Professional Documents

Culture Documents

Hydraulic Symbols

Hydraulic Symbols

Uploaded by

MehmetGörkemDemir0 ratings0% found this document useful (0 votes)

253 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

253 views1 pageHydraulic Symbols

Hydraulic Symbols

Uploaded by

MehmetGörkemDemirCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

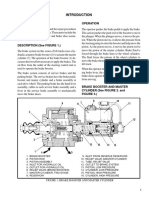

Hydraulic symbols

Energy conversion Energy transfer Actuation Valves Valves Valves

line, supply line, return line, component framing

Manual actuation Basic symbols Directional control valves Stop valves

and symbol boxed in

A A B

internal and external pilot line, leakage oil line, shut-off valve 3-way stop-cock

hydraulic pump with constant delivery rate purging line, exhaust line by by by pulling

pushing pulling and pushing P T P T

Function unit for valves with main ports. 3/2-way valve with 4/2-way valve with two non-return valve non-return valve with spring

The number of ports corresponds to the number solenoid coil, directly solenoid coils, directly B A2 B2

frames for several components of lines shown above and below a square. actuated, reset by actuated, with detent

by by by spring and manual (double solenoid valve)

hydraulic variable displacement pump with alternating turning lever rocker override with detent

direction of delivery at constant direction of rotation tubing line A B A X A1 B1

Mechanical actuation piloted non-return double non-return valve,

valve with spring piloted

X1 P T X2 B B

line crossing closed exhaust

connection line port 4/3-way valve, hydraulically actuated, spring-centred A1 A2 A1 A2

reversible hydraulic pump/hydraulic motor unit with by by by roller lever, actuation

plunger roller in one direction of travel basic elements with 2, 3, 4 switching positions A B

two directions of flow and variable displacement shuttle valve dual-pressure valve

volume, external leakage oil line and two directions only

pressure supply port, plug within a fluid line (OR function) (AND function)

of rotation. A

closed

P T

4/3-way proportional valve, directly actuated

Flow control valves

P T A B

hydraulic tank connection, ending actuated in initial position G G

A B flow control flow control orifice, fixed

energy source below and above the oil level

hydraulic motor with rotary drive/semi-rotary valve, fixed valve, adjustable

constant displacement/ drive with limited angle Pressure actuation

B B1 B2

absorption capacity and of rotation and two paths and directions of flow through a valve X P T Y

two directions of rotation directions of flow reservoir closed reservoir open to

with cover atmosphere 4/3-way servo valve piloted by a control solenoid,

with closed-loop position control of main and pilot

pneumatically hydraulically stage, with integrated electronics, external pilot

actuated actuated function: leak-tight locking, hydraulic seat A A

supply and drain

electric motor one-way flow control flow distributor

A B valve, adjustable

Electrical actuation

B T B

motor shaft points to pump shaft points to

directional control valve with intermediate

the right (preferably) the left (preferably)

positions – dynamic control valve P T

or to the left or to the right

A B 4/3-way servo valve, piloted, solenoid coil with two

by solenoid coil with one winding windings, with mechanical feedback of the valve slide

– active direction – active direction A

position to the pilot stage A

towards the away from the 1M1 1M2

compact gear unit (simplified representation) valving element valving element X P T Y 3-way flow control 2-way flow control

A valve, adjustable valve, non-adjustable

hydraulic pump and hydraulic motor with shaft A examples for connection

coupling identification:

A = port Accessories

by solenoid coil with two windings, active direction P T

single-acting cylinder double-acting cylinder T L B = port

to and from the valving element 3/2-way poppet valve with solenoid coil and

with piston rod at one end, with piston rod at one end

quick decoupler with quick decoupler with

P = pump

limit switch

Measurement and display devices

spring chamber with T = reservoir

two non-return valves, two non-return valves,

leakage oil connection X = control oil supply

decoupled; coupled

Y = control oil relief

i.e. line closed 1M1

L = leakage oil

Pressure control valves

by electric motor with by stepper motor M = solenoid coil

continuous rotary motion A pressure gauge temperature gauge

Connections must be marked on the circuit diagram P (thermometer)

using the identification marked on the component,

double-acting cylinder with through piston rod of

different diameters, with adjustable cushioning Combined actuation sub-base or block (ISO 1219-2).

