Professional Documents

Culture Documents

Film Forming Spray A Comprehensive Review

Film Forming Spray A Comprehensive Review

Copyright:

Available Formats

You might also like

- Iso 14644-13-2017Document43 pagesIso 14644-13-2017dukeplus100% (4)

- Chapter 18 Financial Markets Test BankDocument16 pagesChapter 18 Financial Markets Test BankNicholas60% (5)

- Black & DeckerDocument28 pagesBlack & DeckerSunny ShresthaNo ratings yet

- 2014 Nissan Maxima 42297 TMDocument195 pages2014 Nissan Maxima 42297 TMPHÁT NGUYỄN THẾNo ratings yet

- BS Databook2002Document93 pagesBS Databook2002Dani WijayaNo ratings yet

- Mohit Sharma Zonal HeadDocument4 pagesMohit Sharma Zonal HeadKriday SharmaNo ratings yet

- Religions of The World Infographics by SlidesgoDocument33 pagesReligions of The World Infographics by SlidesgocaspianNo ratings yet

- Using Pony in FlaskDocument90 pagesUsing Pony in FlaskPrivilege MudzingeNo ratings yet

- GFRP of Cargo ShipDocument135 pagesGFRP of Cargo ShipAgus SantosoNo ratings yet

- The Elasticity of Demand For Books, Resale Price Maintenanca and The Lerner IndexDocument20 pagesThe Elasticity of Demand For Books, Resale Price Maintenanca and The Lerner IndexAnahí SalazarNo ratings yet

- Extraction and Characterization of Nigeria Shea Butter OilDocument7 pagesExtraction and Characterization of Nigeria Shea Butter OilJordon AlvaradoNo ratings yet

- Immune BoostersDocument18 pagesImmune Boosterspraveena dasamukhaNo ratings yet

- Secret Scents ReportDocument28 pagesSecret Scents Reportzer reNo ratings yet

- PaintDocument28 pagesPaintAnna KateurinaNo ratings yet

- KrisWorld Magazine V2Document87 pagesKrisWorld Magazine V2Freddy TamuedjounNo ratings yet

- A Case Study On Customer Relationship Management Strategy LaveshDocument72 pagesA Case Study On Customer Relationship Management Strategy LaveshNIKHIL SAPKALENo ratings yet

- Safety Data Sheet Tyre ShineDocument8 pagesSafety Data Sheet Tyre ShineShailendra AgrawalNo ratings yet

- Aloe Vera Candy - For GrammarianDocument92 pagesAloe Vera Candy - For GrammarianErne FlorNo ratings yet

- NDMA Annual Report 20 21Document120 pagesNDMA Annual Report 20 21RaghuNo ratings yet

- Crown Paints Company ProfileDocument26 pagesCrown Paints Company ProfileLela MwasiNo ratings yet

- Acs - Jchemed.8b00736 2Document4 pagesAcs - Jchemed.8b00736 2Andrea CabezasNo ratings yet

- Strategic Formulation NotesDocument40 pagesStrategic Formulation NotesSonia SarkarNo ratings yet

- Module No 7: Technology of Manufacturing Spice Oil & OleoresinsDocument3 pagesModule No 7: Technology of Manufacturing Spice Oil & OleoresinsmadeshNo ratings yet

- NECS 0202T-0612T Technical BulletinDocument42 pagesNECS 0202T-0612T Technical BulletinVictor AANo ratings yet

- Module III - Pharma Calculation - Methods of Expressing Concentrations - SY 2021Document59 pagesModule III - Pharma Calculation - Methods of Expressing Concentrations - SY 2021Mina BiancaNo ratings yet

- ISOLATION AND EXTRACTION OF nATURAL PRODCUTSDocument4 pagesISOLATION AND EXTRACTION OF nATURAL PRODCUTSAlvina RiazNo ratings yet

- 8 Experiment No. 8 Aldehydes Ket Answer SheetDocument7 pages8 Experiment No. 8 Aldehydes Ket Answer SheetMaej OragaNo ratings yet

- Dry Eyes and Digital Devices 1Document11 pagesDry Eyes and Digital Devices 1Koas HAYUU 2022No ratings yet

- The 10 Principles of Food Industry Sustainability - 2015 - Baldwin - Front MatterDocument7 pagesThe 10 Principles of Food Industry Sustainability - 2015 - Baldwin - Front MatterNaaomy DuqueNo ratings yet

- Challan (MTR Form Number-6)Document1 pageChallan (MTR Form Number-6)Kajal AvchareNo ratings yet

- Reasearch Paper 5Document7 pagesReasearch Paper 5Q-MT Branch HQ 497 OM&MNo ratings yet

- Formulation and Evaluation of Nail Lacquer Containing Anti Fungal Griseofulvin For The Treatment of OnychomycosisDocument13 pagesFormulation and Evaluation of Nail Lacquer Containing Anti Fungal Griseofulvin For The Treatment of OnychomycosisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- ESBP End Term AssignmentDocument18 pagesESBP End Term Assignmentvasudha kabraNo ratings yet

- Is 15317 1 2003Document21 pagesIs 15317 1 2003Trupti PawarNo ratings yet

- 4 Cream PDFDocument27 pages4 Cream PDFremo sNo ratings yet

- FINLATICS Pfizer Company ProfileDocument9 pagesFINLATICS Pfizer Company ProfileVISHAL GUPTANo ratings yet

- Final PP 1 CompressedDocument26 pagesFinal PP 1 Compressedapi-596919522No ratings yet

- "Mosquito Repellants" A Case StudyDocument10 pages"Mosquito Repellants" A Case StudyLewis SimonNo ratings yet

- Applsci 12 10040 v2Document11 pagesApplsci 12 10040 v2Juan VelasquezNo ratings yet

- Rishav OIP-2021 PREB1Document59 pagesRishav OIP-2021 PREB1Khan aqsaNo ratings yet

- Tipe Tipe DianalDocument4 pagesTipe Tipe DianalLiestia NoorNo ratings yet

- Tron Various PDFDocument27 pagesTron Various PDFSindhu ThomasNo ratings yet

- AswagandhaDocument9 pagesAswagandhaBuilders ArenaNo ratings yet

- Episodes 22 & 23 - Corpo LawDocument7 pagesEpisodes 22 & 23 - Corpo LawBarem Salio-anNo ratings yet

- Fevicryl CatalogueDocument64 pagesFevicryl CatalogueCambridge GT100% (1)

- Review On Market Available Herbal Antioxidant Content of Facewashes in IndiaDocument7 pagesReview On Market Available Herbal Antioxidant Content of Facewashes in IndiaSacop ProjectNo ratings yet

- Development Project Management Planning Tools and Techniques Final Project ReportDocument8 pagesDevelopment Project Management Planning Tools and Techniques Final Project ReportRupam Pratikshya100% (1)

- Vinnapas Solid Resins Brochure 2016 - 7409 - ENDocument24 pagesVinnapas Solid Resins Brochure 2016 - 7409 - ENJohnNo ratings yet

- Plants Hormones, Responses and Feedback Mechanisms Week 3 Gen Bio 2Document3 pagesPlants Hormones, Responses and Feedback Mechanisms Week 3 Gen Bio 2kurt jenricNo ratings yet

- Development of Mosquito Repellent FormulDocument8 pagesDevelopment of Mosquito Repellent Formulsri wahyuniNo ratings yet

- Incompatibilities - PhysicalDocument5 pagesIncompatibilities - PhysicalestherNo ratings yet

- Biology Investigatory ProjectDocument27 pagesBiology Investigatory ProjectBarsha DasNo ratings yet

- Tea Project - 106a33217Document121 pagesTea Project - 106a33217dilini100% (1)

- International Numbering System For Food AdditivesDocument94 pagesInternational Numbering System For Food AdditivessuryadbugNo ratings yet

- Preparation and Evaluation of Catharanthus Roseus Face Sheet Mask SerumDocument4 pagesPreparation and Evaluation of Catharanthus Roseus Face Sheet Mask SerumInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Polymer: IUPAC DefinitionDocument14 pagesPolymer: IUPAC DefinitionSashimiTourloublancNo ratings yet

- HP 3rd AssignmentDocument8 pagesHP 3rd Assignmentmrcopy xeroxNo ratings yet

- Comparative Analysis of Zingiber Officinalis Lotion in Different Ratio With Quality ControlDocument5 pagesComparative Analysis of Zingiber Officinalis Lotion in Different Ratio With Quality ControlAgiv AlghivariNo ratings yet

- Cambridge IGCSE™: Geography 0460/12 May/June 2021Document18 pagesCambridge IGCSE™: Geography 0460/12 May/June 2021Aja Saidylee.No ratings yet

- DIET Hassan Science EM Q Bank 2022-23Document60 pagesDIET Hassan Science EM Q Bank 2022-23masoodmohsinNo ratings yet

- Salscent (SST) : A Self-Encapsulation Fragrance TechnologyDocument2 pagesSalscent (SST) : A Self-Encapsulation Fragrance TechnologyRaisha RamadantiNo ratings yet

