Professional Documents

Culture Documents

Javaid Resume

Javaid Resume

Uploaded by

Javaid IqbalOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Javaid Resume

Javaid Resume

Uploaded by

Javaid IqbalCopyright:

Available Formats

JAVAID IQBAL

DCS Panel Operator

Postal Address: House No.669 Ward No 14-c Pattle Road Pir Basher Market Mulana

Chowk near Salfi wala Madras District Kot Addu Pakistan

Mobile: +923346995280

Skype ID: Javeed.iqbal80

E-Mail:Javaid.awan786@gmail.com

Technical Certificates

2 Years Apprenticeship Training (Process Plant Operator) Programme at Pak-American Fertilizer Ltd from

AUG 2009 to AUG 2011.

One Year Technical Diploma of Chemical Process from NFS Institute of Engineering & Technological

Training Multan 2009.

03 Month Training at Ammonia Plant at Pak-American Fertilizer ltd Iskandrabad.

Experience Summary Total Experience: 12+ Years

Having more than 12+ Years hand experience In Refinery and Petrochemical/Fertilizer Industry as

DCS/Field Operator in following sections NHT, PENEX-ISOM, HPU/HGU, SRU, AMU/ATU, AGR, HRU, SWS.

Currently I performing duty as DCS PANEL OPERATOR at NHT-Isomerization unit (Light Naphtha Hydro

treating, Penex-DIH) in ATTOCK REFINERY LIMITED from April 2019 To Till Date.

I have 9.08 years of worked experience as DCS Panel & Field Operator at Ammonia Plant (Gas

Processing) In AGRI TECH FERTILZER LTD (Formally Pak-American Fertilizer Ltd) From August 2009

To April 2019.

I was part of the team that worked on PAFL capacity enhancement project (PACE-125) & Full

involvement in all stages of Plant Revamp, errection, pre- & commissioning of the plant &and initial start-

up activities including flushing, blowing chemical cleaning and pressure testing.

I was part of the team that worked on PAFL reactors catalyst loading & unloading activities like,

Hydrotreator & Desulfurizer, Low Temp Shift Converter , Primary & Secondary Reformer (Socks Method)

I was part of the team that worked on Catalyst Loading and Unloading of LHT-Hydrotreating Reactor

and Replacement of Molecule Sieves Dryers In Attock Refinery Ltd.

Experience Details

Attock Refinery Limited:

Duration : April 2019 to Present

DCS PKS 401 HONY WELL TOYO JAPAN

ISOMERIZATION Unit Attock Refinery Ltd.

Currently I performing my duty as DCS Panel Operator at NHT-Isomerization Unit (Light Naphtha

Hydrotreator, Penex-DIH) its production capacity is 7000 BSPD and product RONC is 89 for Motor

Gasoline.

I have hand experience as Field Operator on following section,

Splitter Section, Hydrotreator Unit (Light Naphtha Hydro treating ), HOT Penex with DIH Section, Makeup

Gas and liquid Feed Dryer & Regeneration system, Stabilizer (RVP Control), NGS (Net Gas Scrubber)

Sweetening of Gas, Natural draft furnace (Fuel Gas + Fuel Oil) Electric heater, Hydrogen Compressor

(Double acting single stage, PD Compressor), Fin Fan Coolers, 2 & 3 Phase Separator, Cooling Tower,

Chemical Dosing like PCE & DMDS and Wash water injection in system, Oil Mist Generation System.

Agri Tech Fertilizer Limited (Formerly PAFL)

Duration : August 2009 to April 2019

DCS PANEL OPERATOR (DCS TDC-3000X HONY WELL TOYO JAPAN)

Worked as a DCS PANNEL OPERATOR At Ammonia Plant having capacity 750 MTPD, on

Amine Regeneration Unit (Acid Gas Removal), Sour Water Stripping Unit (SWS),

Methenation unit, Hydrogen & Ammonia Recovery Unit (HRU), and Steam let-down system.

FIELD AREA AMMONIA PLANT (Gas Processing)

(HPU) Hydrogen Production Unit through Methane Steam Reforming reaction. (Gas Processing)

SRU Unit (HDS-Sulphur Removing), CO-CO2 shift reactors.

