Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

17 viewsD3 - Us5554020a

D3 - Us5554020a

Uploaded by

Ignace TackCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- D4 - Wo2008088600a1Document30 pagesD4 - Wo2008088600a1Ignace TackNo ratings yet

- D2 - Us4466785aDocument6 pagesD2 - Us4466785aIgnace TackNo ratings yet

- 1 - Wo18134758Document25 pages1 - Wo18134758Ignace TackNo ratings yet

- Wo 20065504Document25 pagesWo 20065504Ignace TackNo ratings yet

- Wo 20065505Document22 pagesWo 20065505Ignace TackNo ratings yet

- Wo 19043470Document25 pagesWo 19043470Ignace TackNo ratings yet

- Wo 20065506Document24 pagesWo 20065506Ignace TackNo ratings yet

- Wo 17096438Document39 pagesWo 17096438Ignace TackNo ratings yet

D3 - Us5554020a

D3 - Us5554020a

Uploaded by

Ignace Tack0 ratings0% found this document useful (0 votes)

17 views8 pagesOriginal Title

D3 - US5554020A

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

17 views8 pagesD3 - Us5554020a

D3 - Us5554020a

Uploaded by

Ignace TackCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 8

‘US00S5S4020A,

United States Patent 1) tn Patent Number: 5,554,020

Rao et al. 45] Date of Patent: Sep. 10, 1996

54] SOLED LUBRICANT COATING FOR FLUID 4,285,640 8/1981 Mukai

PUMP OR COMPRESSOR 4309998 ADM. Nabayana esl

4490102 12/986 Cam etal wonseanwnnne ABVITB

175] Inventors ¥. Darga N. Rao, Bloomfield 4551385 eae Lord

Township: Carte, Fectar, fEI6365 abIsee Hate SA ca ETS

ington Hills, bod “ 4.695.440 2/1987 Mura et al. “ 418/178,

662267 5/96? Kaka et a

(73) Assignee: HAiS Motor Company, Dearborn, 4.717322 1/1988 Masuda ee ake... 41878

4827,119 5/1990 Most

BAT Appl No. 319,909 Primary Examiner—Chaties G, Preay

(2 Fle 7, 884 Face ison or Ft es Mote

ts rac 20805 assraacr

2 aigpcoarne .

ts 7%: 816 Say eeny pom, vn eae moa pes

i ‘constituted of a light weight raiertal and a coating on at

428/416, 458, 411.1 ease one of the parts Io effect essentially zero clearance

it between te parts wheze they merge togother The coating is

ba Rete Cited of solid lubricants in a polymer resin matrix,

U.S, PATENT DOCUMENTS stable up to 709" F.

097.522 7977 Iooshiwe ta

4.209.288 5/1980. Schwan.

9 Claims, 3 Drawing Sheets

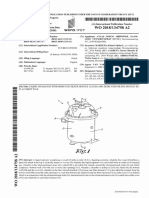

U.S. Patent Sep. 10, 1996 Sheet 1 of 3 5,554,020

WS

f NL

20. CXS

X= 19

FIG.L \ iN “4

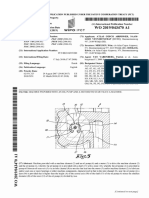

USS. Patent Sep. 10, 1996 Sheet 2 of 3 5,554,020

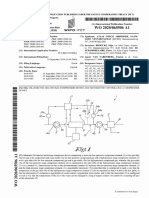

U.S. Patent Sep. 10, 1996 Sheet 3 of 3 5,554,020

5,554,020

1

SOLID LUBRICANT COATING FOR FLUID

PUMP OR COMPRESSOR.

BACKGROUND OF THE INVENTION

1. Technical Field

‘This inveotion relates to modification of pump designs for

twansferring liquids and to modification of compressor

‘designs for transfering geses (the écanaferred fluid being in

shea‘), 19 increase efficiency and reliability of the Suid

transfer,

2, Discussion of the Prior Art

The state of the prior an for design of pumps and

compressors have attained only limited efficiencies, Efi

ciency is usually defined to mean the rato of the amount of

‘energy siored in the pumped fluid to the energy put into the

pump. Indicators of high efficiencies not only arc less

leakage, but higher output density and pressure. Gas fluid

‘pumps, such as aiomotive turbochargers, have an eiiclency

Uypically of 50-60%, liquid pumps typically of 70-85% and

some speciah automotive off pumps of up to 90%. The

‘miied elicieney ofthe prior an is indicative of leakage: an

‘deal pomp or compressor would sllow no leakage beiween

the relatively moving parts therein which do the pumping. In

‘edition, ainity or adhesion of the fuid to the pamping,

surfaces causes shear losses which result in heating of the

fui.