- WAX WTFluorescentWaterDispersionsDocument3 pagesWAX WTFluorescentWaterDispersionsaparnaNo ratings yet

- Natural and Organic Cosmetics: Beneficial Properties For The Environment and HealthDocument6 pagesNatural and Organic Cosmetics: Beneficial Properties For The Environment and HealthIJAERS JOURNALNo ratings yet

- SIPS Two Days National Seminar 10 & 11 FEB 2023 Abstract BookDocument115 pagesSIPS Two Days National Seminar 10 & 11 FEB 2023 Abstract BookAvinash MansukNo ratings yet

- Carbomer 940Document2 pagesCarbomer 940Mario EssamNo ratings yet

- Technical Presentation Report On FFDCDocument24 pagesTechnical Presentation Report On FFDCApurv RajNo ratings yet

- BMS CDD 2020 285+rev3Document16 pagesBMS CDD 2020 285+rev3m.monir.saNo ratings yet

- A Review On MicrocapsulesDocument12 pagesA Review On MicrocapsulesfarihaulfahNo ratings yet

- AI Robots in Various SectorDocument3 pagesAI Robots in Various SectorInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Nurturing Corporate Employee Emotional Wellbeing, Time Management and the Influence on FamilyDocument8 pagesNurturing Corporate Employee Emotional Wellbeing, Time Management and the Influence on FamilyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Effects of Liquid Density and Impeller Size with Volute Clearance on the Performance of Radial Blade Centrifugal Pumps: An Experimental ApproachDocument16 pagesThe Effects of Liquid Density and Impeller Size with Volute Clearance on the Performance of Radial Blade Centrifugal Pumps: An Experimental ApproachInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Intrusion Detection and Prevention Systems for Ad-Hoc NetworksDocument8 pagesIntrusion Detection and Prevention Systems for Ad-Hoc NetworksInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Dynamic Analysis of High-Rise Buildings for Various Irregularities with and without Floating ColumnDocument3 pagesDynamic Analysis of High-Rise Buildings for Various Irregularities with and without Floating ColumnInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Integration of Information Communication Technology, Strategic Leadership and Academic Performance in Universities in North Kivu, Democratic Republic of CongoDocument7 pagesIntegration of Information Communication Technology, Strategic Leadership and Academic Performance in Universities in North Kivu, Democratic Republic of CongoInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Fuzzy based Tie-Line and LFC of a Two-Area Interconnected SystemDocument6 pagesFuzzy based Tie-Line and LFC of a Two-Area Interconnected SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Geotechnical Assessment of Selected Lateritic Soils in Southwest Nigeria for Road Construction and Development of Artificial Neural Network Mathematical Based Model for Prediction of the California Bearing RatioDocument10 pagesGeotechnical Assessment of Selected Lateritic Soils in Southwest Nigeria for Road Construction and Development of Artificial Neural Network Mathematical Based Model for Prediction of the California Bearing RatioInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- An Explanatory Sequential Study of Public Elementary School Teachers on Deped Computerization Program (DCP)Document7 pagesAn Explanatory Sequential Study of Public Elementary School Teachers on Deped Computerization Program (DCP)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Innovative Mathematical Insights through Artificial Intelligence (AI): Analysing Ramanujan Series and the Relationship between e and π\piDocument8 pagesInnovative Mathematical Insights through Artificial Intelligence (AI): Analysing Ramanujan Series and the Relationship between e and π\piInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Novel Approach to Template Filling with Automatic Speech Recognition for Healthcare ProfessionalsDocument6 pagesA Novel Approach to Template Filling with Automatic Speech Recognition for Healthcare ProfessionalsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Analysis of Factors Obstacling Construction Work in The Tojo Una-Una Islands RegionDocument9 pagesAnalysis of Factors Obstacling Construction Work in The Tojo Una-Una Islands RegionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Classifying Crop Leaf Diseases Using Different Deep Learning Models With Transfer LearningDocument8 pagesClassifying Crop Leaf Diseases Using Different Deep Learning Models With Transfer LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Diode Laser Therapy for Drug Induced Gingival Enlaregement: A CaseReportDocument4 pagesDiode Laser Therapy for Drug Induced Gingival Enlaregement: A CaseReportInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Breaking Down Barriers To Inclusion: Stories of Grade Four Teachers in Maintream ClassroomsDocument14 pagesBreaking Down Barriers To Inclusion: Stories of Grade Four Teachers in Maintream ClassroomsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Mediating Effect of Encouraging Attitude of School Principals On Personal Well-Being and Career Ethics of TeachersDocument10 pagesMediating Effect of Encouraging Attitude of School Principals On Personal Well-Being and Career Ethics of TeachersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Importance of Early Intervention of Traumatic Cataract in ChildrenDocument5 pagesImportance of Early Intervention of Traumatic Cataract in ChildrenInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Organizational Factors That Influence Information Security in Smes: A Case Study of Mogadishu, SomaliaDocument10 pagesOrganizational Factors That Influence Information Security in Smes: A Case Study of Mogadishu, SomaliaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Comparison of JavaScript Frontend Frameworks - Angular, React, and VueDocument8 pagesComparison of JavaScript Frontend Frameworks - Angular, React, and VueInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Disseminating The Real-World Importance of Conjunct Studies of Acculturation, Transculturation, and Deculturation Processes: Why This Can Be A Useful Technique To Analyze Real-World ObservationsDocument15 pagesDisseminating The Real-World Importance of Conjunct Studies of Acculturation, Transculturation, and Deculturation Processes: Why This Can Be A Useful Technique To Analyze Real-World ObservationsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- An Investigation Model To Combat Computer Gaming Delinquency in South Africa, Server-Based Gaming, and Illegal Online GamingDocument15 pagesAn Investigation Model To Combat Computer Gaming Delinquency in South Africa, Server-Based Gaming, and Illegal Online GamingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Occupational Safety: PPE Use and Hazard Experiences Among Welders in Valencia City, BukidnonDocument11 pagesOccupational Safety: PPE Use and Hazard Experiences Among Welders in Valencia City, BukidnonInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Influence of Artificial Intelligence On Employment Trends in The United States (US)Document5 pagesThe Influence of Artificial Intelligence On Employment Trends in The United States (US)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Gender-Based Violence: Engaging Children in The SolutionDocument10 pagesGender-Based Violence: Engaging Children in The SolutionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Relationship of Total Quality Management Practices and Project Performance With Risk Management As Mediator: A Study of East Coast Rail Link Project in MalaysiaDocument19 pagesThe Relationship of Total Quality Management Practices and Project Performance With Risk Management As Mediator: A Study of East Coast Rail Link Project in MalaysiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Integrating Multimodal Deep Learning For Enhanced News Sentiment Analysis and Market Movement ForecastingDocument8 pagesIntegrating Multimodal Deep Learning For Enhanced News Sentiment Analysis and Market Movement ForecastingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Pecha Kucha Presentation in The University English Classes: Advantages and DisadvantagesDocument4 pagesPecha Kucha Presentation in The University English Classes: Advantages and DisadvantagesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Total Cost of Ownership of Electric Car and Internal Combustion Engine Car With Performance NormalizationDocument11 pagesTotal Cost of Ownership of Electric Car and Internal Combustion Engine Car With Performance NormalizationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Development of Creative Thinking: Case Study of Basic Design StudioDocument9 pagesDevelopment of Creative Thinking: Case Study of Basic Design StudioInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Relationship Between Knowledge About Halitosis and Dental and Oral Hygiene in Patients With Fixed Orthodontics at The HK Medical Center MakassarDocument4 pagesThe Relationship Between Knowledge About Halitosis and Dental and Oral Hygiene in Patients With Fixed Orthodontics at The HK Medical Center MakassarInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Iso 3613 2000 FR PDFDocument6 pagesIso 3613 2000 FR PDFJeannie VargasNo ratings yet

- Great Ideas in Reversing The Tytera MD380 by Travis GoodspeedDocument48 pagesGreat Ideas in Reversing The Tytera MD380 by Travis GoodspeedmbozhoNo ratings yet

- Teledermatology: Concepts and Applications in MedicineDocument6 pagesTeledermatology: Concepts and Applications in MedicineJesse AguirreNo ratings yet

- Budgeting Vs Financial ForecatingDocument3 pagesBudgeting Vs Financial ForecatingRohit BajpaiNo ratings yet

- PUP Enrollment Payment VoucherDocument3 pagesPUP Enrollment Payment VoucherGel ArceoNo ratings yet

- Endnotes 1 AA Atkinson and GA FelthamDocument4 pagesEndnotes 1 AA Atkinson and GA FelthamLina JapNo ratings yet

- Franchising: An Entrepreneur's Guide 4e: by Richard J. Judd and Robert T. JustisDocument20 pagesFranchising: An Entrepreneur's Guide 4e: by Richard J. Judd and Robert T. JustisSeminar Group09No ratings yet

- ALI BAUG (Gardens of Ali)Document38 pagesALI BAUG (Gardens of Ali)Manal KhatibNo ratings yet