Start-up & Shut down of Balance draft furnace.

Amine Regeneration Unit (BASF) & Benfield Gas Processing (Hot Potash) (CO2, H2S )

Sour water stripping unit ,Methenation, Steam let-down system

High Pressure Steam Generation system (125 kg/cm2) >HRSG System> Auxiliary Boiler

Compression Section (NG, AIR, SYN GAS, REFIGANT GAS Compressor)

Surface Condenser (Vacuum Condenser )

Centrifugal Pumps (Single and Multistage)

HP Steam Turbines (Condensing and Non Condensing)

Ammonia Synthesis (packed fixed bed horizontal type reactor) and Refrigerant section

MSD, The dehydration Package reduces the water content to the required product water specification

from the process gas stream to avoid corrosion & water freezing in ammonia converter.

Ammonia recovery system

Hydrogen Recovery Unit (HRU)

Key Skills/Responsibilities

Responsible to monitoring & control over all plant operation (Field+ Control Room) and maintain the

operating conditions under desired limits.

Take decisive actions and communicate with production supervisor, field operators in case of

troubleshooting, emergency, equipment failure or any process deviations.

Monitor and log all operating parameters ensuring that all irregularities are reported to immediate

supervisor for advice and/or resolution .

Prepare field equipment in allocated work area for maintenance activities and follow-up execution, and

recommission equipment upon satisfactory completion of work. Apply all Permits to Work requirements

and expectations throughout Permit to Work issuance in the field and during PTW field audits.

Perform electrical isolation and de-isolation work of low voltage electrical equipment in preparation of

equipment for maintenance activities in line with approved procedure.

Good understanding & reading skills about P&ID & PFD

Develop and review the Standard Operating Procedures.

Performs system start-up and shut-down as per procedures.

Risk Assessment and Job Safety Analysis.

Should have high level of communication and supervisory skills.

Full knowledge of pneumatic, hydraulic valves and actuators.

Good degree of oral / written and reading knowledge of English.

Ensure incoming shift operator is fully briefed on current operating status and significant events during

previous shift to ensure seamless hand-over of responsibilities.

Knowledge of applicable codes and standards for emergency response NFPA, API and British Standards.

Safety& Trainings

Permit to Work System Handling, JSA, Risk Assessment

Operating Maximo system.

H2S Safety, H2S Hazards awareness and Emergency handling & Fire Fighting

Training for hazardous handling like Hydrogen, Ammonia, Hydrazine, Phosphate, MDEA, DMDS H2S, PCE,

Oil and make necessary steps to prepare the plant OSHA audit.

Academic Qualification

Diploma Chemical Process from NFC Institute Engineering & Technological Multan in 2009 (75.8%)

FS.c (Pre-Engineering) from DG KHAN Board in 2008. (59.3%) (Higher Secondary School 12 TH)

Matriculation (Science) from DG KHAN Board in 2006. (78.3%)

Personal Details

Father’s Name: Muhammad Hussain

Date of birth: 14-08-1990

Nationality: Pakistan

Marital Status: Married

Religion: Islam

CNIC# 32303-1539607-3

Passport No: QC1336072

You might also like

- Petroleum Refinery Relocation Projects: 5-Phases of Project ManagementFrom EverandPetroleum Refinery Relocation Projects: 5-Phases of Project ManagementNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Lead Commissioning Engineer - Process Bala ResumeDocument5 pagesLead Commissioning Engineer - Process Bala ResumeMidha Neer50% (2)

- Hydraulic Analogy of Supersonic Flow - Lab Notes: EUROAVIA SymposiumDocument9 pagesHydraulic Analogy of Supersonic Flow - Lab Notes: EUROAVIA SymposiumaminvelayatNo ratings yet

- Hpe 2010 en PDFDocument102 pagesHpe 2010 en PDFdineshdubeyNo ratings yet

- Field Operator: - EDUCATIONDocument3 pagesField Operator: - EDUCATIONjohn MNo ratings yet

