Professional Documents

Culture Documents

Digital Tachometer

Digital Tachometer

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Digital Tachometer

Digital Tachometer

Copyright:

Available Formats

Volume 7, Issue 12, December – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Digital Tachometer

Priyanshu Kumar Rouniyar 1, Sashank Shrestha2, Ujjwal Raj poudel3, Aship Chaudhary4, Paras Panta5, Aashutosh Chaudhary6

1-5

Department of Electrical and Electronics Engineering, Kathmandu University, Dhulikhel

6

Department of Computer Science, Chhattisgarh Swami Vivekananda Technical University, Bhilai

Abstract:- The measurement of instantaneous torque in second stage a digital counter based 4-digit counter IC 74C926

terms of voltage displaying rotating speed in revolution per is used for the construction of the tachometer. A 5V regulated

minute (RPM) of a rotating shaft is known as a digital power supply circuit and an infrared light source circuit are

tachometer. An infrared module is used as the input that also used. The instrument can measure speed up to 9999 RPM

senses the interruption in terms of beam of rays caused by [2].

rotating shaft, generating a pulse. The usual method of

counting pulse coming from the encoder in a fixed period Another paper named” A Digital Tachometer for

of time produces a high precision velocity estimate in the Measurement of Very low Speeds” a new approach to the

high-speed range. The encoded signal is latched and digital measurement of angular velocity is presented. This new

further sent to decoder that decodes the latched pulse i.e. instrument performs the division by time that has been

speed displayed in 7 segment display. This paper mainly carefully avoided in the existing instruments. The accuracy

focuses on developing a contact-less digital tachometer of and resolution of the transducer does not depend upon the

maximum 3digit with the help of integrated circuits (ICs). number of revolutions. The measurements can be made in a

very short time, leading to up to 14,700 samples per second

I. INTRODUCTION [1].

A tachometer is an instrument which measures the Similarly, a paper named” Contactless Speed Monitoring

rotation speed of a shaft or disk, as in a motor or other and Displaying” contactless tachometer measures the speed in

machine. It displays the speed in revolution per minute (RPM). RPM is designed with the help of microcontroller and diodes.

Tachometer is also known as revolution-counter, and its The author uses At89s52 as a microcontroller. This is

operating principle can be electromagnetic, electronic, or programmed in c program and complied using keil complier

optical-based. Tachometers can be analog or digital indicating [3].

meters; however, this article focuses only on the digital

tachometer based on IC. A tachometer that does not need any III. OVERVIEW OF THE SYSTEM

physical contact with the rotating shaft is called a non-contact

digital tachometer. Digital tachometers are more common This system basically contains of timer IC, Decade

these days and they provide numerical readings instead of counter, gate driver, IR transmitter/receiver, seven segment

gauge that usually displays the RPM on a calibrated analogue display unit and some led. At first timer IC configured as

dials and needles. Digital tachometers are used in different monostable and it produce timing pulse for certain time when

applications such as automobiles, airplanes, and medical and switch is pressed, the LED indicates the sensing duration. The

instrumentation applications. IR transmitter and receiver are used to produce changing logic

levels depends on the blocking or interrupting IR light beams.

II. LITERATURE REVIEW Logic gate enables decade counter and decade counter drives

seven segment display. There are three-decade counter and

A tachometer is also known by several other terms as a three seven segment display to show RPS from 000 to 999.

revcounter and rpm gauge. It was first used to measure speed This illustration shows how to make a rotating interrupter,

on a vehicle (a locomotive) in 1840. Even though the first measure the slot width and depth of the shaft or rotating

petrol or gasoline powered automobile was developed in 1886 machine. One interruption to the IR beam by the rotating disc,

by Karl Benz, it is unclear when the first car featured a which will take as one count and total count of rotation is RPS,

tachometer [1]. The first mechanical tachometer was similar by this way multiplying 60 to RPS revolution per minute

in operation to a centrifugal governor. The inventor of the first (RPM) can be obtained.

mechanical tachometer is assumed to be a German engineer

Dietrich.

