Professional Documents

Culture Documents

LAB 5 - CBR Test OEL 1

LAB 5 - CBR Test OEL 1

Uploaded by

ZULFAQAR BIN MOHAMMAD NIZAMCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LAB 5 - CBR Test OEL 1

LAB 5 - CBR Test OEL 1

Uploaded by

ZULFAQAR BIN MOHAMMAD NIZAMCopyright:

Available Formats

SCHOOL OF CIVIL ENGINEERING

UNIVERSITI TEKNOLOGI MARA

LABORATORY 7

COURSE HIGHWAY ENGINEERING

COURSE CODE ECG344

LEVEL OF OPENNESS 1

CATEGORY PARTIALLY OPEN ENDED

DEGREE OF OPEN-ENDED (%) 33

PERIOD OF ACTIVITY 1 WEEK

TITLE CALIFORNIA BEARING RATIO (CBR)

INTRODUCTION

Level 1 laboratory activity refers to condition where the problem and ways &

means are guided and given to the students. However the answers to the

assignment are left to the students to solve using the group creativity and

innovativeness. The activity is hoping to slowly introduce and inculcates

independent learning amongst students and prepare them for a much harder

task of open-ended laboratory activities.

In this laboratory session, students will be exposed to the apparatus and

appropriate methods to carry out test to determine CBR of soil.

OBJECTIVE

The objective of the test is:

• To determine CBR of subgrade soil for design of flexible pavement.

PREAMBLE

LEARNING OUTCOMES

At the end of the laboratory activity, students would be able to:

1. Identify ad use the correct apparatus/tools to carry out CBR test.

2. Analyse data correctly and present it in a typical format.

3. Work in a group to produce technical report.

THEORETICAL BACKGROUND

The California Bearing Ratio or CBR test as it is usually called, is an empirical

test which was first developed in California, USA for estimating the bearing

value or evaluates the strength of highway sub bases and subgrades for

designing the flexible pavement.

The CBR test is performed by measuring the pressure required to penetrate

a soil sample with a standard circular plunger. The measured force is then

©UiTM OCT 2021

SCHOOL OF CIVIL ENGINEERING

UNIVERSITI TEKNOLOGI MARA

LABORATORY 7

divided by the standard force to achieve an equal penetration on a standard

crushed rock material. The harder the surface, the higher the CBR value.

𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀 𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓

𝐶𝐶𝐶𝐶𝐶𝐶 = × 100%

𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆 𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓𝑓

The ratio is usually determined for penetration of 2.5 mm and 5.0 mm. The

standard forces corresponding to penetrations of 2.5 and 5 mm are 13.24 kN

and 19.96 kN.

PROBLEM STATEMENT

Students are required to prepare sample and conduct the CBR test in order

PROBLEM

to determine the bearing value of subgrade soil. The group must carry out

STATEMENT

the test following the procedures outline and subsequently analyse the data

and present it in a proper technical format.

APPARATUS

• Moulds with base plate,

• Collar

• Spacer disc

• compaction rammer

• Loading machine

• Penetration plunger

• Dial gauge

• IS sieve

• Mixing bowl

• Scales

• oven

Procedures

WAYS AND

MEANS 1. There are two types of methods in compacting soil specimen in the

CBR moulds (Static Compaction Method or Dynamic Compaction

Method)

2. The material used in the above two methods shall pass 19 mm sieve

for fine grained soils and 37.5 mm sieve for coarse materials up to

37.5 mm.

3. Replace the material retained on 19 mm sieve by an equal amount of

material passing 19mm sieve and retained on 4.75mm sieve.

4. Replace the material retained on 3.75 mm sieve by an equal amount

of material passing 37.5 mm sieve and retained on 4.75mm sieve.

a. Preparing Test Specimen

Dynamic Compaction

1. Take representative sample of soil weighing approximately 6 kg and

mix thoroughly at OMC.

2. Record the empty weight of the mould with base plate, with extension

collar removed (m1).

