Professional Documents

Culture Documents

Scotch: Super 33+ Vinyl Electrical Tape

Scotch: Super 33+ Vinyl Electrical Tape

Uploaded by

Donato PirroCopyright:

Available Formats

You might also like

- Transmision 02G StandarDocument141 pagesTransmision 02G Standargayt333100% (3)

- Bompani BO 02 727Document21 pagesBompani BO 02 727zavaidoc700% (1)

- Hino 700 - Truck PartsDocument6 pagesHino 700 - Truck PartsHugo Valle SierraNo ratings yet

- Joining of Nickel Alloys-ExtractDocument1 pageJoining of Nickel Alloys-ExtractrmjiranNo ratings yet

- Scotch Super 88 Vinyl Electrical Tape: Data SheetDocument2 pagesScotch Super 88 Vinyl Electrical Tape: Data Sheetsaururja saururjaNo ratings yet

- 3M Super 33+ PDFDocument3 pages3M Super 33+ PDFvivek jayswalNo ratings yet

- Scotch Super 33+ Vinyl Electrical Tape: Data SheetDocument2 pagesScotch Super 33+ Vinyl Electrical Tape: Data SheetArmenta EdwinNo ratings yet

- Catalogo Cintas 3mDocument12 pagesCatalogo Cintas 3mLauro Landazuri MontenegroNo ratings yet

- Scotch Super 33+ Vinyl Electrical Tape: Data Sheet November 2020Document2 pagesScotch Super 33+ Vinyl Electrical Tape: Data Sheet November 2020Kishan MohtaNo ratings yet

- 3m Electrical Tape PDFDocument2 pages3m Electrical Tape PDFefmartin21No ratings yet

- 3M 130C DatasheetDocument2 pages3M 130C DatasheetDean LefebvreNo ratings yet

- Catalogue Băng Keo Alberta 80 GuardDocument2 pagesCatalogue Băng Keo Alberta 80 GuardHà Trần MạnhNo ratings yet

- 3m - Scotch - 2228 Rubber Mastic TapeDocument3 pages3m - Scotch - 2228 Rubber Mastic TapeLuis NovaisNo ratings yet

- Cinta 23 - 3MDocument5 pagesCinta 23 - 3MDesiré Quispe FarfánNo ratings yet

- Photovoltaic Cable (Solar) : Solar Energy. Ful Lling The Energy Needs of TomorrowDocument4 pagesPhotovoltaic Cable (Solar) : Solar Energy. Ful Lling The Energy Needs of TomorrowNitinNo ratings yet

- Catalogue Băng Keo Alberta 80 CoinDocument2 pagesCatalogue Băng Keo Alberta 80 CoinHà Trần MạnhNo ratings yet

- Technical Specifications For 33 KV Xlpe Insulated Underground Cables 1. ScopeDocument22 pagesTechnical Specifications For 33 KV Xlpe Insulated Underground Cables 1. Scopethumula.rameshNo ratings yet

- HT Cable Termination Kit 14.3.22Document8 pagesHT Cable Termination Kit 14.3.22JIGSNo ratings yet

- Technical Specifications For 11 KV Xlpe Insulated Underground Cables 1.0 ScopeDocument22 pagesTechnical Specifications For 11 KV Xlpe Insulated Underground Cables 1.0 Scopethomas chinNo ratings yet

- Circuit Breaker Boxes For The Installation of DIN Rail Equipment Up To 100 A FP 1100Document2 pagesCircuit Breaker Boxes For The Installation of DIN Rail Equipment Up To 100 A FP 1100Prabhu GurusamyNo ratings yet

- Catalogue Băng Keo Alberta 80 SemiDocument2 pagesCatalogue Băng Keo Alberta 80 SemiHà Trần MạnhNo ratings yet

- 3M™ Tape # 2228 TdsDocument3 pages3M™ Tape # 2228 TdsKishan MohtaNo ratings yet

- Electrical TapeDocument2 pagesElectrical TapemmartincikNo ratings yet

- 44a0111-20-0 44a0111-20-9 44a0111-22-0 44a0111-22-9 44a0111-24-9 44a1121-22-0/9-9 44a0111-18-0 44a0111-26-2Document6 pages44a0111-20-0 44a0111-20-9 44a0111-22-0 44a0111-22-9 44a0111-24-9 44a1121-22-0/9-9 44a0111-18-0 44a0111-26-2عبدالغني القباطيNo ratings yet

