Professional Documents

Culture Documents

Recommendations-Precautions MCP Piloted Manual Gearbox Peugeot 3008

Recommendations-Precautions MCP Piloted Manual Gearbox Peugeot 3008

Uploaded by

thierry.fifieldoutlook.comOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Recommendations-Precautions MCP Piloted Manual Gearbox Peugeot 3008

Recommendations-Precautions MCP Piloted Manual Gearbox Peugeot 3008

Uploaded by

thierry.fifieldoutlook.comCopyright:

Available Formats

Recommendations/precautions : MCP piloted manual gearbox

B2CK0107P0 Recommendations/precautions : MCP piloted manual gearbox

MC MANUAL GEARBOX

1. Foreword

The operations must be carried out by qualified personnel, informed about the control system

and the safety recommendations and precautions to be taken.

The features of the MCP piloted manual gearbox make it essential to observe the safety

instructions given below.

2. Safety recommendations

ESSENTIAL : Before carrying out any work on the piloting actuator, depressurise the piloted

manual gearbox hydraulic circuit.

ESSENTIAL : After sales checks performed with the engine running should be carried out with

gear "N" engaged and the handbrake applied (except where explicitly mentioned otherwise in the

repair procedures).

ESSENTIAL : During the piloted manual gearbox programming operations, do not allow anyone

to walk or stand in front of the vehicle.

ESSENTIAL : Work on the piloting actuator with the engine running is prohibited (no tool, no

hand).

3. Working conditions

Recommendations for cleanliness :

The working area should be clean and tidy

Parts being repaired should be protected from dust

The operator must wear clean clothing

Following removal, immediately close all of the openings using plugs to prevent the entry

of impurities into the pipes and parts of the piloting actuator

Quality of work :

Observe the tightening torques using a torque wrench which is checked regularly

Observe the operations described in the repair methods

4. Repairs to the electrical components

Do not disconnect :

The battery with the engine running

The ECUs : Ignition on

During electrical checks :

The battery must be fully charged

Never use a voltage source greater than 16 V

Never use a test lamp

Before re-connecting a connector, check :

The condition of the various contacts (distortion, corrosion ...)

The presence and condition of the mechanical unlocking

5. Driving

Never push the vehicle in an attempt to start it (impossible with a piloted manual gearbox).

6. Towing

In the presence of a piloted manual gearbox fault or malfunction, the vehicle may remain

immobilised with a gear engaged.

If the vehicle remains immobilised with a gear engaged, it is imperative that the front of the

vehicle is lifted when towing.

CAUTION : The vehicle can only be pushed or pulled if the gearbox is in neutral.

If a gear is engaged and "jammed", try to engage gear "N" ; Using the diagnostic equipment.

There is no mechanical unlocking device.

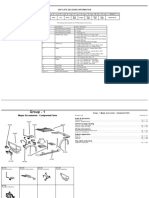

7. Preliminary operations

List of operations to be carried out before replacement or removal-refitting of the mechanical

components.

7.1. Protection of the piloting actuator

javascript:FullScreen('','b2cp4bcd_1','Figure','b

2cp4bcd','/AP/img/inf_inc/cd/b2cp/

Figure : b2cp4bcd

b2cp4bcd.jpg'); javascript:FullScreen('','b2cp

4bcd_1','Figure','b2cp4bcd','/AP/img/inf_inc/

cd/b2cp/b2cp4bcd.jpg');

Put the handle G.0346 in place when removing-refitting the piloting actuator or the piloted

manual gearbox.

ESSENTIAL : The handle [1] is essential to avoid damaging the hydraulic reservoir (1) and the

pressure accumulator (2) when the piloted manual gearbox rests on the ground. The handle [1]

also permits a better grip on the piloted manual gearbox when it is removed-refitted.

7.2. Depressurizing the system

The operating pressure is 37 bars ; The pressure accumulator permits the storing of a pressure

which may pose a risk to the technician if he opens the hydraulic circuit.

