-498-1578

Fax: +33 (0) 134 81 03 59 Tel: +86 755 3330 5088

Sales: pfg.cs.amer@meas-spec.com

Sales: pfg.cs.emea@meas-spec.com Fax: +86 755 3330 5099

Sales: pfg.cs.asia@meas-spec.com

The information in this sheet has been carefully reviewed and is believed to be accurate; however, no responsibility is assumed for

inaccuracies. Furthermore, this information does not convey to the purchaser of such devices any license under the patent rights to the

manufacturer. Measurement Specialties, Inc. reserves the right to make changes without further notice to any product herein. Measurement

Specialties, Inc. makes no warranty, representation or guarantee regarding the suitability of its product for any particular purpose, nor does

Measurement Specialties, Inc. assume any liability arising out of the application or use of any product or circuit and specifically disclaims

any and all liability, including without limitation consequential or incidental damages. Typical parameters can and do vary in different

applications. All operating parameters must be validated for each customer application by customer’s technical experts. Measurement

Specialties, Inc. does not convey any license under its patent rights nor the rights of others.

1210 Sub psi www.meas-spec.com September 2010

4/4

You might also like

- BS60080 2020 Technical Note - Flame DetectionDocument7 pagesBS60080 2020 Technical Note - Flame DetectionmaheshNo ratings yet

- A Guide to Electronic Maintenance and RepairsFrom EverandA Guide to Electronic Maintenance and RepairsRating: 4.5 out of 5 stars4.5/5 (7)

- Bosch Plena Amplifier DatasheetDocument3 pagesBosch Plena Amplifier DatasheetcboueidNo ratings yet

- Eng DS 1210 B6Document6 pagesEng DS 1210 B6Asad AhmedNo ratings yet

- Pressure Transducer: SpecificationsDocument9 pagesPressure Transducer: SpecificationsWILLIAM AGUDELONo ratings yet

- SCXL004DN: Precision Compensated, Low Pressure SensorsDocument3 pagesSCXL004DN: Precision Compensated, Low Pressure Sensorsloza_2912004No ratings yet

- Eds 300 ShippingDocument2 pagesEds 300 ShippingARINo ratings yet

- XDB102 2 (A)Document3 pagesXDB102 2 (A)Young WuNo ratings yet

- 24PC Pressure SensorsDocument4 pages24PC Pressure SensorsrngNo ratings yet

- SMT2001Document10 pagesSMT2001Lavanya ReddyNo ratings yet

- XDB102 4Document4 pagesXDB102 4Young WuNo ratings yet

- XDB102 6Document4 pagesXDB102 6Young WuNo ratings yet

- XDB102 3Document3 pagesXDB102 3Young WuNo ratings yet

- M3200 DatasheetDocument22 pagesM3200 DatasheetWilliams RobinsonNo ratings yet

- MBS3300Document8 pagesMBS3300บัณฑิตย์ จันทร์ทาNo ratings yet

- Pressure Sensor HoneywellDocument6 pagesPressure Sensor Honeywellamol_aradwadNo ratings yet

- Pressure Transmitter: Description: Technical DataDocument2 pagesPressure Transmitter: Description: Technical DataCristianNo ratings yet

- Pressure Transducer: Special FeaturesDocument4 pagesPressure Transducer: Special FeaturesIMP PROYECTONo ratings yet

- MS763Document4 pagesMS763Biosens BioNo ratings yet

- Sensor de PresionDocument4 pagesSensor de PresionjoseNo ratings yet

- Pressure Transmitter For Air and Water Applications: Type MBS 1900Document4 pagesPressure Transmitter For Air and Water Applications: Type MBS 1900chandras20No ratings yet

- Pt303 Pt308 (Ashcroft)Document4 pagesPt303 Pt308 (Ashcroft)Serge LapointeNo ratings yet

- 2 Inch D1dip-Mv Flu Diferencial de PresionDocument6 pages2 Inch D1dip-Mv Flu Diferencial de PresionFernando CharryNo ratings yet

- Pressure Switch: Up To 2 Switching Outputs Analogue OutputDocument4 pagesPressure Switch: Up To 2 Switching Outputs Analogue OutputОстап ФеренсовичNo ratings yet

- 40PC Series: Fully Signal Conditioned Pressure TransducerDocument8 pages40PC Series: Fully Signal Conditioned Pressure TransducerAbdel HassibNo ratings yet

- En18321 3 02 18 - As1000Document2 pagesEn18321 3 02 18 - As1000witriusNo ratings yet

