Professional Documents

Culture Documents

Man Mi-112en En1

Man Mi-112en En1

Uploaded by

Ricardo AzevedoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Man Mi-112en En1

Man Mi-112en En1

Uploaded by

Ricardo AzevedoCopyright:

Available Formats

Crosshead Pin Bearing Clearance Check

Original instructions

Reference: TDO No. 2057326

Instruction for Field Service

Engineers

MI-112en

Crosshead Pin Bearing

Clearance Check

PL1/PL3

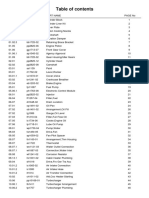

2 Revisions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Contact Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

4 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4 Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5 Measuring crosshead pin bearing clearance . . . . . . . . . . . . 4

5.1 Method No. 1 - with Piston Rod installed . . . . . . . 4

5.2 Method No. 2 - without installed piston rod . . . . . . 5

5.3 Method No. 3 - Lifting with a crowbar . . . . . . . . . . 7

13.09.2016 Rev. 001/mittner_r PL1 / PL3 MI-112en 1

Crosshead Pin Bearing Clearance Check

Revisions

1 Revisions

Book Chapter Technical Date Page Description

revision revision writer

001 rmi 12.09.2016 First release

2 Contact Address

Please contact your local Burckhardt Compression Office or Burckhardt

Compression Agent.

For details visit our website www.burckhardtcompression.com.

Find your nearest Agent or Service Center on www.burckhardtcompres-

sion.com/Contact and choose “Service Centers Worldwide” or “Agents

Worldwide”.

In case of an incident, contact our 24-hour emergency service:

Tel. +41 52 262 53 53

Contact in Switzerland: Burckhardt Compression AG

Services Division

Sulzer-Allee 25

8404 Winterthur

Switzerland

Tel. +41 52 262 54 77 Fax +41 52 262 00 53

www.burckhardtcompression.com

info@burckhardtcompression.com

2 MI-112en PL1 / PL3 Rev. 001/mittner_r 13.09.2016

Crosshead Pin Bearing Clearance Check

Introduction

3 Introduction

This technical document describes three methods to measure the cross-

head pin bearing clearance of Laby® compressors.

The crosshead pin bearing clearance must be measured according to the

compressor relevant clearance table. Take the measurements before run-

ning-in of pistons of new compressors or after exchange of pin bearings.

In case the value is equal or smaller than the given min. value in the In-

struction Manual, please inform the Technical Support.

4 Background

This TDO is based on the BCA internal important advice "Bearing clear-

ances of Laby® compressors (December 4, 2009)". It states:

“We have to inform you, that we had several damages on crosshead pin

bearings during commissioning or short time after commissioning in the

past months. Compressors with valve unloaders (50% capacity runs) are

mostly affected.”

The root cause of the damages is not very clear in all this cases, but we

strongly believe that the clearance of the crosshead pin bearing is on the

lower limit.

For this reason we advise you to check the clearance of the crosshead pin

bearing before running-in of pistons of new compressors or after exchange

of pin bearings. Please inform us if the value is equal or smaller than the

given min. value in the Instruction Manual. We will check the figures and

inform you if any adjustments are required. After execution of the requested

modifications, the field service engineers are authorized to start the com-

pressor.

We hope to avoid further damages and warranty cases with this procedure.

Not to follow this procedure could result in high costs for Burckhardt Com-

pression AG and be harmful for our reputation.

13.09.2016 Rev. 001/mittner_r PL1 / PL3 MI-112en 3

Crosshead Pin Bearing Clearance Check

Measuring Crosshead Pin Bearing Clearance

5 Measuring Crosshead Pin Bearing Clearance

5.1 Method No. 1 - With Piston Rod Installed

Tool and Parts • Dial gauge

• Screw with nut (min. M16)

• Two open spanners

Procedure 1. Prepare and set up dial gauge (see Fig. 5-1). Adjust it to 0/5.

2. Prepare screw and nut as shown in Fig. 5-1

LA_M4_0020a_01

Fig. 5-1 Prepare and set up dial gauge

3. Install screw and nut between connecting rod and piston rod (see Fig.

5-2)

LA_M4_0021a_01

Fig. 5-2 Install screw and nut between connecting rod and piston rod

4 MI-112en PL1 / PL3 Rev. 001/mittner_r 13.09.2016

Crosshead Pin Bearing Clearance Check

Measuring Crosshead Pin Bearing Clearance

4. Tighten nut and screw with two spanners (see Fig. 5-3) and record the

value shown on the dial gauge.