Before removal, it is imperative that the piloting actuator is depressurised using the diagnostic

tool.

7.3. Reading of the counters

This operation permits reading of the gear engagement counter and number of clutch cycles

counter written in the piloted manual gearbox ECU.

Read the counters if the following components are to be replaced ; Using the diagnostic

equipment :

Piloted manual gearbox ECU

Actuator electro-hydraulics

PILOTING actuator

N.B. : Make a note of or print the values in order to write them to the new piloted manual

gearbox ECU.

8. Additional operations

List of operations to be carried out following replacement or removal-refitting of the mechanical

components.

8.1. Writing of the counters

Write the values read previously in the counters if the following components are replaced ; Using

the diagnostic equipment :

Piloted manual gearbox ECU

Actuator electro-hydraulics

PILOTING actuator

8.2. Pressurising

To obtain an operational pressure in the hydraulic circuit, activate the electric motor to fill the

pressure accumulator ; Using the diagnostic equipment.

8.3. Bleeding of the air in the hydraulic circuit

Pressurise the hydraulic circuit.

Using the diagnostic tool, this function activates engagement of the gears and releasing of the

clutch to bleed the air as far as the piloted manual gearbox hydraulic reservoir.

8.4. Initialisation of the bite point

Using the diagnostic tool, this function activates the hydraulic clutch stop to define the actual

position of the stop in relation to the clutch wear.

8.5. Programming of the piloted manual gearbox grille

Using the diagnostic tool, this function activates the engagement of all of the gears to enable the

piloting actuator to define the position of the gearbox grille.

8.6. Learning : Value of the engine torque transmitted to the clutch

By means of a dynamic test, this function makes it possible to define the position of the clutch in

relation to the engine torque transmitted. The gearbox grille and the point of load bearing must

be programmed first.

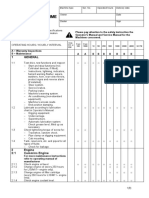

9. Summary table of the preliminary and additional operations

Operations to be carried out ; Using the diagnostic equipment.

N.B. : 1, 2, 3, 4, 5, 6, 7, 8 : Order number of the operations to be carried out.

9.1. Clutch

Replacement :

Removing - Replacement of the

Operations to be performed clutch release

refitting : Clutch clutch

bearing

Reading of the counters No OK No OK No OK

7 (Reset the clutch

Writing of the counters No OK No OK

cycles counter to zero)

Depressurisation of the piloting 1 (Before 1 (Before

1 (Before replacement)

actuator replacement) replacement)

Pressurisation of the piloting 2 (After 2 (After

2 (After replacement)

actuator replacement) replacement)

Bleeding of the air in the hydraulic

3 3 3

circuit

Initialisation of the bite point 4 4 5

Programming of the piloted

No OK No OK 6

manual gearbox grille

Reinitialisation of the programmed

No OK No OK 4

values

Learning : Value of the engine

No OK No OK 8

torque transmitted to the clutch

9.2. Controlled manual gearbox

Operations to be performed Removing - Refitting Replacement

Reading of the counters No OK No OK

2 (Writing of the gear

Writing of the counters No OK

engagement counters)

Depressurisation of the piloting No OK (Yes for clutch stop No OK (Yes for clutch stop

actuator removal-refitting) removal-refitting)

Pressurisation of the piloting No OK (Yes for clutch stop No OK (Yes for clutch stop

actuator removal-refitting) removal-refitting)

Bleeding of the air in the No OK (Yes for clutch stop No OK (Yes for clutch stop

hydraulic circuit removal-refitting) removal-refitting)

Initialisation of the bite point No OK No OK

Programming of the piloted

1 (After refitting) 1 (After replacement)

manual gearbox grille

9.3. PILOTING actuator

Removing -

Operations to be performed Replacement

Refitting

1 (Reading of all of the counters

Reading of the counters No OK

before replacement)

Writing of the counters No OK 7 (Writing of all of the counters)