©UiTM OCT 2021

SCHOOL OF CIVIL ENGINEERING

UNIVERSITI TEKNOLOGI MARA

LABORATORY 7

3. Replace the extension collar of the mould.

4. Insert a spacer disc over the base plate and place a coarse filter paper

on top of the spacer disc.

5. Place the mould on a solid base such as a concrete floor or plinth and

compact the wet soil in to the mould in five layers of approximately

equal mass each layer being given 56 blows with 4.90 kg hammer

equally distributed and dropped from a height of 45 cm above the soil.

6. The amount of soil used shall be sufficient to fill the mould, leaving

not more than about 6mm to be struck off when the extension collar

is removed.

7. Remove the extension collar and carefully level the compacted soil to

the top of the mould by means of a straight edge.

8. Remove the spacer disc by inverting the mould and weigh the mould

with compacted soil (m2).

9. Place a filter paper between the base plate and the inverted mould.

10. Replace the extension collar of the mould.

11. Prepare two more specimens in the same procedure as described

above.

b. Penetration Test

1. Place the mould on the lower plate of the testing machine with top

face exposed.

2. To prevent upheaval of soil in to the hole of surcharge weights, place

2.5 kg annular weights on the soil surface prior to seating the

penetration plunger after which place the reminder of the surcharge

weights.

3. Set the plunger under a load of 4 kg so that full contact is established

between the surface of the specimen and the plunger.

4. Set the stress and strain gauges to zero.

5. Consider the initial load applied to the plunger as the zero load.

6. Apply the load at the rate of 1.25 mm/min.

7. Take the readings of the load at penetration of 0, 0.5, 1.0, 1.5, 2.0,2.5,

3.0, 4, 5, 7.5, 10 and 12.5.

8. Raise the plunger and detach the mould from the loading equipment.

9. All data obtain to be recorded onto the data sheet in Form 1 as

attached.

3.3 Data Acquisition

Calculation of CBR from Load Penetration Curve

1. Plot the load penetration curve in natural scale, load on Y-axis

and penetration on x- axis as shown in Fig 2.

2. If the curve is uniformly convex upwards although the initial

portion of the curve may be concave upwards due to surface

irregularities make correction by drawing a tangent to the upper

curve at the point of contra flexure as below 0, 2.5, 5.0, 7.5, 10

and 12.5.

©UiTM OCT 2021

SCHOOL OF CIVIL ENGINEERING

UNIVERSITI TEKNOLOGI MARA

LABORATORY 7

3. Take the intersection point of the tangent and the X-axis as the

origin. Calculate the CBR values for penetration of 2.5 mm and 5

mm.

4. Corresponding to the penetration value at which CBR is to be

desired, take the corrected load values from the load penetration

curve and calculate the CBR from the equation,

𝑃𝑃𝑇𝑇 𝑥𝑥𝐶𝐶𝑓𝑓

California Bearing Ratio = 𝑥𝑥 100

𝑃𝑃𝑠𝑠

PT = Corrected unit test load corresponding to the chosen

penetration from load penetration curve

Ps = Total standard load for the same depth of penetration, which

can be taken from the Table below.

Cf =Proving ring correction factor

5. Report the CBR value to the nearest second decimal.

6. Take the average of three test specimens of CBR value

7. Generally, the BCR value at 2.50 mm penetration will be greater

than 5.00mm penetration and in such case take value at 2.50 mm

as CBR value.

8. If the CBR value of 5.00 mm penetration greater than 2.50mm

penetration, repeat the test. If identical result follow, take the

value corresponding to 5.00 mm as the CBR value.

©UiTM OCT 2021

SCHOOL OF CIVIL ENGINEERING

UNIVERSITI TEKNOLOGI MARA

LABORATORY 7

Analysis of Result

Students have to acquire ways to present collected data and to determine

important parameters from the study.

All references have to be listed using standard format or given by the lecturer.

Discussion and Conclusion

RESULTS

(OPEN) Students have to write discussion and conclusion based on the objectives of

the study.

The group is required to submit the technical report of the laboratory results

highlighting the apparatus used, the procedures undertaken for the test, data

acquisition process, analysis carried out and the relevancy of the set-out output

to address the given problem. The format of the technical report is left to the

creativity discretion of the group.

