Professional Documents

Culture Documents

Sliding Repeating Bow: Modification History

Sliding Repeating Bow: Modification History

Uploaded by

Andrzej RogalaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sliding Repeating Bow: Modification History

Sliding Repeating Bow: Modification History

Uploaded by

Andrzej RogalaCopyright:

Available Formats

Sliding Repeating Bow v1.

https://youtu.be/lyPXGM5R--o

This is a hybridWood/3D printed sliding repeating bow from Master Jörg. The goal was to have the

easiest woodwork as possible. Nevertheless the arrow rail is still a difficult work to achieve. I asked

a professional wood worker to get a really straight rail.

I use it with a Mission Hammr compound bow. Since the draw weight can be really high on

compound bow I really advise to have the Triggered done in aluminium.

Here what it mine looks like at the moment, still changing the bulkiness regularly that is why the

pictures are not all consistent. See the first test video for a better overview.

Modification History

News in V1.3 :

bow bracket enhancement

front handle enhancement

short arrow adapter

Most parts are now grooved to increase the stiffness and have better look

News in V1.2 :

Aluminium trigger is now better for the string

The sight is now operational

News in V1.1 :

STEP files to have the trigger done in aluminium + trigger improvement + documentation

improvement

Riesling repeating bow – hybride 3D printed/wood project v1.3 1/9

3D parts

I printed all the parts in with ASA filament since it is pretty similar to ABS and can endure lots of

stress. Careful of the flanks which should be printed twice , and one is mirrored.

Bracket attached to the bow:

• Bracket.STL

• Bracket_1.STL

• Bracket_2.STL

Front Block:

• CentralFlanc.STL

• CentralFlanc1.STL

• FrontStop.STL

• Lever.STL

• Fronthandle.STL

• ShortArrowAdapter.STL

Sights:

• Sight_Front01.STL

• Sight_Back00.STL

Rear Block (Handle):

• BackLock.STL

• BackStop.STL

• Flancs_X2Mirror.STL

• Handle.STL

• Handle_LeftTT.STL

• Handle_RightTT.STL

• Trigger.STL

• TriggerAluThumb.STL : If you have access to an aluminium worker you want his trigger,

• TriggerAlu_AP###.STEP : STEP file for trigger aluminium work

Wood parts

First you will need a bow. Then the wood parts cut in 10mm thick wood or plywood. Using laser

cut wood makes a lot of ashes and I think a good electric saw with guides is better for the work.

Depending on the draw length of your bow you can change change the length of the two part below.

• 1 rail 800x42x10mm. With a 40x4x3mm groove all along

• 2x Woodflancs 670x65x10mm

The rail have a 10x40mm notch to fit the handle rear block

Riesling repeating bow – hybride 3D printed/wood project v1.3 2/9

The plywood flanks have a tendency to bend on way or the other, so I put the 2 wood flanks in such

way that they would both bend outward. One bending compensate the other and the device should

stay straight.

Drilling the wood

The wood flank can be drilled using the 3D part as template:

Riesling repeating bow – hybride 3D printed/wood project v1.3 3/9

Screws & bolts & springs

The 3D printed parts are designed to work with M3 screws which are really common all around the

world except for those using imperial units. But I am sure there is a x/64th inch screw/bolts which

would fit really nicely.

• 11x M3 wood insert bolt

• 8x M3 Metal insert bolt

• 8x M3 nuts for the left & right handle

• 22x M3 x 14-16mm screws

• 1x M3 x 25mm screws with no thread at the base for the trigger

• 1x M3 x 30mm screws with no thread at the base for the lever

• 3x M3 x 40mm screws

• 2 or 4x 5mm diameter compression spring for the trigger an the lever

• Some washers to even the screws heads pressure on the woods

Riesling repeating bow – hybride 3D printed/wood project v1.3 4/9

The Trigger

Once again, I really advise to have the triggered done in aluminium, or a tuff wood. The STEP

files are available to have it done in Aluminium OR ABS/ASA 3D printing. Though I would rather

count on an aluminium trigger for the long run, and heavy draw weight.

The shape of the trigger is most important since it must hold the bow string whatever the strength.

And the trigger must hold its position even without the spring, meaning the trigger whole and the

string position in the trigger hook should be aligned with the arrow, so the trigger does not let go by

it self.

The trigger hook should also be shaped to prevent the trigger from letting go. The angle illustrated

below is really important. Too law and the trigger will let go by it self, Too high and the trigger will

be hard to pull.

Here is the Aluminium trigger part and the trigger assembled: TriggerAlu + TriggerAluThumb

Riesling repeating bow – hybride 3D printed/wood project v1.3 5/9

Sights

The front and back sights should be attached to the wood top flanc.the front one can be adjusted left

or right.