at both ends T

filter tank – ventilation filter

P L flow rate display flow meter

by solenoid coil by solenoid coil or directly actuated sequence valve,

and pilot valve manual override and pressure relief valve, self-actuating, with

single-acting cylinder, plunger cylinder pilot valve 2/2-way valve with 2 ports, 2 switching positions

for 2 flow directions. adjustable bypass valve

– normally closed – normally open A A fluid level display tachometer

position position (sight glass)

filter with bypass valve with optical contamination

indicator and switch by solenoid coil by solenoid coil or

telescope cylinder, telescope cylinder, P L P L P

or manual override manual override with

single-acting double-acting detent directly actuated piloted 2-way pressure pressure switch, electro- pressure sensor,

p1 2-way pressure regulator regulator with external mechanical, adjustable analogue output signal

p2

3/2-way valve with 4/2-way valve with with external control control oil relief

Mechanical components 3 ports and 4 ports and oil relief

cooler without flow lines heating 5 2 switching positions, 2 switching positions P

pressure booster, single-acting, which for the direction of flow normally closed position A A pressure switch, electronically adjustable,

converts a pneumatic pressure p1 into a of coolant output signal switching

higher hydraulic pressure p2 Detents are to be symmetrically matched with the

mechanical connection. P T T G G

G G With more than three detent positions the number displacement encoder displacement encoder

of positions can be displayed above the detent 3-way pressure regulator accumulator charging valve with analogue output with digital output signal

element. signal

P T

gas pressure accumulator, separation of G

double-acting cylinder double-acting cylinder

media through: X

with displacement with integrated

encoder on the piston rod displacement encoder diaphragm bladder piston reset by spring spring-centred T P optical indicator digital display

(diaphragm (bladder (piston 4/3-way valve with 4 ports and 3 switching

positions – various mid-position variants shut-off/ proportional pressure L

accumulator) accumulator) accumulator) counterbalancing valve relief valve, directly

4

1 1 actuated with closed-loop

2 2 position control of fluid level switch with electrical fluid level

3 3 solenoid coil and with 4 normally closed monitoring with analogue

three-way rotary connection integrated electronics contacts output signal and

digital display

053032 en © Festo Didactic GmbH & Co. KG www.festo-didactic.com

You might also like

- RE4F03BDocument118 pagesRE4F03Bossoski100% (2)

- 495bi ErbDocument408 pages495bi ErbWalisson100% (1)

- Hydraulic Schematic SymbolsDocument12 pagesHydraulic Schematic SymbolsswainpiyushNo ratings yet

- Basic Hydraulics: Pressure Control Circuits Pressure Control CircuitsDocument50 pagesBasic Hydraulics: Pressure Control Circuits Pressure Control CircuitsJose Manuel Barroso PantojaNo ratings yet

- Hyd Book 2Document269 pagesHyd Book 2hanifpanja100% (1)

- Festo Electrical, Pneumatic and Logic SymbolsDocument1 pageFesto Electrical, Pneumatic and Logic SymbolsAvtomatika Kole Nehtenin67% (3)

- Lecture 1 ElectrohydraulicsDocument62 pagesLecture 1 ElectrohydraulicsAhmedNo ratings yet

- Simbologia PDFDocument1 pageSimbologia PDFMartin Abraham Perez UriasNo ratings yet

- Hydraulics 4 PDFDocument25 pagesHydraulics 4 PDFVenkat KrishnaNo ratings yet

- Intro To Hyd SymbolsDocument51 pagesIntro To Hyd SymbolsFatholla SalehiNo ratings yet

- HYDAC Understanding Hydraulics2 MAR 2015Document4 pagesHYDAC Understanding Hydraulics2 MAR 2015marc271986No ratings yet

- Basic Hydraulics A IlyasDocument64 pagesBasic Hydraulics A IlyasshafiqNo ratings yet

- MEM341 Fluid Power TechnologyDocument31 pagesMEM341 Fluid Power TechnologyEdwin Orozco ReyesNo ratings yet

- The Pneumatics Installation Guide: Festo Worldwide WWW - FestoDocument216 pagesThe Pneumatics Installation Guide: Festo Worldwide WWW - FestorzezniccNo ratings yet

- Volume5 Study of Hydraulic CircuitsDocument64 pagesVolume5 Study of Hydraulic CircuitsMdp Dhandapani100% (1)

- Hydroirma Catalog Gear PumpDocument104 pagesHydroirma Catalog Gear PumpEng-Mohammed Salem100% (1)

- 1.6 Hoses, Pipes & FittingsDocument17 pages1.6 Hoses, Pipes & FittingsAndikaNo ratings yet

- Leseprobe enDocument60 pagesLeseprobe enphankhoa83No ratings yet

- Transmission Circuit RecommendationsDocument40 pagesTransmission Circuit RecommendationsanandsubbiahNo ratings yet

- Industrial Hydraulic CircuitsDocument16 pagesIndustrial Hydraulic CircuitskingkakingNo ratings yet

- Hydraulic Brake Systems and Components For Off-Highway Vehicles and EquipmentDocument10 pagesHydraulic Brake Systems and Components For Off-Highway Vehicles and EquipmentJenner Volnney Quispe ChataNo ratings yet

- 02 Textbook TP501 enDocument236 pages02 Textbook TP501 enAlexander PenadoNo ratings yet