The report must be submitted 7 days after the completion of the test.

©UiTM OCT 2021

SCHOOL OF CIVIL ENGINEERING

UNIVERSITI TEKNOLOGI MARA

LABORATORY 7

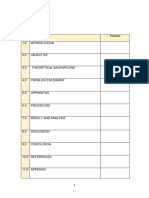

FORM 1

CAL I FORN I A BE ARI N G RATI O ( CBR) TE ST

Job no. Site BH/Pit no.

Project Sample no.

Client Depth (m)

No. of layers Rammer kg Diameter mm Volume cm³

Blows per layer Drop mm Height mm Load kg

Test on TOP / BASE surface As compacted soaked days Surcharge rings No.

Load kg

PENETRATI ON TES T

Penetration Load dial Ring factor Load Load ring No

mm divs. N/div kN Capacity kN

0.50

1.00

1.50 Container no. 1 2 3

2.00 Mass of container g g g

2.50 Mass of container + wet soil g g g

3.00 Mass of container + dry soil g g g

3.50 Mass of water g g g

4.00 Mass of dry soil g g g

4.50 W ATER CONTENT (%)

5.00

5.50

6.00 DENS I TY

6.50 Mass of mould kg

7.00 Mass of mould + wet soil kg

7.50 Mass of wet soil kg

8.00 Bulk density Mg/m³

8.50 Moisture content %

9.00 Dry density Mg/m³

9.50

10.00

10.50

11.00

11.50

12.00

Tested by Checked by Date

©UiTM OCT 2021

You might also like

- Gateway B2 Review 1 Test ADocument5 pagesGateway B2 Review 1 Test AАнна Диденко0% (1)

- California Bearing Ratio DeterminationDocument8 pagesCalifornia Bearing Ratio DeterminationDasari RohithNo ratings yet

- SymmetryDocument60 pagesSymmetryDeepak TholiaNo ratings yet

- LAB 14-California Bearing Ratio (Level 0) WEEK 13Document8 pagesLAB 14-California Bearing Ratio (Level 0) WEEK 13CoiNo ratings yet

- Pavement ManualDocument4 pagesPavement ManualdantezNo ratings yet

- C B R T: Alifornia Earing Atio (CBR) ESTDocument11 pagesC B R T: Alifornia Earing Atio (CBR) ESTEr Santosh KaparNo ratings yet

- C B R T: Alifornia Earing Atio ESTDocument11 pagesC B R T: Alifornia Earing Atio ESTHarisNo ratings yet

- Lab 11 CBR - Level 1 - Manual & ReportDocument3 pagesLab 11 CBR - Level 1 - Manual & ReporttashaNo ratings yet

- California Bearing Ratio Test: 1. ObjectiveDocument3 pagesCalifornia Bearing Ratio Test: 1. ObjectivePanchadcharam PushparubanNo ratings yet

- California Bearing Ratio Test: 1. ObjectiveDocument3 pagesCalifornia Bearing Ratio Test: 1. ObjectiveVickyNo ratings yet

- California Bearing Ratio Test: 1. ObjectiveDocument3 pagesCalifornia Bearing Ratio Test: 1. ObjectivesiddharthNo ratings yet

- California Bearing Ratio TestDocument11 pagesCalifornia Bearing Ratio TestMuhammad Arslan AfzalNo ratings yet

- The California Bearing Ratio Test: Standard Loads at Specified PenetrationsDocument5 pagesThe California Bearing Ratio Test: Standard Loads at Specified Penetrationsبه شدار ازاد عبدالرحمن عليNo ratings yet

- California Bearing Ratio Test (CBR Test) (IS: 2720 PART-16) : Test Load Standar D LoadDocument8 pagesCalifornia Bearing Ratio Test (CBR Test) (IS: 2720 PART-16) : Test Load Standar D LoadBad BadNo ratings yet