LA_M4_0022a_01

Fig. 5-3 Tighten nut and screw

5. Loose nut and screw and repeat step 4 two or three times.

5.2 Method No. 2 - Without Installed Piston Rod

Tool and Parts • Screw or thread bar with nut (min. M16) (1)

• Steel plate with thread in the centre (2)

• Open spanner (3)

• Dial gauge

1 2 3

LA_M4_0023b_01

Fig. 5-4 Tools and parts for method No. 2

13.09.2016 Rev. 001/mittner_r PL1 / PL3 MI-112en 5

Crosshead Pin Bearing Clearance Check

Measuring Crosshead Pin Bearing Clearance

Procedure 1. Install plate and thread bar or screw (see Fig. 5-5)

LA_M4_0024a_01

Fig. 5-5 Install plate and thread bar

2. Install dial gauge (see Fig. 5-6) and set it to 0/5.

3. Tighten thread bar or screw and record the value shown on the dial

gauge.

LA_M4_0025a_01

Fig. 5-6 Tighten thread bar

4. Loose thread bolt or screw and repeat step 3 two or three times.

6 MI-112en PL1 / PL3 Rev. 001/mittner_r 13.09.2016

Crosshead Pin Bearing Clearance Check

Measuring Crosshead Pin Bearing Clearance

5.3 Method No. 3 - Lifting With a Crowbar

Tools and Parts • Crowbar

• Wooden block

• Dial gauge

Procedure 1. Install dial gauge, wooden block and crowbar as shown in Fig. 5-7.

2. Set dial gauge to 0/5.

LA_M4_0026a_01

Fig. 5-7 Install dial gauge, wooden block and crowbar

3. Lift crosshead with crowbar and record the value shown on the dial

gauge.

4. Repeat step 4 two or three times.

13.09.2016 Rev. 001/mittner_r PL1 / PL3 MI-112en 7

Crosshead Pin Bearing Clearance Check

Measuring Crosshead Pin Bearing Clearance

8 MI-112en PL1 / PL3 Rev. 001/mittner_r 13.09.2016

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- Honda BF2D Outboard Motors Shop ManualDocument5 pagesHonda BF2D Outboard Motors Shop ManualChrisStainton0% (3)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Volvo Workshop Manuals XC90 AWD V8-4.... Formation Specifications Page 5947Document2 pagesVolvo Workshop Manuals XC90 AWD V8-4.... Formation Specifications Page 5947Lisandro SisternaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- All Original Piaggio Spare Parts PDFDocument139 pagesAll Original Piaggio Spare Parts PDFSaddik Kahn80% (5)

- C7-Specifications Systems Operation Testing and AdjustingDocument88 pagesC7-Specifications Systems Operation Testing and AdjustingAdi Pinem100% (12)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Aircraft Engine IdentificationDocument6 pagesAircraft Engine IdentificationEarl Michaelo R. Kalacas100% (1)

- Man Mi-100en En1 01Document261 pagesMan Mi-100en En1 01Ricardo Azevedo100% (1)

- Doosan DX225LCA Excavator Parts ManualDocument714 pagesDoosan DX225LCA Excavator Parts ManualTHIERRY JEAN BERNARD PALLUD100% (2)

- Lovol - Fl936-Dhbo6g0131Document140 pagesLovol - Fl936-Dhbo6g0131LuzioNetoNo ratings yet

- Parts Manual: Onan Generator Set For RVDocument64 pagesParts Manual: Onan Generator Set For RVThePathToHomeNo ratings yet

- Glow Plug Cross ReferenceDocument6 pagesGlow Plug Cross ReferenceArturo Montes F.No ratings yet

- VDS2E+Brochure+3 0Document3 pagesVDS2E+Brochure+3 0Ricardo AzevedoNo ratings yet

- VDT Highly Flexible CouplingsDocument188 pagesVDT Highly Flexible CouplingsRicardo AzevedoNo ratings yet