1 (Before

Depressurisation of the piloting actuator 2 (Before replacement)

removal)

2 (After

Pressurisation of the piloting actuator 3 (After replacement)

refitting)

3 (After

Bleeding of the air in the hydraulic circuit 4

refitting)

5 (After

Initialisation of the bite point 6

refitting)

Programming of the piloted manual gearbox 4 (After

5

grille refitting)

Learning : Value of the engine torque

No OK 8

transmitted to the clutch

9.4. Electro-hydraulic unit

Operations to be performed Removing - Replacement

Refitting

1 (Reading of all of the counters before

Reading of the counters No OK

replacement)

Writing of the counters No OK 7 (Writing of all of the counters)

Depressurisation of the piloting 1 (Before

2 (Before replacement)

actuator removal)

2 (After

Pressurisation of the piloting actuator 3 (After replacement)

refitting)

Bleeding of the air in the hydraulic 3 (After

4

circuit refitting)

Initialisation of the bite point No OK 6

Programming of the piloted manual

No OK 5

gearbox grille

9.5. Actuator electro-pump

Removing -

Operations to be performed Replacement

Refitting

Reading of the counters No OK No OK

4 (Reset the electric motor counter to

Writing of the counters No OK

zero)

1 (Before

Depressurisation of the piloting actuator 1 (Before replacement)

removal)

Pressurisation of the piloting actuator 2 (After refitting) 2 (After replacement)

Bleeding of the air in the hydraulic

3 (After refitting) 3

circuit

Initialisation of the bite point No OK No OK

Programming of the piloted manual

No OK No OK

gearbox grille

9.6. Piloted manual gearbox ECU

Removing -

Operations to be performed Replacement

Refitting

1 (Reading of all of the counters

Reading of the counters No OK

before replacement)

Writing of the counters No OK 7 (Writing of all of the counters)

1 (Before

Depressurisation of the piloting actuator 2 (Before replacement)

removal)

2 (After

Pressurisation of the piloting actuator 3 (After replacement)

refitting)

3 (After

Bleeding of the air in the hydraulic circuit 4 (After replacement)

refitting)

Initialisation of the bite point No OK 6 (After replacement)

Programming of the piloted manual gearbox

No OK 5 (After replacement)

grille

Learning : Value of the engine torque

No OK 8

transmitted to the clutch

9.7. Piloting electrovalves - Pressure sensor

Operations to be performed Removing - Refitting Replacement

Reading of the counters No OK No OK

Writing of the counters No OK No OK

Depressurisation of the piloting actuator 1 (Before removal) 1 (Before replacement)

Pressurisation of the piloting actuator 2 (After refitting) 2 (After replacement)

Bleeding of the air in the hydraulic circuit 3 (After refitting) 3 (After replacement)

Initialisation of the bite point No OK No OK

Programming of the piloted manual gearbox grille No OK No OK

9.8. Position sensors

Operations to be performed Removing - Refitting Replacement

Reading of the counters No OK No OK

Writing of the counters No OK No OK

Depressurisation of the piloting actuator No OK No OK

Pressurisation of the piloting actuator No OK No OK

Bleeding of the air in the hydraulic circuit No OK No OK

Initialisation of the bite point No OK No OK

Programming of the piloted manual gearbox grille 1 (After refitting) 1 (After replacement)

9.9. Actuator electro-pump unit electric motor

Removing -

Operations to be performed Replacement

Refitting

Reading of the counters No OK No OK

4 (Reset the electric motor counter to

Writing of the counters No OK

zero)

1 (Before

Depressurisation of the piloting actuator 1 (Before replacement)

removal)

Pressurisation of the piloting actuator 2 (After refitting) 2 (After replacement)

Bleeding of the air in the hydraulic

3 3

circuit

Initialisation of the bite point No OK No OK

Programming of the piloted manual

No OK No OK

gearbox grille

9.10. Pressure accumulator

Operations to be performed Removing - Refitting Replacement

Reading of the counters No OK No OK

Writing of the counters No OK No OK

Depressurisation of the piloting actuator 1 (Before removal) 1 (Before replacement)