- Process Operator Experience 08 Years Muhammad Faisal: Details of Experience at LNG Plant Ras GasDocument3 pagesProcess Operator Experience 08 Years Muhammad Faisal: Details of Experience at LNG Plant Ras GasMuhammad Hamza NaveedNo ratings yet

- Meshak Control Room OperatorDocument7 pagesMeshak Control Room Operatormsk649No ratings yet

- Alpesh Patel: Career ObjectiveDocument4 pagesAlpesh Patel: Career Objectivejohn MNo ratings yet

- Field Operator: INDIA: +91 9791875175 Skype: Thiyagu RDocument4 pagesField Operator: INDIA: +91 9791875175 Skype: Thiyagu Rjohn MNo ratings yet

- Sunil Kumar. R: Supervisor (Pre-Commissioning & Commissioning)Document5 pagesSunil Kumar. R: Supervisor (Pre-Commissioning & Commissioning)JBKSV FAMNo ratings yet

- Abdul Hameed EPCL CCPPDocument3 pagesAbdul Hameed EPCL CCPPMuhammad Hamza NaveedNo ratings yet

- Anzirresume - Dip ChemDocument6 pagesAnzirresume - Dip ChemMuthuKumar ArunachalamNo ratings yet

- Utility Operator CVDocument5 pagesUtility Operator CVLogan EthanNo ratings yet

- Production Specialist: Adberg Jeyson SolomonDocument4 pagesProduction Specialist: Adberg Jeyson SolomonSam JjNo ratings yet

- (Resume) Ewhubare O. JohnDocument9 pages(Resume) Ewhubare O. JohnJohn EwhubareNo ratings yet

- Venkat ResumeDocument3 pagesVenkat ResumevenkiksaNo ratings yet

- Personal Details: Curriculum VitaeDocument4 pagesPersonal Details: Curriculum Vitaejohn MNo ratings yet

- My CV Senior OeratorDocument8 pagesMy CV Senior OeratorSandesh RamdharneNo ratings yet

- Bebin Field OperatorDocument5 pagesBebin Field Operatorjohn MNo ratings yet

- Field Operator ViralDocument5 pagesField Operator ViralGodwin GodwinNo ratings yet

- Curriculum Vitae: Om Prakash Mohanty Principal Commissioning Engineer (Lead)Document6 pagesCurriculum Vitae: Om Prakash Mohanty Principal Commissioning Engineer (Lead)soumya19800000000No ratings yet

- Magesh SUPTNT FpsoDocument4 pagesMagesh SUPTNT FpsoAnish AniNo ratings yet

- Anandha Rajan.rDocument5 pagesAnandha Rajan.rjohn MNo ratings yet

- Shoban Aftab Sindhu - I&C Technician (2) - 1Document4 pagesShoban Aftab Sindhu - I&C Technician (2) - 1muhammad.wajahat194No ratings yet

- Sagar ResumeDocument3 pagesSagar Resumekaush132No ratings yet

- Dangote Refinery ResumeDocument2 pagesDangote Refinery ResumemjunaidNo ratings yet

- Pm03-Truongtanduong-Production EngineerDocument9 pagesPm03-Truongtanduong-Production EngineerTrương Tấn DươngNo ratings yet

- Hafiz M Abubakar - OriginalDocument4 pagesHafiz M Abubakar - OriginalMuhammad ShehzadNo ratings yet

- DennyDocument5 pagesDennyGodwin GodwinNo ratings yet

- Email ID: Contact No: +971562398104, +917358302902: Name: R.VishnushankarDocument6 pagesEmail ID: Contact No: +971562398104, +917358302902: Name: R.VishnushankarJêmš NavikNo ratings yet

- Pon Vijay Gas Processing OpDocument4 pagesPon Vijay Gas Processing Opjohn MNo ratings yet

- Md. OriginalDocument4 pagesMd. OriginalMd. Tazir UddinNo ratings yet

- Asad ResumeDocument3 pagesAsad ResumeAsad AliNo ratings yet

- Naukri DharmeshPipaliya (15y 0m)Document4 pagesNaukri DharmeshPipaliya (15y 0m)Anitha NNo ratings yet