- HYDAC Understanding Hydraulics3 JAN 2015Document3 pagesHYDAC Understanding Hydraulics3 JAN 2015marc271986No ratings yet

- Lab Manual-H & P-1me2603Document40 pagesLab Manual-H & P-1me2603Hi helloNo ratings yet

- DCVDocument35 pagesDCVTanoj Patro100% (1)

- HydraulicsDocument253 pagesHydraulicsvelavansuNo ratings yet

- Chapter2 Hydraulics Control in Machine ToolsDocument67 pagesChapter2 Hydraulics Control in Machine ToolsBasha KumeraNo ratings yet

- Cartridge ValvesDocument2 pagesCartridge Valves1sympatyagaNo ratings yet

- Department of Mechanical Engineering Question Bank 2017 (Regulation) ME8694-Hydraulics and PneumaticsDocument15 pagesDepartment of Mechanical Engineering Question Bank 2017 (Regulation) ME8694-Hydraulics and PneumaticsSC 8D musicNo ratings yet

- Hydraulic FluidDocument4 pagesHydraulic FluidBaskar KannaiahNo ratings yet

- Solenoid Control Hk66o102Document40 pagesSolenoid Control Hk66o102seaqu3stNo ratings yet

- Basic HydraulicsDocument53 pagesBasic Hydraulicsabhinay02meNo ratings yet

- Katalog Hagglunds Motor CBM TypeDocument28 pagesKatalog Hagglunds Motor CBM TypeRudianto SakkaNo ratings yet

- Moduldokumentation HydraulicsDocument66 pagesModuldokumentation HydraulicsJordi El MariachetNo ratings yet

- Product GuideDocument64 pagesProduct Guidecheyenne_iqNo ratings yet

- Basic Hydraulic Circuits - AnalysisDocument49 pagesBasic Hydraulic Circuits - AnalysisMohamed ZahranNo ratings yet

- Drive and Control Systems For TractorsDocument12 pagesDrive and Control Systems For TractorsHasse Hasib SejdinovićNo ratings yet

- Automation StudioDocument88 pagesAutomation StudioKr Ish NaNo ratings yet

- Industrial Hydraulic Circuits Slide ShareDocument35 pagesIndustrial Hydraulic Circuits Slide ShareUMIPL HydNo ratings yet

- Bukh DV 36-48 Workshop ManualDocument196 pagesBukh DV 36-48 Workshop Manualasaturday85No ratings yet

- 1 Fluid Power Devices CircuitsDocument20 pages1 Fluid Power Devices CircuitshamidouNo ratings yet

- Me55 - Applied Hydraulics & Pneumatics PDFDocument12 pagesMe55 - Applied Hydraulics & Pneumatics PDFPandiya RajanNo ratings yet

- Hyd TrainingDocument72 pagesHyd TrainingJuned Hamid KhanNo ratings yet

- Unloading Pressure Hk66j102Document12 pagesUnloading Pressure Hk66j102seaqu3stNo ratings yet

- Hydraulics and PneumaticsDocument20 pagesHydraulics and Pneumaticsharishme028100% (2)

- Denison Hydraulics Proportional Directional Valves Cetop 07: Series 4DP03-E/HDocument19 pagesDenison Hydraulics Proportional Directional Valves Cetop 07: Series 4DP03-E/Hpostolache mariusNo ratings yet

- Bul 36115 Servo Valve OperationDocument12 pagesBul 36115 Servo Valve Operationrikkitech100% (1)

- Yuken Directional Control ValvesDocument193 pagesYuken Directional Control ValvesphaindikaNo ratings yet

- Chapter 1 Introduction To Fluid PowerDocument33 pagesChapter 1 Introduction To Fluid PowerSiraj Busse100% (4)

- Session 12 en Logic Element-Cartridge Valve NoRestrictionDocument5 pagesSession 12 en Logic Element-Cartridge Valve NoRestrictionahmed elkhoulyNo ratings yet

- Short Description Content: 13 Learning Modules, 600 Training Pages, 120 Test QuestionsDocument4 pagesShort Description Content: 13 Learning Modules, 600 Training Pages, 120 Test QuestionsTun Lin NaingNo ratings yet

- Introduction To Hydraulics For Industry Professionals: Hydraulic Systems Volume 1Document20 pagesIntroduction To Hydraulics For Industry Professionals: Hydraulic Systems Volume 1Narasimha DNo ratings yet

- Technical Manual ICVD 1111Document24 pagesTechnical Manual ICVD 1111Angelo MedinaNo ratings yet

- CH 21 AnswersDocument26 pagesCH 21 AnswersArjav DesaiNo ratings yet

- Hydraulic and Pneumatic SymbolsDocument6 pagesHydraulic and Pneumatic SymbolsFinito TheEnd100% (1)

