Professional Documents

Culture Documents

TLS-350J UST Monitoring System: Available in Easy To Order 2-, and 3-Tank Kits

TLS-350J UST Monitoring System: Available in Easy To Order 2-, and 3-Tank Kits

Uploaded by

schmersalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TLS-350J UST Monitoring System: Available in Easy To Order 2-, and 3-Tank Kits

TLS-350J UST Monitoring System: Available in Easy To Order 2-, and 3-Tank Kits

Uploaded by

schmersalCopyright:

Available Formats

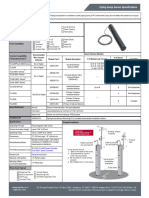

FROM VEEDER-ROOT

TLS-350J UST Monitoring System

Available in easy to order

2-, and 3-tank kits

3 GPH leak tests to meet all EPA compliance requirements.

Veeder-Root’s electronic line leak detection is suitable for a

variety of pipe types.

The TLS-350J will accommodate three (3) Veeder-Root float switch

sensors, including: interstitial sensors for both steel and fiberglass

tanks, piping sump sensors, hydrostatic sensors and discriminating

dispenser pan and containment sump sensors.

The TLS-350J systems are equipped with audible and visual

alarms, triggered by in-tank and interstitial alarm conditions. Any of

the in-tank alarm limits can also be tied to relays to trigger on-site

◆ The total compliance solution for 2- and 3- devices, such as overfill alarms, or to shutdown submersibles.

tank/line systems

◆ Supports up to 3 tanks Get the most out of the system by communicating with the TLS-

350J through the built-in SiteFax module. The SiteFax module

◆ Supports up to 3 sensors for dispenser pan allows the TLS to automatically transmit information at user defined

or containment sump sensing intervals or when certain events occur. SiteFax is also fully compat-

◆ Supports PLLD or WPLLD for up to 3 lines ible with InformTM, Veeder-Root’s remote communication software.

◆ Continuous Statistical Leak Detection (CSLD)

Optional Capabilities

capability for 0.2 GPH tank leak detection

without tank shutdown Additional communication boards. The communication compart-

◆ Built-in SiteFax module for easy dial-in and/or ment of the TLS-350J comes with built in SiteFax, leaving 2 slots

automatic dial-out of user defined events available for additional options. These slots can be filled with any

standard TLS-350 communication board.

◆ Proven design means safe and simple set up

and installation Input/Output relays.The high power compartment of the TLS-350J

◆ Standard integral printer will accept up to 8 input/output modules. The inputs provide for solid

◆ UL/CUL approved state or switch type input from external devices. The output relays

provide for overfill and external audible and visual warning devices.

Either relay can shut down the submersible if power to the monitor

Veeder-Root’s TLS-350J UST monitoring system features in-tank is lost or a leak is detected.

leak detection, electronic leak detection and discriminating sensing

capability for up to 3 tanks/lines/sensors to meet regulatory

compliance requirements at your site.

The system comes equipped with CSLD, the only continuous

in-tank leak detection system approved under EPA recognized

protocols. Protect yourself with the most advanced and reliable and

yet easy-to-use 0.2 GPH leak detection technology available in the

industry today. CSLD requires no tank shutdown, providing continu-

ous 24-hour leak detection; no lost business; no lost operating time.

All systems support up to three (3) Series 8473 Magnetostric-

tive Probes. The Mag probes handle a wide variety of fuels and

fluids at a third party certified performance level which exceeds

U.S. EPA standards.

The TLS-350J comes equipped with standard or wireless elec-

tronic pressurized line leak detection for up to three 3 lines. The

risk management software will perform 0.1 GPH, 0.2 GPH and

Easy-to-order 2- and 3-tank kit

Kit Form No. Description

350J-2-W or 350J-2-P TLS-350J console with integral printer, SiteFax modem, CSLD, any two (2)

standard length Mag 1 probes; and any two (2) 4" float kits with 5' cables.