Uhlhorn, he used it for measuring the speed of machines

in 1817 [2]. Since then it has been used to measure the speed

of locomotives in automobiles, trucks. Early tachometers

design was based on the principle of monostable multivibrator,

which has one stable state and one quasi-stable state. A paper

named “Design of a high-performance digital tachometer with

a microcontroller” describes the basic construction of a low-

cost optical tachometer and analyzes its performance. The

basic tachometer circuit consists of two stages. In the first

stage monostable wired around IC NE555 is used, and in the Fig 1: Block Diagram

IJISRT22DEC1272 www.ijisrt.com 1104

Volume 7, Issue 12, December – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

The given Fig 1 is the block diagram of the system. The calculators, and other electronic devices that display numerical

decade counter gets the pulse input from the output of the gate information. The output data from the decoder is displayed

driver. The output of the IR transmitter and receiver is fed to using a seven-segment display which is one of the most

the gate logic with the monostable timer and which is fed to important section. We use three seven segments display to

the latch pin of the decoder by inverting it, in order to display show RPS from 000 to 999.

the value in the seven-segment display after certain time by

converting it into RPM. G. IR Transmitter/Receiver

IR transmitter receiver works by letting one component

The basic principle behind converting the RPS reading flash an infrared light in a particular pattern, which another

into RPM is shown below: component can pick up and translate into an instruction. These

transmitter receivers are used in our remote and televisions.

Counting time: 10 secs Basically, the concept of transmitter and receiver is for the

Then, no. of pulses in 10 secs = x purpose of generating pulses which is further detected by

Now, in 1 sec no. of pulses = x/10 CD4026 decade counter. The transmitter sends the IR through

In 60 sec no. of pulses = (x/10) *60 i.e. x*6 a rotating disc and reflects towards the receiver that counts the

Now if we have 6 holes/areas to read then the rpm is simply pulse. The IR module is sensitive towards the direct sunlight

(x*6)/6 which may fluctuate the generated pulse.

So, we get the data directly in RPM. I.e. x

H. Logic Gates

By this way the required speed of the rotating shaft is Logic gates are basic building blocks of any digital

determined in the terms of per minute i.e. RPM. system. It is a circuit having one or more than one input

followed by only one output. AND gate and NOT gate is used

IV. DESCRIPTION OF DESIGN in this project as shown in the circuit diagram. The output of

T1 timer (monostable state for 10sec) and pulse generated

A. Counter from the rotating disc is send to the output as input. The NE555

A special type of sequential circuit used to count the timer is in monostable state that reads the pulses only for 10

pulse is known as a counter, or a collection of flip flops where seconds. The main purpose of AND gate is to read high and

the clock signal is applied is known as counters. low pulses for 10 second. The data read is multiplied by 6 to

convert it to RPM whereas the rotating disc is also designed

B. Latch with the reflecting surfaces accordingly with the pulses read

A latch is a storage device that holds the data using the for 10 second. The output of AND gate is sent to CD4026 IC

feedback lane. The latches have low and high two stable. for counter for counting purpose.

Latches operate with enable signal, which is level sensitive

states. The NOT gate is used to invert the receiving signal as an

input for decoder to display through common cathode seven

C. Decoder segment displays.

The combinational circuit that change the binary

information into 2N output lines is known as decoders. The I. Capacitor

binary information is passed in the form Of N input lines. The A capacitor is a device that stores electrical energy in an

output lines define the 2N-bit code for the binary information. electric field. It is a passive electronic component with two

terminals. The effect of a capacitor is known as capacitance.

D. CD 4026

The IC CD4026 is an IC which can perform the function J. Resistor

of both a counter as well a 7-segment Driver. The whole A resistor is a passive two-terminal electrical component

function of counter, latch and decoder is done by an IC of that implements electrical resistance as a circuit element. In

CMOS series of 4026 as shown in block diagram. Its operating electronic circuits, resistors are used to reduce current flow,

voltage is 5v. adjust signal levels, to divide voltages, bias active elements,

and terminate transmission lines, etc.

E. NE555

The NE555 is a highly stable controller capable of K. Rotating Disk

producing accurate timing pulse. The operation, the time delay A rotating disk is a simple disc divided into 12 small

and the frequency are controlled by external resistors and regions coated with black and white colors alternately as

capacitors. A timer can be used as linear ramp, pulse position shown in figure below. A DC motor is attached to the rotating

modulation, pulse width modulation, frequency divider and in disk which rotates it.

astable, monostable and bistable mode. Here, we have used the

timer in Monostable mode to generate the pulse width

modulated waves.

