Professional Documents

Culture Documents

345GC Brochure

345GC Brochure

Uploaded by

Ros SocheaCopyright:

Available Formats

You might also like

- Komatsu 170 Parts ManualDocument5 pagesKomatsu 170 Parts Manualmuhammad ali100% (1)

- Ficha Técnica CAT323D3Document16 pagesFicha Técnica CAT323D3Milson MoreiraNo ratings yet

- Failure Code (Da2Rmc) Can Discon (Pump Controller Detected) - Komatsu Galeo PC138US-8 Shop Manual (Page 599) ManualsLibDocument1 pageFailure Code (Da2Rmc) Can Discon (Pump Controller Detected) - Komatsu Galeo PC138US-8 Shop Manual (Page 599) ManualsLibjames frankNo ratings yet

- BEML Product VehicleDocument5 pagesBEML Product VehicleSohibul AminNo ratings yet

- ZX110 - 135TO - Technical Manual (Operational Principle)Document307 pagesZX110 - 135TO - Technical Manual (Operational Principle)Kike MesaNo ratings yet

- R140W 9SDocument182 pagesR140W 9SАлександр БрусовNo ratings yet

- PC130F-7 4Document14 pagesPC130F-7 4Aditya Wisnu Wardhana100% (2)

- Series: L&T-Komatsu LimitedDocument4 pagesSeries: L&T-Komatsu LimitedAshokNo ratings yet

- PC1250-11 Eenss20363 2203Document20 pagesPC1250-11 Eenss20363 2203amelNo ratings yet

- Product Presentation CLG925 D: Customer Support DepartmentDocument30 pagesProduct Presentation CLG925 D: Customer Support DepartmentVanHieu LuyenNo ratings yet

- Kobelco Construction Machinery Co.,LtdDocument16 pagesKobelco Construction Machinery Co.,LtdAshokNo ratings yet

- ECR First Generation ModelsDocument8 pagesECR First Generation ModelsMMM-MMMNo ratings yet

- Profi Tractor Guide-Six Cylinder Models 2018 0 PDFDocument23 pagesProfi Tractor Guide-Six Cylinder Models 2018 0 PDFGroupement foncier agricole KerlambertNo ratings yet

- Hitachi Hydraulic Excavator Zx470 7 Zx670 7 Zx870 7 Class Operators Manual Enmjaq En1 2Document17 pagesHitachi Hydraulic Excavator Zx470 7 Zx670 7 Zx870 7 Class Operators Manual Enmjaq En1 2mskimberlymclaughlin080893cprNo ratings yet

- Komatsu HM400-3M0Document16 pagesKomatsu HM400-3M0Jorge Reyes AguilarNo ratings yet

- Sebp5810 00 00 AllDocument625 pagesSebp5810 00 00 AllAlan AyaNo ratings yet

- 336 EngDocument16 pages336 EngPample HouetteNo ratings yet

- SM PC200,210,220,230LC-6 96514,96514,30980,52852,10177 Sebd010106 PDFDocument1,278 pagesSM PC200,210,220,230LC-6 96514,96514,30980,52852,10177 Sebd010106 PDFHeber AgurtoNo ratings yet

- Sany Sy75c Excavator 4pg Specsheet d1Document4 pagesSany Sy75c Excavator 4pg Specsheet d1Nathan ScarpaNo ratings yet

- Excavator: Cummins 6C-8.3 152 KW (204 HP) 31,800 KG 1.4 - 1.6 M Cummins 6C-8.3 174 KW (233 HP) 35,000 KG 1.6 - 1.9 MDocument13 pagesExcavator: Cummins 6C-8.3 152 KW (204 HP) 31,800 KG 1.4 - 1.6 M Cummins 6C-8.3 174 KW (233 HP) 35,000 KG 1.6 - 1.9 MFitra noviandaNo ratings yet

- B Series ModelsDocument10 pagesB Series ModelsMMM-MMMNo ratings yet

- Komatsu PW150ES-6K - K35001 Operation & Maintenance ManualDocument277 pagesKomatsu PW150ES-6K - K35001 Operation & Maintenance ManualZvezdan Miladinović100% (1)

- Hydraulic ExcavatorsDocument24 pagesHydraulic ExcavatorsGuido MarconiNo ratings yet

- AP - (Standarisasi Sparepart Sesuai Dengan Policy Maintenance (Target 15 Item) )Document3 pagesAP - (Standarisasi Sparepart Sesuai Dengan Policy Maintenance (Target 15 Item) )Muhammad FatahillahNo ratings yet

- Content: R410A Tropical Split Type AC Technical Manual ContentDocument166 pagesContent: R410A Tropical Split Type AC Technical Manual ContentRizwanNo ratings yet

- SK130 10 PDFDocument8 pagesSK130 10 PDFSuper SxNo ratings yet

- Caterpillar 740B Articulated Dump Truck Specs & Dimensions - RitchieSpecsDocument7 pagesCaterpillar 740B Articulated Dump Truck Specs & Dimensions - RitchieSpecsSandipNo ratings yet

- Komatsu PC 300 Service ManualDocument747 pagesKomatsu PC 300 Service ManualMiguel Valter100% (1)

- Courtesy of Machine - MarketDocument9 pagesCourtesy of Machine - MarketAkkhaded SrionNo ratings yet

- Hitachi ZX330LC-5G Ka-En249Document11 pagesHitachi ZX330LC-5G Ka-En249li longNo ratings yet

- 345BL II InglésDocument30 pages345BL II InglésAlvaro HSNo ratings yet

- Excavatoare Pneuri KomatsuDocument24 pagesExcavatoare Pneuri Komatsucercel63100% (1)

- GD675-3EO 51000 UpDocument307 pagesGD675-3EO 51000 UpPepeTRBKNo ratings yet

- BD Report 12Document54 pagesBD Report 12Kcc Alwar100% (1)