Also included: (W)PLLD risk management software, six input, three output line

leak interfaces and two (2) standard line leak detectors for FE Petro or Red

Jacket pumps.

To order a 3-tank kit, just add one (1) Mag 1 probe and one (1) line leak detector for FE Petro or Red Jacket pumps.

Console/Sensor Compatibility

The following sensors are compatible with the TLS-350J UST monitoring system

Sensor Form No. Description

794390-401 Interstitial sensor for fiberglass tanks

794390-420 Interstitial sensor for steel tanks

794390-205 Piping sump sensor

794380-301 Single-float hydrostatic sensor

794380-302 Dual-float hydrostatic sensor

794380-322 Discriminating dispenser pan sensor

794380-352 Discriminating containment sump sensor

1/4” Hole Dimensions

4 Places 1 7/8”

16”

13”

11”

12”

11 1/4”

Front View

1”

20”

3/4, 1, 1 1/4 I.P.S. Knockouts

(Top and Bottom)

9 11/16” 3 1/8” 2 9/16” 3 1/8”

7”

5 1/4”

To Power To Intrinsically

Area Safe Area

19 3/4”

Back View

125 Powder Forest Drive, Post Office Box 2003, Simsbury, CT 06070-2003 TEL: (860) 651-2700, FAX: (860) 651-2719 TECH SUPPORT: (860) 651-2753

BRAZIL: Sao Paulo • CANADA: Mississauga, Ontario • ENGLAND: Richmond Surrey • FRANCE: Aulnay-Sous-Bois • GERMANY: Aldingen • SINGAPORE: Singapore

Printed

VROW12 in 99

13679 P/N 576047-021 Rev. A U .S . A .

You might also like

- Delta V Training 7009-1Document68 pagesDelta V Training 7009-1zhangyili100% (1)

- MT LevelSensing Control-7.21 PDFDocument12 pagesMT LevelSensing Control-7.21 PDFAndrewcaesarNo ratings yet

- ESP-LXME Control System Installation & Troubleshooting GuideDocument21 pagesESP-LXME Control System Installation & Troubleshooting GuidesabummathewNo ratings yet

- 577014-452 Automatic Tank GaugeDocument3 pages577014-452 Automatic Tank GaugeorlandotacheNo ratings yet

- Manual Sensores de Detección Electrónica de FugasDocument2 pagesManual Sensores de Detección Electrónica de FugasEmiliano CamarenaNo ratings yet

- Flx380-30X Flextester 3 OtdrDocument6 pagesFlx380-30X Flextester 3 OtdrMostafa GaafarNo ratings yet

- DS1120Document4 pagesDS1120Hoc chung khoan MIEN PHINo ratings yet

- PD484947Document15 pagesPD484947Jose PeñalozaNo ratings yet

- TWFL PF00697Document12 pagesTWFL PF00697luislucas13No ratings yet

- 3 0 Data SheetsDocument8 pages3 0 Data SheetsMohammed sabatinNo ratings yet

- 7UT51xx Catalog SIP2004s enDocument2 pages7UT51xx Catalog SIP2004s enHeudes JuniorNo ratings yet

- FLT 93 Themal Flow TransmiterDocument8 pagesFLT 93 Themal Flow TransmiterSALAM ALINo ratings yet

- FG-ALS4-EN - v1 3 1Document2 pagesFG-ALS4-EN - v1 3 1Hadi Aja Panggil GueNo ratings yet

- TLS-450PLUS Automatic Tank GaugeDocument5 pagesTLS-450PLUS Automatic Tank GaugeJamesNo ratings yet

- 2 - Transmisor de Temperatura FOXBORO RTT80 PDFDocument32 pages2 - Transmisor de Temperatura FOXBORO RTT80 PDFjcdavid24No ratings yet

- LCM & LEM 320 Control and Expander Modules Data SheetDocument2 pagesLCM & LEM 320 Control and Expander Modules Data SheetGabriel OsorioNo ratings yet