F. Seven Segment Display

A seven-segment display is a form of electronic display

for displaying decimal numerals that is an alternative to the

more complex dot matrix displays. Seven-segment displays

are widely used in digital clocks, electronic meters, basic Fig 2: CAD Design of Rotating Disc with DC motor

IJISRT22DEC1272 www.ijisrt.com 1105

Volume 7, Issue 12, December – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

V. HARDWARE IMPLEMENTATION

Firstly, the IR sensor calibration was done and feeding

some arbitrary values according to the conditions after striking

on the plate which is mounted on the motor shaft according to

the varying speed of the motor. The output of the IR sensor

was seen in the digital Oscilloscope as in the Fig 5. After that

555Timer was operated in the monostable mode for 10

seconds because only the data of 10 sec was taken for

converting it to the rpm by relating it to the rotating disc

mounted on the shaft of the motor.

Fig 3: Proteus Simulation of the Circuit

Fig 5: Overall Output Graph of the System

The basic principle behind converting the RPS reading The reason behind for taking the data of 10 sec is mention

into RPM is shown below: above clearly. The data input of 10 sec should be counted. So,

Counting time: 10 secs it should be passed from the AND gate, i.e. which gives only

Then, no. of pulses in 10 secs = x high output when both the inputs are high. One input of the

Now, in 1 sec no. of pulses = x/10 In 60 sec no. of pulses = AND gate is the output of the timer IC and another is output

(x/10) *60 i.e. x*6 of the IR sensor. The output of the AND gate is fed into the

Now if we have 6 holes/areas to read then the rpm is simply clock input of the Decade counter 4026. So, with the help of

(x*6)/6 AND gate after 10 Sec that data fed into the Decade counter

So, we get the data directly in RPM. I.e. x will be zero. The output graphs of the 555 timer, IR module

and Clock input in the decade Counter is shown in the Figure

By this way the required speed of the rotating shaft is 5.

determined in the terms of per minute i.e. RPM. Channel A- Yellow- 555 timer output

Channel B- Blue – IR Module

Channel C- Pink- AND gate output/Input for Decade Counter

After the data/signal is fed into the clock pin of the 4026

IC, it converts the data and act as the decoder and display the

RPM into the seven-segment display. The same output of the

555 timer is passed through the not gate to the display pin of

the 4026 IC which will display the value after 10 sec exactly

by doing the calculation. Cascading three 4026 IC is done for

threedigit display. Similarly, to display N number of digit

cascading of N 4026 must be used with N number of 7-

segement display. For the new reading a reset pin is connected

to the 4026 IC to reset the latched value manually. Fig 6,

shows the developed digital tachometer.

Fig 4: Methodology of Hardware Implementation

IJISRT22DEC1272 www.ijisrt.com 1106

Volume 7, Issue 12, December – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Fig 7: Bar Graph of Obtained Results

ACKNOWLEDGMENT

We would like to express our sincere gratitude to the

Department of Electrical and Electronics Engineering

Fig 6: Developed System (DoEEE), Kathmandu University for granting permission and

supporting the project. Also, we would like to thank our

VI. APPLICATION project coordinator Dr. Anup Thapa and project supervisor

Assistant Professor Pramish Shrestha and all faculty members

Tachometer is a measuring device that measures the of DoEEE for their assistance, support and guidance

revolution speed of the rotating objects. It is used for throughout the project.

measuring the rotation frequency or speed of a rotating object

such as shafts or disk, in the motor vehicles or in other REFERENCES

machines where rotation speed is the driving force.

[1]. A. Mukhtar, "A Digital Tachometer for Measurement of

VII. DISCUSSION AND RESULTS very low speeds," IEEE, vol. 72, 1984.

[2]. R. Bonert, "Design of a high performance digital

A simple digital tachometer has been constructed with tachometer with a microcontroller," Instrumentration

standard CMOS integrated circuits for maximum three digits. and Measurement , vol. 38, pp. 1104,1108, 1989.