Pressurisation of the piloting actuator 2 (After refitting) 2 (After replacement)

Bleeding of the air in the hydraulic circuit 3 (After refitting) 3 (After replacement)

Initialisation of the bite point No OK No OK

Programming of the piloted manual gearbox grille No OK No OK

9.11. Hydraulics reservoir

Removing - Check the oil level - Changing the

Operations to be performed Replacement

Refitting Topping up the oil level oil

Reading of the counters No OK No OK No OK No OK

Writing of the counters No OK No OK No OK No OK

Depressurisation of the 1 (Before 1 (Before 1 (Before

1 (Before check)

piloting actuator removal) replacement) fluid change)

Pressurisation of the piloting 2 (After 2 (After 2 (After fluid

2 (After check)

actuator refitting) replacement) change)

Bleeding of the air in the 3 (After 3 (After 3 (After fluid

No OK

hydraulic circuit refitting) replacement) change)

Initialisation of the bite

No OK No OK No OK No OK

point

Programming of the piloted

No OK No OK No OK No OK

manual gearbox grille

You might also like

- GREAT WRITING 1: Great Sentences For Great Paragraphs: Unit 1 Sentence BasicsDocument19 pagesGREAT WRITING 1: Great Sentences For Great Paragraphs: Unit 1 Sentence Basicssara90% (30)

- Renault Trafic x82 Workshop Manual 2014-2018Document2,019 pagesRenault Trafic x82 Workshop Manual 2014-2018Mattia Boran0% (1)

- Audi 0B5 TPI 2039534 - Repair Instructions (By Keldo)Document9 pagesAudi 0B5 TPI 2039534 - Repair Instructions (By Keldo)Keldo Gliana100% (3)

- Toyota Engine 2gr Fe Repair ManualDocument20 pagesToyota Engine 2gr Fe Repair Manualanna98% (40)

- Philips MicroDose-L30-full CalibrationDocument12 pagesPhilips MicroDose-L30-full CalibrationTony Kututo100% (1)

- User Manual Bioksel 6100Document49 pagesUser Manual Bioksel 6100TRUNG Lê ThànhNo ratings yet

- ME Manual AppendixDocument641 pagesME Manual AppendixAnonymous uTO1WI0% (1)

- MG3 Circuit DiagramDocument76 pagesMG3 Circuit Diagrammehdi100% (1)

- 4传动系统 (行星 YD13) PDFDocument27 pages4传动系统 (行星 YD13) PDFadelmomoura100% (3)

- BioPsychoSocial JongsmaDocument4 pagesBioPsychoSocial Jongsmarredmond100% (2)

- Service Program - CE Excapator KOREADocument8 pagesService Program - CE Excapator KOREAtele123No ratings yet

- Timing - Calibrate (RENR5012-03)Document5 pagesTiming - Calibrate (RENR5012-03)MichaelMonguiNo ratings yet

- Timing - CalibrateDocument7 pagesTiming - Calibratebenjir shuvoNo ratings yet

- Required Maintenance Operations: Gaining Access To The ValvesDocument5 pagesRequired Maintenance Operations: Gaining Access To The Valves87b94rw52nNo ratings yet

- WM Claas CeltisDocument1,537 pagesWM Claas Celtisboylers95No ratings yet

- Commissioning Example LHEXDocument12 pagesCommissioning Example LHEXlinkangjun0621No ratings yet

- Relief Valve (Implement) - Test and Adjust: Essai Et RéglageDocument3 pagesRelief Valve (Implement) - Test and Adjust: Essai Et Réglageabboubi abdellatifNo ratings yet

- 2021.12.24 R-ME-HC-S-020 Governor System Commissioning ProcedureDocument12 pages2021.12.24 R-ME-HC-S-020 Governor System Commissioning Procedurerotimi olalekan fataiNo ratings yet