- Presentation in English For Senior TourismDocument2 pagesPresentation in English For Senior TourismMitra FortunaNo ratings yet

- PDF Engineering Optimization: Applications, Methods and Analysis First Edition Rhinehart All ChapterDocument7 pagesPDF Engineering Optimization: Applications, Methods and Analysis First Edition Rhinehart All Chaptergurinmosati100% (3)

- Ce Feb16 FinalDocument76 pagesCe Feb16 Finaltest2012No ratings yet

- Experiment 13 PPDocument3 pagesExperiment 13 PPMohit Patil (PC)No ratings yet

- Siasat V IACDocument14 pagesSiasat V IACCathy BelgiraNo ratings yet

- Grade 10 T.L.E CUR MAPDocument6 pagesGrade 10 T.L.E CUR MAPGregorio RizaldyNo ratings yet

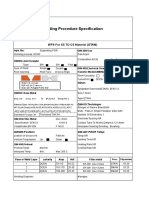

- Welding Procedure Specification: WPS For SS TO CS Material (GTAW)Document1 pageWelding Procedure Specification: WPS For SS TO CS Material (GTAW)Lipika GayenNo ratings yet

- 2 - Introduction To CompilationDocument13 pages2 - Introduction To CompilationShaddyNo ratings yet

- Ccc221coalpowerR MDocument58 pagesCcc221coalpowerR Mmfhaleem@pgesco.comNo ratings yet

- Projects Synopsis: 1. Surendra Singh (08esmec104) 2. Surender Singh (08esmec102)Document7 pagesProjects Synopsis: 1. Surendra Singh (08esmec104) 2. Surender Singh (08esmec102)Hamza HebNo ratings yet

- A330 Supplementary Checklist: Direction Des Operations AeriennesDocument12 pagesA330 Supplementary Checklist: Direction Des Operations AeriennesHache HBNo ratings yet

- Unit 5: Transition Paths: Manage Your Solution in The Configure Your SoluDocument1 pageUnit 5: Transition Paths: Manage Your Solution in The Configure Your Solushree.patil20028558No ratings yet

- 5-4-3 Wire Apartment Intercom Amp: Wiring InstructionsDocument8 pages5-4-3 Wire Apartment Intercom Amp: Wiring InstructionsVlasta Polic ZileNo ratings yet

- Chapter I: Assessment: Comprehensive Nursing Process RubricDocument4 pagesChapter I: Assessment: Comprehensive Nursing Process RubricErika Cadawan100% (1)

Film Forming Spray A Comprehensive Review

Film Forming Spray A Comprehensive Review

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Film Forming Spray A Comprehensive Review

Film Forming Spray A Comprehensive Review

Copyright:

Available Formats

Volume 7, Issue 12, December – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Film Forming Spray: A Comprehensive Review

Priyanka Mohite*, Harshil Patel, Mansi Patel, Chainesh Shah, Umesh Upadhyay

Sigma Institute of Pharmacy, Bakrol, Vadodara- 390019

Abstract:- In comparison to traditional topical II. FILM-FORMING SPRAYERS [5-9]

preparations, film-forming sprays have a number of

benefits, including uniform drug distribution and dose, A. Ordinal Spray

enhanced bioavailability, decreased incidence of The ordinal spray is a form of spray that typically uses a

irritation, continuous drug release, and quicker wound plastic or aluminium container with a dip tube diameter of

healing through moisture control. Polymers and 1.2 mm and an aperture size of 0.3 mm. This sort of spray

excipients used in film-forming sprays work to increase does not require any special technology during the spraying

the properties of preparations and the stability of active process. The spray produced has an average angle of 78.69-

ingredients. Different excipient and polymer 87.39°, 0.11-0.35 g or - mL of film-forming solution can

combinations will result in films with various often be sprayed. An ordinary spray container has an

characteristics. The potential for developing average leakage rate of 0.01–0.03%. 34 An ordinal spray

compositions of spray film-forming systems has may be vertical or horizontal. It has been claimed that the 3

substantially increased thanks to the current state of K® Horizontal Spray Nozzle can keep the film-forming

polymer development and composite synthesis. fluid sterile while being stored and used. The type and

Therefore, in order to create a film-forming spray that is concentration of the polymer utilised affects the ordinal

more effective, it is necessary to evaluate the various spray's spray force as well. 31 The preparation of extracts

types of polymers and excipients and their assessment can also be done with the ordinal spray.

criteria.

B. Metered Dose Spray

Keywords:- film-forming spray, film-forming polymer, The metered dose spray (MDS) is a spraying tool that

topical drug delivery. has a variable spray output. This device is typically used to

provide medications via the transdermal or transmucosal

I. DEFINITION AND MECHANISM OF A FILM- route to the systemic compartment. Because it is related to

FORMING SPRAY [1-4] the medication dose, the spray volume must be taken into

account when evaluating a film-forming spray. The amount

An FFS is a drug delivery system that sprays a solution of MDS that can be sprayed can be affected by the bottle's

at a specific therapeutic site, where it contacts the site and capacity, how evenly the particles are dispersed, and where

uses the polymer as a matrix for film formation to build a the container is placed while being used. 45 The typical

film. 20,25,30 The drug will be released from the polymer volume of FFS that can be sprayed is between 90 and 102

matrix housing the drug over time after the film has been mL. 30,32,33 MDS has an 83.51° spray angle on average.

formed, much like a patch. However, unlike topical patches 20 An MDS container has an average leakage rate of 0.01 to

and other topical medicines, films adhere to the contours of 0.02%. 30.

the skin or wound because minute droplets of the film-

forming solution can enter deep indentations. Naturally, this C. Electrostatic Spray

makes it much easier for drugs to reach their target tissues. A common technique for applying pesticides in

Drug dosages can also be changed in a film-forming spray agriculture is electrostatic spray (ES). ES can improve loss

depending on the amount of solution per spray to control from drift, droplet formation speed, cover-age uniformity,

any local or systemic symptoms. Additionally, an FFS offers and deposition efficiency. 46 The effectiveness of ES

a good spread and an even distribution of medications. depends on the viscosity, surface tension, and electrical

Patient compliance may also rise with simplicity of usage. It resistivity of the solution. The conductivity of a solution

is simple to remove the thin film with water. Comparing this must be between 108 and 105 S/m in order to be sprayed

thin, non-sticky film to patches, ointments, gels, etc., which with ES. The droplets produced by ES have an average

have a rough, sticky texture when applied, boosts patient diameter of 6.3 to 26 m.

comfort during activities. 35,36 To keep the equilibrium, the

thin film also makes it easier for wound moisture to D. Ultrasonic Spray

permeate. The use of patch preparations can result in Excellent potential exists for film-forming solutions to be

inappropriate wound humidity, which can lead to infection delivered by ultrasonic spray. The resulting droplet has thin-

or irritation. film properties and can approach the nano scale. The

ultrasonic spray nozzle can operate at both low and high

The film-forming fluid is sprayed using any type of pressures, generating consistent droplets with less than 10 m

sprayer to create droplets. Each sprayer has unique features in diameter. The droplet diameter of the ultrasonic spray is

and purposes, but they all have potential for usage in 1–10 m, and the nozzle is 0.5 mm in diameter. The electrode

medical settings. The potential uses of several sprayer types being used has a resonance frequency of 10 MHz. Layer-by-

as medication delivery mechanisms in film-forming systems layer (LBL) coating films can be produced using an

are described below. ultrasonic spray for medical applications that have greater

particle size uniformity. Specifications for each type of

IJISRT22DEC1449 www.ijisrt.com 1163

Volume 7, Issue 12, December – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

sprayer correspond to particular polymers. The FFS system E. Minimum fill or package tightness

has utilised a variety of polymers, both natural and Given that the delivery systems under consideration are

manufactured. disperse, the characteristics of sprays and aerosols, such as

package tightness/pump seal efficiency (aerosols), minimum

III. STANDARDIZATION PARAMETERS [10-19] fill, pressure test, delivery rate and delivered amount, and

aerodynamic distribution of particles, must be included in

It is important to standardise spray film-forming the standardisation parameters. Less frequently mentioned

system parameters both before and after the phase shift, are the spraying angle, the form and distribution of droplets

which occurs in all in situ systems. The majority of authors by size, and the spray pattern.

who discuss the development of spray films distinguish

between mandatory standardisation parameters that are F. Mucoadhesion

distributed between the liquid/spray and solid phases of the The mucoadhesion of the film-forming liquid defines the

delivery system (included in the specification for the dosage most crucial delivery system indicators, such as the

form) and additional standardisation parameters that are capability of local application and exposure time, and

determined during the development stage for a pool of directly influences the characteristics of the in situ film

mulations. formed, such as thickness, uniformity, and rate. It is

significant to highlight that studies devoted to the creation of

A. pH spray film-forming systems do not fully define measuring

To strengthen the stability of the ingredients in the methodologies for mucoadhesive characteristics. At least a

composition and for extra therapeutic purposes, the pH dozen reliable, proven approaches, including in vivo, ex

value of the film-forming liquid is tested and regularly vivo, and in vitro techniques, are now known for

adjusted. For the treatment of heat injury, the ideal pH value determining this indication.