- L Series Crawler Dozers: 1650L XLT 1650L WT 1650L LGPDocument12 pagesL Series Crawler Dozers: 1650L XLT 1650L WT 1650L LGPJefri Heriyanto PanjaitanNo ratings yet

- Harga Spare Part 2022Document2 pagesHarga Spare Part 2022mar rhumy100% (1)

- Mitsu Sr6 PtaDocument80 pagesMitsu Sr6 PtaAlmasNo ratings yet

- May Catalogue pg1-44Document44 pagesMay Catalogue pg1-44Aten HarisNo ratings yet

- Wdc390-En-00 2Document412 pagesWdc390-En-00 2alexzandr81No ratings yet

- Rerecomadantion Part List 2Document1 pageRerecomadantion Part List 2planner samulosNo ratings yet

- Costruction Book5Document116 pagesCostruction Book5Rifqi FajriNo ratings yet

- KTC Parts Price From TenderDocument59 pagesKTC Parts Price From Tenderboobalan_shriNo ratings yet

- KomatsuDocument16 pagesKomatsuGeorge BowenNo ratings yet

- PC200-8 (THA) SN 70000-UpDocument517 pagesPC200-8 (THA) SN 70000-UpLerd Bounphamaly100% (1)

- Cab Glass Draco CatalogDocument9 pagesCab Glass Draco CatalogSoni WagitiNo ratings yet

- Aaa VolvoDocument1 pageAaa Volvohaitham AtefNo ratings yet

- Unigrout Flex M - Technical Specification - EnglishDocument8 pagesUnigrout Flex M - Technical Specification - EnglishEmrah MertyürekNo ratings yet

- DX200ADocument11 pagesDX200AasepNo ratings yet

- D21P-8 (JPN) - Interim Tier4 Ten00269-03 O&mDocument197 pagesD21P-8 (JPN) - Interim Tier4 Ten00269-03 O&mhaimay118No ratings yet

- D85EX-15 Operator CabDocument9 pagesD85EX-15 Operator CabQuy Le Thanh100% (1)

- XG932III SpecsDocument3 pagesXG932III SpecsDiego GonzálezNo ratings yet

- ProductBrochure EC250D EC300D EN C4 20026776-BDocument36 pagesProductBrochure EC250D EC300D EN C4 20026776-Bbabacar keita0% (1)

- Checking The High-Pressure Relief Valve For Leakage On C6.6 and C4.4 EnginesDocument5 pagesChecking The High-Pressure Relief Valve For Leakage On C6.6 and C4.4 Enginesahmed mohamedNo ratings yet

- TEN00356 01 (Jun10)Document391 pagesTEN00356 01 (Jun10)zarni zarniNo ratings yet

- Rent Receipt FormatDocument1 pageRent Receipt FormatRobert SinatraNo ratings yet

- 5e866553688a683b44df6822 - PC18MR-3 ManualDocument284 pages5e866553688a683b44df6822 - PC18MR-3 ManualTrung LêNo ratings yet

- Allison 6630 Ors Pressure CheckDocument3 pagesAllison 6630 Ors Pressure CheckNoor Rahman100% (1)

- Excavator: Cummins QSB 4.5 84.3 KW (113 HP) 15,400 KG 0.6 MDocument9 pagesExcavator: Cummins QSB 4.5 84.3 KW (113 HP) 15,400 KG 0.6 MKoay B HNo ratings yet

- CM20181112 50357 30701Document12 pagesCM20181112 50357 30701vitaliyNo ratings yet

- Optimization of The Fleet Per Shovel Productivity in Surface Mining Case Study of Chilanga Cement Lusaka ZambiaDocument17 pagesOptimization of The Fleet Per Shovel Productivity in Surface Mining Case Study of Chilanga Cement Lusaka ZambiaRos SocheaNo ratings yet

- Ahsh77 Operator Manual CompressedDocument362 pagesAhsh77 Operator Manual CompressedRos SocheaNo ratings yet

- Crushing Process: Trainer: Mr. SEM Kosal Trainee: SOCHEA RosDocument12 pagesCrushing Process: Trainer: Mr. SEM Kosal Trainee: SOCHEA RosRos SocheaNo ratings yet

- Dump Truck Cycle TimeDocument1 pageDump Truck Cycle TimeRos SocheaNo ratings yet

- Quarry Department: Trainee: ROS Sochea Position: Junior Engineer Trainee Trainer: TUY ChhunlengDocument20 pagesQuarry Department: Trainee: ROS Sochea Position: Junior Engineer Trainee Trainer: TUY ChhunlengRos SocheaNo ratings yet

- Safety Training: Name: Mr. Sochea ROS Trainer: Khun. CHAIWAT LampikulsarpDocument13 pagesSafety Training: Name: Mr. Sochea ROS Trainer: Khun. CHAIWAT LampikulsarpRos SocheaNo ratings yet

- Grad ReportDocument92 pagesGrad ReportHaitham Mohammed Fawzy Ali Ali ElshaterNo ratings yet

- Week 1-Elements of Communication system-COMS3100-20202Document16 pagesWeek 1-Elements of Communication system-COMS3100-20202Mesut OzilNo ratings yet

- Human Resource Information Systems 2nd Edition Kavanagh Test BankDocument9 pagesHuman Resource Information Systems 2nd Edition Kavanagh Test Bankdulciethanhonjja4No ratings yet

- Quotation For OIS PriceDocument4 pagesQuotation For OIS PriceKasarachi AmadiNo ratings yet

- Unit 2 Installation and Configuration of AndroidDocument23 pagesUnit 2 Installation and Configuration of AndroidAtharv KadamNo ratings yet

- Project Scope Management: Study NotesDocument18 pagesProject Scope Management: Study NotesHammad AhmedNo ratings yet

- Endsem Question Paper DSADocument18 pagesEndsem Question Paper DSAayushNo ratings yet