- 1.crankshaft DeflectionDocument2 pages1.crankshaft DeflectionPraveen Singh Chauhan60% (5)

- Calibracion de EmbragguesDocument8 pagesCalibracion de EmbragguesRomeo WilliamsNo ratings yet

- Foreword 2. Ignition Timing: Service ProcedureDocument16 pagesForeword 2. Ignition Timing: Service Procedurevadim vadimNo ratings yet

- 803 14Document8 pages803 14Cesar AbarcaNo ratings yet

- Adjusting Valve Cummins QSBDocument4 pagesAdjusting Valve Cummins QSBMoch Imron100% (1)

- Engine Speed - Timing Sensor - Calibrate (RENR5096)Document5 pagesEngine Speed - Timing Sensor - Calibrate (RENR5096)Josip MiškovićNo ratings yet

- DTC P0016 Crankshaft Position - Camshaft Position Corre-Lation (Bank 1 Sensor A)Document2 pagesDTC P0016 Crankshaft Position - Camshaft Position Corre-Lation (Bank 1 Sensor A)robin blahoutNo ratings yet

- Engagement Pressure For The Transmission Clutch - CalibrateDocument8 pagesEngagement Pressure For The Transmission Clutch - CalibrateVictor NunezNo ratings yet

- Operational Performance Test / Engine Test: Valve Clearance AdjustmentDocument5 pagesOperational Performance Test / Engine Test: Valve Clearance AdjustmentArdi Heineken PradaNo ratings yet

- Sa227 Series: Maintenance ManualDocument28 pagesSa227 Series: Maintenance ManualKIKENo ratings yet

- 03 Ts 51Document4 pages03 Ts 51giovanni ampueroNo ratings yet

- IT62G Integrated Toolcarrier and 950G and 962G Wheel Loaders-Before OperationDocument7 pagesIT62G Integrated Toolcarrier and 950G and 962G Wheel Loaders-Before OperationRODOLFO ESTEBAN VARGAS TORONo ratings yet

- QuickServe Online - (4021499) K19 Service ManualDocument10 pagesQuickServe Online - (4021499) K19 Service Manualengmohsen.ramadanhotmail.com100% (1)

- Cat Engine Timing - CompressDocument8 pagesCat Engine Timing - CompressUma A. UcheNo ratings yet

- 081 100 PDFDocument20 pages081 100 PDFMike DoudoudisNo ratings yet

- f5071240 WLST1305-02W.book PDFDocument6 pagesf5071240 WLST1305-02W.book PDFdhanysiregarNo ratings yet

- SIS 2.0 320c Akh00182Document5 pagesSIS 2.0 320c Akh00182Jorge RojasNo ratings yet

- NUMBER: 4-10-13 S.M. REF.: Listed in Table ENGINE: EPA07 Series 60 DATE: April 2013Document12 pagesNUMBER: 4-10-13 S.M. REF.: Listed in Table ENGINE: EPA07 Series 60 DATE: April 2013Walter A Gómez de la CruzNo ratings yet

- Method Statement For Testing & Commissioning of Diesel GeneratorDocument6 pagesMethod Statement For Testing & Commissioning of Diesel Generatorvin ss100% (1)

- MD6420 Test 3Document4 pagesMD6420 Test 3Miguel Angel Garrido CardenasNo ratings yet

- Troubleshooting Transmisi Automatic Skt80s-1Document14 pagesTroubleshooting Transmisi Automatic Skt80s-1Yosan CahyaNo ratings yet

- Calibration For HA43RJDocument16 pagesCalibration For HA43RJQussai BitarNo ratings yet

- Proportional Reducing Valve Sweep - Test: Pruebas y AjustesDocument2 pagesProportional Reducing Valve Sweep - Test: Pruebas y AjustesAugusto BellezaNo ratings yet