will be lower than 7.32, whilst the optimal acidity of the

solution will vary in the range of values from 4 to 6, for The authors' drive to carry out comprehensive studies

diabetic wounds the range will be from 6.5 to 8, and so on. in this field may be fueled by the profitability of in vivo

The pH level can influence not only how quickly the wound studies of mucoadhesion. It is recommended to employ

surface heals, but it can also influence how well a substance models with purified mucin (such as mucin from the porcine

can pass through skin barriers when delivered transdermally. stomach) and polymer membranes with specified parameters

for a comparative evaluation of mucoadhesive capabilities in

B. Isotonicity a pool of samples during screening (moisture content,

Another trait of the film-forming system that might be adsorption capacity, pore size, etc.). Various models are

evaluated is the solution's isotonicity. It relies on the level of built based on these characteristics, depending on the

tonicity needed for the application's location and intended planned location and type of system application (to estimate

use on specific afflicted areas, like wound surfaces and the separation force, flow rate, etc.). For assessing the

mucous membranes. Non-isotonic medications might irritate mucoadhesive qualities by rotational viscometry, there is

and hurt the mucous membranes. Because of this, it is information on the creation of reliable, correlated with in

possible to determine and modify the tonicity of vivo procedures.

medications, for instance using the Kahara method.

G. Film formation

C. Viscosity, density The production of the film and its evaluation can be

One more characteristic of the film-forming system is carried out in vivo as well as in vitro (on glass surfaces,

that the solution isotonicity. It depends on the level of standardised membranes, nonwoven textiles, etc.). Both

tonicity needed for the application and the afflicted areas in approaches have benefits and drawbacks.

question, such as mucosal membranes and wound surfaces.

Non-isotonic medications might irritate mucous membranes The location of application, the skin's surface

and hurt. Due to this, the tonicity of medications can be temperature, its moisture content, the condition of the

determined and modified, for instance using the Kahara epidermis, humidity, ambient temperature, and other factors

method (Umar et al., 2020). can all affect film development in situ. When analysing in

vivo for the drying rate and other properties of the film, the

D. Surface tension authors of the majority of research use diverse application

The surface tension and contact angle are calculated for zones, such as delivering a dosage to the arms, shoulders,

the same reason. This characteristic is more important for inner thighs, or abdomen before the creation of a thin

standardisation and description of the properties of sprays bioadhesive film on the skin. The utilisation of these factors

than aerosols since it appears to be solely related to the film varies depending on how these elements are different. The

generation mechanism linked to solvent evaporation. Both substance is undesired for the screening procedure and a

the solution's distributivity and the solvent's rate of dispassionate evaluation of the sample pool, nevertheless.

evaporation may be impacted by surface tension. The most The evaluation of film formation is quite popular due to the

common method is to measure the surface tension angle high simplicity, reproducibility, and ease of use of in vitro

using a surface tension analyzer or high-resolution cameras, methods. According to Kathe K. and Kathpalia H., the films

and then to compute it using specialised or general-purpose developed in a Petri dish. Glass was used as the test surface

software. in this instance because some scientists think that it can be

compared to human tissue. In addition, it should be

IJISRT22DEC1449 www.ijisrt.com 1164

Volume 7, Issue 12, December – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

emphasised that the film forms in situ on a surface with its K. Strength

own moisture content that is heated (typically to 32 °C, with The strength of the separated film is determined using

pathologies reaching 35–37 °C). By doing this, the drying texture analyzer or in experiments for breaking under the

process replicated on the glass surface is adjusted. It may be action of the weight of the load. Along with the strength of

advised to cover a glass plate with a membrane or non- the film, it is possible to measure the elongation and

woven covering to boost the in vivo/in vitro correlation and elasticity of the film using various techniques.

to conduct an experiment in which the temperature is

controlled by a thermostat. L. Flexibility

The flexibility of the film correlates with elasticity. The

None of the researches considered Studies ex-vivo did flexibility parameter is usually measured by skin tension.

not mention SFFSs, indicating their low prevalence in this Some authors describe the possibility to determine this

field of development despite all the benefits of this characteristic in vivo by stretching the skin in 2–3

approach, such as high representativeness, close directions; the film will be considered flexible if there are no

applicability to real conditions on the mucous membrane or cracks in the film or skin fixation disorders.

wound surface, and absence of the need to consult an ethics

committee, which undoubtedly lengthens development time M. Stratum corneum, dermis / systemic effect / kinetics of

and negatively affects production profitability. drug transport / transport of active substances / release

of active substances

H. Moisture content Although topical systems are mentioned, it might be

To fix the conclusion of the process of its construction crucial to prove that transdermal action exists. Transdermal

and pinpoint the precise drying period, the moisture content action, as opposed to local action, is concerned with the

of the produced film is assessed. Humidity is studied using delivery of active substances via the dermis into the

pharmacopoeial techniques (gravimetry) and readily bloodstream (Euro- pean pharmacopoeia). Dermal transit

available equipment (moisture metres, humidity analyzers). can occur through a variety of chemical and physical routes.

The end of film formation can also be determined by a The molecule of the active drug must be lipophilic (logP =

stickiness test, which is practical and affordable. A 1-4 or less), have a mass of no more than 500 Da, and be

separation test is advised by certain writers. If cotton wool is neutral. There is no doubt that even such stringent criteria

put to the film before drying, the cotton wool fibres will for the active component molecule are insufficient for

disappear. This shows that the film has at last dried out. transdermal absorption. When Penetration Enhancers are

added to the dosage form, the skin is affected in a variety of

Due to the risk of elasticity loss and skin harm from ways, including across the stratum corneum and below the

solid film particles, severe drying of the film makes hair follicle. and down sweat glands. Low molecular

moisture assessment in dynamics conceivable. weight compounds can move through and among epidermal

cells in the trans epidermal pathway. Larger molecules can

I. Thickness pass via the trans follicular channel, but because each

After the film has been removed from the surface, its person's follicle count varies and they don't cover the full

thickness is measured using specialised equipment. It should skin surface, the amount of active chemicals that can pass

be highlighted that separating the formed film from the through is reduced. However, excipient properties can also

surface, which was not accomplished by researchers for all make a difference in permeability. For instance, the use of

compositions being created, is required in order to analyse polymers and the methods for applying them that result in

the parameters of the system's ultimate state in situ. occlusion can make the skin more permeable. Other

However, in our opinion, these examinations are necessary, technical methods, such comminuting active substances or

particularly for in vitro films (for example, on a glass plate). producing microemulsions and nanoemulsions, can improve

It is challenging to predict the behaviour of the produced the flow of active chemicals through the skin. The direct

film in vivo and the adherence of patients to therapy relationship between the methods' safety. Affecting the

utilising it if it is not possible to separate the film from the skin's capacity to reestablish the natural barrier, for instance,

surface and measure its mechanical and other properties. protein denaturation is a destructive technique that is by

J. Morphology definition unsafe. The goal of local or topical action is not to

Transmission or scanning electron microscopy can be transport active ingredients into the systemic circulation, but

used to examine the morphology of the film. The film's rather to treat either healthy or injured skin. The idea that the

homogeneity, surface roughness, and microscopic shape are active ingredients in these preparations shouldn't reach the

assessed. A visual description of the pattern, gloss, etc. systemic circulation and that their release into the

serves as the sole indicator of the film's uniformity. In situ bloodstream should be regulated if the skin is damaged is

spray film-forming systems, whose film coating is rarely rational yet disputed. The stratum corneum acts as a

visible, are described in several investigations. The quality reservoir for the active substances since the dermis' deeper

indicators for the film's properties that were described are layers are less lipophilic, and their release from this layer is

not appropriate for such developments. In these situations, it prolonged.

is vital to create and use tests that unequivocally show the Despite this, it is important to take into account both

protective properties of the pharmaceutical composition in topical and transdermal preparations when SFFSs are

order to demonstrate the efficacy of the wound surface discussed because the excipients' placebo effect may or may

dressing. not increase the permeability of the components. Therefore,

IJISRT22DEC1449 www.ijisrt.com 1165

Volume 7, Issue 12, December – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

a placebo prototype preparation intended for topical use may a) Chitosan

conceivably also double as a transdermal composition. It Aside from being a filmmaker, chitosan also has

makes sense to focus primarily on topical preparations antimicrobial, antioxidant, and mucoadhesive

because the demands for the final films will vary in terms of activity, making it suitable for use in topical drug

their physical and chemical properties. delivery. Chitosan has a relatively high surface

tension. The surface tension of chitosan increases

N. Water washability with increasing concentration and molecular weight,

Many authors also recommend using cotton swabs to but these properties make chitosan difficult to

determine the water washability, also known as the moisture dissolve in water. Surfactants are usually used to

erasability, which can be done. The dry film can be used to improve the solubility of chitosan.