Bracket

Though the bracket should be specific to each bow, I made it so it should be easy to be set on many

type of bow, since it uses the arrow rest screw.

Riesling repeating bow – hybride 3D printed/wood project v1.3 6/9

Optional Front Handle

This handle act as a tension reliever. It allows to hold the tension really easily. It is snap in place and

one or several M3 screw can be used fix it safely.

Optional short arrow adapter

This is an adapter to be able to shoot short (<17cm) bolts, if the bolt is heavy enough. Because the

arrow should be heavy enough depending on the bow. This is still a work in progress since I do not

have short arrow yet, and I did not design a lever to hold the shot arrows in place :

Riesling repeating bow – hybride 3D printed/wood project v1.3 7/9

Assembly

It is pretty straight forward, but takes about 5min when everything is well prepared. I put 2 springs

for the Lever since I only have weak springs. One spring is enough for the trigger since we want it

to be smooth and catch the string without having to pull it.

Riesling repeating bow – hybride 3D printed/wood project v1.3 8/9

Riesling repeating bow – hybride 3D printed/wood project v1.3 9/9

You might also like

- The Box Tube MAC-11 (Practical Scrap Metal Small Arms Vol.2) PDFDocument22 pagesThe Box Tube MAC-11 (Practical Scrap Metal Small Arms Vol.2) PDFBangBoomBang90% (126)

- DIY Vol 2 - The Box Tube MAC-11 by Professor Parabellum (PRT 21 Pages Copy On Bond Paper 15 To 20)Document21 pagesDIY Vol 2 - The Box Tube MAC-11 by Professor Parabellum (PRT 21 Pages Copy On Bond Paper 15 To 20)fritzthecat5296% (23)

- Metralleta Casera Sin Torno TRADUCIDO AL FINALDocument12 pagesMetralleta Casera Sin Torno TRADUCIDO AL FINALMiguel Omar Pieszko100% (5)

- Kumiko Jigs Japanese Woodworking PDFDocument9 pagesKumiko Jigs Japanese Woodworking PDFJaime Montiel100% (1)

- RS CNC Mechanical Manual Assembly-1Document117 pagesRS CNC Mechanical Manual Assembly-1Pedro MartinhoNo ratings yet

- BridgesDocument48 pagesBridgeskisaki66100% (6)

- What Next After 10th, Inter, DegreeDocument10 pagesWhat Next After 10th, Inter, DegreeBlue JaguarNo ratings yet

- The Box Tube MAC-11 (Practical Scrap Metal Small Arms Vol.2)Document21 pagesThe Box Tube MAC-11 (Practical Scrap Metal Small Arms Vol.2)K Scott Wyatt86% (7)

- SIL Hybrid: Pump-Action Repeating Bow With Ammo ClipsDocument53 pagesSIL Hybrid: Pump-Action Repeating Bow With Ammo ClipsMihai Robert100% (1)

- Wooden Gear Clock - Clock Instructions 9Document66 pagesWooden Gear Clock - Clock Instructions 9bird100% (1)

- Global Reporting System User Manual GRS-Rig V4.0: TitleDocument161 pagesGlobal Reporting System User Manual GRS-Rig V4.0: Titlevikrant911No ratings yet

- 3D Photography Slide-Bars, How to Make 3D Camera Slide-Bars and Twin-Cam Mounting BarsFrom Everand3D Photography Slide-Bars, How to Make 3D Camera Slide-Bars and Twin-Cam Mounting BarsNo ratings yet

- 4x5 Film View CameraDocument122 pages4x5 Film View CameraNatalia NelsonNo ratings yet

- A Low Cost 3D Printer With Basic ToolsDocument171 pagesA Low Cost 3D Printer With Basic ToolsJose Luis SabinoNo ratings yet

- Project From Wooden Clamp Plan Page 1 of 11Document11 pagesProject From Wooden Clamp Plan Page 1 of 11Juan Manuel ColaneriNo ratings yet

- Build Your Own 3d Printing Filament Factory Filame PDFDocument25 pagesBuild Your Own 3d Printing Filament Factory Filame PDFCesar AzcargortaNo ratings yet

- Professor Parabellum - The DIY STEN Gun - Practical Scrap Metal Small Arms Volume 3. 3-Professor ParabellumDocument23 pagesProfessor Parabellum - The DIY STEN Gun - Practical Scrap Metal Small Arms Volume 3. 3-Professor Parabellumzaid hashem100% (3)