- 2013 launched GenTrax 4.4kVA Inverter generator is a dream come true for satisfying your need of portable 240V Pure Sine Wave power. GenTrax 4.4kva is by far our most popular models. Its 3.5kW capacity allows it to run a few accessories at the same time. Powered by an advanced 150cc over head Cam 4 stroke engine, this machine is capable of powering all your camping appliances including kettle, toaster, frying pan and more. It can also run AIR CONDITIONER with low start up draw. With microcomputer-controlled sinewave inverter, the GenTrax 4.4kVA produces high quality, stable pure sine wave power perfect for sensitive equipment such as laptops and tv. Economy mode can be switched on when running small appliances like laptop to save fuel extending maximum running time up to 10 hours. This model comes with dual weatherproof Australian Approved 240V 15Amps outlet. It also has a single DC outlet which allows you to use it to run 12v appliances or charge up your 12v battery. Design compaDocument20 pages2013 launched GenTrax 4.4kVA Inverter generator is a dream come true for satisfying your need of portable 240V Pure Sine Wave power. GenTrax 4.4kva is by far our most popular models. Its 3.5kW capacity allows it to run a few accessories at the same time. Powered by an advanced 150cc over head Cam 4 stroke engine, this machine is capable of powering all your camping appliances including kettle, toaster, frying pan and more. It can also run AIR CONDITIONER with low start up draw. With microcomputer-controlled sinewave inverter, the GenTrax 4.4kVA produces high quality, stable pure sine wave power perfect for sensitive equipment such as laptops and tv. Economy mode can be switched on when running small appliances like laptop to save fuel extending maximum running time up to 10 hours. This model comes with dual weatherproof Australian Approved 240V 15Amps outlet. It also has a single DC outlet which allows you to use it to run 12v appliances or charge up your 12v battery. Design compaJulie McRaeNo ratings yet

- 4M41Document10 pages4M41Guadalupe GuerreroNo ratings yet

- Troubleshooting Guide: Diesel - Gasoline - LPGDocument168 pagesTroubleshooting Guide: Diesel - Gasoline - LPGmauricio carmonaNo ratings yet

- GD705A-5 Adjusting ValveDocument3 pagesGD705A-5 Adjusting ValveSurya FaniNo ratings yet

- Additions, Revisions, or Updates: Subject DateDocument5 pagesAdditions, Revisions, or Updates: Subject DateKevinCalderonNo ratings yet

- Control Moment Gyroscope: C A C g1 g2Document20 pagesControl Moment Gyroscope: C A C g1 g2Puti FikriNo ratings yet

- Engine Valve Lash - Inspect/AdjustDocument4 pagesEngine Valve Lash - Inspect/AdjustHrvoje ŠkaricaNo ratings yet

- DTC 11 Actuator Motor Circuit DTC 15 Actuator Motor CircuitDocument2 pagesDTC 11 Actuator Motor Circuit DTC 15 Actuator Motor CircuitIcaro FerreiraNo ratings yet

- Group 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDocument16 pagesGroup 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddydioneslealNo ratings yet

- Windshield Wipers and WashersDocument6 pagesWindshield Wipers and WashersPelis CloneNo ratings yet

- HKC Elect Ric Quart Er T Urn Act Uat or 'HQ' Series Inst Ruct Ion and Maint Enance ManualDocument32 pagesHKC Elect Ric Quart Er T Urn Act Uat or 'HQ' Series Inst Ruct Ion and Maint Enance ManualFlo MarineNo ratings yet

- 15C (4JA1) enDocument5 pages15C (4JA1) enARIF RACHMANNo ratings yet

- Installation of Governor On 1U7326 Governor Calibration Bench... 3114, 3116 and 3126 MUI Engine Governors #I01154203 CaterpillarDocument8 pagesInstallation of Governor On 1U7326 Governor Calibration Bench... 3114, 3116 and 3126 MUI Engine Governors #I01154203 CaterpillargiovanebalzaniNo ratings yet

