Professional Documents

Culture Documents

Part I-Fundamental

Part I-Fundamental

Uploaded by

သူ ရိန်Copyright:

Available Formats

You might also like

- TD2310-02EN Troubleshooting Manual 3000 - 4000 5th GenDocument1,113 pagesTD2310-02EN Troubleshooting Manual 3000 - 4000 5th Genabdelhadi houssinNo ratings yet

- Kompakt Recu: Series Air Handling Units With C2 Control System Electrical Installation and Operation ManualDocument20 pagesKompakt Recu: Series Air Handling Units With C2 Control System Electrical Installation and Operation ManualRamoNo ratings yet

- Voltage Drop Calculation: Riyadh Cable Group CompanyDocument1 pageVoltage Drop Calculation: Riyadh Cable Group CompanyKhizer Amin100% (1)

- BNWAS Flyer ROCKSON-GuardianV11Document6 pagesBNWAS Flyer ROCKSON-GuardianV11djoko susantoNo ratings yet

- Cable Termination 291209 PDFDocument110 pagesCable Termination 291209 PDFzarchiwin05100% (1)

- Cable Termination I-FundamentalDocument35 pagesCable Termination I-Fundamentalသူ ရိန်No ratings yet

- Optimizer2008 2Document99 pagesOptimizer2008 2Victor Hugo RojasNo ratings yet

- Schematic Diagram CWQMDocument1 pageSchematic Diagram CWQMAhyar Bin IdrisNo ratings yet

- CuS Chalcogenide Letters 2017Document6 pagesCuS Chalcogenide Letters 2017JOAM MANUEL RINCÓN ZULUAGANo ratings yet

- Attachment 11.2 LFDocument5,716 pagesAttachment 11.2 LFGeetha BirudalaNo ratings yet

- 1.1 KV Cable Voltage Drope CalculationDocument3 pages1.1 KV Cable Voltage Drope CalculationParmod SainiNo ratings yet

- A Power Line Communication Tutorial Challenges andDocument17 pagesA Power Line Communication Tutorial Challenges andzeeshanmianNo ratings yet

- 2 FIGURE1 1 Model PDFDocument1 page2 FIGURE1 1 Model PDFdeyanshu7No ratings yet

- 1 LongDocument1 page1 Longjohn02 deanNo ratings yet

- Elmeasure Split Core CT CatalogDocument1 pageElmeasure Split Core CT CatalogManikandan BNo ratings yet

- Remote Field Eddy CurrentDocument4 pagesRemote Field Eddy CurrentExsan OthmanNo ratings yet

- Relay Test Set: MOT - RTS: FeaturesDocument2 pagesRelay Test Set: MOT - RTS: Featuresamiya_driemsNo ratings yet

- EMI RFI Suppression Capacitors Film IEC 60384-14 International StandardDocument1 pageEMI RFI Suppression Capacitors Film IEC 60384-14 International StandardmubafawNo ratings yet

- R E5 L3+MC+Volumetric+Assessment - XLSMDocument92 pagesR E5 L3+MC+Volumetric+Assessment - XLSMokonuttynineNo ratings yet

- Synopsis SumitDocument10 pagesSynopsis SumitKamal ChapagainNo ratings yet

- Sample Electrical LayoutDocument1 pageSample Electrical LayoutBentesais Bente UnoNo ratings yet

- EMD Power Utilities Termination Whitepaper - USDocument12 pagesEMD Power Utilities Termination Whitepaper - USfaisalardy20No ratings yet

- (Physics) - FINAL - SR IIT CO SUPER CHAINA& CO SC N120& N1202023-24) - REVISION TEST SCHEDULE (CODE - 09-10-2023)Document22 pages(Physics) - FINAL - SR IIT CO SUPER CHAINA& CO SC N120& N1202023-24) - REVISION TEST SCHEDULE (CODE - 09-10-2023)avinash.aa4623No ratings yet

- Fiche Technique Alpha-N-2Document1 pageFiche Technique Alpha-N-2Anis MeftehNo ratings yet

- Energy StorageDocument16 pagesEnergy StorageRaed Al-HajNo ratings yet

- Fiche Technique Alpha-NDocument1 pageFiche Technique Alpha-NHaifa MabroukNo ratings yet

- Electrical Works 35 ReportDocument6 pagesElectrical Works 35 ReportMohamad Aboelsoud HessenNo ratings yet

- Activity 2Document3 pagesActivity 2Om SinghNo ratings yet

- 7 Schedule of Loads PDFDocument1 page7 Schedule of Loads PDFLeonardo YenNo ratings yet

- Typical 33kV GTPDocument9 pagesTypical 33kV GTPsridhar_gandra1253No ratings yet

- Cigre 2014: 21, Rue D'artois, F-75008 PARISDocument9 pagesCigre 2014: 21, Rue D'artois, F-75008 PARISNamLeNo ratings yet