- ZFaisalCV Experienced Facilities EngineerDocument7 pagesZFaisalCV Experienced Facilities EngineerlukmpiNo ratings yet

- MutharasanDocument4 pagesMutharasanGodwin GodwinNo ratings yet

- M.S.Kirubhananth: Senior Instrument TechnicianDocument4 pagesM.S.Kirubhananth: Senior Instrument TechnicianDonNo ratings yet

- NaveenDocument4 pagesNaveenGodwin GodwinNo ratings yet

- ModelDocument8 pagesModelSubnevaash SvNo ratings yet

- Viral Ahir HydrocarbonDocument6 pagesViral Ahir HydrocarbonfreeNo ratings yet

- CV Dcs Operator / Panel Operator: Please Contact Us Oil CV/Resume Oil Industry DatabaseDocument5 pagesCV Dcs Operator / Panel Operator: Please Contact Us Oil CV/Resume Oil Industry DatabaseArghadeep DebnathNo ratings yet

- Benin Field Operator CV UpdateDocument5 pagesBenin Field Operator CV UpdatebeninNo ratings yet

- Mohamed Ashraf: Mechanical Engineer Dubai-UAEDocument2 pagesMohamed Ashraf: Mechanical Engineer Dubai-UAEMohamed ElshaerNo ratings yet

- Rafiq - S CV TerminalDocument3 pagesRafiq - S CV Terminalaqeelkhan7942No ratings yet

- Oil MovementDocument3 pagesOil MovementmjunaidNo ratings yet

- Siva Raj Operations Foreman: ST NDDocument4 pagesSiva Raj Operations Foreman: ST NDjohn MNo ratings yet

- 2 ManimechDocument8 pages2 ManimechfreeNo ratings yet

- Amit Pandey Dehradun 4.00 YrsDocument3 pagesAmit Pandey Dehradun 4.00 YrsmeenuNo ratings yet

- DCS/CCR Operator: Sri Ramraj.GDocument4 pagesDCS/CCR Operator: Sri Ramraj.GDonNo ratings yet

- Curriculum Vitae: Chetan P. Kumbhani (Utility & Boiler Plant Operator)Document7 pagesCurriculum Vitae: Chetan P. Kumbhani (Utility & Boiler Plant Operator)Akhil AklNo ratings yet

- Abdou CV EditedDocument4 pagesAbdou CV Editedbernard djagui kellyNo ratings yet

- Dilman Ramazan Hama Ameen: EducationDocument2 pagesDilman Ramazan Hama Ameen: EducationDelman R. Hama AminNo ratings yet

- Wajih Abbas: Personal InformationDocument2 pagesWajih Abbas: Personal InformationNisha zehraNo ratings yet

- Plant Operator PDFDocument3 pagesPlant Operator PDFHarisNo ratings yet

- HVAC Engineer CVDocument4 pagesHVAC Engineer CVfollowersvaanga02No ratings yet

- Antonyarulrogger: Antony Arul RogerDocument4 pagesAntonyarulrogger: Antony Arul Rogerjohn MNo ratings yet

- Resume: Name Nationality DOB Contact Details Home of Record (Nearest Airport) Home AddressDocument4 pagesResume: Name Nationality DOB Contact Details Home of Record (Nearest Airport) Home AddressAhmed El HawariNo ratings yet

- Resume eDocument3 pagesResume ekhansartaj19995No ratings yet

- M Kalaiselvam: Riyadh, Saudi ArabiaDocument6 pagesM Kalaiselvam: Riyadh, Saudi ArabiaAnonymous gXCcNeItMNo ratings yet

- Mekki CV 2016Document5 pagesMekki CV 2016Bamsi DirilisNo ratings yet

- Mohd Fahad: - CAREER HIGHLIGHTSDocument4 pagesMohd Fahad: - CAREER HIGHLIGHTSFahad RockingNo ratings yet

- Operation Manual: Pneumatic Ribbon CoderDocument6 pagesOperation Manual: Pneumatic Ribbon CoderLuis Enrique Barreto GarciaNo ratings yet