State of the art pumps or compressors incorporate. a

‘centain degree of intentional looseness between the cela

tively moving pasts, such as a rotor and housing, @ accom:

moda differential thermal expansion of the parts snd t0

feduce the losses due to shear since the shear losses increase

asthe viscous film thickness decreases. Such expansion will

@) cause rabeing or mechanical contact (i increase friction

between such parts, and (ii) increase friction as 2 result of

surface viscous friction that arises between the moving parts

due to fiuid shear, if not alleviated by designed looseness.

Such designed looseness thus limits efficiency.

‘There also exists im the prior art an inability to use lightee

weight, lower strength metal materials (Le. aluminum) for

the compressor designs which experience high unit uid

loadings. Such loadings can distor. such lower strengch

telals which thereby tend to exaggerate leakage or crease

fiction resulting in additional poor efficiency.

SUMMARY OF THE INVENTION

nis an object of ths invention o provide a fluid pomping

‘spoaratus thet has selatvely-moving intemal parts consti-

uted of a fight weight material, such as alumioum or

magnesium, t0 promote less mass panicularly for automo-

tive vebicle applications, while 2 the sarae time enhancing,

pumping efficiency with essentially zero fluid leakage.

Ina frst aspect, the invention is 2 high efficiency fluid

‘pump for compressing gases or pumping liquids, the appa-

‘ates comprising (a) means for effecting pumping action by

use of relatively movable parts which cyclically move

together and move apart aia 2on8 0 wansfer uid, the parts

being constituted ofa light weight material selected from the

‘group consisting of aluminum, magnesivm, titanium, cop-

er, bronze, ceramics, such a8 silicon nitride, cordierire

(magnesium zluminam silicate), (b) a coating on at least one.

of the pars insufficient thickness 10 provice essentially 2270

‘clearance when said parts have moved together at said zone,

‘the coating compzisiag solid lubricants in a polymer resin

marx stable up to 700° F. In case of ceramic parts, a thicker

1s

2s

ss

2

‘costing is applied on a rough machined or as-moided surface

‘nd finished by a standard grinding operstion. This facile

totes very rapid sizing at a substantial savings in process.

cost, relative to uncoated ceramic pars,

‘The invention, in enother aspect, is a method of making

a high efficiency fuid pumping apparatus for ges compres-

sors or liquid transfer, compesing: (6) forming aluminum

based relatively movable parts that entrain and effect a

puraping action of a Aid, che pans having surfaces that

fyclically merge together and move apart io transfer id by

placing a sbear load on such surfaces; (b) machining seid

surlaces 10 a finish of 100-150 microns per inch: (c)

preparing said ough-mschined surfaces by etching or phos-

hating to effect a dimpled texture; (€) depositing e thin

eating on the prepared surface by spraying or rolling, the

costing consisting of a mixture of solid lubricant particles

and hect curable resin that attracts gas or liquid molecules

‘and 48 siable up to a temapereture of 700° F., the solid

lubricant partictes having an average pasticle sie withio the

range of 0.5 to 10 rmicrons, the costing being deposied in a

thickness to create a slight interference at said zones; ()

slowly heating the deposited coating to © temperature of

about 200° F. and holding sai temperature fora east fifteen

minutes followed by additional 13 minutes at 375°-400"

and (f)afterretorning the temperatute of the coating vo room

emperature, operating said pump to abrade said coated

surfaces 10 essentially a nero clearance between said rela-

tively moving parts

‘An advantage of this invention is an enhancement of

pomping efficiency by 5-11% and ar increase in pumped

‘volume (density and pressure).