The system reads the signal from IR module for 10 seconds, [3]. S. Das, "Contactless Speed Monitoring and Displaying,"

the obtained data is further encoded, latched and decoded by International Research Journal Of engineering and

an IC CD 4026 and displays the resultant speed (RPM) in 7- Technology, vol. 3, 2016.

segment display. This approach eliminates rapid changes in

the frequency, one must start over for the new reading by

pressing reset button. The speed in RPM of a particular

rotating shaft was taken by varying its voltage for each reading

with the lab’s tachometer and developed tachometer is shown

in table 1. Bar graph of the obtained data from the table 1 is

represented in figure 7.

Table 1: Obtained Results

S.N. Lab Tachometer Developed Error

(RPM) Tachometer

(RPM)

1 230 228 2

2 285 285 0

3 368 369 1

4 567 565 2

5 654 654 0

6 732 734 2

7 888 891 3

8 925 920 5

IJISRT22DEC1272 www.ijisrt.com 1107

You might also like

- Normas NES M1019Document12 pagesNormas NES M1019Margarita Torres FloresNo ratings yet

- The OdysseyDocument9 pagesThe OdysseyJacob IlaganNo ratings yet

- Stroboscope With RPM Indicator Full ReportDocument26 pagesStroboscope With RPM Indicator Full Reportthreephasefault100% (2)

- Digital Integrated CircuitDocument33 pagesDigital Integrated CircuitottoporNo ratings yet

- Prepaid Energy Meter Using Pic MicrocontrollerDocument31 pagesPrepaid Energy Meter Using Pic Microcontrolleronepointer67% (6)

- Digital Tachometer Project ReportDocument57 pagesDigital Tachometer Project Reportcooldharap70% (10)

- Feedback Control Systems by S C Goyal U A Bakshi PDFDocument2 pagesFeedback Control Systems by S C Goyal U A Bakshi PDFHeather29% (7)

- Digital Tachometer Using Arduino Plus Speed Control.Document3 pagesDigital Tachometer Using Arduino Plus Speed Control.elvergonzalez1No ratings yet

- Tachometer Using ArduinoDocument4 pagesTachometer Using ArduinoJamMnx_100% (1)

- Design and Implementation of A Digital TachometerDocument3 pagesDesign and Implementation of A Digital TachometerInnovative Research Publications0% (1)

- Digital TachometerDocument12 pagesDigital TachometerHariniNo ratings yet

- Tachometers: Balmaceda, Chris Francisco, MilfrenDocument15 pagesTachometers: Balmaceda, Chris Francisco, Milfrenjude100% (1)

- Small Engine Ignition Systems CH10Document30 pagesSmall Engine Ignition Systems CH10Manny AnacletoNo ratings yet

- Ic 7805 PDFDocument3 pagesIc 7805 PDFNilabha DasNo ratings yet

- Hioki 3532 50 LCR MeterDocument8 pagesHioki 3532 50 LCR MeterSourabh ChoudharyNo ratings yet

- Monitor and Control of Greenhouse EnvironmentDocument2 pagesMonitor and Control of Greenhouse EnvironmentTushara Chand100% (1)

- Arduino Based Sensorless Speed Control of BLDC Motor Using GSMDocument6 pagesArduino Based Sensorless Speed Control of BLDC Motor Using GSMRaja Ramesh DNo ratings yet

- A Dual-Voltage Self-Clamped IGBT For Automotive Ignition ApplicationsDocument3 pagesA Dual-Voltage Self-Clamped IGBT For Automotive Ignition ApplicationslionpjrNo ratings yet

- Seven Segments ReportDocument12 pagesSeven Segments ReportJun TobiasNo ratings yet

- Design and Micro Controller Implementation of A Three Phase SCR Power ConverterDocument8 pagesDesign and Micro Controller Implementation of A Three Phase SCR Power ConverterIsmael Ochoa JimenezNo ratings yet

- SC Diy Tci TriggerDocument15 pagesSC Diy Tci TriggerElias CoronelNo ratings yet

- MICROCONTROLLER-based DC Motor Speed ControllerDocument8 pagesMICROCONTROLLER-based DC Motor Speed Controllerranjithsim100% (1)