- Cavi RychemDocument4 pagesCavi RychemmammolloNo ratings yet

- With or Without Terminals K 9504Document3 pagesWith or Without Terminals K 9504Irvan FauziNo ratings yet

- Hensel ElectricDocument3 pagesHensel ElectricSơn PhạmNo ratings yet

- 12T0020X00 Anixter WW Temperature Ratings W&C EN USDocument1 page12T0020X00 Anixter WW Temperature Ratings W&C EN USFelipe GustavoNo ratings yet

- 08 Marine CableDocument30 pages08 Marine CableWahyu HartonoNo ratings yet

- Krympslang Boxco 20 Sidor A4Document20 pagesKrympslang Boxco 20 Sidor A4Mas KahfiNo ratings yet

- D 9045 Hensel ElectricDocument2 pagesD 9045 Hensel ElectricThuan NguyenNo ratings yet

- K 9065 - Hensel - ElectricDocument2 pagesK 9065 - Hensel - ElectricThuan NguyenNo ratings yet

- 35 DS PDFDocument2 pages35 DS PDFFerdinand Ramos EspirituNo ratings yet

- Astm D 4388 - 02Document3 pagesAstm D 4388 - 02TAEWARAT RAKRUANGNo ratings yet

- FT Temflex 165Document2 pagesFT Temflex 165Felipe AndresNo ratings yet

- Underground Cables PDFDocument4 pagesUnderground Cables PDFSukhpal SinghNo ratings yet

- With or Without Terminals DK 0606 GDocument3 pagesWith or Without Terminals DK 0606 Gsoporte tecnico memNo ratings yet

- 3M Heavy Wall Heat Shrink Tubing ITCSNDocument4 pages3M Heavy Wall Heat Shrink Tubing ITCSNmuahdibNo ratings yet

- Tape Scotch 27Document2 pagesTape Scotch 27Victor Javier Reyes NavarroNo ratings yet

- Silicon Mulitcore Cable, Flexible, Halogen-Free, Meter MarkingDocument2 pagesSilicon Mulitcore Cable, Flexible, Halogen-Free, Meter Markingandrei_iarcaNo ratings yet

- Tech Specs 1Document22 pagesTech Specs 1headqcNo ratings yet

- Pds Covalence Htlp60 v1 Oct14 Aarps 0193Document2 pagesPds Covalence Htlp60 v1 Oct14 Aarps 0193pepeNo ratings yet

- RTD & Thermocouple Wire & Cable: Internet: EmailDocument7 pagesRTD & Thermocouple Wire & Cable: Internet: EmailmahmudNo ratings yet

- 3 FK 0606Document2 pages3 FK 0606prasun.tcelNo ratings yet

- Brosur HV ConnexDocument5 pagesBrosur HV ConnexH. NurzeinNo ratings yet

- Extreme Temperature, Flexible Cable Assembly: Model 3076ADocument3 pagesExtreme Temperature, Flexible Cable Assembly: Model 3076Ashibu TNo ratings yet

- "Weatherproof" For Outdoor Installation KF 1006 GDocument3 pages"Weatherproof" For Outdoor Installation KF 1006 GRavi KrishnanNo ratings yet

- Hensel - Electric (KF 1006 G) PDFDocument3 pagesHensel - Electric (KF 1006 G) PDFRavi KrishnanNo ratings yet

- 226NDocument2 pages226NUmaibalanNo ratings yet

- Scotch 23 Tape Data SheetDocument3 pagesScotch 23 Tape Data SheetKishan MohtaNo ratings yet

- Afico Pipe Insulation PDFDocument4 pagesAfico Pipe Insulation PDFHusni HayathNo ratings yet

- Scotch 2200,2210 DatasheetDocument2 pagesScotch 2200,2210 DatasheetJake AllenNo ratings yet

- Ki XLC 09SDocument2 pagesKi XLC 09SAbhishek HiteshkumarNo ratings yet

- D 9025 Hensel ElectricDocument3 pagesD 9025 Hensel ElectricThuan NguyenNo ratings yet

- Magnet Wires Data SheetDocument17 pagesMagnet Wires Data SheetDavid Isaias Jaimes ReyesNo ratings yet

- Elta Catalogue 2020 11 Online Medium Voltage Cable AccessoriesDocument21 pagesElta Catalogue 2020 11 Online Medium Voltage Cable AccessoriesTXEMANo ratings yet

- Rubber Mastic and Sealant Tapes PDFDocument18 pagesRubber Mastic and Sealant Tapes PDFNikhil MathewNo ratings yet