gauge how easily the film was moistened. After washing the

film with water, it is rated on a scale from readily erased to In making FFS from chitosan, Tween 80 can

moderately erased to poorly erased. be used to reduce the surface tension. The decrease

in surface tension of chitosan goes hand in hand

O. Gas and moisture permeability with an increase in the degree of deacetylation and

Characteristics of gas and moisture permeability are also its concentration, but the trend is not very

controversial among the researchers. The presence of these significant. The use of PEG 400 can also increase

properties in the film, in addition to its hydrogel base, the stability and solubility of drugs in chitosan.

creates a moist environment on the protected surface, which Chitosan also has good conductivity with an

increases regeneration and significantly reduces subsequent increase in molecular weight so that it can be

scarring of wound. The gas permeability of the coating is delivered using a electrostatic spray. Chitosan

necessary for tissue regeneration. viscosity also decreases with increasing degrees of

deacetylation. With these properties, chitosan can

P. Sterility / microbiological purity

form films with denser droplet densities with smaller

The previously mentioned pharmacopoeias provide

droplet diameters, ranging from 4–27 μm. Chitosan

parameters as microbiological purity for non-sterile products

is also more hydrophilic at higher degrees (30–40

and sterility. The sterility parameter is used for product for

°C) such as on the skin and eyes.

injured skin and open wounds. Like other sterile products

SFFSs must be manufactured according to GMP b) Xanthan Gum

requirements in clean rooms. Most composition for film- Based on research conducted, the spray- ability of

forming aerosols/sprays can be sterilized by heat, or by xanthan gum was strongly influenced by its

filtration (if product viscosity allows). In other cases, e.g. for viscosity. The addition of surfactants in the xanthan

thermo- labile substances (biological products, etc.) the gum solution decreased the surface tension and

composition may be prepared aseptically. In addition, the reduced the size of the droplet. Interestingly, the

spray dosage forms have the unique ability to maintain their viscosity and flow proper- ties were not significantly

sterility after the first and sub- sequent applications. changed. In addition, the spray angle and coverage

Spraying creates a spray pressure that avoids microbial area of the xanthan gum solution decreased with

contamination of the product. increasing xanthan gum concentration.

IV. POLYMERS USED IN FILM FORMING SPRAY B. SYNTHETIC POLYMERS [25-29]

a) Carbopol

A. NATURAL AND SEMISYNTHETIC POLYMERS [20-24]

Carbopol also has thixotropy flow properties.

Cellulose & Ethyl cellulose forms films that are easily

Carbopol itself forms an amorphous hydrogel that is

washed away with water.34 The concentration of ethyl

good for open wounds because it can donate or

cellulose that produces films with excellent characteristics is

absorb wound moisture. The viscoelastic nature of

5.- 02–5.25% and is generally combined with Eudragit.

carbopol allows of deacetylation. However, its

HPMC is reported to have a slow drying time. The optimal

hydrophilic nature does not correlate with its

concentration to get excellent film characteristics is 2%. At

permeability to water vapour. The tensile strength of

these concentrations, HPMC produces clear, thin, and

chitosan will also increase with increasing degrees

smooth films.

of deacetylation, contrary to its elongation.

Na-CMC is known to have a thixotropic flow rate that

b) Cyclodextrin

allows it to become thinner when under pressure so that it is

Cyclodextrin is known to maintain drug stability

easy to pass through the nozzle and return to initial

from crystal deformation. Cyclodextrin is also

consistency after being sprayed. The maximum limit of Na-

reported to have a small impact on increasing the

CMC concentration that can be sprayed is 2.5 %. The

viscosity of the film- forming solution, so it is easy

optimal level of Na-CMC that produces films with excellent

to spray.

sticking properties and a constant dose in each spray is

1.5%. Na-CMC has also been reported to maintain stability c) Gellan Gum

and release the drug in a controlled manner, thereby Gellan gum (GG) has viscoelastic properties so that

increasing its therapeutic efficacy. it is easily delivered using a spray system. The

viscoelastic nature allows GG to melt in consistency

IJISRT22DEC1449 www.ijisrt.com 1166

Volume 7, Issue 12, December – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

when sprayed and return to its original texture after crystallisation of testosterone, thereby increasing its

being on the sur- face of the skin. In a spray system, flux.88,89.

GG is also reported to be able to encapsulate cells

and deliver them via gel droplets in situ. g) Kollidon

Kollidon is a synthetic polymer that is also widely

GG has thermosensitive properties that are used in the pharmaceutical world. There are several

very beneficial in spray systems. Its thermosensitive types of Kollidon with different characteristics

nature makes it easy to change shape from solution appropriate for solid, semisolid, and liquid

to gel when contacting surfaces with temperatures preparations. In liquid and semisolid forms,

higher than room temperature increase in the Kollidon can increase solubility and permeability,

diffusion coefficient of the drug. The combination of and control drug release.

Carbopol and Poloxamer is said to be better than

using Carbopol alone. At a concentration of 0.05 %, Kollidon® 30 has been reported to form

the polymer combination produces a film with good transparent, thin, and well-dispersed films. During

spray ability (spray angle, drying time, and uniform 28 days of storage, the pH of Kollidon® 30

content per spray) with an acceptable release of the remained stable without significant changes.43

drug. Carbopol is also known to produce gels with Kollidon® 30 and Kollidon® VA64 have the ability

characteristics that are more resistant to heating. to act as antinucleants that can inhibit testosterone

crystallisation. Drug permeation in the skin has also

d) Eudragit been reported to be increased with the use of

Eudragit is available in various types with different Kollidon® 30 films.

pur- poses for use. Generally, these synthetic

polymers are used as additives to tablets for C. EXCIPIENTS USED IN FILM-FORMING SPRAYS [30-34]

modifying drug release.85 However, Eudragit is also Besides polymers, other excipients are also added for the

known to increase drug permea- tion in the purpose of improving the quality of the preparation and its

skin,34,86,87 so that its application in topical therapeutic efficiency. The following is a list of excipients

preparations is widely developed. (Table 3) commonly used in film-forming spray systems.

a) Crosslinkers

Eudragit EPO, Eudragit E 100, Eudragit S 100, The use of crosslinkers can affect the elasticity,

Eudragit RL 100, and Eudragit RS 100 produce viscosity, solubility, glass transition, and film

transparent and shiny films while Eudragit RSPO stiffness of the polymer. The use of NaCl as a

and RLPO do not. Films produced by Eudragit EPO, crosslinker in gellan gum also affects the gel’s

Eudragit E 100, Eudragit RL 100, and Eudragit RS sensitivity to temperature, so that film formation is

100 cannot be washed away with water. In contrast, better and faster. NaCl also increases cell

Eudragit S100 provides film that can be removed encapsulation in gellan gum.

with water after being applied to the skin. This is

because Eudragit S100 can dissolve above pH 7. b) Permeation Enhancers

Eudragit S100 also does not cause any skin Eutectic mixes are frequently used to increase the

irritation. penetration of drugs. A mixture of menthol and

camphor is one of the strongest eutectic mixtures. It

Eudragit RS 100 has been reported to have is appropriate to use camphor and menthol as a

good spray ability, adhesiveness, and flexibility. penetration enhancer for medications that are also

However, use above a concentration of 15% can hydrophobic since they combine to generate a

reduce the ability to wash with water, whereas hydrophobic combination. However, menthol and

Eudragit RLPO produces better films at a level of camphor might promote skin peeling and the

10.05% in a mixture with ethyl cellulose 5.02 %. development of pores. A blend of camphor and

menthol is characterised by a warm feeling that

e) Lutrol develops into a cold feeling that comes on gradually.

Lutrol F-127 has film characteristics and spray

patterns similar to Carbopol 940 but produces a In a Franz diffusion cell with nylon

more uniform dose of the drug in each spray, with a membranes, the eutectic mixture of camphor and

smaller standard deviation. Lutrol F-127 also menthol significantly improves the penetration of

produces films with better drug release compared to the antifungals fluconazole, clotrimazole, and

Carbopol 940. No skin irritation has been reported. voriconazole. Camphor and menthol can improve

medication penetration by interacting with the lipids

f) Plasdone in the stratum corneum since they have hydrophobic

Research conducted by Lu et al32 shows that characteristics.

Plasdone can increase testosterone permeation better

than other polymers. The best testosterone c) Plasticisers and Stabilising Agents

permeation sequence was Plasdone > Eudragit EPO The plasticizer keeps the film elastic during film

> PVP K30 > Eudragit RL. This was due to the formation and stops it from cracking. Plasticizers

nature of the polymer, which can inhibit the can also improve the penetration of medicines and

keep active molecules stable. According to reports,

IJISRT22DEC1449 www.ijisrt.com 1167

Volume 7, Issue 12, December – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

PEG and PG play a part in enhancing the penetration d) Rheological Properties

of antifungal medications. In addition to its function To ascertain if a substance is thixotropic or not, flow

as a plasticizer, PG also serves as a solubilizer, testing is used. If a mixture possesses certain flow

which is helpful in delivering medications through characteristics, it can readily pass repeatedly through

the skin. Because PG has a sizable impact on the the sprayer nozzle. The film-forming solution can be

viscosity of the film-forming solution, the thinned by this flowing property as it moves past the

concentration must be taken into account. The use of nozzle and becomes strained before returning to its

PG as a mixed solvent to stop the crystallisation of normal viscosity after being sprayed (stress is lost).

testosterone does not work well when combined Thixotropic behaviour is characterised by the

with water or ethanol. 68 Less than 5% of PG is hysteresis circle, which is the region that is covered

necessary to increase medication penetration. by the ascending and descending curves.