- Eic 2024 FlyerDocument1 pageEic 2024 FlyerREMUS LIM HONG YI HCINo ratings yet

- AF33-5 Low Range - First Gear, Engine BrakingDocument4 pagesAF33-5 Low Range - First Gear, Engine BrakinggabotoyoNo ratings yet

- TSB Gen 042Document3 pagesTSB Gen 042Trọng Nghĩa VõNo ratings yet

- Uni Wuppertal Bachelor Thesis FormatDocument7 pagesUni Wuppertal Bachelor Thesis Formatheatherreimerpeoria100% (2)

- Series: ADS-B TransponderDocument2 pagesSeries: ADS-B TransponderIvo SilvaNo ratings yet

- Introduction To: NosqlDocument27 pagesIntroduction To: NosqlDileepp ChoudharyNo ratings yet

- 590 Super R 695 Super R: Section 41 - Steering SystemDocument34 pages590 Super R 695 Super R: Section 41 - Steering SystemTeknik MakinaNo ratings yet

- Cose222 HW4Document5 pagesCose222 HW4namwindowsNo ratings yet

- Dwnload Full Digital Signal Processing Using Matlab A Problem Solving Companion 4th Edition Ingle Solutions Manual PDFDocument36 pagesDwnload Full Digital Signal Processing Using Matlab A Problem Solving Companion 4th Edition Ingle Solutions Manual PDFhaodienb6qj100% (19)

- Prelim GenchemDocument5 pagesPrelim GenchemAd DesignNo ratings yet

- Critical Information Summary: NBN™ Month-To-Month Plan (Consumer)Document2 pagesCritical Information Summary: NBN™ Month-To-Month Plan (Consumer)Imtiaz AzizNo ratings yet

- Chapter 2: Bringing Systems Into BeingDocument39 pagesChapter 2: Bringing Systems Into BeingKhaled ShabanNo ratings yet

- Operations Strategies 101-StrategyDocument17 pagesOperations Strategies 101-StrategySisieNo ratings yet

- ACHIEVEMENT TEST IN MATHEMATICS 3 - Cover SheetDocument2 pagesACHIEVEMENT TEST IN MATHEMATICS 3 - Cover SheetErnal Jovit GavinoNo ratings yet

- Lec04.UDP LinhdtDocument16 pagesLec04.UDP LinhdtHọc Sinh Nghiêm TúcNo ratings yet

- Installation Guide Arch LinuxDocument7 pagesInstallation Guide Arch Linuxlga_scribdNo ratings yet

- Daily Drilling Report: Danan Oilfield DevelopmentDocument3 pagesDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNo ratings yet

- Chapter 7 Demonstrate The Pan in Linux System: 7.1 DemonstrationDocument14 pagesChapter 7 Demonstrate The Pan in Linux System: 7.1 DemonstrationStanislaus Ivantius LimampauwNo ratings yet

- STS - Industrial Revolution (Manabat, Angelika Mae C. - BSBA-MM2A)Document5 pagesSTS - Industrial Revolution (Manabat, Angelika Mae C. - BSBA-MM2A)Angelika Mae ManabatNo ratings yet

- Nomi CVDocument2 pagesNomi CVFozia AnsariNo ratings yet

- Business Presentation: This Is A Subtitle That Can Be EditedDocument15 pagesBusiness Presentation: This Is A Subtitle That Can Be Editedharold hurseNo ratings yet

- Drill Quip PDFDocument8 pagesDrill Quip PDFyasamanNo ratings yet

- Dead-Tank Circuit-Breakers For 72.5 KV Up To 550 KV: Fig. 12: SPS2 / 3AP1 DT 145 KVDocument7 pagesDead-Tank Circuit-Breakers For 72.5 KV Up To 550 KV: Fig. 12: SPS2 / 3AP1 DT 145 KVMichael DavisNo ratings yet

345GC Brochure

345GC Brochure

Uploaded by

Ros SocheaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

345GC Brochure

345GC Brochure

Uploaded by

Ros SocheaCopyright:

Available Formats

345 GC

HYDRAULIC EXCAVATOR

Engine Power 258 kW (346 hp)

Operating Weight 42 200 kg (93,000 lb)

Cat® C9.3B engine meets Brazil MAR-1 and China Nonroad Stage III emission standards, equivalent to U.S. EPA Tier 3 and EU Stage IIIA.

NEXT GENERATION EXCAVATORS

Cat® Next Generation Excavators offer you more choices than ever for your business.

+ MORE MODEL OPTIONS

+ MORE STANDARD TECHNOLOGIES

+ MORE PRICE POINTS

Ready to help you make your business stronger, Cat Next Generation Excavators give you new ways to get the

most work done at the lowest cost – so you put more money in your pocket.

THE The CAT 345 GC offers you the ideal

balance of dependable performance,

CAT 345 GC ® operator productivity features, and

reduced costs. The Cat 345 GC is a

smart choice for operations where

high reliability and low-cost-per-hour

performance are priorities.

RELIABLE. COMFORTABLE. PRODUCTIVE.

2 345 GC HYDRAULIC EXCAVATOR

INCREASE FUEL EFFICIENCY WORK SMART. SAVE MONEY.

UP TO 25% 1

The Cat 345 GC is equipped with two power modes to help

A precise combination of lower engine speed and large manage fuel consumption for your specific applications:

hydraulic pump delivers more work per unit of fuel. Power Mode and the new Smart Mode.

1

Compared to 349D2 Tier 3 global fuel burn averages. Power Mode delivers maximum productivity in high-demand

applications like truck loading and trenching.

Smart Mode automatically matches engine speed and

hydraulic power to demand for the highest fuel efficiency

in any application.

Use Operator ID and the excavator will remember your

mode preference.