- AB Thermal Catalog All Silicone Rubber Fusing Tape SectionDocument50 pagesAB Thermal Catalog All Silicone Rubber Fusing Tape SectionDouglas LimaNo ratings yet

- 3M Scotch 50 51 Data SheetDocument4 pages3M Scotch 50 51 Data SheetPedro Francisco Hernandez MendozaNo ratings yet

- Fiberglass Reinforced Polyester (FRP) Link Boxes: DescriptionDocument2 pagesFiberglass Reinforced Polyester (FRP) Link Boxes: DescriptionlatifNo ratings yet

- "Weatherproof" For Outdoor Installation KF 2525 GDocument3 pages"Weatherproof" For Outdoor Installation KF 2525 GRavi KrishnanNo ratings yet

- 1DB - 49821 - enDocument1 page1DB - 49821 - enFreddy MormontoyNo ratings yet

- Presentation Module IIEE Elec Enthusiast 09102022 PDFDocument29 pagesPresentation Module IIEE Elec Enthusiast 09102022 PDFEarl Jenn AbellaNo ratings yet

- GD-2A Data SheetDocument2 pagesGD-2A Data SheetDonato PirroNo ratings yet

- Spring ConnectorDocument3 pagesSpring ConnectorDonato PirroNo ratings yet

- Gas DetectorsDocument1 pageGas DetectorsDonato PirroNo ratings yet

- Pagina AndysautosportDocument4 pagesPagina AndysautosportDonato PirroNo ratings yet

- Striker CM500 1350mm Mobile Cone CrusherDocument2 pagesStriker CM500 1350mm Mobile Cone CrusherBenjamin MurphyNo ratings yet

- CES EduPack - Exercises With Worked Solutions - 2011Document14 pagesCES EduPack - Exercises With Worked Solutions - 2011E Cos LopezNo ratings yet

- Susp HubbelDocument19 pagesSusp HubbelarchitjhunjhunNo ratings yet

- Device Marker - LS-EMLP (180X180) YE CUS - 8199184: Key Commercial DataDocument2 pagesDevice Marker - LS-EMLP (180X180) YE CUS - 8199184: Key Commercial DataVera SlavnicNo ratings yet

- Legend & Notes: Air-Conditioning System (Supply Duct) For Ground FloorDocument14 pagesLegend & Notes: Air-Conditioning System (Supply Duct) For Ground FloorameerNo ratings yet

- 182661067Document22 pages182661067Arunkumar ChandaranNo ratings yet

- Soldering 101 - Oxidation, Flux and Fire Scale PreventionDocument12 pagesSoldering 101 - Oxidation, Flux and Fire Scale PreventionEdu2k7No ratings yet

- Pressure Vessel Design TemplateDocument3 pagesPressure Vessel Design TemplateRamachandran Venkatesh0% (1)

- Arb Air Locker: CKMTP12 & Ckmtp24Document5 pagesArb Air Locker: CKMTP12 & Ckmtp24nmplyandglass01No ratings yet

- Gws-5a (Test Procedures - Resistance Spot Welding of Steel-)Document25 pagesGws-5a (Test Procedures - Resistance Spot Welding of Steel-)christian_zavalaNo ratings yet

- Basic Metal WorksDocument67 pagesBasic Metal Worksmola aliNo ratings yet

- 2000 Chevy Truck s10 t10 Heater Vent Module ReplacementDocument7 pages2000 Chevy Truck s10 t10 Heater Vent Module ReplacementKiddNo ratings yet

- Automotive SensorsDocument13 pagesAutomotive Sensorsمحمد أمير الهادي عزميNo ratings yet

- K20V MNL-0413Document155 pagesK20V MNL-0413RubenSolisNo ratings yet

- 25mm Cement Board PDFDocument9 pages25mm Cement Board PDFRAJAN GUPTANo ratings yet

- Oils Fats and Waxes NotesDocument3 pagesOils Fats and Waxes NotesArianne BatallonesNo ratings yet

- !! A 3D Model For Collapse Analysis of Soft-Story Light-Frame Wood BuildingsDocument8 pages!! A 3D Model For Collapse Analysis of Soft-Story Light-Frame Wood BuildingsAnonymous hprsT3WlPNo ratings yet

- How To Select MCB MCCBDocument4 pagesHow To Select MCB MCCBguddu1348167% (3)

- Teknologi PanganDocument70 pagesTeknologi PanganRebecca TiaraNo ratings yet

- Testing PEO ObjectivesDocument1 pageTesting PEO ObjectivesBhuva_janaNo ratings yet