- GF DS SFM3019 D1Document18 pagesGF DS SFM3019 D1Vahan KirakosyanNo ratings yet

- Danfoss MBS 3000 and MBS3050Document8 pagesDanfoss MBS 3000 and MBS3050zhenyupanNo ratings yet

- EDS 410 For Series Applications: Pressure SwitchDocument2 pagesEDS 410 For Series Applications: Pressure SwitchDaniel GómezNo ratings yet

- D O S O: Ifferential Utput Ilicon ScillatorDocument8 pagesD O S O: Ifferential Utput Ilicon ScillatorkynixNo ratings yet

- Pressure Transmitter: Description: Technical DataDocument2 pagesPressure Transmitter: Description: Technical Dataendangfarid hidayatNo ratings yet

- (GE) P161 - 3F Gauge Pressure Sensor DieDocument2 pages(GE) P161 - 3F Gauge Pressure Sensor Died5969660No ratings yet

- En18351 3 02 18 - Eds710 - OemDocument2 pagesEn18351 3 02 18 - Eds710 - Oemвиктор колесниковNo ratings yet

- Screw-In Transmitter: Stainless Steel SensorDocument4 pagesScrew-In Transmitter: Stainless Steel SensorjOAONo ratings yet

- 8.press SensorDocument10 pages8.press SensorGaurav MaithilNo ratings yet

- A2 Pressure Transmitter: Data SheetDocument4 pagesA2 Pressure Transmitter: Data SheetpatrickNo ratings yet

- Series PD-33 X: Piezoresistive Differential Pressure Transmitters With Excellent AccuracyDocument7 pagesSeries PD-33 X: Piezoresistive Differential Pressure Transmitters With Excellent AccuracymuhammetnaberNo ratings yet

- Interactive Catalog Replaces Catalog PagesDocument3 pagesInteractive Catalog Replaces Catalog Pagesmohamad_mozaNo ratings yet

- Wika Ac1Document4 pagesWika Ac1DOUBENo ratings yet

- AI244586497020en 001201Document9 pagesAI244586497020en 001201Aditya ShankarNo ratings yet

- DB LMP307 eDocument5 pagesDB LMP307 egilad.leizerNo ratings yet

- Melt Pressure Transmitters MN Series: Voltage OutputDocument4 pagesMelt Pressure Transmitters MN Series: Voltage OutputNilesh WableNo ratings yet

- DTS MN 07-2017 Eng PDFDocument4 pagesDTS MN 07-2017 Eng PDFvipul patelNo ratings yet

- Electronic Pressure Transmitter: (Minimum Order Quantity 500 Units)Document2 pagesElectronic Pressure Transmitter: (Minimum Order Quantity 500 Units)Felipe RodriguesNo ratings yet

- Melt Pressure Transmitters MN Series: Voltage OutputDocument4 pagesMelt Pressure Transmitters MN Series: Voltage OutputGopal HegdeNo ratings yet

- Technical - Data - Sheet Awiflex en 10 Rev10 03Document4 pagesTechnical - Data - Sheet Awiflex en 10 Rev10 03romulus berdeiNo ratings yet

- CRI P 340 - EngDocument4 pagesCRI P 340 - EngJerNo ratings yet

- DB DMP331 eDocument6 pagesDB DMP331 etouili majdiNo ratings yet

- Voltage Transducer LV 25-P I 10 Ma V 10 .. 500 VDocument2 pagesVoltage Transducer LV 25-P I 10 Ma V 10 .. 500 VFilipe PereiraNo ratings yet

- Pressure Transmitter: Increased Functional SafetyDocument2 pagesPressure Transmitter: Increased Functional SafetyMeleștean MihaiNo ratings yet

- Honeywell Sensing Airflow Sensors Awm700 Series Datasheet 32301627 B en PDFDocument7 pagesHoneywell Sensing Airflow Sensors Awm700 Series Datasheet 32301627 B en PDFAlejandro Palomino AmaroNo ratings yet

- Pressure Switches: Up To 2 Switch Outputs Analogue OutputDocument6 pagesPressure Switches: Up To 2 Switch Outputs Analogue OutputНикола СтефановићNo ratings yet

- DTS Ks-Sil2 01-2019 Eng PDFDocument8 pagesDTS Ks-Sil2 01-2019 Eng PDFMiguel Ángel CenamorNo ratings yet

- MPM281 Pressure SensorDocument4 pagesMPM281 Pressure SensorPetr -No ratings yet

- AI309145930291en 000301Document6 pagesAI309145930291en 000301Aicky IkrackNo ratings yet