PEG 400 can also increase the volume per e) Bioadhesive Strength of the Film

spray of film-forming solution. The amount per By sticking a film to the surface of the mouse skin,

spray increases with increasing PEG 400 the bioadhesive strength of the film can be measured

concentrations. The covered spray area also (2 x 5 cm). After that, 0.5 mL of distilled water is

increases with increasing PEG 400 levels. This is used to moisturise the skin. Five minutes are given

associated with a decrease in vapour pressure due to for the film and tissue surface to interact. The

the presence of PEG as a non-volatile solvent. overall force (F) required to separate the film from

the skin's surface is noted.

d) Solvents

Both volatile and non-volatile solvents are utilised in f) Tensile Strength and Elongation of the Film

the FFS system. The goal is to balance the pace of Tensile strength (TS) is the ability of the film to

film drying. Drugs find it difficult to enter and resist applied pressure.117 TS testing aims to

escape from films that dry out too soon and produce determine whether the film formed is resistant to

a hard film. To speed up the drying of the film, the abrasion and flexible so that it can follow the

active ingredient is typically dissolved in the solvent movement of the skin without cracking.

until it reaches saturation.

g) Water Washability

D. EVALUATION TESTS [35-42] The ease of film wetting is assessed in the dried film.

a) pH The film is washed with water and assessed in

To increase the stability of the active ingredient or ordinal scale, ie easily washed, moderately washed,

make it acceptable for the application location, the and poorly washed.34,40 The ease of sprinkling

pH value is tested and modified. The pH of diabetic with water will be useful if the film-forming

wounds ranges from 6.5-8 for skin pH of 4-6, while solutions contact with sensitive areas in the body

burns heal more quickly below pH 7.32. The such as eyes and mouth.

preparation's pH adjustment attempts to stop

inflammation and modifications in the physiological h) Fluid Affinity

state of the wound during the healing process. In This test is carried out to see how the ability of the

addition, the degree of ionisation in the dosage can film formed to absorb moisture from the wound or

influence how much of the medicine permeates the provide moisture to the wound. An adequate supply

skin. of moisture to the injury will speed healing, but

excess moisture can cause erosion of the wound

b) Viscosity tissue.

Each type and concentration variation of the

polymer will result in a different viscosity. The i) Occlusion Potential or Water Vapor Permeability of

viscosity of the film forming solution will affect its the Film

sprayability, so this is an important parameter, It's crucial to establish the film's permeability to wound

especially in MDS. Increasing the concentration of fluid because it influences the wetness of the wound.

the film-forming solution can reduce the coverage Infection will result from too much dampness, which will

area of the spray. promote the growth of microorganisms. For this test,

filter paper is placed over the mouth of a glass beaker

c) Tonicity holding 50 mL of water. A film-forming solution is

The application of film-forming solution to certain sprayed on one of the papers, and then the film is

parts of the body such as wound and eye mucosa allowed to develop. Following that, the beaker is kept at

requires the tonicity adjustment of the film-forming ambient temperature and humidity. Based on the

solution. Non- isotonic preparations can cause decreased water weight in the beaker, the film's water

mucosal irritation and eye pain. For this reason, the permeability is calculated.

tonicity of the preparations needs to be calculated

and adjusted using the Kahar method. The following

equation is used to determine the isotonic

concentration of the materials.

IJISRT22DEC1449 www.ijisrt.com 1168

Volume 7, Issue 12, December – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

j) Surface Morphology of the Film o) In vivo Skin Irritation Test

This test is carried out to determine the microscopic The film-forming solution is applied to the skin of

shape, surface roughness, and homogeneity of the test animals such as mice and rabbits after being

film using scanning electron microscopy (SEM) or shaved. Irritation, inflammation, erythema, oedema,

transmission electron microscopy (TEM). papule forma- tion, flakiness, and dryness are

observed 24 hours – 7 days after application.

k) Film Formation/Drying/Evaporation Time

How rapidly the film forms once the solution is p) Stability Study

sprayed is determined by the drying time of the film. Changes in particle size, chemical and 3D structures,

In some cases, the glass's surface is coated with the levels, and therapeutic action of active compounds

solution, which is then left to air dry at room after storage under various settings are

temperature. In other research, the surface of the characteristics that are frequently investigated.

glass plate is coated with a mixture of activated Thermal analysis is occasionally used to determine

silica gel and dye to provide absorption. whether or not meta- stable active compounds

recrystallize. The medicine can be kept in its original

Applying a film-forming solution to the skin crystalline form thanks to the antinucleon polymer

allows for the direct observation of drying time. A that is being used. The drug's dosage per spray and

glass plate is put against the film without being its spray pattern as a metered-dose spray will be

touched to determine whether the film has dried. The retested in a number of studies. During the storage

film is considered to have dried if there is no sign of term, the dose must be ensured.

water adherence to the glass. The drying time may

differ from using glass plates in the film drying time V. CONCLUSION

test since this approach is more accurate because the

skin contains pores and body heat. FFS can be a promising drug delivery system with

various benefits. Spray film-forming systems are modern

Cotton wool is used to gently press the dry drug delivery systems used for local, topical and transdermal

film. The quantity of cotton wool fibres adhered to delivery. Natural or synthetic polymers can be used as drug

the film serves as a gauge for the viscosity of the matrices and film formers following the need for increased

material. The film's adhesiveness is rated as high if stability and therapeutic effectiveness of the active sub-

there is a thick connected fibre, medium if there is a stance. Sprayers help form droplets with better and more

thin attached fibre, and low if there is little to no uniform distribution and dosage of drugs.

attached fibre. It requires attention when in motion

since stickiness is evaluated to determine whether REFERENCES

the film will easily attach to clothing or other items.

[1.] Sharadha M, Gowda DV, Vishal Gupta N, Akhila

l) Spraying Force AR. An overview on topical drug delivery system –

This test is carried out to find out how much updated review. Int J Res Pharm Sci.

pressure is needed to spray the film-forming 2020;11(1):368–385. doi:10.26452/ijrps.v11i1.1831

solution. The tool that can be used is Plus texture [2.] Kaur J, Kaur J, Jaiswal S, Gupta G. Recent advances

analyser (Stable Micro Systems) in topical drug delivery system. Pharm Res.

2016;6(7).

m) Potential Drug Aggregation [3.] Leppert W, Malec–Milewska M, Zajaczkowska R,

Changes in particle size will undoubtedly affect Wordliczek J. Transdermal and topical drug

sprayabil- ity. Some methods to determine the administration in the treatment of pain. Molecules.

potential for of a drug are zeta potential and size 2018;23(3):681. doi:10.3390/molecules23030681

exclusion chromatography (SEC). [4.] Dayan N. Delivery system design in topically applied

formulations: an overview. In: Delivery System

n) In vitro Drug Penetration/Release Study Handbook for Personal Care and Cosmetic Products.

Franz diffusion cells are typically employed in this Elsevier; 2005:101–118. doi:10.1016/B978-

test as compartment separators together with 081551504-3.50009-2

cellulose membranes (pore size 0.45 m), nylon [5.] Ruela ALM, Perissinato AG. Evaluation of skin

membranes (pore size 0.22 mm), or silicone absorption of drugs from topical and transdermal

membranes. The medium is phosphate buffer with a formulations. Brazilian J Pharm Sci.

pH of 7.4. The film-forming solution is added to the 2016;52(3):527–544. doi:10.1590/s1984-82502016

donor compartment once the compartment system is 000300018

prepared. At specific time intervals, a sample of the [6.] Garg T, Rath G, Goyal AK. Comprehensive review

solution that diffuses through the cells is obtained, on additives of topical dosage forms for drug

and the equipment is then used to measure it. delivery. Drug Deliv. 2015;22 (8):969–987.