- CBR TestDocument9 pagesCBR TestHelmi ZakiuddinNo ratings yet

- Lab 11 - CBR TestDocument9 pagesLab 11 - CBR Testnabil mahadzirNo ratings yet

- CBR ProcedureDocument5 pagesCBR ProcedureRohitNo ratings yet

- California Bearing Ratio TestDocument7 pagesCalifornia Bearing Ratio TestBhaskara Rao KatragaddaNo ratings yet

- C.B.R Test On SoilDocument4 pagesC.B.R Test On Soilrinky091No ratings yet

- CBR Test On AggregatesDocument10 pagesCBR Test On AggregatesDakshraj RathodNo ratings yet

- University of Kirkuk College of Engineering Civil DepartmentDocument8 pagesUniversity of Kirkuk College of Engineering Civil Departmentبه شدار ازاد عبدالرحمن عليNo ratings yet

- Civil and Environmental Engineering DepartmentDocument12 pagesCivil and Environmental Engineering DepartmentMuhd SyahidNo ratings yet

- Experiment 1 FoundationDocument6 pagesExperiment 1 FoundationAlfredo Cerdeña Jr.No ratings yet

- 7 CBR TestDocument5 pages7 CBR TestJahnabi PriyamNo ratings yet

- California Bearing Ratio PrintDocument5 pagesCalifornia Bearing Ratio PrintvethamoortyNo ratings yet

- Experiment No. 2 California Bearing RatioDocument7 pagesExperiment No. 2 California Bearing RatioPatricia TubangNo ratings yet

- California Bearing Ratio TestDocument7 pagesCalifornia Bearing Ratio TestSreejith SNo ratings yet

- California Bearing Ratio TestDocument8 pagesCalifornia Bearing Ratio Testdorbiiteydorgan106No ratings yet

- CBR Test ReportDocument8 pagesCBR Test ReportRubaneswary SridharanNo ratings yet

- LAB 8 - Direct Shear Box Test - LEVEL 1 - Manual & TemplateDocument4 pagesLAB 8 - Direct Shear Box Test - LEVEL 1 - Manual & TemplatetashaNo ratings yet

- California Bearing Ratio TestDocument5 pagesCalifornia Bearing Ratio Testty juNo ratings yet

- LECT-16-Subgrade EvaluationDocument83 pagesLECT-16-Subgrade EvaluationSujitkumar BeheraNo ratings yet

- A Comparison of (CBR) Soaked Test With British Specifications For Fine-Grained Soils From Al-Kut in IraqDocument16 pagesA Comparison of (CBR) Soaked Test With British Specifications For Fine-Grained Soils From Al-Kut in IraqzeekoNo ratings yet

- The California Bearing Ratio TestDocument6 pagesThe California Bearing Ratio Testetec1500m200112No ratings yet

- CBR ReportDocument18 pagesCBR ReportMaitrayee Aditya20% (5)

- The California Bearing Ratio TestDocument6 pagesThe California Bearing Ratio TestNurin Adlina100% (4)

- HIGHWAYLABDocument29 pagesHIGHWAYLABAbel MulugetaNo ratings yet

- CBR TEST CompleteDocument9 pagesCBR TEST CompleteRazman Fozi0% (1)

- Report Highway 5Document6 pagesReport Highway 5Leo AmiraNo ratings yet

- Geotechnical Engineering Lab: Anup KumarDocument7 pagesGeotechnical Engineering Lab: Anup Kumar008 Anup KumarNo ratings yet

- Geotechnical Engineering Lab ReportDocument34 pagesGeotechnical Engineering Lab Reportfaisal hussin100% (1)

- 5.laboratory California Bearing Ratio (CBR)Document3 pages5.laboratory California Bearing Ratio (CBR)kramanaiahNo ratings yet

- 03 Foundation Som SurveyDocument6 pages03 Foundation Som SurveyHarish Ashok SharmaNo ratings yet

- Title: California Bearing Ratio Test (CBR Test)Document2 pagesTitle: California Bearing Ratio Test (CBR Test)Syahirah ZulkifliNo ratings yet