- 2-Wire, RH+T Transmitters: 2 X 4 20 Ma Outputs Ip65/Ip66 Dual LCD Display Flameproof SC805, SC806, SC807Document6 pages2-Wire, RH+T Transmitters: 2 X 4 20 Ma Outputs Ip65/Ip66 Dual LCD Display Flameproof SC805, SC806, SC807Ravi Kant GuptaNo ratings yet

- DB DMP331 eDocument5 pagesDB DMP331 egilad.leizerNo ratings yet

- 2SMPB 02eDocument30 pages2SMPB 02edexkezzNo ratings yet

- Intelimains NTC Basebox DatasheetDocument4 pagesIntelimains NTC Basebox DatasheetEnny ClocielNo ratings yet

- XGZP161 Pressure Sensor-V2Document8 pagesXGZP161 Pressure Sensor-V2samsularief03No ratings yet

- Invoice 03Document1 pageInvoice 03Asad AhmedNo ratings yet

- Pearson Current Monitor MODEL 411Document1 pagePearson Current Monitor MODEL 411Asad AhmedNo ratings yet

- A Comprehensive Guide On WhatApp Customer SupportDocument55 pagesA Comprehensive Guide On WhatApp Customer SupportAsad AhmedNo ratings yet

- TicketDocument2 pagesTicketAsad AhmedNo ratings yet

- AD824Document16 pagesAD824Asad AhmedNo ratings yet

- 0bfac16f-3bd2-4759-bbe9-0daa6cdd1956Document2 pages0bfac16f-3bd2-4759-bbe9-0daa6cdd1956Asad AhmedNo ratings yet

- 108Document1 page108Asad AhmedNo ratings yet

- Microchip Arm926ej S Microcontroller 64 KB 10 Bit TfbgaDocument50 pagesMicrochip Arm926ej S Microcontroller 64 KB 10 Bit TfbgaAsad AhmedNo ratings yet

- 07 31 2020 15.02.26Document1 page07 31 2020 15.02.26Asad AhmedNo ratings yet

- SN54LV4053A, SN74LV4053A Triple 2-Channel Analog Multiplexers/DemultiplexersDocument33 pagesSN54LV4053A, SN74LV4053A Triple 2-Channel Analog Multiplexers/DemultiplexersAsad AhmedNo ratings yet

- Silo - Tips - Cardiostart Defibrillator MonitorDocument92 pagesSilo - Tips - Cardiostart Defibrillator MonitorAsad AhmedNo ratings yet

- Atmel 6438 32 Bit ARM926 Embedded Microprocessor S-2585389Document1,227 pagesAtmel 6438 32 Bit ARM926 Embedded Microprocessor S-2585389Asad AhmedNo ratings yet

- ContinueDocument2 pagesContinueAsad AhmedNo ratings yet

- Vishay Sfernice: FeaturesDocument5 pagesVishay Sfernice: FeaturesAsad AhmedNo ratings yet

- 740 3 005230 2SK1625Document6 pages740 3 005230 2SK1625Asad AhmedNo ratings yet

- Lab 9101aDocument2 pagesLab 9101aAsad AhmedNo ratings yet

- Ecx 10 N 20Document4 pagesEcx 10 N 20Asad AhmedNo ratings yet

- IIMT AMC QutationDocument1 pageIIMT AMC QutationAsad AhmedNo ratings yet

- 1987 Samsung SFET Data BookDocument446 pages1987 Samsung SFET Data BookAsad AhmedNo ratings yet

- Noninvasive Blood Pressure (NIBP) Measurement by Oscillometric PrincipleDocument6 pagesNoninvasive Blood Pressure (NIBP) Measurement by Oscillometric PrincipleAsad AhmedNo ratings yet

- DC-DC Converter YD12 Series Technical Specification V1.0Document6 pagesDC-DC Converter YD12 Series Technical Specification V1.0Asad AhmedNo ratings yet

- DSA00164356Document14 pagesDSA00164356Asad AhmedNo ratings yet

- Red Light Violation Detection SystemDocument2 pagesRed Light Violation Detection SystemAsad AhmedNo ratings yet

- DatasheetDocument12 pagesDatasheetAsad AhmedNo ratings yet

- Infineon IHW30N120R5 DataSheet v02 - 03 ENDocument15 pagesInfineon IHW30N120R5 DataSheet v02 - 03 ENAsad AhmedNo ratings yet

- CI20T120P: Features OutlineDocument4 pagesCI20T120P: Features OutlineAsad AhmedNo ratings yet