- Group 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDocument16 pagesGroup 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyOscar Tello HuaripataNo ratings yet

- Alignment of TwoDocument15 pagesAlignment of TwoquintanacalzadillasjaimeNo ratings yet

- Melody Technical Manual - Chapter04Document10 pagesMelody Technical Manual - Chapter04Nassima BELILNo ratings yet

- Fa 980e-5 A5003-Up Ceaw009702-199-220Document22 pagesFa 980e-5 A5003-Up Ceaw009702-199-220EDSON JONATHAN SALINAS AYALA100% (1)

- Automatic Gearbox Differential RemovalDocument7 pagesAutomatic Gearbox Differential RemovalJohnnoNo ratings yet

- ML B 1900d b19dmm598Document15 pagesML B 1900d b19dmm598ramzi30No ratings yet

- Daewoo G32E-3 SpecificationsDocument61 pagesDaewoo G32E-3 SpecificationsAndrey Tsymbalov100% (2)

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsFrom Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsRating: 1 out of 5 stars1/5 (1)

- Marine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersFrom EverandMarine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersRating: 5 out of 5 stars5/5 (2)

- Yaris: KSP, NCPDocument2 pagesYaris: KSP, NCPthierry.fifieldoutlook.comNo ratings yet

- Entree AtelierDocument2 pagesEntree Atelierthierry.fifieldoutlook.comNo ratings yet

- Fault Code P1739 (Controlled Manual Gearbox ECU)Document1 pageFault Code P1739 (Controlled Manual Gearbox ECU)thierry.fifieldoutlook.comNo ratings yet

- Fault Code P1830 (Controlled Manual Gearbox ECU)Document2 pagesFault Code P1830 (Controlled Manual Gearbox ECU)thierry.fifieldoutlook.comNo ratings yet

- Fuel Sub Tank LC 100Document9 pagesFuel Sub Tank LC 100thierry.fifieldoutlook.comNo ratings yet

- BMW X6 E71 - Breakout Boxes & ConnectorsDocument113 pagesBMW X6 E71 - Breakout Boxes & Connectorsthierry.fifieldoutlook.comNo ratings yet

- 2010 - Caliber JEEP BOITE T355Document484 pages2010 - Caliber JEEP BOITE T355thierry.fifieldoutlook.comNo ratings yet

- Audi A6 2005-2011 - 6-Cyl. TDI Engine (2.7l. 3.0l. 4-Valve Common Rail, EU5), Mechanics - PDFs Free OnlineDocument386 pagesAudi A6 2005-2011 - 6-Cyl. TDI Engine (2.7l. 3.0l. 4-Valve Common Rail, EU5), Mechanics - PDFs Free Onlinethierry.fifieldoutlook.comNo ratings yet

- NURS FPX 6614 Assessment 1 Defining A Gap in PracticeDocument6 pagesNURS FPX 6614 Assessment 1 Defining A Gap in PracticeCarolyn HarkerNo ratings yet

- Works Cited - Senior PaperDocument2 pagesWorks Cited - Senior Paperapi-660800188No ratings yet

- Marking ToolsDocument14 pagesMarking ToolsFabian NdegeNo ratings yet

- Documentation FlutterDocument12 pagesDocumentation FlutterIvhan SalazarNo ratings yet

- Eugenio Ochoa GonzalezDocument3 pagesEugenio Ochoa GonzalezEugenio Ochoa GonzalezNo ratings yet

- Modern Business Statistics With Microsoft Office Excel 4Th Edition Anderson Solutions Manual Full Chapter PDFDocument47 pagesModern Business Statistics With Microsoft Office Excel 4Th Edition Anderson Solutions Manual Full Chapter PDFjerryholdengewmqtspaj100% (11)

- Gas Bill AprilDocument4 pagesGas Bill AprilMozhie OicangiNo ratings yet

- Worksheet MAPEH Arts Q4-W3Document4 pagesWorksheet MAPEH Arts Q4-W3Hezel Mercado EdrozoNo ratings yet