- Manual BaudouinDocument19 pagesManual BaudouinRicardo AzevedoNo ratings yet

- WoodwardDocument110 pagesWoodwardRicardo AzevedoNo ratings yet

- WartsilaDocument16 pagesWartsilaRicardo AzevedoNo ratings yet

- Catalogo de Pecas Sobresselentes AK82 CLP 20210310 101109 PTDocument23 pagesCatalogo de Pecas Sobresselentes AK82 CLP 20210310 101109 PTRicardo AzevedoNo ratings yet

- Man Ci 061enDocument4 pagesMan Ci 061enRicardo AzevedoNo ratings yet

- Man Ci 056enDocument4 pagesMan Ci 056enRicardo AzevedoNo ratings yet

- $TMP MAN 102416-2001743-10 EN1 00Document639 pages$TMP MAN 102416-2001743-10 EN1 00Ricardo AzevedoNo ratings yet

- $TMP MAN 1263 001 00Document66 pages$TMP MAN 1263 001 00Ricardo AzevedoNo ratings yet

- Task 73-21-00-710-805-ADocument9 pagesTask 73-21-00-710-805-AOrlando PérezNo ratings yet

- Desmo Drom IDocument5 pagesDesmo Drom IWilliamNo ratings yet

- Practical #11: To Study Cutaway Models of Petrol and Diesel Engine Heat EngineDocument9 pagesPractical #11: To Study Cutaway Models of Petrol and Diesel Engine Heat EngineMuhammad Arslan AfzalNo ratings yet

- SD313 5 MFI Control System (G4HE/G4HG: EPSILON 1.0L/1.1L M/T)Document1 pageSD313 5 MFI Control System (G4HE/G4HG: EPSILON 1.0L/1.1L M/T)Huy Trần Quốc100% (1)

- CUMMINS QSX15 Engine - Parts Catalog 79007291 3Document1 pageCUMMINS QSX15 Engine - Parts Catalog 79007291 3Bernard ApuritNo ratings yet

- D-6409f - Marketing C2000 GAS HSK78Document2 pagesD-6409f - Marketing C2000 GAS HSK78Edwin Fernando Ariza QuirogaNo ratings yet

- 2806 Spec SheetDocument2 pages2806 Spec SheetqwureyquweryNo ratings yet

- Installation Instructions For:: EMS P/N 30-6820 2004 Subaru WRX STI (USDM 2.5L Turbo)Document21 pagesInstallation Instructions For:: EMS P/N 30-6820 2004 Subaru WRX STI (USDM 2.5L Turbo)Alexandru AvrigeanuNo ratings yet

- Two-Stroke and Four-Stroke Cycle Diesel Engine - AgonoyDocument2 pagesTwo-Stroke and Four-Stroke Cycle Diesel Engine - AgonoyRAE ANGELO AGONOYNo ratings yet

- Honda Civic TimingDocument112 pagesHonda Civic TimingOvid PashkovskyNo ratings yet

- Auxiliary Power UnitDocument40 pagesAuxiliary Power UnitAnupNo ratings yet

- Owner'S Manual: M 9.9D M 18E M 15DDocument78 pagesOwner'S Manual: M 9.9D M 18E M 15DRoss MelvilleNo ratings yet

- Perkins 1104D PDFDocument6 pagesPerkins 1104D PDFYeison Jair Guaca TrujilloNo ratings yet

- CIGUEÑALDocument8 pagesCIGUEÑALJose luis ConsuegraNo ratings yet

- Brake Chamber Pos 2 777DDocument2 pagesBrake Chamber Pos 2 777DKusuma JayaNo ratings yet

- FIP Cal PC130-7Document1 pageFIP Cal PC130-7Agus WijayadiNo ratings yet

- 400058EADocument57 pages400058EAAbi JithNo ratings yet

- Wiseco VW Piston ListDocument4 pagesWiseco VW Piston ListAlper KirmanNo ratings yet

- Parts Catalog For Engine SeriesDocument32 pagesParts Catalog For Engine Seriesagus9hendraNo ratings yet

- 2.0L Gasoline Engine - CAWB, CCTA: Wiring DiagramDocument18 pages2.0L Gasoline Engine - CAWB, CCTA: Wiring DiagramHernán NuñezNo ratings yet

- 3tne88 Etb1Document26 pages3tne88 Etb1miguel sousaNo ratings yet