Following the collection of samples, the same doi:10.3109/10717544.2013.879355

amount of fluid is replaced. [7.] Chang R-K, Raw A, Lionberger R, Yu L. Generic

development of topical dermatologic products:

formulation development, process development, and

IJISRT22DEC1449 www.ijisrt.com 1169

Volume 7, Issue 12, December – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

testing of topical dermatologic products. AAPS J. [23.] Zhuang C, Zhong Y, Zhao Y. Effect of deacetylation

2013;15(1):41–52. doi:10.1208/s12248-012-9411-0 degree on properties of Chitosan films using

[8.] Radhakrishnan A, Kuppusamy G, Karri VVSR. Spray electrostatic spraying technique. Food Control.

bandage strategy in topical drug delivery. J Drug 2019;97:25–31. doi:10.1016/j.foodcont.2018.10.014

Deliv Sci Technol. 2018;43:113–121. [24.] Zhong Y, Zhuang C, Gu W, Zhao Y. Effect of

doi:10.1016/j.jddst.2017.09.018 molecular weight on the properties of chitosan films

[9.] Ibrahim SA. Spray-on transdermal drug delivery prepared using electrostatic spraying technique.

systems. Expert Opin Drug Deliv. 2015;12(2):195– Carbohydrate Polymer. 2019;212(May2018):197–

205. doi:10.1517/17425247.2015. 961419 205. doi:10.1016/j.carbpol.2019.02.048

[10.] Algin-Yapar E, Önal Ö. Transdermal spray in [25.] Tran TTD, Tran PHL. Controlled release film

hormone delivery. Trop J Pharm Res. forming systems in drug delivery: the potential for

2014;13(3):469–474. doi:10.4314/tjpr.v13i3.23 efficient drug delivery. Pharmaceutics.

[11.] Variankaval NE, Jacob KI, Dinh SM. Crystallization 2019;11(6):290. doi:10.3390/pharmaceutics11060290

of estradiol in an acrylic transdermal drug delivery [26.] Baio FHR, Antuniassi UR, Castilho BR, Teodoro PE,

system. J Biomed Mater Res. 1999;44(4):397–406. Silva EE. Correction: factors affecting aerial spray

doi:10.1002/(SICI)1097-4636(19990315) 44:4<397, drift in the Brazilian Cerrado. PLoS One.

AID-JBM5>3.0.CO;2-Q 2019;14(6):e0217957.

[12.] Mandal UK, Chatterjee B, Husna F, Pauzi B. A doi:10.1371/journal.pone.0217957

review on trans- dermal spray: formulation aspect [27.] Gaytan I, Nicolas B, Gouriou F, Leru JP, Mallarach J.

mathews journal of pharmaceu- tical science a review Effect of working pressure, fluid temperature, nozzle

on transdermal spray: formulation aspect. Mathews J type and nozzle orifice size, on spray characteristics

Pharm Sci. 2016;1(March):006. using viscous feed additive DL-2-hydroxy-4-

[13.] Chavan P, Bajaj A, Parab A. Topical sprays: novel (methylthio)-butanoic-acid. Powder Technol.

drug delivery system. Int J Pharm Chem Res. 2018;336(2017):383–392.

2016;2(2):102–111. doi:10.1016/j.powtec.2018.05.045

[14.] Parmar K, Patel MB. A review on sublingual spray: [28.] Bakshi A, Bajaj A, Malhotra G, Madan M, Amrutiya

novel drug delivery system. Int J Pharm Sci Res. N. A novel metered dose transdermal spray

2017;8(11):4533–4539. doi:10.13040/IJPSR.0975- formulation for oxybutynin. Indian J Pharm Sci.

8232.8(11).4533-39 2008;70(6):733–739. doi:10.4103/0250-474X.49094

[15.] Aravindhanthan V, Anjali PB, Radhakrishnan A. [29.] Geh KJ, Stelzl A, Gröne A, Wagner L, Förster B,

Sublingual spray: a new technology oriented Winter G., Development of a sprayable hydrogel

formulation with multiple benefits. Int J Res Pharm formulation for the skin application of therapeutic

Sci. 2019;10(4):2875–2885. antibodies. Eur J Pharm Biopharm. 2019;142

doi:10.26452/ijrps.v10i4.1567 (November2018):123–132.

[16.] Algin-Yapar E, Inal Ö. Transdermal spray in doi:10.1016/j.ejpb.2019.06.015

hormone delivery. Trop J Pharm Res. [30.] Lu W, Luo H, Wu Y, Zhu Z, Wang H. Preparation

2014;13(3):469. doi:10.4314/tjpr.v13i3.23 and characterization of a metered dose transdermal

[17.] Kumar Mandal U, Chatterjee B, Husna F, Pauzi B. A spray for testosterone. Acta Pharm Sin B.

review on transdermal spray: formulation aspect. Rev 2013;3(6):392–399. doi:10.1016/j.apsb.2013.10.003

Transdermal Spray Formul Asp M J Pharma. [31.] Lu W, Luo H, Zhu Z, Wu Y, Luo J, Wang H.

2016;1(1):6. Preparation and the biopharmaceutical evaluation for

[18.] Ranade S, Bajaj A, Londhe V, Babul N, Kao D. the metered dose transdermal spray of dexketoprofen.

Fabrication of topical metered dose film forming J Drug Deliv. 2014;2014:1–12.

sprays for pain management. Eur J Pharm Sci. doi:10.1155/2014/697434

2017;100:132–141. doi:10.1016/j.ejps.2017.01.004 [32.] Paradkar M, Thakkar V, Soni T, Gandhi T, Gohel M.

[19.] Kathe K, Kathpalia H. Film forming systems for Formulation and evaluation of clotrimazole

topical and trans- dermal drug delivery. Asian J transdermal spray. Drug Dev Ind Pharm.

Pharm Sci. 2017;12(6):487–497. 2015;41(10):1718–1725.

doi:10.1016/j.ajps.2017.07.004 doi:10.3109/03639045.2014.1002408

[20.] Frederiksen K, Guy RH, Petersson K. The potential [33.] Dhiman S, Singh TG, Rehni AK. Transdermal

of polymeric film-forming systems as sustained patches: a recent approach to new drug delivery

delivery platforms for topical drugs. Expert Opin system. Int J Pharm Pharm Sci. 2011;3(SUPPL.

Drug Deliv. 2016;13(3):349–360. doi:10. 5):26–34.

1517/17425247.2016.1124412 [34.] Bishop SM, Walker M, Rogers AA, Chen WYJ.

[21.] Kim DS, Kim JS, Lee MC. Thin film forming Importance of moisture balance at the wound-

technique based on hybrid spray coating using dressing interface. J Wound Care. 2003;12(4):125–

electrostatic force and air pressure. Jpn J Appl Phys. 128. doi:10.12968/jowc.2003.12.4.26484

2014;53(5S3):05HC08. [35.] Gohel MC, Nagori SA. Fabrication of modified

doi:10.7567/JJAP.53.05HC08 transport fluconazole transdermal spray containing

[22.] Urkan E, Guler H, Komekci F. A review of ethyl cellulose and eudragit® RS100 as film formers.

electrostatic spraying for agricultural applications. AAPS PharmSciTech. 2009;10 (2):684–691.

Tarim Makinalari Bilim Derg. 2016;12 (4):229–233. doi:10.1208/s12249-009-9256-8

IJISRT22DEC1449 www.ijisrt.com 1170

Volume 7, Issue 12, December – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

[36.] Mori NM, Patel P, Sheth NR, Rathod LV, Ashara

KC. Fabrication and characterization of film-forming

voriconazole transdermal spray for the treatment of

fungal infection. Bull Fac Pharmacy Cairo Univ.

2017;55(1):41–51. doi:10.1016/j. bfopcu.2017.01.001

[37.] Rajab NA. Preparation and evaluation of ketoprofen

as dermal spray film. Kerbala J Pharm Sci. 2013;6:1–

8.

[38.] Saingam W, Chankana N, Madaka F, Sueree L,

Homchuam S. Formulation development of topical

film formimg spray from Piper nigrum L. Thai J

Pharm Sci. 2018;42(supplement):93–97.

doi:10.1134/S0965545X11100087

[39.] Sukhbir K, Navneet K, Sharma AK, Kapil K.

Development of modified transdermal spray

formulation of psoralen extract. Der Pharm Lett.

2013;5(2):85–94.

[40.] Hakim M, Walia H, Rafiq M, Grannell T, Cartabuke

RS, Tobias JD. Oxymetazoline metered dose spray:

factors affecting delivery volume. J Pediatr

Pharmacol Ther. 2016;21(3):247–251.

doi:10.5863/1551-6776-21.3.247

[41.] Ru Y, Gan Y, Zheng J, Zhou H. Design and

experiments on droplet charging device for high-

range electrostatic sprayer, 2008; 1:561–571.

doi:10.5772/18546

[42.] Kwon S-I, Kyung K-H, Park J-Y, et al. Uniform anti-

reflective films fabricated by layer-by-layer ultrasonic

spray method. Colloids Surf a Physicochem Eng Asp.