- Delay 1.0K Millis 2.3K Micros 1.0K Delaymicroseconds 359 Analogwrite 274 Tone 1.4K Notone 76 Servo Library 1.6KDocument11 pagesDelay 1.0K Millis 2.3K Micros 1.0K Delaymicroseconds 359 Analogwrite 274 Tone 1.4K Notone 76 Servo Library 1.6KOthmane Bouzarzar100% (1)

- Electronic Thermostat Circuit Using TransistorsDocument2 pagesElectronic Thermostat Circuit Using Transistorstim schroderNo ratings yet

- Closed Loop DC Motor Speed ControlDocument3 pagesClosed Loop DC Motor Speed ControlKhayaz KunhabduNo ratings yet

- TachometerDocument36 pagesTachometerSheena Mary100% (1)

- Techo GeneratorDocument18 pagesTecho GeneratorBhola KumarNo ratings yet

- cHIPSET AND CONTROLLERDocument9 pagescHIPSET AND CONTROLLERMelody MwhengwereNo ratings yet

- Pure Sine Wave InverterDocument12 pagesPure Sine Wave InverterYakesh VarmaNo ratings yet

- Smart Home Control Using LabviewDocument26 pagesSmart Home Control Using LabviewSiva BadrinathNo ratings yet

- Measuring InstrumentsDocument10 pagesMeasuring Instrumentsmohsin931No ratings yet

- 2B Mini Project Report 22-23 Arduino Based Tachometer 4 PDFDocument18 pages2B Mini Project Report 22-23 Arduino Based Tachometer 4 PDF10SHARMA SUMIT RAMADHINNo ratings yet

- Mini Project Report On Automatic Room LiDocument35 pagesMini Project Report On Automatic Room LiRamishNo ratings yet

- Automatic Room Lighting System Using MicrocontrollerDocument6 pagesAutomatic Room Lighting System Using MicrocontrollerRavindra Parab100% (1)

- Couplings and ClutchesDocument14 pagesCouplings and ClutchesBhotka BhutkiNo ratings yet

- Highway Speed CheckerDocument24 pagesHighway Speed Checkerritesh chauhanNo ratings yet

- Power Rectifier ASIC ControllerDocument5 pagesPower Rectifier ASIC ControllerQuang TaNo ratings yet

- Speed Control of Stepper MotorDocument15 pagesSpeed Control of Stepper MotormydearbhavaNo ratings yet

- Speed Control of Induction Motor by Using IR11Document16 pagesSpeed Control of Induction Motor by Using IR11Anuj TripathiNo ratings yet

- DC Motor Speed Control Using Pulse Width Modulation (PWM)Document30 pagesDC Motor Speed Control Using Pulse Width Modulation (PWM)अमरेश झाNo ratings yet

- Digital Power-Conversion For The Analog EngineerDocument12 pagesDigital Power-Conversion For The Analog EngineerfjwoemcuNo ratings yet

- Arduino Timer and InterrupDocument10 pagesArduino Timer and InterrupFabian Monteleone100% (1)

- Esp32-S3 Technical Reference Manual enDocument787 pagesEsp32-S3 Technical Reference Manual enANo ratings yet

- Governing, Ignition System, Fire OrderDocument33 pagesGoverning, Ignition System, Fire OrderProf. Jignesh Sohaliya100% (1)

- GSM Based Automatic Irrigation System Using 8051 MicrocontrollerDocument6 pagesGSM Based Automatic Irrigation System Using 8051 Microcontrolleramism24100% (1)

- Digital TachometerDocument61 pagesDigital TachometernavyaNo ratings yet

- Iraudamp1 PDFDocument22 pagesIraudamp1 PDFamijoski6051No ratings yet

- Phase Locked Loops-A Control Centric TutorialDocument50 pagesPhase Locked Loops-A Control Centric TutorialStephen Dunifer100% (6)

- Develop Ineo-250 Error C2557Document2 pagesDevelop Ineo-250 Error C2557Tariq MajeedNo ratings yet

- GSM (SMS) Controlled DC MotorDocument6 pagesGSM (SMS) Controlled DC Motortalk2neel12No ratings yet

- Handbook - Chairman's Message & PrefaceDocument8 pagesHandbook - Chairman's Message & PrefacemakrsnakminesNo ratings yet