BRIEF DESCRIPTION OF THE DRAWINGS

FIG. 1 is 2 central sectional view of @ lobed compressor

‘employing the principles of this invention:

FIG. 2 is @ perspective view of the housing for the

apparatus of FIG. 1:

FIG. 3 is a perspecsive view of the lobe rotors for the

‘apparamus of FIG, 1, the roiors being separated for conve-

nicnce of ilustration;

FIGS. 4 ard 4B are schematic central sectional views of

‘a vane oil pump embodying the principles af this invention,

the views ilustrating different stages of the pumping action;

and.

FIGS, 5-7 are schematic sectional views of pumps

‘employing the principles of this invemtioa, FIG. 5 ilustrat-

ing & schematic sectional view of an internal gear pump.

FIG. 6 illustrating a schematic sectional view of an external

‘gear pump, and FIG. 7 illustrating a schomatie central

sectional view of @ Bares gear punrp.

DETAILED DESCRIPTION AND BEST MODE

‘This invention applies a low friction, wear resistant solid

film lubrieast coating (whch costing is compatible with and

‘has ality for convemional liquid lubricants such as lub

cating oil) to af least critical, if not all, the potential rubbing

and wearing surfaces of internal cowponeats of the appara-

tus, namely the rotor housing, the Tolor, gear and scroll

surfaces in the case of generator type oil pump, vanes in the

‘case of vane type oil pumps, and swash plates and pistons in

the case of swash plate type oil pumps. Those devices have

\ypically been eonsiracted of east iron or steel with some

recent designs using forged or precision die cest high

strength aluminum alloy. Unfortunately, when these purnp

5,554,020

3

designs are vs0d for motor vehicle applications such as for

pumping oil or transmission fuid, or air in the case of

Superchargers, the pumping efficney limits the ability of

such pumps to provide proper oil (or fiuid) flow rates

Without enlarging the size of the pump beyond that tolerated

by the weight and desigo specifications for automotive

pumps, Ineveasing the pimp size is undesirable from the

iewpoint not only of packaging within a very crowded

vehicle eavelope bul the added weight, 2 a zesull of the

increased pump size, patally negates the weight advantage

of the device to reduce Tue] consumpiion and emissions for

the vehicle. By replacing the cast iron or hardened stee]_

components with forged high strength 390 aluminum alloy

Components, a weight reduction in the oil pump mass 1s

achieved. But in the past such substitution of aluminum bas

not been deemed successful because of high wear rates and

Tack of durability and interference from thermal expansion.

FIG. | illustrates for atypical ges compressor 10 used for

engine super-charging. A low fiction. Woar resistant solid

Sen lubrieam coating 11, which is compatible with and has

affinity for conventional liquid engine lubricants (or can

promote gas squeeze film lubrication with close gap con-

tro), i applied to a leat surfaces 12 that cyclically merge

together and move apart at a zone 13 to tranafer fluid that

places a shear load on such surfaces; sach coating is thus

Applied to at leas: enitical f not all be potential rubbing and

wearing surfaces of the supercharger compressor compo

neni, namely the rotor housing 14 and rotor 15.16 as

selatively-moving pats, Such relaively-moving pars 14,15,

16 are constructed here of precision die cast bigh strength

aluminum alloy.

‘The coating 1h is deposited in acontolled thickness 17 of

approximately 0:5 ram, to promote an intially interforing ft

‘which abrades toa substantially ze clearance upon start up

‘of the pump. In pumps that involve fluid shear and com-

pression, its advantageous lo use coating that is actually

fia phobie (ie. tungsten disulphide or PTFE (elon) or in

a thermoset polymer). With a fluid phobic coating, zero

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- D4 - Wo2008088600a1Document30 pagesD4 - Wo2008088600a1Ignace TackNo ratings yet

- D2 - Us4466785aDocument6 pagesD2 - Us4466785aIgnace TackNo ratings yet

- 1 - Wo18134758Document25 pages1 - Wo18134758Ignace TackNo ratings yet

- Wo 20065504Document25 pagesWo 20065504Ignace TackNo ratings yet

- Wo 20065505Document22 pagesWo 20065505Ignace TackNo ratings yet

- Wo 19043470Document25 pagesWo 19043470Ignace TackNo ratings yet

- Wo 20065506Document24 pagesWo 20065506Ignace TackNo ratings yet

- Wo 17096438Document39 pagesWo 17096438Ignace TackNo ratings yet