- Genshin AchievementsDocument31 pagesGenshin AchievementsHilmawan WibawantoNo ratings yet

- Ignou Regional and Study CentersDocument5 pagesIgnou Regional and Study Centersbtech_dksNo ratings yet

- MB0052-Strategic Management and Business Policy (Assignment-1)Document9 pagesMB0052-Strategic Management and Business Policy (Assignment-1)Anil KumarNo ratings yet

- The Discriminant: Given A Quadratic Equation Use The Discriminant To Determine The Nature of The RootsDocument17 pagesThe Discriminant: Given A Quadratic Equation Use The Discriminant To Determine The Nature of The RootsdianneNo ratings yet

- Pembelajaran Literasi Membaca Di Pondok Pesantren Sidogiri Kraton PasuruanDocument17 pagesPembelajaran Literasi Membaca Di Pondok Pesantren Sidogiri Kraton Pasuruanpriyo hartantoNo ratings yet

- Annotated BibliographyDocument2 pagesAnnotated Bibliographyapi-214882950No ratings yet

- VFR 800Document159 pagesVFR 800christian maritzNo ratings yet

- HDHR-242U: High Density PolyethyleneDocument1 pageHDHR-242U: High Density Polyethylenefrancisca ulloa riveraNo ratings yet

- Tiago Tigor Infotainment GuideDocument2 pagesTiago Tigor Infotainment GuidejotowekidNo ratings yet

- Advancements in Concrete Design: Self-Consolidating/Self-Compacting ConcreteDocument4 pagesAdvancements in Concrete Design: Self-Consolidating/Self-Compacting ConcreteMikhaelo Alberti Dela CruzNo ratings yet

- BSBWOR404 Assessment Task 1Document6 pagesBSBWOR404 Assessment Task 1SearaNo ratings yet

- Consequences of Stress: Kushaal Saraf Luv Kumar Jain Shivank Kedia Himashu RawtaniDocument21 pagesConsequences of Stress: Kushaal Saraf Luv Kumar Jain Shivank Kedia Himashu RawtaniSaraf KushalNo ratings yet

- MR - Tushar Thombare Resume PDFDocument3 pagesMR - Tushar Thombare Resume PDFprasadNo ratings yet

- Control System Kec 602Document2 pagesControl System Kec 602Nitya MishraNo ratings yet

- 99tata Motors Ltd. Letter of Offer 18.09.08Document403 pages99tata Motors Ltd. Letter of Offer 18.09.08Sharmilanoor Nurul BasharNo ratings yet

- Classification of FinishesDocument5 pagesClassification of FinishesOjasvee Kashyap100% (1)

- [Artificial Intelligence] Ranjan, Sumit, Senthamilarasu, Dr. S. - Applied Deep Learning and Computer Vision for Self-Driving Cars_ Build Autonomous Vehicles Using Deep Neural Networks and Behavi (2020, Packt Publishing) - LibgDocument320 pages[Artificial Intelligence] Ranjan, Sumit, Senthamilarasu, Dr. S. - Applied Deep Learning and Computer Vision for Self-Driving Cars_ Build Autonomous Vehicles Using Deep Neural Networks and Behavi (2020, Packt Publishing) - Libgerik skiNo ratings yet

- Des-F1025p-E DSDocument3 pagesDes-F1025p-E DSNaing Win ZawNo ratings yet

- Belzona 5111 Product Data SheetDocument2 pagesBelzona 5111 Product Data SheetPeter RhoadsNo ratings yet

![[Artificial Intelligence] Ranjan, Sumit, Senthamilarasu, Dr. S. - Applied Deep Learning and Computer Vision for Self-Driving Cars_ Build Autonomous Vehicles Using Deep Neural Networks and Behavi (2020, Packt Publishing) - Libg](https://imgv2-1-f.scribdassets.com/img/document/692994234/149x198/3054a0a56e/1702779147?v=1)