- InstructionsDocument4 pagesInstructionsclipopiNo ratings yet

- Balsa Propellers For ULS: Connector ChoiceDocument4 pagesBalsa Propellers For ULS: Connector ChoiceFabricio AmadoNo ratings yet

- Cutting Board TrioDocument12 pagesCutting Board Triokcc2012100% (1)

- Table Saw Miter Sled PDFDocument8 pagesTable Saw Miter Sled PDF88No1Fan100% (2)

- Tutorial Magnum Spy PistolDocument6 pagesTutorial Magnum Spy PistolchopenNo ratings yet

- Unimat Pages 26-30Document5 pagesUnimat Pages 26-30remendabNo ratings yet

- Makerbot Replicator 2 Aluminum Z-Axis Stage Upgrade: InstructablesDocument10 pagesMakerbot Replicator 2 Aluminum Z-Axis Stage Upgrade: InstructablesViktar SamuelNo ratings yet

- Half Lite Stunter Building InstructionsDocument37 pagesHalf Lite Stunter Building InstructionsCarlos Manuel GonzálezNo ratings yet

- (Click Here For Home Page: Www.3rguitars - Co.uk) : 1960s Style SC or TC Neck BuildDocument38 pages(Click Here For Home Page: Www.3rguitars - Co.uk) : 1960s Style SC or TC Neck BuildAbraham TedyNo ratings yet

- The Recumbent Bicycle and Human Powered Vehicle Information Center12Document1 pageThe Recumbent Bicycle and Human Powered Vehicle Information Center12Marcel PiersonNo ratings yet

- 2 Ball Peen HammerDocument16 pages2 Ball Peen HammerCHESTER JAN BOSONGNo ratings yet

- Air GunDocument24 pagesAir GunAleksandarRadovanovic86% (7)

- Professor Parabellum - The DIY Sheet Metal Self Loading Pistol - Practical Scrap Metal Small Arms Volume 1. 1-Professor ParabellumDocument15 pagesProfessor Parabellum - The DIY Sheet Metal Self Loading Pistol - Practical Scrap Metal Small Arms Volume 1. 1-Professor ParabellumKobi Zada100% (1)

- Giant Wooden Clothes Pegs: InstructablesDocument19 pagesGiant Wooden Clothes Pegs: InstructablesToeNo ratings yet

- Chopstick 2 Helicopter PlansDocument13 pagesChopstick 2 Helicopter PlansZeljko LekovicNo ratings yet

- Panther User's ManualDocument37 pagesPanther User's ManualAnthony Fields100% (2)

- Ender 3 XL Parts and Build InstructionsDocument13 pagesEnder 3 XL Parts and Build InstructionsCarlos Ivan Ojeda SandovalNo ratings yet

- CNC Plasma TableDocument37 pagesCNC Plasma Tablenjsoffice100% (1)

- Wooden Scrub Plane From ScrapDocument9 pagesWooden Scrub Plane From ScrapRod HyattNo ratings yet

- Everyday Electronics 1974 10.CV01Document6 pagesEveryday Electronics 1974 10.CV01marcosscarato0% (1)

- Adjustable Taper Ripping JigDocument6 pagesAdjustable Taper Ripping Jiggmand68No ratings yet

- Module 2 - Master LuthierDocument20 pagesModule 2 - Master LuthierTim JacobsNo ratings yet

- Electric Ukulele Plan NotesDocument9 pagesElectric Ukulele Plan Notesmking_6100% (1)

- 9.cutting StagesDocument3 pages9.cutting Stagesartimpresro9108No ratings yet

- Cutting Aluminum With A CNC RouterDocument8 pagesCutting Aluminum With A CNC RouterAntrellNo ratings yet

- Mod 7 Book 2 ToolsDocument83 pagesMod 7 Book 2 Toolsranjit prasad100% (1)

- The Box Tube MAC-11: The Ultimate DIY Machine PistolDocument24 pagesThe Box Tube MAC-11: The Ultimate DIY Machine PistolPatrick Peres100% (1)

- Wood HingesDocument15 pagesWood HingesLuis Valens100% (1)

- Belt Driven Ender 3: How ToDocument17 pagesBelt Driven Ender 3: How TokylixNo ratings yet

- Mapúa University: Shop Exercise No. 1Document15 pagesMapúa University: Shop Exercise No. 1Eriane GarciaNo ratings yet

- ShopNotes Issue 131Document64 pagesShopNotes Issue 131florinel860289% (9)

- AWKDocument14 pagesAWKMcMgNo ratings yet

- Saw HandleDocument7 pagesSaw Handleانغي رحمنيNo ratings yet

- American Woodworker: OCTOBER 2002Document9 pagesAmerican Woodworker: OCTOBER 2002JvlValenzuelaNo ratings yet