- M 275 ContentDocument40 pagesM 275 ContentAnonymous DQ4wYUmNo ratings yet

- Marley PRG 11B L PDFDocument64 pagesMarley PRG 11B L PDFIlku100% (1)

- Road Markings - Product Application Chart: HIGHWAY MARKINGS LTD - Kilshanroe, Enfield, Co. Meath & Charlestown, Co. MayoDocument1 pageRoad Markings - Product Application Chart: HIGHWAY MARKINGS LTD - Kilshanroe, Enfield, Co. Meath & Charlestown, Co. MayoShams KhattakNo ratings yet

- CADMIUM 23 3869 enDocument4 pagesCADMIUM 23 3869 enThejaswiniNo ratings yet

- WPS and PQR of DSAW (Helical Welding)Document9 pagesWPS and PQR of DSAW (Helical Welding)魏利强No ratings yet

- DSI-DYWIDAG GEWI Threadbar System New 02Document12 pagesDSI-DYWIDAG GEWI Threadbar System New 02sonic8981No ratings yet

Scotch: Super 33+ Vinyl Electrical Tape

Scotch: Super 33+ Vinyl Electrical Tape

Uploaded by

Donato PirroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scotch: Super 33+ Vinyl Electrical Tape

Scotch: Super 33+ Vinyl Electrical Tape

Uploaded by

Donato PirroCopyright:

Available Formats

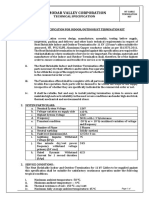

Scotch

Super 33+ Vinyl Electrical Tape

Data Sheet

Product Description: Applications:

Scotch Super 33+ Vinyl Electrical • Primary electrical insulation Ultimate Elongation

Tape is a premium grade, 7 mil for all wire and cable splices ASTM D1000

thick, all–weather vinyl-insulating rated up to 600 volts and 22°C (72°F) 250%

tape. It is designed to perform 105°C (220°F). –18°C (0°F) 100%

continuously in ambient

temperatures up to 105°C (220°F). • Primary electrical insulation Flammability (Maximum)

The tape is conformable for cold for 600 volt bus applications, UL 510 1 sec.

and protective jacketing for ASTM D1000 4 sec.

weather application down to –18°C

low and high voltage bus.

(0°F). It has excellent resistance to

Accelerated Aging

abrasion, moisture, alkalies, acids, • Protective jacketing for high

corrosion and varying weather ASTM D1000 80%

voltage cable splices and

conditions (including ultraviolet repairs.

exposure). The combination of Flagging

elastic backing and aggressive • Harnessing of wires and ASTM D1000 <0.1 inch

adhesive provides moisture–tight cables.

electrical and mechanical Telescoping

protection with minimum bulk. Typical Data / 24 Hours @ 50°C <0.1 inch

Super 33+ is an Underwriters’ (120°F).

Laboratories Listed and Canadian

Physical Properties:

Standards Association Certified Temperature Rating:

“Insulating Tape”. UL 510 80°C (176°F) Electrical Properties:

• UL Listed; UL 510 Standard

“Insulating Tape” (product CSA

Voltage Rating

category OANZ), File E129200 C22.2 No. 197–M1983

UL 510 600V

Handling –18°C (0°F)

• CSA Certification; Standard Continuous Dielectric Strength

C22.2 No.197–M1983 “PVC Operation 105°C (220°F) ASTM D1000

Insulating Tape,” File LR 48769

Color Black Standard Condition 1150

• Polyvinyl chloride (PVC) V/mil

backing. Thickness High Humidity 90% of std.

• Pressure–sensitive rubber ASTM D1000 7 mils

Insulation Resistance

based adhesive. 6

Adhesion to Steel ASTM D1000 >1 x10

• Compatible with solid dielectric ASTM D1000 megohms

cable insulations. 22°C (72°F) 28 oz./in. (High Humidity Method)

–18°C (0°F) 60 oz./in.

• Compatible with rubber and Note: These are typical values

synthetic splicing compounds, Adhesion to Backing and should not be used for

as well as epoxy and ASTM D1000 specification purposes.

polyurethane resins. 22°C (72°F) 25 oz./in.

–18°C (0°F) 60 oz./in.

• Inhibits corrosion of electrical

conductors. Breaking Strength

• For indoor or outdoor ASTM D1000

applications. 22°C (72°F) 15lbs./in.