- FG ALS4 EN V1.8inglesDocument2 pagesFG ALS4 EN V1.8inglesssiNo ratings yet

- 15572780611481jqvee Nari Stub ProtDocument2 pages15572780611481jqvee Nari Stub ProtKelly chatNo ratings yet

- Ds 1664 SMDocument4 pagesDs 1664 SMWumWendelin0% (1)

- DS D LIST LHD 220706Document2 pagesDS D LIST LHD 220706Comercial FirenoNo ratings yet

- WFDTN Series DataSheet WFDS880Document2 pagesWFDTN Series DataSheet WFDS880Paola LopezNo ratings yet

- Broken Tool Detection Broken Bit Detection Machining Processes Tool PositionDocument6 pagesBroken Tool Detection Broken Bit Detection Machining Processes Tool PositionTamilarasan ChettiyannanNo ratings yet

- LR Is FL - enDocument2 pagesLR Is FL - enjames_hartleyNo ratings yet

- TranspondersDocument11 pagesTransponderskhalidNo ratings yet

- D-Agent - 1 - Work-460-S-Upload-3300 XL 8 MM Proximity Transducer System Datasheet - 141194Document42 pagesD-Agent - 1 - Work-460-S-Upload-3300 XL 8 MM Proximity Transducer System Datasheet - 141194Phan CườngNo ratings yet

- FCD-155E: STM-1/OC-3 Add-Drop MultiplexerDocument8 pagesFCD-155E: STM-1/OC-3 Add-Drop MultiplexerGintang PrabowoNo ratings yet

- Stratix Family Reference ChartDocument2 pagesStratix Family Reference Chartrabt1No ratings yet

- TelexDocument44 pagesTelexgatito1971No ratings yet

- I56 3738 004 - Manual - B501 WHITE B501 IVDocument2 pagesI56 3738 004 - Manual - B501 WHITE B501 IVNafis TyagiNo ratings yet

- Flyer - RCS-931 Line Differential RelayDocument2 pagesFlyer - RCS-931 Line Differential Relayhizbi7100% (1)

- D-Agent - 1 - Work-388-S-Upload-3300 XL 8mm Proximity Transducer System Datasheet - 141194Document42 pagesD-Agent - 1 - Work-388-S-Upload-3300 XL 8mm Proximity Transducer System Datasheet - 141194Moises Alejandro Ordoñez GuerraNo ratings yet

- Key FeaturesDocument11 pagesKey Featuresghostrider1098No ratings yet

- SEL-487E-3, - 4 Transformer Protection Relay: Three-Phase Transformer Protection, Automation, and Control SystemDocument4 pagesSEL-487E-3, - 4 Transformer Protection Relay: Three-Phase Transformer Protection, Automation, and Control Systemghostrider1098No ratings yet

- 3-A Output Single Synchronous Step Down Switcher With Integrated Fet (Swift)Document22 pages3-A Output Single Synchronous Step Down Switcher With Integrated Fet (Swift)distefanoNo ratings yet

- KSZ8863MLLDocument104 pagesKSZ8863MLLToastysterNo ratings yet

- TPS54328 4.5-V To 18-V Input, 3-A Synchronous Step-Down Converter With Eco-Mode™Document31 pagesTPS54328 4.5-V To 18-V Input, 3-A Synchronous Step-Down Converter With Eco-Mode™Gus Khoir SrNo ratings yet

- Technical Data LT460Document4 pagesTechnical Data LT460Prince Al RossiNo ratings yet

- Moxa PT g503 Series Datasheet v1.2Document6 pagesMoxa PT g503 Series Datasheet v1.2dejectdNo ratings yet

- 7SV512x Catalog SIP2004s en PDFDocument2 pages7SV512x Catalog SIP2004s en PDFmarkgaloNo ratings yet

- Field Devices - Flow: Product SpecificationsDocument32 pagesField Devices - Flow: Product SpecificationsMohd JannahNo ratings yet