- XR3C 6 Element Triband Yagi 20-15-10MDocument18 pagesXR3C 6 Element Triband Yagi 20-15-10Msboonuy331No ratings yet

- Presentation WORK HOLDING DEVICESDocument28 pagesPresentation WORK HOLDING DEVICESJohn ProtoctisNo ratings yet

- Helical 2 4 GHZDocument12 pagesHelical 2 4 GHZtaruna nasutionNo ratings yet

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosFrom EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNo ratings yet

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- Metalworking for Home Machinists: 53 Practical Projects to Build YourselfFrom EverandMetalworking for Home Machinists: 53 Practical Projects to Build YourselfNo ratings yet

- Tip-Over Stability Estimation and Simulation of aDocument32 pagesTip-Over Stability Estimation and Simulation of aAndrzej RogalaNo ratings yet

- 3D Printing Trends Q1 2019Document22 pages3D Printing Trends Q1 2019Andrzej RogalaNo ratings yet

- Vibrodynamics - FH40Document2 pagesVibrodynamics - FH40Andrzej RogalaNo ratings yet

- Vibrodynamics - HH48Document2 pagesVibrodynamics - HH48Andrzej RogalaNo ratings yet

- Jet Steam Underwater EngineDocument6 pagesJet Steam Underwater EngineAndrzej RogalaNo ratings yet

- Steam Propulsion PatentDocument3 pagesSteam Propulsion PatentAndrzej RogalaNo ratings yet

- How To Correctly Use Spectrum Analyzers For EMC Pre-Compliance TestsDocument22 pagesHow To Correctly Use Spectrum Analyzers For EMC Pre-Compliance TestsAndrzej RogalaNo ratings yet

- 3412 01 UKCA-DoC MDR-Ind 2022-02 202205271016123903Document1 page3412 01 UKCA-DoC MDR-Ind 2022-02 202205271016123903Andrzej RogalaNo ratings yet

- Termoformierka Manual-FMDH660 - UK - V3.0 - 140616 - LowresDocument57 pagesTermoformierka Manual-FMDH660 - UK - V3.0 - 140616 - LowresAndrzej RogalaNo ratings yet

- Export RoHS 20220621 22243924Document2 pagesExport RoHS 20220621 22243924Andrzej RogalaNo ratings yet

- Vibrodynamics - HH28Document2 pagesVibrodynamics - HH28Andrzej RogalaNo ratings yet

- Vibration Theory GeneralDocument13 pagesVibration Theory GeneralAndrzej RogalaNo ratings yet

- Vibrodynamics - FH48Document2 pagesVibrodynamics - FH48Andrzej RogalaNo ratings yet

- VIM-brochure OptimizedDocument6 pagesVIM-brochure OptimizedAndrzej RogalaNo ratings yet

- Socitec - MP17Document2 pagesSocitec - MP17Andrzej RogalaNo ratings yet

- Stiffness Characteristics of A Polycal Wire Rope IDocument9 pagesStiffness Characteristics of A Polycal Wire Rope IAndrzej RogalaNo ratings yet

- Vibrodynamics - MP24Document2 pagesVibrodynamics - MP24Andrzej RogalaNo ratings yet

- Determination of The Bending Properties of Wire Rope Used in Cable Barrier Systems - 49587Document22 pagesDetermination of The Bending Properties of Wire Rope Used in Cable Barrier Systems - 49587Andrzej RogalaNo ratings yet

- Socitec - HH16Document2 pagesSocitec - HH16Andrzej RogalaNo ratings yet

- Data Sheet Machine Tools 1Document2 pagesData Sheet Machine Tools 1Andrzej RogalaNo ratings yet

- Experimental Study On Vertical Static StiffnessesDocument9 pagesExperimental Study On Vertical Static StiffnessesAndrzej RogalaNo ratings yet

- Rohscert 3203323Document3 pagesRohscert 3203323Andrzej RogalaNo ratings yet

- Kapton 3M92Document2 pagesKapton 3M92Andrzej RogalaNo ratings yet

- Comfort Arm and Vest FLYCAMDocument10 pagesComfort Arm and Vest FLYCAMAndrzej RogalaNo ratings yet

- Blank Risk Assessment Template No 74Document1 pageBlank Risk Assessment Template No 74Andrzej RogalaNo ratings yet

- KAPTON Scapa-1801Document2 pagesKAPTON Scapa-1801Andrzej RogalaNo ratings yet

- Articulo-Watson Crick PDFDocument2 pagesArticulo-Watson Crick PDFAjedrez ItineranteNo ratings yet