345 GC HYDRAULIC EXCAVATOR 3

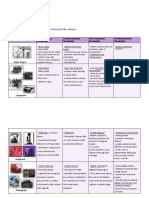

LOWER MAINTENANCE COSTS

UP TO 30%

With extended maintenance intervals, you get more done

345 GC

at a lower cost compared to the 349D2 Tier 3 excavator. INTERVAL

D2 SERIES NEXT

IMPROVEMENTS

Consolidated filter locations make service faster. Hydraulic, GENERATION

air, and fuel filters have increased capacity and longer life.

Interval Interval

– hours – hours

KEY MAINTENANCE COST REDUCTIONS INCLUDE:

Replace Fuel Filters 500 1,000

+ Consolidated filter locations to reduce service time.

+ Oil and fuel filters with extended maintenance intervals. Replace Hydraulic System

2,000 3,000

Return Filter

+ New hydraulic filter with higher dirt holding capacity.

Replace Hydraulic System No pilot

+ New Cat air filter with double the dust holding capacity 1,000

Pilot Filter filter needed

of the previous filter.

Clean mesh

Replace Hydraulic System

1,000 + magnet

Case Drain Filter

as needed

Replace Fuel Tank Cap Filter 1,000 2,000

Lube Swing Bearing 250 500

4 345 GC HYDRAULIC EXCAVATOR

CAT LINK TECHNOLOGY

TAKES THE GUESSWORK OUT OF MANAGING YOUR EQUIPMENT

CAT LINK telematics technology helps take the complexity out of managing your jobsites – by gathering data generated by your

equipment, materials, and people – and serving it up to you in customizable formats.

PRODUCT LINK™

Product Link™ collects data automatically and accurately

from your assets – any type and any brand. Information such as

location, hours, fuel usage, productivity, idle time, maintenance

alerts, diagnostic codes, and machine health can be viewed

online through web and mobile applications.

VISIONLINK®

Access information anytime, anywhere with VisionLink® –

and use it to make informed decisions that boost productivity,

lower costs, simplify maintenance, and improve safety and

security on your jobsite. With different subscription level options,

your Cat dealer can help you configure exactly what you need

to connect your fleet and manage your business, without paying

for extras you don’t want. Subscriptions are available with cellular

or satellite reporting (or both).

345 GC HYDRAULIC EXCAVATOR 5

CAB TAKES Sites where excavators typically

work are rugged and challenging.

THE HARD

That’s why it’s important that the

345 GC cab protects the operator

as much as possible from

OUT OF WORK fatigue, stresses, sounds, and

temperatures of the job.

WE’VE GOT YOUR BACK.

BACK PAIN IS ONE OF THE MOST

COMMON REASONS PEOPLE MISS WORK.*

NEW CAB:

All controls are in front of the

operator. That means almost

no twisting is required.

OLD CAB: 2,000+ twists a year to reach controls

in back of cab that can strain your back.

ASSUME 1 TWIST PER HOUR

1 TWIST × 8-HOUR WORKDAY = 8 TWISTS PER DAY

8 TWISTS × 5 WORKDAYS PER WEEK = 40 TWISTS PER WEEK

40 TWISTS × 52 WEEKS PER YEAR = 2,080 TWISTS PER YEAR

*SOURCE: HTTPS://WWW.NINDS.NIH.GOV/DISORDERS/PATIENT-CAREGIVER-

EDUCATION/FACT-SHEETS/LOW-BACK-PAIN-FACT-SHEET

ISO-CERTIFIED ALL-AROUND EASY ACCESS,

ROPS CAB VISIBILITY CONNECTIVITY,

The ISO-certified ROPS cab is sound Large windows at the front, sides, and AND STORAGE

suppressed and sealed. The windows rear give excellent visibility in all directions

Convenience features include Bluetooth®

and lower front profile of the machine from the operator seat. The ROPS structure

integrated radio, USB ports for charging

give outstanding visibility to the work uses narrow front cab pillars to allow a

and phone connectivity, 12V DC outlets

area without the strain of constantly wider field of view to the front. Plus, with

and AUX port, ample front and back

leaning forward. the standard rearview camera, operators

storage, and cup and bottle holders.

will always be aware of what’s surrounding

the excavator.

6 345 GC HYDRAULIC EXCAVATOR

TOUCHSCREEN MONITOR

Most machine settings can be controlled

through the high-resolution touchscreen

monitor. It offers 42 languages and is easy to

reach from the seat – no twisting or turning

to reach switches. A handy jog dial control

and shortcut keys are also ergonomically

positioned on the right console.

SEAT AND CONSOLE

Efficiency of movement is critical to keeping

operators productive and alert all shift long.

The 345 GC seat is wide and adjustable so

operators of any size can work comfortably.

CUSTOMIZABLE JOYSTICKS

Joystick function can be customized through

the monitor. Joystick pattern as well as

response can be set to match operator

preference. All preferences are saved

with Operator ID and restored at log in.

KEYLESS PUSH START

The 345 GC uses a keyless push-button

engine start. This adds security for the

machine by using Operator ID codes to limit

and track machine access. Codes can be

entered manually, via an optional Bluetooth

key fob, or smartphone app.

345 GC HYDRAULIC EXCAVATOR 7

1,148 WAYS TO STAY SAFE.

SAFETY FEATURES FACT:

SLIPPING IS ONE OF THE

BIGGEST CONTRIBUTORS

LOOK OUT FOR YOUR PEOPLE TO WORKPLACE INJURIES.*

AND YOUR EQUIPMENT

Routine maintenance checks can be performed faster, easier,

and safer with ground-level access to the air precleaner, the

fuel water separator, fuel tank water and sediment drains, and

cooling system coolant level check. Getting up to the engine

compartment is aided with handrails and anti-skid surfaces.