- PIC Single-Chip 4-Digit 99-Minute Timer: DiscussionDocument4 pagesPIC Single-Chip 4-Digit 99-Minute Timer: Discussionravikiran1955No ratings yet

- Ac Meters Part 1Document22 pagesAc Meters Part 1Vam ArmodiaNo ratings yet

- Digital ClockDocument42 pagesDigital ClockPuneet Jain100% (2)

- DC Motor Speed Control Using PWMDocument4 pagesDC Motor Speed Control Using PWMInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- EdSim51 - Notes On The 8051Document16 pagesEdSim51 - Notes On The 8051Pawan KaswanNo ratings yet

- 3 934584 30 6Document3 pages3 934584 30 6Juan Manuel FernandezNo ratings yet

- Project Synopsis 2Document21 pagesProject Synopsis 2shailesh devaneNo ratings yet

- Project Report KanojDocument17 pagesProject Report KanojKanoj Bsn100% (3)

- Design of A Low-Cost Contact-Less Digital - Like PDFDocument3 pagesDesign of A Low-Cost Contact-Less Digital - Like PDFMed MaxNo ratings yet

- Digital Tachometer: Nelson Murwariya (100104077) Rohit Raj (100104108) Sumit Rajput (100104130Document14 pagesDigital Tachometer: Nelson Murwariya (100104077) Rohit Raj (100104108) Sumit Rajput (100104130Sumit RajputNo ratings yet

- Contact Less Digital Tachometer: Mini Project OnDocument45 pagesContact Less Digital Tachometer: Mini Project OnMayur Chandak0% (1)

- Degital Techacometer.Document5 pagesDegital Techacometer.poornarithikNo ratings yet