Specification: Engineering/Architec Installation

Product: tural Specification: Techniques:

The tape is based on polyvinyl Primary electrical insulation The tape shall be applied in half–

chloride (PVC) and/or its (branch wiring in wet or dry lapped layers with sufficient

copolymers and has a rubber– locations): All splices for 600 volt tension to produce a uniform

based, pressure–sensitive adhesive. wind (for most applications this

wire rated 105°C (220°F) and

The tape shall be 7 mils thick, and tension will reduce the tape’s

below shall be insulated with a

be UL Listed and marked per UL width to approximately 5/8 of its

minimum of two half–lapped

Standard 510 as “Flame Retardant, original width). On pigtail

layers of Scotch Super 33+ Vinyl

Cold and Weather Resistant.” The splices, the tape shall be wrapped

Electrical Tape. All connectors

tape must be applicable at beyond the end of the wires and

having irregular surfaces shall be

temperatures ranging from 0°F then folded back, leaving a

padded with Scotchfil Electrical

through 100°F (–18°C through Insulation Putty or Scotch 130C protective cushion to resist cut–

38°C) without loss of physical Rubber Splicing Tape prior to through. Wrap tape up–hill,

properties. The tape shall be insulating with Scotch Super 33+ taping from a smaller diameter

classified for use in both indoor and Vinyl Electrical Tape. surface to a larger diameter

outdoor environments. The tape surface. Apply the tape with no

shall be compatible with synthetic Mechanical protection (outer tension on the last wrap to

cable insulations, jackets and jacketing): All rubber and prevent flagging.

splicing compounds. The tape will thermoplastic insulating high

remain stable and will not telescope voltage power cable tape splices Shelf Life:

more than 0.1 inches when and repairs shall be overwrapped

maintained at temperatures below with at least two half–lapped Scotch Super 33+ Vinyl Electrical

120°F (50°C). layers of Scotch Super 33+ Vinyl Tape complies with the requirements

Electrical Tape of UL 510 for storage. When

maintained under normal storage

conditions the tape will remain stable

and has a five year shelf–life.

Availability:

Scotch Super 33+ Vinyl Electrical

Tape is available from your local

3M authorized distributor in the

following standard roll sizes:

3/4 in. x 66 ft.

3/4 in. x 44 ft.

3/4 in. x 20 ft.

Other lengths and widths are

available by special request.

Scotch and Scotchfil are trademarks of 3M.

Important Notice

All statements, technical information and recommendations related to of all warranties, expressed or implied, including but not limited to the

the Seller’s products are based on information believed to be reliable, implied warranties of merchantability and fitness for a particular

but the accuracy or completeness thereof is not guaranteed. Before purpose which warranties are hereby expressly disclaimed.

utilizing the product, the user should determine the suitability of the SELLER SHALL NOT BE LIABLE TO THE USER OR ANY OTHER

product for its intended use. The user assumes all risks and liability PERSON UNDER ANY LEGAL THEORY, INCLUDING BUT NOT

whatsoever in connection with such use. LIMITED TO NEGLIGENCE OR STRICT LIABILITY, FOR ANY

Any statements or recommendations of the Seller which are not INJURY OR FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL

contained in the Seller’s current publications shall have no force or OR CONSEQUENTIAL DAMAGES SUSTAINED OR INCURRED BY

effect unless contained in an agreement signed by an authorized REASON OF THE USE OF ANY OF THE SELLER’S PRODUCTS

officer of the Seller. The statements contained herein are made in lieu THAT WERE DEFECTIVE.

Electrical Products Division

6801 River Place Blvd.

Austin, TX 78726-9000

800 245 3573 © 3M 1998

http://www.3m.com/elpd 78-8124-4841-9(A)

You might also like

- Transmision 02G StandarDocument141 pagesTransmision 02G Standargayt333100% (3)

- Bompani BO 02 727Document21 pagesBompani BO 02 727zavaidoc700% (1)

- Hino 700 - Truck PartsDocument6 pagesHino 700 - Truck PartsHugo Valle SierraNo ratings yet

- Joining of Nickel Alloys-ExtractDocument1 pageJoining of Nickel Alloys-ExtractrmjiranNo ratings yet

- Scotch Super 88 Vinyl Electrical Tape: Data SheetDocument2 pagesScotch Super 88 Vinyl Electrical Tape: Data Sheetsaururja saururjaNo ratings yet

- 3M Super 33+ PDFDocument3 pages3M Super 33+ PDFvivek jayswalNo ratings yet

- Scotch Super 33+ Vinyl Electrical Tape: Data SheetDocument2 pagesScotch Super 33+ Vinyl Electrical Tape: Data SheetArmenta EdwinNo ratings yet