- Fluid Power Symbols PDFDocument4 pagesFluid Power Symbols PDFArdian20No ratings yet

- Fluid Power Symbols PDFDocument4 pagesFluid Power Symbols PDFHeno ArdianNo ratings yet

- Fluid Power Symbols PDFDocument4 pagesFluid Power Symbols PDFPavle KrstevskiNo ratings yet

- Woodward TG ActuatorDocument12 pagesWoodward TG Actuatorali shairNo ratings yet

- Hydraulic Symbols: Service Training Manual ECM 720Document24 pagesHydraulic Symbols: Service Training Manual ECM 720victor lara100% (1)

- ECM720 Train CompleteDocument205 pagesECM720 Train Completevitor santos100% (1)

- Tambahan Materi HydraulicDocument19 pagesTambahan Materi Hydrauliceht eivomNo ratings yet

- 5ton Forklift TrainingDocument87 pages5ton Forklift TrainingPyae Phyoe Aung100% (2)

- 2 37Document10 pages2 37Amit Chopra AmitNo ratings yet

- LeeBoy 785 Grader Transmission Manual1 PDFDocument51 pagesLeeBoy 785 Grader Transmission Manual1 PDFoprez oprez100% (2)

- Transmission: Operação Dos SistemasDocument12 pagesTransmission: Operação Dos SistemashelioNo ratings yet

- Edta Scheme in Wards For 500 & 600 MWDocument4 pagesEdta Scheme in Wards For 500 & 600 MWjp mishraNo ratings yet

- Pm-Up6-5-15 - Up-UqDocument106 pagesPm-Up6-5-15 - Up-Uqdarkomega21100% (2)

- Brake System - Hyundai TruckDocument57 pagesBrake System - Hyundai Truckphanduy12102003No ratings yet

- The Big Catalog (Full) PDFDocument1,018 pagesThe Big Catalog (Full) PDFAlex García ZamudioNo ratings yet

- Whitsworth MechanismDocument16 pagesWhitsworth Mechanism22R435 - MULLAINATHAN V HNo ratings yet

- Valvulas Samson Modulantes V2001Document10 pagesValvulas Samson Modulantes V2001AndresNo ratings yet

- RMZ450L6 Manual de PartesDocument71 pagesRMZ450L6 Manual de Partesromero motorsNo ratings yet

- Duyar KatalogDocument8 pagesDuyar Katalogcvolkan1No ratings yet

- The Brake SystemDocument15 pagesThe Brake SystemweldsaidiNo ratings yet

- LST PP 004 - 1Document12 pagesLST PP 004 - 1Pandi KokoyNo ratings yet

- Typical Ammonia Pump System DrawingDocument1 pageTypical Ammonia Pump System DrawingShekhar PhaseNo ratings yet

- Reciprocating Pump Single and Multi StageDocument3 pagesReciprocating Pump Single and Multi StageDylanAdamsNo ratings yet

- Errorcodes GS33Document87 pagesErrorcodes GS33alirezaNo ratings yet

- 05 PR-Pressure Reducing Valves CatalogDocument13 pages05 PR-Pressure Reducing Valves CatalogHIDRAULICA MANSE SERVICIO TECNICONo ratings yet

- A5SR1 Repair and Troubleshooting Guide For The 5-Speed Automatic Gearbox Kia Sorento 2008Document205 pagesA5SR1 Repair and Troubleshooting Guide For The 5-Speed Automatic Gearbox Kia Sorento 2008Leonardo Alves Fiusa100% (2)

- 03 RT-Flex Hydraulic UPDATEDDocument5 pages03 RT-Flex Hydraulic UPDATEDfun0608No ratings yet

- Abr Unit 4 DMM II Helical GearDocument29 pagesAbr Unit 4 DMM II Helical GearMechanizers 40.0No ratings yet

- Fire Pump Installation Systems: 2006 Approval GuideDocument184 pagesFire Pump Installation Systems: 2006 Approval GuideRAJESHNo ratings yet

- Great Plains Parts Manual NTA3010 & NTA3510Document112 pagesGreat Plains Parts Manual NTA3010 & NTA3510a04205No ratings yet

- Template - Checklist of Spare PartDocument1 pageTemplate - Checklist of Spare PartAshish MishraNo ratings yet

- Pump Affinity (K0 SNW)Document6 pagesPump Affinity (K0 SNW)Myat Kyaw HeinNo ratings yet

- SP-058 Pipe Hangers & Supports, Matl, Design, MFGDocument26 pagesSP-058 Pipe Hangers & Supports, Matl, Design, MFGcarlos tovarNo ratings yet

- Mi SwacoDocument8 pagesMi SwacoSanju laaNo ratings yet

- Expanded Air Valve Program 1Document8 pagesExpanded Air Valve Program 1Capital Diesel SASNo ratings yet