- T Lab 07Document12 pagesT Lab 07Qaim ShahNo ratings yet

- California Bearing Ratio Test (IS: 2720-1979 (Part XVI) ) ObjectiveDocument11 pagesCalifornia Bearing Ratio Test (IS: 2720-1979 (Part XVI) ) ObjectiveDevansh TiwariNo ratings yet

- Sourav Kabiraj - Professional Practice, Law & Ethics Ca1Document12 pagesSourav Kabiraj - Professional Practice, Law & Ethics Ca1souravkabiraj.ce.2817No ratings yet

- Geotechnical Engineering LAB: Subhadip PalDocument8 pagesGeotechnical Engineering LAB: Subhadip PalGolu kumarNo ratings yet

- Method Obtaining Sam Determination: A Simple For Undisturbed Soil Pies For CBRDocument8 pagesMethod Obtaining Sam Determination: A Simple For Undisturbed Soil Pies For CBRMimicry TarnNo ratings yet

- Experiment 1Document26 pagesExperiment 1Mathewos EndeshawNo ratings yet

- Transportation Engineering - Lab ReportDocument14 pagesTransportation Engineering - Lab ReportlearnafrenNo ratings yet

- Civil - Highway Lab Manual - 2018Document17 pagesCivil - Highway Lab Manual - 2018Altamash NadimallaNo ratings yet

- CBR Test ManualDocument6 pagesCBR Test ManualHarsh HarkhaniNo ratings yet

- CBR Test ManualDocument6 pagesCBR Test ManualmmNo ratings yet

- CBR Test ProcedureDocument8 pagesCBR Test ProcedureAmit RathNo ratings yet

- Determination of California Bearing Ratio of Laboratory Compacted SoilsDocument10 pagesDetermination of California Bearing Ratio of Laboratory Compacted SoilsMazharYasinNo ratings yet

- Final Report CBR - K05 - Muhammad Arvarefo Aulia Rahman - 2106658490Document14 pagesFinal Report CBR - K05 - Muhammad Arvarefo Aulia Rahman - 2106658490refoNo ratings yet

- (Type The Document Title) : Title - California Bearing RatioDocument7 pages(Type The Document Title) : Title - California Bearing RatioDebasish Dev BarmaNo ratings yet

- Laboratory Test: 6.1 CBR (California Bearing Ratio) 6.1.1 Apparatus CBR TestDocument9 pagesLaboratory Test: 6.1 CBR (California Bearing Ratio) 6.1.1 Apparatus CBR TestCondro darmoNo ratings yet

- Lab Manual Foundation EngineeringDocument39 pagesLab Manual Foundation Engineeringartiraha100% (1)

- Lime Hemp and Rice Husk-Based Concretes for Building EnvelopesFrom EverandLime Hemp and Rice Husk-Based Concretes for Building EnvelopesNo ratings yet

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsFrom EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechNo ratings yet

- LAB 2 - Running Speed (Method 1) OEL 1Document4 pagesLAB 2 - Running Speed (Method 1) OEL 1ZULFAQAR BIN MOHAMMAD NIZAMNo ratings yet

- LAB 2 - Running Speed (Method 2) OEL 1Document3 pagesLAB 2 - Running Speed (Method 2) OEL 1ZULFAQAR BIN MOHAMMAD NIZAMNo ratings yet

- LAB 11 - Sand Patch Method OEL 1Document3 pagesLAB 11 - Sand Patch Method OEL 1ZULFAQAR BIN MOHAMMAD NIZAMNo ratings yet

- LAB 10 - Skid Resistant Test OEL 1Document4 pagesLAB 10 - Skid Resistant Test OEL 1ZULFAQAR BIN MOHAMMAD NIZAMNo ratings yet

- Aluminium Window CostingDocument2 pagesAluminium Window CostingNitesh YadavNo ratings yet

- Skripsi Tablet FeDocument7 pagesSkripsi Tablet FeYessiana Luthfia BahriNo ratings yet

- Steven Epstein - A Queer Encounter - Sociology and The Study of SexualityDocument16 pagesSteven Epstein - A Queer Encounter - Sociology and The Study of SexualityAnaliziraj Ovo100% (1)