- 208 Report Analysis: Company ConfidentialDocument6 pages208 Report Analysis: Company ConfidentialManinder SinghNo ratings yet

- Ksz8873Mll/Fll/Rll: Integrated 3-Port 10/100 Managed Switch With PhysDocument95 pagesKsz8873Mll/Fll/Rll: Integrated 3-Port 10/100 Managed Switch With PhyskushliakNo ratings yet

- WR 11-12Document32 pagesWR 11-12barsplisNo ratings yet

- TPS54427 4.5-V To 18-V Input, 4-A Output Single Synchronous Step-Down Switcher With Integrated FETDocument32 pagesTPS54427 4.5-V To 18-V Input, 4-A Output Single Synchronous Step-Down Switcher With Integrated FETBhadreshkumar SharmaNo ratings yet

- Delta V Course 7009-1Document68 pagesDelta V Course 7009-1Freddy Torres100% (1)

- Foxboro RTT80-Fieldbus PssDocument24 pagesFoxboro RTT80-Fieldbus PssJose Bernabe Herrera RivasNo ratings yet

- Basic Ethernet Demarcation Device: Smart Demarcation Point Between The Service Provider and Customer NetworksDocument4 pagesBasic Ethernet Demarcation Device: Smart Demarcation Point Between The Service Provider and Customer NetworksPetriea AlexandruNo ratings yet

- The RET 541/543/545 Transformer TerminalsDocument2 pagesThe RET 541/543/545 Transformer TerminalsRagesh ChettiarNo ratings yet

- Wolftrack: Installation ManualDocument19 pagesWolftrack: Installation ManualchauduonguyenNo ratings yet

- 74lvc540at20 13Document10 pages74lvc540at20 13G U I 2 KNo ratings yet

- Foxboro Vortex Flow MetersDocument24 pagesFoxboro Vortex Flow Metersmuhammad naufal anisNo ratings yet

- EST3 Hardwired Module IDC8 - 4Document4 pagesEST3 Hardwired Module IDC8 - 4Fernando Campos100% (1)

- Endress-Hauser Tank Side Monitor NRF81 ENDocument3 pagesEndress-Hauser Tank Side Monitor NRF81 ENFaisal WaheedNo ratings yet

- Lanswitch Xe 3s Asr920 Book Chapter 011Document22 pagesLanswitch Xe 3s Asr920 Book Chapter 011Vansh MalikNo ratings yet

- 4.5V To 18V Input, 3-A SYNCHRONOUS STEP DOWN CONVERTERDocument26 pages4.5V To 18V Input, 3-A SYNCHRONOUS STEP DOWN CONVERTERFelipeAndrésLondoñoGrandaNo ratings yet

- Tps 54329Document27 pagesTps 54329Saul BustamanteNo ratings yet

- 4.5V To 18V Input, 3-A Synchronous Step Down Converter: Features DescriptionDocument26 pages4.5V To 18V Input, 3-A Synchronous Step Down Converter: Features DescriptionFelipeAndrésLondoñoGrandaNo ratings yet

- The Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsFrom EverandThe Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsSylvain ClercNo ratings yet

- Gain-Cell Embedded DRAMs for Low-Power VLSI Systems-on-ChipFrom EverandGain-Cell Embedded DRAMs for Low-Power VLSI Systems-on-ChipNo ratings yet

- Healthcare Provider Directory User Stories 20170126Document5 pagesHealthcare Provider Directory User Stories 20170126Mohamed SaidNo ratings yet

- Wireless World 1988 12Document108 pagesWireless World 1988 12alexmihai_scribd100% (1)

- Application For Teaching AssistantshipDocument2 pagesApplication For Teaching Assistantshipayan guptaNo ratings yet

- Determine Best Fit Information SheetDocument101 pagesDetermine Best Fit Information Sheetmuluken100% (2)