- Catalogo Cintas 3mDocument12 pagesCatalogo Cintas 3mLauro Landazuri MontenegroNo ratings yet

- Scotch Super 33+ Vinyl Electrical Tape: Data Sheet November 2020Document2 pagesScotch Super 33+ Vinyl Electrical Tape: Data Sheet November 2020Kishan MohtaNo ratings yet

- 3m Electrical Tape PDFDocument2 pages3m Electrical Tape PDFefmartin21No ratings yet

- 3M 130C DatasheetDocument2 pages3M 130C DatasheetDean LefebvreNo ratings yet

- Catalogue Băng Keo Alberta 80 GuardDocument2 pagesCatalogue Băng Keo Alberta 80 GuardHà Trần MạnhNo ratings yet

- 3m - Scotch - 2228 Rubber Mastic TapeDocument3 pages3m - Scotch - 2228 Rubber Mastic TapeLuis NovaisNo ratings yet

- Cinta 23 - 3MDocument5 pagesCinta 23 - 3MDesiré Quispe FarfánNo ratings yet

- Photovoltaic Cable (Solar) : Solar Energy. Ful Lling The Energy Needs of TomorrowDocument4 pagesPhotovoltaic Cable (Solar) : Solar Energy. Ful Lling The Energy Needs of TomorrowNitinNo ratings yet

- Catalogue Băng Keo Alberta 80 CoinDocument2 pagesCatalogue Băng Keo Alberta 80 CoinHà Trần MạnhNo ratings yet

- Technical Specifications For 33 KV Xlpe Insulated Underground Cables 1. ScopeDocument22 pagesTechnical Specifications For 33 KV Xlpe Insulated Underground Cables 1. Scopethumula.rameshNo ratings yet

- HT Cable Termination Kit 14.3.22Document8 pagesHT Cable Termination Kit 14.3.22JIGSNo ratings yet

- Technical Specifications For 11 KV Xlpe Insulated Underground Cables 1.0 ScopeDocument22 pagesTechnical Specifications For 11 KV Xlpe Insulated Underground Cables 1.0 Scopethomas chinNo ratings yet

- Circuit Breaker Boxes For The Installation of DIN Rail Equipment Up To 100 A FP 1100Document2 pagesCircuit Breaker Boxes For The Installation of DIN Rail Equipment Up To 100 A FP 1100Prabhu GurusamyNo ratings yet

- Catalogue Băng Keo Alberta 80 SemiDocument2 pagesCatalogue Băng Keo Alberta 80 SemiHà Trần MạnhNo ratings yet

- 3M™ Tape # 2228 TdsDocument3 pages3M™ Tape # 2228 TdsKishan MohtaNo ratings yet

- Electrical TapeDocument2 pagesElectrical TapemmartincikNo ratings yet

- 44a0111-20-0 44a0111-20-9 44a0111-22-0 44a0111-22-9 44a0111-24-9 44a1121-22-0/9-9 44a0111-18-0 44a0111-26-2Document6 pages44a0111-20-0 44a0111-20-9 44a0111-22-0 44a0111-22-9 44a0111-24-9 44a1121-22-0/9-9 44a0111-18-0 44a0111-26-2عبدالغني القباطيNo ratings yet

- Cavi RychemDocument4 pagesCavi RychemmammolloNo ratings yet

- With or Without Terminals K 9504Document3 pagesWith or Without Terminals K 9504Irvan FauziNo ratings yet

- Hensel ElectricDocument3 pagesHensel ElectricSơn PhạmNo ratings yet

- 12T0020X00 Anixter WW Temperature Ratings W&C EN USDocument1 page12T0020X00 Anixter WW Temperature Ratings W&C EN USFelipe GustavoNo ratings yet

- 08 Marine CableDocument30 pages08 Marine CableWahyu HartonoNo ratings yet

- Krympslang Boxco 20 Sidor A4Document20 pagesKrympslang Boxco 20 Sidor A4Mas KahfiNo ratings yet

- D 9045 Hensel ElectricDocument2 pagesD 9045 Hensel ElectricThuan NguyenNo ratings yet

- K 9065 - Hensel - ElectricDocument2 pagesK 9065 - Hensel - ElectricThuan NguyenNo ratings yet