- A Study to Effect of Reminiscence Therapy on Psychological Well-Being among Elderly Residing in Selected Old Age HomeDocument5 pagesA Study to Effect of Reminiscence Therapy on Psychological Well-Being among Elderly Residing in Selected Old Age HomeInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Application of Project Management using CPM (Critical Path Method) and Pert (Project Evaluation and Review Technique) in the Nava House Bekasi Cluster Housing Development ProjectDocument12 pagesApplication of Project Management using CPM (Critical Path Method) and Pert (Project Evaluation and Review Technique) in the Nava House Bekasi Cluster Housing Development ProjectInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Analysis of Opaque, Peel-Off and Flex Rejects in the Electro Plating Process Using the Six Sigma Dmaic MethodDocument18 pagesAnalysis of Opaque, Peel-Off and Flex Rejects in the Electro Plating Process Using the Six Sigma Dmaic MethodInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Rare Complication: Cardiac Arrest and Pulmonary Embolism in Polyarteritis NodosaDocument5 pagesA Rare Complication: Cardiac Arrest and Pulmonary Embolism in Polyarteritis NodosaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Application of the Economic Order Quantity (EOQ) Method on the Supply of Chemical Materials in the Laboratory of PT. Fajar Surya Wisesa TbkDocument15 pagesApplication of the Economic Order Quantity (EOQ) Method on the Supply of Chemical Materials in the Laboratory of PT. Fajar Surya Wisesa TbkInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Quality Control to Reduce Appearance Defects at PT. Musical InstrumentDocument11 pagesQuality Control to Reduce Appearance Defects at PT. Musical InstrumentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Forecasting PM10 Concentrations Using Artificial Neural Network in Imphal CityDocument10 pagesForecasting PM10 Concentrations Using Artificial Neural Network in Imphal CityInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Comprehensive Review on the Therapeutic Potential of PectinDocument6 pagesA Comprehensive Review on the Therapeutic Potential of PectinInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Impact of Integrated Border Security System on Human Trafficking in Bangladesh: The Mediating Effect of the Use of Advanced TechnologyDocument12 pagesThe Impact of Integrated Border Security System on Human Trafficking in Bangladesh: The Mediating Effect of the Use of Advanced TechnologyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Quizlet's Usefulness for Vocabulary Learning: Perceptions of High-Level and Low-Level Chinese College EFL LearnersDocument5 pagesQuizlet's Usefulness for Vocabulary Learning: Perceptions of High-Level and Low-Level Chinese College EFL LearnersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Analysis of Carton Packaging Quality Control Using Statistical Quality Control Methods at PT XYZDocument10 pagesAnalysis of Carton Packaging Quality Control Using Statistical Quality Control Methods at PT XYZInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Health Care - An Android Application Implementation and Analyzing user Experience Using PythonDocument7 pagesHealth Care - An Android Application Implementation and Analyzing user Experience Using PythonInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Entrepreneurial Adult Education as a Catalyst for Youth Employability in Disadvantaged AreasDocument9 pagesEntrepreneurial Adult Education as a Catalyst for Youth Employability in Disadvantaged AreasInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Visitor Perception Related to the Quality of Service in Todo Tourism VillageDocument10 pagesVisitor Perception Related to the Quality of Service in Todo Tourism VillageInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Enhancing Estimating the Charge Level in Electric Vehicles: Leveraging Force Fluctuation and Regenerative Braking DataDocument6 pagesEnhancing Estimating the Charge Level in Electric Vehicles: Leveraging Force Fluctuation and Regenerative Braking DataInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A New Model of Rating to Evaluate Start-ups in Emerging Indian MarketDocument7 pagesA New Model of Rating to Evaluate Start-ups in Emerging Indian MarketInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Proof of Concept Using BLE to Optimize Patients Turnaround Time (PTAT) in Health CareDocument14 pagesA Proof of Concept Using BLE to Optimize Patients Turnaround Time (PTAT) in Health CareInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Gravity Investigations Applied to the Geological Framework Study of the Mambasa Territory in Democratic Republic of CongoDocument9 pagesGravity Investigations Applied to the Geological Framework Study of the Mambasa Territory in Democratic Republic of CongoInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Developing Digital Fluency in Early Education: Narratives of Elementary School TeachersDocument11 pagesDeveloping Digital Fluency in Early Education: Narratives of Elementary School TeachersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Intrusion Detection System with Ensemble Machine Learning Approaches using VotingClassifierDocument4 pagesIntrusion Detection System with Ensemble Machine Learning Approaches using VotingClassifierInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Crop Monitoring System with Water Moisture Levels Using ControllerDocument8 pagesCrop Monitoring System with Water Moisture Levels Using ControllerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Naturopathic Approaches to Relieving Constipation: Effective Natural Treatments and TherapiesDocument9 pagesNaturopathic Approaches to Relieving Constipation: Effective Natural Treatments and TherapiesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Inclusive Leadership in the South African Police Service (SAPS)Document26 pagesInclusive Leadership in the South African Police Service (SAPS)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Optimizing Bio-Implant Materials for Femur Bone Replacement:A Multi-Criteria Analysis and Finite Element StudyDocument5 pagesOptimizing Bio-Implant Materials for Femur Bone Replacement:A Multi-Criteria Analysis and Finite Element StudyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Year Wise Analysis and Prediction of Gold RatesDocument8 pagesYear Wise Analysis and Prediction of Gold RatesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Synthetic and Natural Vitamin C Modulation of Leaded Paint-Induced Nephrotoxicity of Automobile Painters in Ile-Ife, Nigeria.Document21 pagesSynthetic and Natural Vitamin C Modulation of Leaded Paint-Induced Nephrotoxicity of Automobile Painters in Ile-Ife, Nigeria.International Journal of Innovative Science and Research TechnologyNo ratings yet

- Design and Implementation of Software-Defined ReceiverDocument8 pagesDesign and Implementation of Software-Defined ReceiverInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Financial Prudence as Determinant of Employees’ Interest in Graduate StudyDocument13 pagesFinancial Prudence as Determinant of Employees’ Interest in Graduate StudyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Role of Leadership Training in Developing Effective Police SupervisorsDocument17 pagesThe Role of Leadership Training in Developing Effective Police SupervisorsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Fahfi/Mochaina Illegal Gambling Activities and its Average Turnover within Limpopo ProvinceDocument8 pagesFahfi/Mochaina Illegal Gambling Activities and its Average Turnover within Limpopo ProvinceInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Whyte Human Rights and The Collateral Damage oDocument16 pagesWhyte Human Rights and The Collateral Damage ojswhy1No ratings yet

- Data Sheets Ecc I On AdoraDocument23 pagesData Sheets Ecc I On AdoraAlanAvtoNo ratings yet