- The Integration of Core and BHI and Resulting Depo Model - Moreni Field Central Romania, EAGE, 2012Document4 pagesThe Integration of Core and BHI and Resulting Depo Model - Moreni Field Central Romania, EAGE, 2012Paul V GrechNo ratings yet

- Diagram SankeyDocument5 pagesDiagram SankeyNur WidyaNo ratings yet

- Lin Cot 2005Document9 pagesLin Cot 2005londemonNo ratings yet

- Extension of MDRRMO OfficeDocument12 pagesExtension of MDRRMO OfficeJustin YuabNo ratings yet

- NPS Drilling Safety Induction Rev 1Document108 pagesNPS Drilling Safety Induction Rev 1Sameer Parambath100% (1)

- 9.3 Standards and ReferencesDocument6 pages9.3 Standards and ReferencesAfshadNo ratings yet

- Flow Switches: Series VH... / VK..Document20 pagesFlow Switches: Series VH... / VK..eaglego00No ratings yet

- Class II Oral QuestionsDocument18 pagesClass II Oral QuestionsStewardGriffindorNo ratings yet

- Columns Modeling Using Ansys and Effect of ConfinementDocument8 pagesColumns Modeling Using Ansys and Effect of ConfinementAboalmaaliNo ratings yet

- Topographic Map of GillettDocument1 pageTopographic Map of GillettHistoricalMapsNo ratings yet

- Jurnal 2001 - Textural Analysis of FatReduced Vanilla-AIMEDocument10 pagesJurnal 2001 - Textural Analysis of FatReduced Vanilla-AIMEMuhamad RizalNo ratings yet

- Guide Du Propriétaire Owner's Guide Guía Del Usuario: Robot Aspirateur Robot AspiradorDocument37 pagesGuide Du Propriétaire Owner's Guide Guía Del Usuario: Robot Aspirateur Robot AspiradoralelendoNo ratings yet

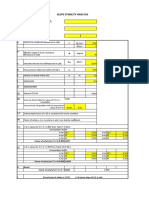

- Software Slope Stabilty Analysis FinalDocument1 pageSoftware Slope Stabilty Analysis FinalETTL UDAIPURNo ratings yet

- Flow Properties and Design Procedures For Coal Storage Bins PDFDocument401 pagesFlow Properties and Design Procedures For Coal Storage Bins PDFEmaVanni100% (2)

- Coal Conveyor Belt Fault DetectionDocument4 pagesCoal Conveyor Belt Fault Detectionc pawarNo ratings yet

- RR2009 - Generale-RrDocument39 pagesRR2009 - Generale-Rrhemant9315No ratings yet

- Explicit Frequency Equation and Mode Shapes of A Cantilever Beam Coupled in Bending and Torsion PDFDocument15 pagesExplicit Frequency Equation and Mode Shapes of A Cantilever Beam Coupled in Bending and Torsion PDFHossam T BadranNo ratings yet

- Seismic: VvinuDocument528 pagesSeismic: VvinuLucas ScartonNo ratings yet

- Electro-Hydraulic Actuation Systems Design, Testing, Identification and ValidationDocument70 pagesElectro-Hydraulic Actuation Systems Design, Testing, Identification and ValidationAkbarmoradiNo ratings yet

- Beautiful Soup DocumentationDocument61 pagesBeautiful Soup DocumentationWestNo ratings yet

- CV Shanmugaraj.rDocument2 pagesCV Shanmugaraj.rpreanandNo ratings yet

- LEDocument13 pagesLErahul rNo ratings yet

- Tek 17-02aDocument9 pagesTek 17-02aRaquelNo ratings yet

- Colfax Product CatalogDocument36 pagesColfax Product CatalogPrasanna BalrajNo ratings yet

- Moisture BarriersDocument31 pagesMoisture BarriersraviciviltNo ratings yet

- 32 Samss 011Document27 pages32 Samss 011naruto256No ratings yet

- 6060 Tank Pumps Drive ControllerDocument25 pages6060 Tank Pumps Drive ControllerEdison Pfoccori BarrionuevoNo ratings yet