2019;580((August):123785):123785.

doi:10.1016/j.colsurfa.2019.123785

IJISRT22DEC1449 www.ijisrt.com 1171

You might also like

- Iso 14644-13-2017Document43 pagesIso 14644-13-2017dukeplus100% (4)

- Chapter 18 Financial Markets Test BankDocument16 pagesChapter 18 Financial Markets Test BankNicholas60% (5)

- Black & DeckerDocument28 pagesBlack & DeckerSunny ShresthaNo ratings yet

- 2014 Nissan Maxima 42297 TMDocument195 pages2014 Nissan Maxima 42297 TMPHÁT NGUYỄN THẾNo ratings yet

- BS Databook2002Document93 pagesBS Databook2002Dani WijayaNo ratings yet

- Mohit Sharma Zonal HeadDocument4 pagesMohit Sharma Zonal HeadKriday SharmaNo ratings yet

- Religions of The World Infographics by SlidesgoDocument33 pagesReligions of The World Infographics by SlidesgocaspianNo ratings yet

- Using Pony in FlaskDocument90 pagesUsing Pony in FlaskPrivilege MudzingeNo ratings yet

- GFRP of Cargo ShipDocument135 pagesGFRP of Cargo ShipAgus SantosoNo ratings yet

- The Elasticity of Demand For Books, Resale Price Maintenanca and The Lerner IndexDocument20 pagesThe Elasticity of Demand For Books, Resale Price Maintenanca and The Lerner IndexAnahí SalazarNo ratings yet

- Extraction and Characterization of Nigeria Shea Butter OilDocument7 pagesExtraction and Characterization of Nigeria Shea Butter OilJordon AlvaradoNo ratings yet

- Immune BoostersDocument18 pagesImmune Boosterspraveena dasamukhaNo ratings yet

- Secret Scents ReportDocument28 pagesSecret Scents Reportzer reNo ratings yet

- PaintDocument28 pagesPaintAnna KateurinaNo ratings yet

- KrisWorld Magazine V2Document87 pagesKrisWorld Magazine V2Freddy TamuedjounNo ratings yet

- A Case Study On Customer Relationship Management Strategy LaveshDocument72 pagesA Case Study On Customer Relationship Management Strategy LaveshNIKHIL SAPKALENo ratings yet

- Safety Data Sheet Tyre ShineDocument8 pagesSafety Data Sheet Tyre ShineShailendra AgrawalNo ratings yet

- Aloe Vera Candy - For GrammarianDocument92 pagesAloe Vera Candy - For GrammarianErne FlorNo ratings yet

- NDMA Annual Report 20 21Document120 pagesNDMA Annual Report 20 21RaghuNo ratings yet

- Crown Paints Company ProfileDocument26 pagesCrown Paints Company ProfileLela MwasiNo ratings yet

- Acs - Jchemed.8b00736 2Document4 pagesAcs - Jchemed.8b00736 2Andrea CabezasNo ratings yet

- Strategic Formulation NotesDocument40 pagesStrategic Formulation NotesSonia SarkarNo ratings yet

- Module No 7: Technology of Manufacturing Spice Oil & OleoresinsDocument3 pagesModule No 7: Technology of Manufacturing Spice Oil & OleoresinsmadeshNo ratings yet

- NECS 0202T-0612T Technical BulletinDocument42 pagesNECS 0202T-0612T Technical BulletinVictor AANo ratings yet

- Module III - Pharma Calculation - Methods of Expressing Concentrations - SY 2021Document59 pagesModule III - Pharma Calculation - Methods of Expressing Concentrations - SY 2021Mina BiancaNo ratings yet

- ISOLATION AND EXTRACTION OF nATURAL PRODCUTSDocument4 pagesISOLATION AND EXTRACTION OF nATURAL PRODCUTSAlvina RiazNo ratings yet

- 8 Experiment No. 8 Aldehydes Ket Answer SheetDocument7 pages8 Experiment No. 8 Aldehydes Ket Answer SheetMaej OragaNo ratings yet

- Dry Eyes and Digital Devices 1Document11 pagesDry Eyes and Digital Devices 1Koas HAYUU 2022No ratings yet

- The 10 Principles of Food Industry Sustainability - 2015 - Baldwin - Front MatterDocument7 pagesThe 10 Principles of Food Industry Sustainability - 2015 - Baldwin - Front MatterNaaomy DuqueNo ratings yet

- Challan (MTR Form Number-6)Document1 pageChallan (MTR Form Number-6)Kajal AvchareNo ratings yet

- Reasearch Paper 5Document7 pagesReasearch Paper 5Q-MT Branch HQ 497 OM&MNo ratings yet

- Formulation and Evaluation of Nail Lacquer Containing Anti Fungal Griseofulvin For The Treatment of OnychomycosisDocument13 pagesFormulation and Evaluation of Nail Lacquer Containing Anti Fungal Griseofulvin For The Treatment of OnychomycosisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- ESBP End Term AssignmentDocument18 pagesESBP End Term Assignmentvasudha kabraNo ratings yet

- Is 15317 1 2003Document21 pagesIs 15317 1 2003Trupti PawarNo ratings yet

- 4 Cream PDFDocument27 pages4 Cream PDFremo sNo ratings yet

- FINLATICS Pfizer Company ProfileDocument9 pagesFINLATICS Pfizer Company ProfileVISHAL GUPTANo ratings yet

- Final PP 1 CompressedDocument26 pagesFinal PP 1 Compressedapi-596919522No ratings yet

- "Mosquito Repellants" A Case StudyDocument10 pages"Mosquito Repellants" A Case StudyLewis SimonNo ratings yet

- Applsci 12 10040 v2Document11 pagesApplsci 12 10040 v2Juan VelasquezNo ratings yet

- Rishav OIP-2021 PREB1Document59 pagesRishav OIP-2021 PREB1Khan aqsaNo ratings yet

- Tipe Tipe DianalDocument4 pagesTipe Tipe DianalLiestia NoorNo ratings yet

- Tron Various PDFDocument27 pagesTron Various PDFSindhu ThomasNo ratings yet

- AswagandhaDocument9 pagesAswagandhaBuilders ArenaNo ratings yet

- Episodes 22 & 23 - Corpo LawDocument7 pagesEpisodes 22 & 23 - Corpo LawBarem Salio-anNo ratings yet

- Fevicryl CatalogueDocument64 pagesFevicryl CatalogueCambridge GT100% (1)

- Review On Market Available Herbal Antioxidant Content of Facewashes in IndiaDocument7 pagesReview On Market Available Herbal Antioxidant Content of Facewashes in IndiaSacop ProjectNo ratings yet

- Development Project Management Planning Tools and Techniques Final Project ReportDocument8 pagesDevelopment Project Management Planning Tools and Techniques Final Project ReportRupam Pratikshya100% (1)

- Vinnapas Solid Resins Brochure 2016 - 7409 - ENDocument24 pagesVinnapas Solid Resins Brochure 2016 - 7409 - ENJohnNo ratings yet

- Plants Hormones, Responses and Feedback Mechanisms Week 3 Gen Bio 2Document3 pagesPlants Hormones, Responses and Feedback Mechanisms Week 3 Gen Bio 2kurt jenricNo ratings yet

- Development of Mosquito Repellent FormulDocument8 pagesDevelopment of Mosquito Repellent Formulsri wahyuniNo ratings yet

- Incompatibilities - PhysicalDocument5 pagesIncompatibilities - PhysicalestherNo ratings yet

- Biology Investigatory ProjectDocument27 pagesBiology Investigatory ProjectBarsha DasNo ratings yet

- Tea Project - 106a33217Document121 pagesTea Project - 106a33217dilini100% (1)

- International Numbering System For Food AdditivesDocument94 pagesInternational Numbering System For Food AdditivessuryadbugNo ratings yet

- Preparation and Evaluation of Catharanthus Roseus Face Sheet Mask SerumDocument4 pagesPreparation and Evaluation of Catharanthus Roseus Face Sheet Mask SerumInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Polymer: IUPAC DefinitionDocument14 pagesPolymer: IUPAC DefinitionSashimiTourloublancNo ratings yet

- HP 3rd AssignmentDocument8 pagesHP 3rd Assignmentmrcopy xeroxNo ratings yet

- Comparative Analysis of Zingiber Officinalis Lotion in Different Ratio With Quality ControlDocument5 pagesComparative Analysis of Zingiber Officinalis Lotion in Different Ratio With Quality ControlAgiv AlghivariNo ratings yet

- Cambridge IGCSE™: Geography 0460/12 May/June 2021Document18 pagesCambridge IGCSE™: Geography 0460/12 May/June 2021Aja Saidylee.No ratings yet

- DIET Hassan Science EM Q Bank 2022-23Document60 pagesDIET Hassan Science EM Q Bank 2022-23masoodmohsinNo ratings yet

- Salscent (SST) : A Self-Encapsulation Fragrance TechnologyDocument2 pagesSalscent (SST) : A Self-Encapsulation Fragrance TechnologyRaisha RamadantiNo ratings yet

- WAX WTFluorescentWaterDispersionsDocument3 pagesWAX WTFluorescentWaterDispersionsaparnaNo ratings yet

- Natural and Organic Cosmetics: Beneficial Properties For The Environment and HealthDocument6 pagesNatural and Organic Cosmetics: Beneficial Properties For The Environment and HealthIJAERS JOURNALNo ratings yet

- SIPS Two Days National Seminar 10 & 11 FEB 2023 Abstract BookDocument115 pagesSIPS Two Days National Seminar 10 & 11 FEB 2023 Abstract BookAvinash MansukNo ratings yet

- Carbomer 940Document2 pagesCarbomer 940Mario EssamNo ratings yet