- OutDocument318 pagesOutBet HalNo ratings yet

- A Kinsha 2013Document698 pagesA Kinsha 2013alexander2beshkovNo ratings yet

- Dermatology TreatmentsDocument6 pagesDermatology TreatmentsMayar MostafaNo ratings yet

- Email Writing by Syeda Narjis FatimaDocument38 pagesEmail Writing by Syeda Narjis FatimaBadar MughairaNo ratings yet

- Drill #1 With RationaleDocument12 pagesDrill #1 With RationaleRellie CastroNo ratings yet

- Not in His Image (15th Anniversary Edition) - Preface and IntroDocument17 pagesNot in His Image (15th Anniversary Edition) - Preface and IntroChelsea Green PublishingNo ratings yet

- International Law: Savarkar CaseDocument15 pagesInternational Law: Savarkar CaseArunesh Chandra100% (1)

- Answer KeyDocument21 pagesAnswer KeyJunem S. Beli-otNo ratings yet

- Electric Circuits - M. Navhi and J. A. Edminister PDFDocument113 pagesElectric Circuits - M. Navhi and J. A. Edminister PDFNamratha ThataNo ratings yet

- Case Digest Extinguishment of ObligationsDocument25 pagesCase Digest Extinguishment of ObligationsLyneth GarciaNo ratings yet

- Annual Return For A Company Limited by GuaranteeDocument4 pagesAnnual Return For A Company Limited by GuaranteeAtisang Tonny SethNo ratings yet

- Multiple Choice - JOCDocument14 pagesMultiple Choice - JOCMuriel MahanludNo ratings yet

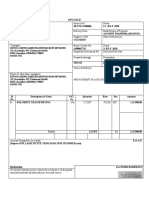

- Invoice: Qrt. No - : Cc-15, Civil Township Rourkela, Dist - (Sundargarh (Odisha) - 769012 GSTIN - 21ACWFS2234G1Z4Document2 pagesInvoice: Qrt. No - : Cc-15, Civil Township Rourkela, Dist - (Sundargarh (Odisha) - 769012 GSTIN - 21ACWFS2234G1Z4PUNYASHLOK PANDANo ratings yet

- Muscle Memo Workout - Guitar Coach MagDocument28 pagesMuscle Memo Workout - Guitar Coach Magpeterd87No ratings yet

- Question Bank FormatDocument5 pagesQuestion Bank Formatmahidpr18No ratings yet

- SPOUSES SALVADOR ABELLA v. SPOUSES ROMEO ABELLADocument2 pagesSPOUSES SALVADOR ABELLA v. SPOUSES ROMEO ABELLAAlia Arnz-Dragon100% (1)

- R30 CFA Level 3Document19 pagesR30 CFA Level 3Ashna0188No ratings yet

- Year3 GL Style Maths Practice Paper PrintableDocument4 pagesYear3 GL Style Maths Practice Paper PrintableLolo ImgNo ratings yet

- Republic of Rhetoric by Abhinav ChandrachudDocument356 pagesRepublic of Rhetoric by Abhinav ChandrachudVinayak Gupta100% (1)

- A Legal Walkway For Business Success: Le IntelligensiaDocument63 pagesA Legal Walkway For Business Success: Le IntelligensiaSanjay PrakashNo ratings yet

- Present Continuous - Present Simple Vs Present ContinuousDocument2 pagesPresent Continuous - Present Simple Vs Present ContinuouseewuanNo ratings yet

- Metaverse Report - Thought Leadership 1Document17 pagesMetaverse Report - Thought Leadership 1Tejas KNo ratings yet

- APPLICATION FOR REGISTRATION/ACCREDITATION AS AN ECOZONE SERVICE ENTERPRISE (For Customs Broker, Freight Forwarder/Trucker and Security Agency)Document7 pagesAPPLICATION FOR REGISTRATION/ACCREDITATION AS AN ECOZONE SERVICE ENTERPRISE (For Customs Broker, Freight Forwarder/Trucker and Security Agency)Albert YsegNo ratings yet

- Diagnostic Exam 2Document5 pagesDiagnostic Exam 2Tomzki Cornelio50% (2)

- TVGOS Training ManualDocument44 pagesTVGOS Training ManualFranciscoStarNo ratings yet