- Order Details PDFDocument3 pagesOrder Details PDFAsad AhmedNo ratings yet

- Projecttronics Robotics FinalDocument4 pagesProjecttronics Robotics FinalRushikesh MoonNo ratings yet

- CS438 Midterm SolDocument6 pagesCS438 Midterm SolDavide SlanziNo ratings yet

- E2 14 03 04Document6 pagesE2 14 03 04dinakaran2020No ratings yet

- FY21xxS User's Manual - V2.2Document7 pagesFY21xxS User's Manual - V2.2xoltrialNo ratings yet

- Unit 3: Step 3 - Understand Technology CommercializationDocument15 pagesUnit 3: Step 3 - Understand Technology CommercializationCAROL CASTRONo ratings yet

- Project Report: Project Topic: Role of Prime Bank LTD On Encouraging EntrepreneursDocument2 pagesProject Report: Project Topic: Role of Prime Bank LTD On Encouraging EntrepreneursZahid Bin Islam100% (1)

- E Learning in Timor-Leste, Paper by Sara Moreira On e Learning at The National University of Timor Loro Sa'eDocument3 pagesE Learning in Timor-Leste, Paper by Sara Moreira On e Learning at The National University of Timor Loro Sa'ePapers and Powerpoints from UNTL-VU Joint Conferenes in DiliNo ratings yet

- Saving Reading UploadingDownloading Mechanism of CSV File and Text File Using Csharp AspnetDocument4 pagesSaving Reading UploadingDownloading Mechanism of CSV File and Text File Using Csharp AspnetLajapathy ArunNo ratings yet

- Inspection Report 865 Reese Creek RDDocument48 pagesInspection Report 865 Reese Creek RDAlice LemaNo ratings yet

- Simulation Projects (Ece) Digital Signal Processing (Adsp & Texas) Image ProcessingDocument2 pagesSimulation Projects (Ece) Digital Signal Processing (Adsp & Texas) Image Processingpradeepkumar1826No ratings yet

- Annotated Bibliography FinalDocument6 pagesAnnotated Bibliography Finalapi-355201975No ratings yet

- Technical Data Sheet For Ep 7-12 (12V 7ah) Vrla BatteryDocument3 pagesTechnical Data Sheet For Ep 7-12 (12V 7ah) Vrla BatteryJegadeshwaran RNo ratings yet

- 4 Study of Small Scale LNG CarrierDocument25 pages4 Study of Small Scale LNG CarrierSangeethRoshan100% (1)

- Diameter Protocol Introduction - Base & DCCA - 20131128Document32 pagesDiameter Protocol Introduction - Base & DCCA - 20131128Tsai Chunyeh100% (2)

- Energy Audit in Textile Industry-A Study With Ring Frame MotorDocument5 pagesEnergy Audit in Textile Industry-A Study With Ring Frame MotorNarender Mehra SethNo ratings yet

- Penske Shock ManualDocument32 pagesPenske Shock ManualUfix FabricationNo ratings yet

- Chimney CalculationsDocument3 pagesChimney CalculationsSteve WanNo ratings yet

- Radio Path SurveyDocument12 pagesRadio Path SurveyJon Snow-StarkNo ratings yet

- ImgDocument1 pageImgWann PutraNo ratings yet

- Construction Check Sheet Tank B-0004A: MechanicalDocument1 pageConstruction Check Sheet Tank B-0004A: MechanicalhrimklimNo ratings yet

- SIMCA 13 Multivariate Batch Process ModelingDocument2 pagesSIMCA 13 Multivariate Batch Process ModelingJbel PiNo ratings yet

- ECG Abstract PDFDocument2 pagesECG Abstract PDFgangadhara0% (1)

- PTS Thermal InsulationDocument44 pagesPTS Thermal InsulationJustin LowNo ratings yet

- List of Manufacturer UG&OHTL For MaterialDocument8 pagesList of Manufacturer UG&OHTL For MaterialHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Yamaha MU100R SoundlistDocument134 pagesYamaha MU100R SoundlistAntuan Anartista MultidisciplinarNo ratings yet

- PETRONAS Hydraulic Series v2. 23-05-2016Document4 pagesPETRONAS Hydraulic Series v2. 23-05-2016Roter DiamNo ratings yet

- ABB Technical Data Sheet Electrical Machines: No. Data Unit RemarksDocument8 pagesABB Technical Data Sheet Electrical Machines: No. Data Unit RemarksIngenieria DyconNo ratings yet