- 35 DS PDFDocument2 pages35 DS PDFFerdinand Ramos EspirituNo ratings yet

- Astm D 4388 - 02Document3 pagesAstm D 4388 - 02TAEWARAT RAKRUANGNo ratings yet

- FT Temflex 165Document2 pagesFT Temflex 165Felipe AndresNo ratings yet

- Underground Cables PDFDocument4 pagesUnderground Cables PDFSukhpal SinghNo ratings yet

- With or Without Terminals DK 0606 GDocument3 pagesWith or Without Terminals DK 0606 Gsoporte tecnico memNo ratings yet

- 3M Heavy Wall Heat Shrink Tubing ITCSNDocument4 pages3M Heavy Wall Heat Shrink Tubing ITCSNmuahdibNo ratings yet

- Tape Scotch 27Document2 pagesTape Scotch 27Victor Javier Reyes NavarroNo ratings yet

- Silicon Mulitcore Cable, Flexible, Halogen-Free, Meter MarkingDocument2 pagesSilicon Mulitcore Cable, Flexible, Halogen-Free, Meter Markingandrei_iarcaNo ratings yet

- Tech Specs 1Document22 pagesTech Specs 1headqcNo ratings yet

- Pds Covalence Htlp60 v1 Oct14 Aarps 0193Document2 pagesPds Covalence Htlp60 v1 Oct14 Aarps 0193pepeNo ratings yet

- RTD & Thermocouple Wire & Cable: Internet: EmailDocument7 pagesRTD & Thermocouple Wire & Cable: Internet: EmailmahmudNo ratings yet

- 3 FK 0606Document2 pages3 FK 0606prasun.tcelNo ratings yet

- Brosur HV ConnexDocument5 pagesBrosur HV ConnexH. NurzeinNo ratings yet

- Extreme Temperature, Flexible Cable Assembly: Model 3076ADocument3 pagesExtreme Temperature, Flexible Cable Assembly: Model 3076Ashibu TNo ratings yet

- "Weatherproof" For Outdoor Installation KF 1006 GDocument3 pages"Weatherproof" For Outdoor Installation KF 1006 GRavi KrishnanNo ratings yet

- Hensel - Electric (KF 1006 G) PDFDocument3 pagesHensel - Electric (KF 1006 G) PDFRavi KrishnanNo ratings yet

- 226NDocument2 pages226NUmaibalanNo ratings yet

- Scotch 23 Tape Data SheetDocument3 pagesScotch 23 Tape Data SheetKishan MohtaNo ratings yet

- Afico Pipe Insulation PDFDocument4 pagesAfico Pipe Insulation PDFHusni HayathNo ratings yet

- Scotch 2200,2210 DatasheetDocument2 pagesScotch 2200,2210 DatasheetJake AllenNo ratings yet

- Ki XLC 09SDocument2 pagesKi XLC 09SAbhishek HiteshkumarNo ratings yet

- D 9025 Hensel ElectricDocument3 pagesD 9025 Hensel ElectricThuan NguyenNo ratings yet

- Magnet Wires Data SheetDocument17 pagesMagnet Wires Data SheetDavid Isaias Jaimes ReyesNo ratings yet

- Elta Catalogue 2020 11 Online Medium Voltage Cable AccessoriesDocument21 pagesElta Catalogue 2020 11 Online Medium Voltage Cable AccessoriesTXEMANo ratings yet

- Rubber Mastic and Sealant Tapes PDFDocument18 pagesRubber Mastic and Sealant Tapes PDFNikhil MathewNo ratings yet

- AB Thermal Catalog All Silicone Rubber Fusing Tape SectionDocument50 pagesAB Thermal Catalog All Silicone Rubber Fusing Tape SectionDouglas LimaNo ratings yet

- 3M Scotch 50 51 Data SheetDocument4 pages3M Scotch 50 51 Data SheetPedro Francisco Hernandez MendozaNo ratings yet

- Fiberglass Reinforced Polyester (FRP) Link Boxes: DescriptionDocument2 pagesFiberglass Reinforced Polyester (FRP) Link Boxes: DescriptionlatifNo ratings yet

- "Weatherproof" For Outdoor Installation KF 2525 GDocument3 pages"Weatherproof" For Outdoor Installation KF 2525 GRavi KrishnanNo ratings yet

- 1DB - 49821 - enDocument1 page1DB - 49821 - enFreddy MormontoyNo ratings yet

- Presentation Module IIEE Elec Enthusiast 09102022 PDFDocument29 pagesPresentation Module IIEE Elec Enthusiast 09102022 PDFEarl Jenn AbellaNo ratings yet