- Analisis Daya Dukung Pondasi Bored Pile Berdasarkan Data Pengujian Lapangan N-Standart Penetration Test Pada Proyek Jembatan Sei Alalak BanjarmasinDocument10 pagesAnalisis Daya Dukung Pondasi Bored Pile Berdasarkan Data Pengujian Lapangan N-Standart Penetration Test Pada Proyek Jembatan Sei Alalak BanjarmasinSamuel HarisNo ratings yet

- Assessment 3A - Tuckman Model For Team DevelopmentDocument3 pagesAssessment 3A - Tuckman Model For Team DevelopmentkhadijjatariqNo ratings yet

- Critical Reading and WritingDocument86 pagesCritical Reading and WritingWahyu Adi PurnomoNo ratings yet

- Signal Design Using Webster'S Method (4 Legged Intersection)Document7 pagesSignal Design Using Webster'S Method (4 Legged Intersection)Nor Hidayah Mohd RazaliNo ratings yet

- Coupling Inspection SOP GSE FinalDocument11 pagesCoupling Inspection SOP GSE FinalPravin Kangne100% (1)

- Effective Lesson Planning: Presenter: Kifle Yilma SMASEE Regional TrainerDocument31 pagesEffective Lesson Planning: Presenter: Kifle Yilma SMASEE Regional TrainerbezawitwubshetNo ratings yet

- Chapter IIIDocument3 pagesChapter IIIRatu TriaNo ratings yet

- An R Package For Item Response ModellingDocument39 pagesAn R Package For Item Response ModellingAnusorn KoedsriNo ratings yet

- Edwards-Discourse and CognitionDocument367 pagesEdwards-Discourse and CognitionRaúl Armando Santana Rivas100% (2)

- SurveyDocument3 pagesSurveyChristine Jane DueroNo ratings yet

- Error EdmDocument22 pagesError EdmFaizan FathizanNo ratings yet

- Sampaio2017 PDFDocument12 pagesSampaio2017 PDFCamilo DiazNo ratings yet

- Ymrtc LogDocument62 pagesYmrtc LogOctavi Ikat100% (3)

- Brodifacoum Residue Analysis in Water, Soil, Invertebrates, and Birds After Rat Eradication On Lady Alice IslandDocument3 pagesBrodifacoum Residue Analysis in Water, Soil, Invertebrates, and Birds After Rat Eradication On Lady Alice IslandJeffrey AcostaNo ratings yet

- Teaching English One To OneDocument65 pagesTeaching English One To OneAlba Casado100% (3)

- Texwipe PDA Cleaning and Cleaning Validation Chapter19Document26 pagesTexwipe PDA Cleaning and Cleaning Validation Chapter19davincicode888100% (1)

- PR Guide Undue Influence PolicyDocument2 pagesPR Guide Undue Influence PolicyPariksha aryaNo ratings yet

- Markem Imaje SmartDate 5 DS HQ A1 SDocument2 pagesMarkem Imaje SmartDate 5 DS HQ A1 SmatthewNo ratings yet

- DLUBALDocument64 pagesDLUBALJEMAYERNo ratings yet

- Addie d2 Worksheet-1 1Document6 pagesAddie d2 Worksheet-1 1api-262457652No ratings yet

- Higgs BosonDocument22 pagesHiggs BosonMehjabin AbdurrazaqueNo ratings yet

- A New Teaching Strategy For ReadingDocument10 pagesA New Teaching Strategy For ReadingSavira Ramadhani100% (1)

- CCCCCCCCCC CCCCCCCCC: Cccccs CCCCCC CCCCCCDocument8 pagesCCCCCCCCCC CCCCCCCCC: Cccccs CCCCCC CCCCCCVanitha DeviNo ratings yet

- Top 10 Motivational Books of All TimeDocument5 pagesTop 10 Motivational Books of All Timelionheartpeter999967% (3)

- Aerodynamic Modeling & Simulation of HGVDocument26 pagesAerodynamic Modeling & Simulation of HGVManjunath PattarNo ratings yet