KEEP YOUR EXCAVATOR SECURE

Use your PIN code on the monitor, the optional Bluetooth

key fob, or your smartphone to enable the push-button OUR ANTI-SKID PLATES FEATURE

starting feature. 1,000+ INDIVIDUAL PERFORATIONS

FOR BETTER TRACTION

*SOURCE: HTTPS://WWW.OSHA.GOV/DTE/GRANT_MATERIALS/FY07/SH-16625-07/SLIPSTRIPSFALLS.PPT

8 345 GC HYDRAULIC EXCAVATOR

INCREASE YOUR PRODUCTIVITY AND PROFIT

WITH CAT ATTACHMENTS

You can easily expand the performance of your machine by utilizing any of the variety of Cat attachments.

Each Cat attachment is designed to fit the weight and horsepower of Cat excavators for improved

performance, safety, and stability.

BUCKETS HYDRAULIC HAMMERS PREVENT HAMMER WEAR AND TEAR

Auto hammer stop shuts the hammer

off after 30 seconds of continuous

firing to prevent the tool and excavator

from overworking.

ATTACHMENT

TRACKING

MADE EASY

The Cat PL161 Attachment

Locator is a Bluetooth device that

makes finding your attachments

QUICK COUPLERS VIBRATORY PLATE COMPACTORS

and other gear quick and easy.

The Cat App on your phone will

locate the device automatically.

345 GC HYDRAULIC EXCAVATOR 9

TECHNICAL SPECIFICATIONS

See cat.com for complete specifications.

ENGINE DIMENSIONS

Engine Model C9.3B Boom Reach 6.9 m (22'8")

Engine Power – ISO 9249 258 kW 346 hp Stick Reach R2.9TB (9'6")

Engine Power – ISO 14396 259 kW 347 hp Bucket HD 2.41 m³ (3.15 yd³)

Engine RPM Shipping Height (top of cab) 3230 mm 10'7"

Operation 1,750 rpm Handrail Height 3370 mm 11'0"

Travel 1,900 rpm Shipping Length 11 620 mm 38'1"

Bore 115 mm 5 in Tail Swing Radius 3530 mm 11'6"

Stroke 149 mm 6 in Counterweight Clearance 1300 mm 4'3"

Displacement 9.3 L 568 in³ Ground Clearance 520 mm 1'8"

Track Length 5030 mm 16'6"

HYDRAULIC SYSTEM

Length to Center of Rollers 4040 mm 13'3"

Main System – Maximum Flow – Implement 630 L/min 166 gal/min

(315 L/min (83 gal/min Track Gauge 2740 mm 8'11"

× 2 pumps) × 2 pumps) Transport Width – 600 mm (24") Shoes 3340 mm 10'11"

Maximum Pressure – Equipment – Implement 35 000 kPa 5,076 psi

WORKING RANGES AND FORCES

Maximum Pressure – Travel 35 000 kPa 5,076 psi

Boom Reach 6.9 m (22'8")

Maximum Pressure – Swing 28 000 kPa 4,061 psi

Stick Reach R2.9TB (9'6")

SWING MECHANISM Bucket HD 2.41 m³ (3.15 yd³)

Swing Speed 8.27 rpm Maximum Digging Depth 7200 mm 23'7"

Maximum Swing Torque 155 kN·m 114,543 lbf-ft Maximum Reach at Ground Line 11 290 mm 37'0"

WEIGHTS Maximum Cutting Height 10 540 mm 34'6"

Operating Weight 42 200 kg 93,000 lb Maximum Loading Height 7210 mm 23'7"

Reach boom, R2.9TB (9'6") stick, HD 2.41 m³ (3.15 yd³) bucket, 600 mm (24") Minimum Loading Height 3130 mm 10'3"

double grouser shoes, 9 mt (19,842 lb) counterweight. Maximum Depth Cut for 2240 mm (8'0") 7040 mm 23'1"

Level Bottom

SERVICE REFILL CAPACITIES

Maximum Vertical Wall Digging Depth 5390 mm 17'8"

Fuel Tank Capacity 600 L 158.5 gal

Bucket Digging Force (ISO) 235 kN 52,860 lbf

Cooling System 40 L 10.5 gal

Stick Digging Force (ISO) 198 kN 44,550 lbf

Engine Oil (with filter) 32 L 8.5 gal

Swing Drive 18 L 4.8 gal

Final Drive (each) 8L 2.1 gal

Hydraulic System (including tank) 423 L 111.7 gal

Hydraulic Tank (including suction pipe) 186 L 49.1 gal

10 345 GC HYDRAULIC EXCAVATOR

STANDARD & OPTIONAL EQUIPMENT

Standard and optional equipment may vary. Consult your Cat dealer for details.

CAB STANDARD OPTIONAL BOOMS AND STICKS STANDARD OPTIONAL

ROPS, standard sound suppression 6.55 m (21'6") Mass boom

High-resolution 203 mm (8 in) 6.9 m (22'8") Reach boom

LCD touchscreen monitor

2.55 m (8'4") Mass stick

Mechanically adjustable seat

2.9 m (9'6") Reach stick

ENGINE STANDARD OPTIONAL 2.9 m (9'6") HD Reach stick

Cold start block heaters 3.0 m (9'10") Mass stick

Two selectable modes: Power, Smart 3.35 m (11'0") Reach stick

Automatic engine speed control 3.35 m (11') HD Reach stick

Up to 3300 m (10,830 ft) altitude capability

ELECTRICAL SYSTEM STANDARD OPTIONAL

52° C (126° F) high-ambient cooling capacity

Maintenance-free 1,000 CCA batteries (×2)