- 2009-11-05Document20 pages2009-11-05The University Daily KansanNo ratings yet

- Typical Details of Switchyard RequirementDocument364 pagesTypical Details of Switchyard RequirementEspro100% (1)

- Rex International Holding Limited Preliminary Offer DocumentDocument723 pagesRex International Holding Limited Preliminary Offer DocumentInvest StockNo ratings yet

- Purpose - Device - Ravana - OSHODocument2 pagesPurpose - Device - Ravana - OSHOChitter SinghNo ratings yet

- Bed Ict 3rd Year Revised Note For e LearningDocument12 pagesBed Ict 3rd Year Revised Note For e Learningsanjeev_999bhan100% (1)

- Introduction To System Analysis and DesignDocument22 pagesIntroduction To System Analysis and DesignHiranya100% (2)

- Matrix - An IntroductionDocument10 pagesMatrix - An IntroductionMajid AbNo ratings yet

- ? - 1000 BTC Bitcoin Challenge Transaction - Private Keys DirectoryDocument9 pages? - 1000 BTC Bitcoin Challenge Transaction - Private Keys DirectorynelsonbmbavoNo ratings yet

- License Plate RecognitionDocument3 pagesLicense Plate RecognitionSen PaiiNo ratings yet

- Pairing Scheme 1st Year 2024 BY PHYSICS INN ACDEMIA M.A. JAVEDDocument1 pagePairing Scheme 1st Year 2024 BY PHYSICS INN ACDEMIA M.A. JAVEDabdull phyNo ratings yet

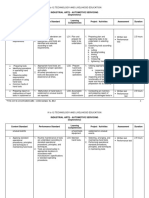

- Industrial Arts - Automotive Servicing (Exploratory) : K To 12 Technology and Livelihood EducationDocument7 pagesIndustrial Arts - Automotive Servicing (Exploratory) : K To 12 Technology and Livelihood Educationjayson acunaNo ratings yet

- BAUR Cable Locator: Data SheetDocument2 pagesBAUR Cable Locator: Data Sheetwinston11No ratings yet

- BIO Genetics Eukaryote TranscriptionDocument23 pagesBIO Genetics Eukaryote TranscriptionAnonymous SVy8sOsvJDNo ratings yet

- Preterm Prelabor Rupture of Membranes - Clinical Manifestations and Diagnosis - UpToDateDocument26 pagesPreterm Prelabor Rupture of Membranes - Clinical Manifestations and Diagnosis - UpToDateCristinaCaprosNo ratings yet

- CCBoot Manual - Server SettingsDocument89 pagesCCBoot Manual - Server SettingsHasnan IbrahimNo ratings yet

- 11 HUMSS JQR - Family Earthquake PreparednessDocument4 pages11 HUMSS JQR - Family Earthquake PreparednessCLARIZZE JAINE MANALONo ratings yet

- Ganesh Balasubramanian (Eds.) - Advances in Nanomaterials - Fundamentals, Properties and Applications-Springer International Publishing (2018)Document181 pagesGanesh Balasubramanian (Eds.) - Advances in Nanomaterials - Fundamentals, Properties and Applications-Springer International Publishing (2018)Jesus Moreno Castillo100% (1)

- IELTS All 4 Tests at Méthode Barnes Anglais RecommanderDocument21 pagesIELTS All 4 Tests at Méthode Barnes Anglais Recommanderbarnes method books internationalNo ratings yet

- Spe 199993 MSDocument28 pagesSpe 199993 MSHussam AgabNo ratings yet

- EN Quick Reference Guide Fabian HFOi-V4.0Document30 pagesEN Quick Reference Guide Fabian HFOi-V4.0Tanzimul IslamNo ratings yet

- Bend TestDocument38 pagesBend TestAzan Safril100% (1)

- Buildability ScoreDocument6 pagesBuildability ScoreVachara PeansupapNo ratings yet

- CMGT 544 Creating Organizational Identity (Aka Communicating Branding) Fall 2018Document22 pagesCMGT 544 Creating Organizational Identity (Aka Communicating Branding) Fall 2018greym111No ratings yet

- Lecture 06Document30 pagesLecture 06Martis88No ratings yet

- MA 231 MATHEMATICS III 2006 Question PaperDocument3 pagesMA 231 MATHEMATICS III 2006 Question Paperyasin muhamedNo ratings yet

- Modification and Characterization of PolypropyleneDocument7 pagesModification and Characterization of PolypropyleneSaba MalikNo ratings yet

- Camera ConfidenceDocument13 pagesCamera ConfidenceCont ReadNo ratings yet