- GD-2A Data SheetDocument2 pagesGD-2A Data SheetDonato PirroNo ratings yet

- Spring ConnectorDocument3 pagesSpring ConnectorDonato PirroNo ratings yet

- Gas DetectorsDocument1 pageGas DetectorsDonato PirroNo ratings yet

- Pagina AndysautosportDocument4 pagesPagina AndysautosportDonato PirroNo ratings yet

- Striker CM500 1350mm Mobile Cone CrusherDocument2 pagesStriker CM500 1350mm Mobile Cone CrusherBenjamin MurphyNo ratings yet

- CES EduPack - Exercises With Worked Solutions - 2011Document14 pagesCES EduPack - Exercises With Worked Solutions - 2011E Cos LopezNo ratings yet

- Susp HubbelDocument19 pagesSusp HubbelarchitjhunjhunNo ratings yet

- Device Marker - LS-EMLP (180X180) YE CUS - 8199184: Key Commercial DataDocument2 pagesDevice Marker - LS-EMLP (180X180) YE CUS - 8199184: Key Commercial DataVera SlavnicNo ratings yet

- Legend & Notes: Air-Conditioning System (Supply Duct) For Ground FloorDocument14 pagesLegend & Notes: Air-Conditioning System (Supply Duct) For Ground FloorameerNo ratings yet

- 182661067Document22 pages182661067Arunkumar ChandaranNo ratings yet

- Soldering 101 - Oxidation, Flux and Fire Scale PreventionDocument12 pagesSoldering 101 - Oxidation, Flux and Fire Scale PreventionEdu2k7No ratings yet

- Pressure Vessel Design TemplateDocument3 pagesPressure Vessel Design TemplateRamachandran Venkatesh0% (1)

- Arb Air Locker: CKMTP12 & Ckmtp24Document5 pagesArb Air Locker: CKMTP12 & Ckmtp24nmplyandglass01No ratings yet

- Gws-5a (Test Procedures - Resistance Spot Welding of Steel-)Document25 pagesGws-5a (Test Procedures - Resistance Spot Welding of Steel-)christian_zavalaNo ratings yet

- Basic Metal WorksDocument67 pagesBasic Metal Worksmola aliNo ratings yet

- 2000 Chevy Truck s10 t10 Heater Vent Module ReplacementDocument7 pages2000 Chevy Truck s10 t10 Heater Vent Module ReplacementKiddNo ratings yet

- Automotive SensorsDocument13 pagesAutomotive Sensorsمحمد أمير الهادي عزميNo ratings yet

- K20V MNL-0413Document155 pagesK20V MNL-0413RubenSolisNo ratings yet

- 25mm Cement Board PDFDocument9 pages25mm Cement Board PDFRAJAN GUPTANo ratings yet

- Oils Fats and Waxes NotesDocument3 pagesOils Fats and Waxes NotesArianne BatallonesNo ratings yet

- !! A 3D Model For Collapse Analysis of Soft-Story Light-Frame Wood BuildingsDocument8 pages!! A 3D Model For Collapse Analysis of Soft-Story Light-Frame Wood BuildingsAnonymous hprsT3WlPNo ratings yet

- How To Select MCB MCCBDocument4 pagesHow To Select MCB MCCBguddu1348167% (3)

- Teknologi PanganDocument70 pagesTeknologi PanganRebecca TiaraNo ratings yet

- Testing PEO ObjectivesDocument1 pageTesting PEO ObjectivesBhuva_janaNo ratings yet

- M 275 ContentDocument40 pagesM 275 ContentAnonymous DQ4wYUmNo ratings yet

- Marley PRG 11B L PDFDocument64 pagesMarley PRG 11B L PDFIlku100% (1)

- Road Markings - Product Application Chart: HIGHWAY MARKINGS LTD - Kilshanroe, Enfield, Co. Meath & Charlestown, Co. MayoDocument1 pageRoad Markings - Product Application Chart: HIGHWAY MARKINGS LTD - Kilshanroe, Enfield, Co. Meath & Charlestown, Co. MayoShams KhattakNo ratings yet

- CADMIUM 23 3869 enDocument4 pagesCADMIUM 23 3869 enThejaswiniNo ratings yet

- WPS and PQR of DSAW (Helical Welding)Document9 pagesWPS and PQR of DSAW (Helical Welding)魏利强No ratings yet

- DSI-DYWIDAG GEWI Threadbar System New 02Document12 pagesDSI-DYWIDAG GEWI Threadbar System New 02sonic8981No ratings yet