–18° C (0° F) cold start capability

Centralized electrical disconnect switch

–32° C (–25° F) cold start capability

LED chassis light, RH and LH boom lights,

Double element air filter with cab lights

integrated precleaner

CAT TECHNOLOGY STANDARD OPTIONAL

Biodiesel capability up to B20

Cat Product Link

HYDRAULIC SYSTEM STANDARD OPTIONAL

Auto Hammer Stop

Boom and stick regeneration circuit

SERVICE AND MAINTENANCE STANDARD OPTIONAL

Electronic main control valve

Automatic hydraulic oil warm up Grouped location of engine oil and fuel filters

Reverse swing damping valve Scheduled Oil Sampling (S·O·SSM)

sampling ports

Automatic swing parking brake

Electric refueling pump with automatic shutoff

High performance hydraulic return filter

Two speed travel SAFETY AND SECURITY STANDARD OPTIONAL

Bio hydraulic oil capability Caterpillar One Key security system

Fine swing Lockable external tool/storage box

Combined two-way auxiliary circuit Lockable door, fuel, and hydraulic tank locks

Combined two-way auxiliary circuit Lockable fuel drain compartment

with hammer return filter Service platform with anti-skid plate

and recessed bolts

UNDERCARRIAGE AND STRUCTURES STANDARD OPTIONAL

RH handrail and hand hold

Long undercarriage (ISO 2867:2011 Compliant)

Towing eye on base frame Signaling/warning horn

9 mt (19,842 lb) counterweight Standard visibility mirror package

600 mm (24") double grouser, triple grouser, Ground-level secondary engine

HD triple grouser track shoes shutoff switch

700 mm (28") triple grouser track shoes Rearview camera and right-hand-side mirror

Not all features are available in all regions. Please check with your local Cat dealer for specific offering availability in your area.

For additional information, refer to the Technical Specifications brochures for the 345 GC available at www.cat.com or your Cat dealer.

345 GC HYDRAULIC EXCAVATOR 11

For more complete information on Cat products, dealer services and industry solutions, visit us on the web AEXQ2465-01

at www.cat.com Replaces AEXQ2465

Build Number: 07B

© 2019 Caterpillar. All Rights Reserved.

VisionLink is a trademark of Trimble Navigation Limited, registered in the United States and in other countries.

Materials and specifications are subject to change without notice. Featured machines in photos may include

additional equipment. See your Cat dealer for available options.

CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Yellow,” the “Power Edge”

and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks

of Caterpillar and may not be used without permission.

www.cat.com www.caterpillar.com

You might also like

- Komatsu 170 Parts ManualDocument5 pagesKomatsu 170 Parts Manualmuhammad ali100% (1)

- Ficha Técnica CAT323D3Document16 pagesFicha Técnica CAT323D3Milson MoreiraNo ratings yet

- Failure Code (Da2Rmc) Can Discon (Pump Controller Detected) - Komatsu Galeo PC138US-8 Shop Manual (Page 599) ManualsLibDocument1 pageFailure Code (Da2Rmc) Can Discon (Pump Controller Detected) - Komatsu Galeo PC138US-8 Shop Manual (Page 599) ManualsLibjames frankNo ratings yet

- BEML Product VehicleDocument5 pagesBEML Product VehicleSohibul AminNo ratings yet

- ZX110 - 135TO - Technical Manual (Operational Principle)Document307 pagesZX110 - 135TO - Technical Manual (Operational Principle)Kike MesaNo ratings yet

- R140W 9SDocument182 pagesR140W 9SАлександр БрусовNo ratings yet

- PC130F-7 4Document14 pagesPC130F-7 4Aditya Wisnu Wardhana100% (2)

- Series: L&T-Komatsu LimitedDocument4 pagesSeries: L&T-Komatsu LimitedAshokNo ratings yet

- PC1250-11 Eenss20363 2203Document20 pagesPC1250-11 Eenss20363 2203amelNo ratings yet

- Product Presentation CLG925 D: Customer Support DepartmentDocument30 pagesProduct Presentation CLG925 D: Customer Support DepartmentVanHieu LuyenNo ratings yet

- Kobelco Construction Machinery Co.,LtdDocument16 pagesKobelco Construction Machinery Co.,LtdAshokNo ratings yet

- ECR First Generation ModelsDocument8 pagesECR First Generation ModelsMMM-MMMNo ratings yet

- Profi Tractor Guide-Six Cylinder Models 2018 0 PDFDocument23 pagesProfi Tractor Guide-Six Cylinder Models 2018 0 PDFGroupement foncier agricole KerlambertNo ratings yet

- Hitachi Hydraulic Excavator Zx470 7 Zx670 7 Zx870 7 Class Operators Manual Enmjaq En1 2Document17 pagesHitachi Hydraulic Excavator Zx470 7 Zx670 7 Zx870 7 Class Operators Manual Enmjaq En1 2mskimberlymclaughlin080893cprNo ratings yet

- Komatsu HM400-3M0Document16 pagesKomatsu HM400-3M0Jorge Reyes AguilarNo ratings yet

- Sebp5810 00 00 AllDocument625 pagesSebp5810 00 00 AllAlan AyaNo ratings yet

- 336 EngDocument16 pages336 EngPample HouetteNo ratings yet

- SM PC200,210,220,230LC-6 96514,96514,30980,52852,10177 Sebd010106 PDFDocument1,278 pagesSM PC200,210,220,230LC-6 96514,96514,30980,52852,10177 Sebd010106 PDFHeber AgurtoNo ratings yet

- Sany Sy75c Excavator 4pg Specsheet d1Document4 pagesSany Sy75c Excavator 4pg Specsheet d1Nathan ScarpaNo ratings yet

- Excavator: Cummins 6C-8.3 152 KW (204 HP) 31,800 KG 1.4 - 1.6 M Cummins 6C-8.3 174 KW (233 HP) 35,000 KG 1.6 - 1.9 MDocument13 pagesExcavator: Cummins 6C-8.3 152 KW (204 HP) 31,800 KG 1.4 - 1.6 M Cummins 6C-8.3 174 KW (233 HP) 35,000 KG 1.6 - 1.9 MFitra noviandaNo ratings yet