- Cyber Security Global Information InfrastructureDocument7 pagesCyber Security Global Information InfrastructureonesnoneNo ratings yet

- 1-1 Digital Computers and Digital Systems SummaryDocument8 pages1-1 Digital Computers and Digital Systems SummaryXhaNo ratings yet

- FinalDocument23 pagesFinalMariana BraileanuNo ratings yet

- MicroBit CULMINATING Project Rubric - ROBOTICS Space ExplorationDocument3 pagesMicroBit CULMINATING Project Rubric - ROBOTICS Space Explorationjaspal.ughraNo ratings yet

- MP ProgramsDocument24 pagesMP Programstameromar1971No ratings yet

- Quality Management in Procurement (1FM - IN) : Test Script SAP S/4HANA - 08-05-20Document60 pagesQuality Management in Procurement (1FM - IN) : Test Script SAP S/4HANA - 08-05-20sowjanyaNo ratings yet

- Analysys Mason Case Study - NEXIGN - Digital TransformationDocument19 pagesAnalysys Mason Case Study - NEXIGN - Digital TransformationAndrey PritulyukNo ratings yet

- NITK Placement Gyan 2014 PDFDocument216 pagesNITK Placement Gyan 2014 PDFrajesh jalodiyaNo ratings yet

- QR Code - Wikipedia, The Free EncyclopediaDocument5 pagesQR Code - Wikipedia, The Free EncyclopediaAgnihotraNo ratings yet

- DS KH6220 LE1 - Video Intercom Network Indoor Station - Datasheet - V1.0.0Document3 pagesDS KH6220 LE1 - Video Intercom Network Indoor Station - Datasheet - V1.0.0Rafael MejiaNo ratings yet

- Alcatel 7340 H-ONT: Installs Easily - Ideal For Initial Rollout and Widespread DeploymentDocument2 pagesAlcatel 7340 H-ONT: Installs Easily - Ideal For Initial Rollout and Widespread Deploymentomer tariqNo ratings yet

- CMS (Version 3.22.2) PDFDocument125 pagesCMS (Version 3.22.2) PDFManoj ParasherNo ratings yet

- Cs2312 Lab ManualDocument43 pagesCs2312 Lab ManualAbishek A PriyanNo ratings yet

- Powerpoint Presentation of ps1 Final GbuDocument9 pagesPowerpoint Presentation of ps1 Final Gbuapi-238896663No ratings yet

- TC6 HLDocument103 pagesTC6 HLashish118No ratings yet

- PS800SM ClassA r7 PDFDocument368 pagesPS800SM ClassA r7 PDFbruce huNo ratings yet

- Fec Box II Ip Ip DatasheetDocument3 pagesFec Box II Ip Ip Datasheetlaszlo-368875No ratings yet

- MST WRN Overview UsDocument4 pagesMST WRN Overview UsedgarNo ratings yet

- DaknetDocument19 pagesDaknetJosslin ThomasNo ratings yet

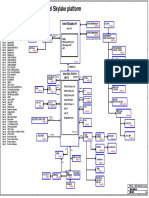

- Msi GT62VR-6RD MS-16L21 0a PDFDocument43 pagesMsi GT62VR-6RD MS-16L21 0a PDFEverAguiarNo ratings yet

- Maryam Tohidi - Building The Right Product and Getting It RightDocument79 pagesMaryam Tohidi - Building The Right Product and Getting It RightRickyNo ratings yet

- IFES Alarm Panel Operator Manual V17.01 - 055612Document15 pagesIFES Alarm Panel Operator Manual V17.01 - 055612DiNo ratings yet

- SS and CD Lab PGMDocument14 pagesSS and CD Lab PGMbobbudigereNo ratings yet

- Artificial Intelligence HandBookDocument27 pagesArtificial Intelligence HandBookHasen SeidNo ratings yet

- Cloud Native SuccessDocument17 pagesCloud Native SuccessVictor SantiagoNo ratings yet