- B Series ModelsDocument10 pagesB Series ModelsMMM-MMMNo ratings yet

- Komatsu PW150ES-6K - K35001 Operation & Maintenance ManualDocument277 pagesKomatsu PW150ES-6K - K35001 Operation & Maintenance ManualZvezdan Miladinović100% (1)

- Hydraulic ExcavatorsDocument24 pagesHydraulic ExcavatorsGuido MarconiNo ratings yet

- AP - (Standarisasi Sparepart Sesuai Dengan Policy Maintenance (Target 15 Item) )Document3 pagesAP - (Standarisasi Sparepart Sesuai Dengan Policy Maintenance (Target 15 Item) )Muhammad FatahillahNo ratings yet

- Content: R410A Tropical Split Type AC Technical Manual ContentDocument166 pagesContent: R410A Tropical Split Type AC Technical Manual ContentRizwanNo ratings yet

- SK130 10 PDFDocument8 pagesSK130 10 PDFSuper SxNo ratings yet

- Caterpillar 740B Articulated Dump Truck Specs & Dimensions - RitchieSpecsDocument7 pagesCaterpillar 740B Articulated Dump Truck Specs & Dimensions - RitchieSpecsSandipNo ratings yet

- Komatsu PC 300 Service ManualDocument747 pagesKomatsu PC 300 Service ManualMiguel Valter100% (1)

- Courtesy of Machine - MarketDocument9 pagesCourtesy of Machine - MarketAkkhaded SrionNo ratings yet

- Hitachi ZX330LC-5G Ka-En249Document11 pagesHitachi ZX330LC-5G Ka-En249li longNo ratings yet

- 345BL II InglésDocument30 pages345BL II InglésAlvaro HSNo ratings yet

- Excavatoare Pneuri KomatsuDocument24 pagesExcavatoare Pneuri Komatsucercel63100% (1)

- GD675-3EO 51000 UpDocument307 pagesGD675-3EO 51000 UpPepeTRBKNo ratings yet

- BD Report 12Document54 pagesBD Report 12Kcc Alwar100% (1)

- L Series Crawler Dozers: 1650L XLT 1650L WT 1650L LGPDocument12 pagesL Series Crawler Dozers: 1650L XLT 1650L WT 1650L LGPJefri Heriyanto PanjaitanNo ratings yet

- Harga Spare Part 2022Document2 pagesHarga Spare Part 2022mar rhumy100% (1)

- Mitsu Sr6 PtaDocument80 pagesMitsu Sr6 PtaAlmasNo ratings yet

- May Catalogue pg1-44Document44 pagesMay Catalogue pg1-44Aten HarisNo ratings yet

- Wdc390-En-00 2Document412 pagesWdc390-En-00 2alexzandr81No ratings yet

- Rerecomadantion Part List 2Document1 pageRerecomadantion Part List 2planner samulosNo ratings yet

- Costruction Book5Document116 pagesCostruction Book5Rifqi FajriNo ratings yet

- KTC Parts Price From TenderDocument59 pagesKTC Parts Price From Tenderboobalan_shriNo ratings yet

- KomatsuDocument16 pagesKomatsuGeorge BowenNo ratings yet

- PC200-8 (THA) SN 70000-UpDocument517 pagesPC200-8 (THA) SN 70000-UpLerd Bounphamaly100% (1)

- Cab Glass Draco CatalogDocument9 pagesCab Glass Draco CatalogSoni WagitiNo ratings yet

- Aaa VolvoDocument1 pageAaa Volvohaitham AtefNo ratings yet

- Unigrout Flex M - Technical Specification - EnglishDocument8 pagesUnigrout Flex M - Technical Specification - EnglishEmrah MertyürekNo ratings yet

- DX200ADocument11 pagesDX200AasepNo ratings yet

- D21P-8 (JPN) - Interim Tier4 Ten00269-03 O&mDocument197 pagesD21P-8 (JPN) - Interim Tier4 Ten00269-03 O&mhaimay118No ratings yet

- D85EX-15 Operator CabDocument9 pagesD85EX-15 Operator CabQuy Le Thanh100% (1)

- XG932III SpecsDocument3 pagesXG932III SpecsDiego GonzálezNo ratings yet

- ProductBrochure EC250D EC300D EN C4 20026776-BDocument36 pagesProductBrochure EC250D EC300D EN C4 20026776-Bbabacar keita0% (1)

- Checking The High-Pressure Relief Valve For Leakage On C6.6 and C4.4 EnginesDocument5 pagesChecking The High-Pressure Relief Valve For Leakage On C6.6 and C4.4 Enginesahmed mohamedNo ratings yet

- TEN00356 01 (Jun10)Document391 pagesTEN00356 01 (Jun10)zarni zarniNo ratings yet

- Rent Receipt FormatDocument1 pageRent Receipt FormatRobert SinatraNo ratings yet

- 5e866553688a683b44df6822 - PC18MR-3 ManualDocument284 pages5e866553688a683b44df6822 - PC18MR-3 ManualTrung LêNo ratings yet

- Allison 6630 Ors Pressure CheckDocument3 pagesAllison 6630 Ors Pressure CheckNoor Rahman100% (1)

- Excavator: Cummins QSB 4.5 84.3 KW (113 HP) 15,400 KG 0.6 MDocument9 pagesExcavator: Cummins QSB 4.5 84.3 KW (113 HP) 15,400 KG 0.6 MKoay B HNo ratings yet

- CM20181112 50357 30701Document12 pagesCM20181112 50357 30701vitaliyNo ratings yet

- Optimization of The Fleet Per Shovel Productivity in Surface Mining Case Study of Chilanga Cement Lusaka ZambiaDocument17 pagesOptimization of The Fleet Per Shovel Productivity in Surface Mining Case Study of Chilanga Cement Lusaka ZambiaRos SocheaNo ratings yet

- Ahsh77 Operator Manual CompressedDocument362 pagesAhsh77 Operator Manual CompressedRos SocheaNo ratings yet

- Crushing Process: Trainer: Mr. SEM Kosal Trainee: SOCHEA RosDocument12 pagesCrushing Process: Trainer: Mr. SEM Kosal Trainee: SOCHEA RosRos SocheaNo ratings yet

- Dump Truck Cycle TimeDocument1 pageDump Truck Cycle TimeRos SocheaNo ratings yet

- Quarry Department: Trainee: ROS Sochea Position: Junior Engineer Trainee Trainer: TUY ChhunlengDocument20 pagesQuarry Department: Trainee: ROS Sochea Position: Junior Engineer Trainee Trainer: TUY ChhunlengRos SocheaNo ratings yet

- Safety Training: Name: Mr. Sochea ROS Trainer: Khun. CHAIWAT LampikulsarpDocument13 pagesSafety Training: Name: Mr. Sochea ROS Trainer: Khun. CHAIWAT LampikulsarpRos SocheaNo ratings yet

- Grad ReportDocument92 pagesGrad ReportHaitham Mohammed Fawzy Ali Ali ElshaterNo ratings yet

- Week 1-Elements of Communication system-COMS3100-20202Document16 pagesWeek 1-Elements of Communication system-COMS3100-20202Mesut OzilNo ratings yet

- Human Resource Information Systems 2nd Edition Kavanagh Test BankDocument9 pagesHuman Resource Information Systems 2nd Edition Kavanagh Test Bankdulciethanhonjja4No ratings yet

- Quotation For OIS PriceDocument4 pagesQuotation For OIS PriceKasarachi AmadiNo ratings yet

- Unit 2 Installation and Configuration of AndroidDocument23 pagesUnit 2 Installation and Configuration of AndroidAtharv KadamNo ratings yet

- Project Scope Management: Study NotesDocument18 pagesProject Scope Management: Study NotesHammad AhmedNo ratings yet

- Endsem Question Paper DSADocument18 pagesEndsem Question Paper DSAayushNo ratings yet

- Eic 2024 FlyerDocument1 pageEic 2024 FlyerREMUS LIM HONG YI HCINo ratings yet

- AF33-5 Low Range - First Gear, Engine BrakingDocument4 pagesAF33-5 Low Range - First Gear, Engine BrakinggabotoyoNo ratings yet

- TSB Gen 042Document3 pagesTSB Gen 042Trọng Nghĩa VõNo ratings yet

- Uni Wuppertal Bachelor Thesis FormatDocument7 pagesUni Wuppertal Bachelor Thesis Formatheatherreimerpeoria100% (2)

- Series: ADS-B TransponderDocument2 pagesSeries: ADS-B TransponderIvo SilvaNo ratings yet

- Introduction To: NosqlDocument27 pagesIntroduction To: NosqlDileepp ChoudharyNo ratings yet

- 590 Super R 695 Super R: Section 41 - Steering SystemDocument34 pages590 Super R 695 Super R: Section 41 - Steering SystemTeknik MakinaNo ratings yet

- Cose222 HW4Document5 pagesCose222 HW4namwindowsNo ratings yet

- Dwnload Full Digital Signal Processing Using Matlab A Problem Solving Companion 4th Edition Ingle Solutions Manual PDFDocument36 pagesDwnload Full Digital Signal Processing Using Matlab A Problem Solving Companion 4th Edition Ingle Solutions Manual PDFhaodienb6qj100% (19)

- Prelim GenchemDocument5 pagesPrelim GenchemAd DesignNo ratings yet

- Critical Information Summary: NBN™ Month-To-Month Plan (Consumer)Document2 pagesCritical Information Summary: NBN™ Month-To-Month Plan (Consumer)Imtiaz AzizNo ratings yet

- Chapter 2: Bringing Systems Into BeingDocument39 pagesChapter 2: Bringing Systems Into BeingKhaled ShabanNo ratings yet

- Operations Strategies 101-StrategyDocument17 pagesOperations Strategies 101-StrategySisieNo ratings yet

- ACHIEVEMENT TEST IN MATHEMATICS 3 - Cover SheetDocument2 pagesACHIEVEMENT TEST IN MATHEMATICS 3 - Cover SheetErnal Jovit GavinoNo ratings yet

- Lec04.UDP LinhdtDocument16 pagesLec04.UDP LinhdtHọc Sinh Nghiêm TúcNo ratings yet

- Installation Guide Arch LinuxDocument7 pagesInstallation Guide Arch Linuxlga_scribdNo ratings yet

- Daily Drilling Report: Danan Oilfield DevelopmentDocument3 pagesDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNo ratings yet

- Chapter 7 Demonstrate The Pan in Linux System: 7.1 DemonstrationDocument14 pagesChapter 7 Demonstrate The Pan in Linux System: 7.1 DemonstrationStanislaus Ivantius LimampauwNo ratings yet

- STS - Industrial Revolution (Manabat, Angelika Mae C. - BSBA-MM2A)Document5 pagesSTS - Industrial Revolution (Manabat, Angelika Mae C. - BSBA-MM2A)Angelika Mae ManabatNo ratings yet

- Nomi CVDocument2 pagesNomi CVFozia AnsariNo ratings yet

- Business Presentation: This Is A Subtitle That Can Be EditedDocument15 pagesBusiness Presentation: This Is A Subtitle That Can Be Editedharold hurseNo ratings yet

- Drill Quip PDFDocument8 pagesDrill Quip PDFyasamanNo ratings yet

- Dead-Tank Circuit-Breakers For 72.5 KV Up To 550 KV: Fig. 12: SPS2 / 3AP1 DT 145 KVDocument7 pagesDead-Tank Circuit-Breakers For 72.5 KV Up To 550 KV: Fig. 12: SPS2 / 3AP1 DT 145 KVMichael DavisNo ratings yet