- Short Circuit Withstand of Power Cables A Calculation ExampleDocument59 pagesShort Circuit Withstand of Power Cables A Calculation Exampleramadani bimaNo ratings yet

- HướNg DẫN Thông Số Chung Và CáC TrườNg HợP ThườNg XảY Ra Khi Driving Test 3GDocument41 pagesHướNg DẫN Thông Số Chung Và CáC TrườNg HợP ThườNg XảY Ra Khi Driving Test 3GThong LaoNo ratings yet

- Re Revised - SR Iit .Co-Super Chaina Star-II (2023-24) Revision Test Schedule With QP Allotment (Code - Diwali - 11!11!23)Document4 pagesRe Revised - SR Iit .Co-Super Chaina Star-II (2023-24) Revision Test Schedule With QP Allotment (Code - Diwali - 11!11!23)5409627.kag.tejesh.lNo ratings yet

- Four Season Hotel - Dubai Water Canal Voltage Drop Calculation SheetDocument1 pageFour Season Hotel - Dubai Water Canal Voltage Drop Calculation SheetSha Sameer NizamiNo ratings yet

- Unit Sub-Station 160kvaDocument2 pagesUnit Sub-Station 160kvaasifaliabidNo ratings yet

- Bee Fuse2 (Nishant Sir)Document2 pagesBee Fuse2 (Nishant Sir)Md Ali AhmadNo ratings yet

- OKI Reed Switch ORD213Document8 pagesOKI Reed Switch ORD213Daniel HilachoqueNo ratings yet

- 2022 - Heapleach Pad C Stage 1 - Lev 1 Project Milestone (W3-Apr-22)Document4 pages2022 - Heapleach Pad C Stage 1 - Lev 1 Project Milestone (W3-Apr-22)rony 2222No ratings yet

- Harmonic Analysis Hand Calculation For THDDocument3 pagesHarmonic Analysis Hand Calculation For THDFabian Andres Calderon HernandezNo ratings yet

- SPM6-60L 310-330 Watt: Mono Crystalline ModuleDocument2 pagesSPM6-60L 310-330 Watt: Mono Crystalline Modulesami ullahNo ratings yet

- Short - Circuit - Resistance - Diagram - EN - Rittal BusbarsDocument7 pagesShort - Circuit - Resistance - Diagram - EN - Rittal BusbarsR r r H h hNo ratings yet

- Electrical-Dap Report June 20, 2023Document13 pagesElectrical-Dap Report June 20, 2023Rachelle RemigioNo ratings yet

- Power Transformer ProtectionDocument53 pagesPower Transformer ProtectionVasudevan KunjithapathamNo ratings yet

- TG-4033 Dubai Metro - Cables - R70Document18 pagesTG-4033 Dubai Metro - Cables - R70Jason SecretNo ratings yet

- TG-4033 Dubai Metro - Cables - NHT - NewDocument17 pagesTG-4033 Dubai Metro - Cables - NHT - NewJason SecretNo ratings yet

- Philips Master: Ledtube 600 MM High Output T8Document8 pagesPhilips Master: Ledtube 600 MM High Output T8ณัฐดนัย ธนพัชร์อมรกุลNo ratings yet

- Mono P-Type 490-510W 1500VDocument2 pagesMono P-Type 490-510W 1500Vfernando fernandezNo ratings yet

- Column ReportDocument20 pagesColumn ReportChhour CENo ratings yet

- GW122019 CLiP SGLPG - FINAL WebDocument6 pagesGW122019 CLiP SGLPG - FINAL WebMartin CarrascoNo ratings yet

- Work Activity Report-23-2-2022Document4 pagesWork Activity Report-23-2-2022Mohammed ImthiazNo ratings yet

- MCCB Abh403cDocument3 pagesMCCB Abh403chakiman.irecNo ratings yet

- Philips CorePro LEDtube T5 - 180531Document8 pagesPhilips CorePro LEDtube T5 - 180531Deco DluxeNo ratings yet

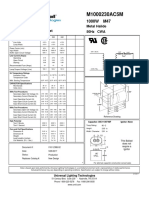

- M1000230AC5MDocument1 pageM1000230AC5MPlant Site KMI-KJANo ratings yet

- Link - Tanah Tinggi To BTS Tanah Datar - Installation - ReportDocument6 pagesLink - Tanah Tinggi To BTS Tanah Datar - Installation - ReportJuple RipunNo ratings yet

- Schematic DiagramDocument1 pageSchematic DiagramJoenyl Fernand CaingcoyNo ratings yet

- Revision of The CBEMA CurveDocument39 pagesRevision of The CBEMA Curveyasir_639No ratings yet

- Selection of CT & PTDocument4 pagesSelection of CT & PTSwagat PradhanNo ratings yet

- Measurements of Electromagnetic Interference in An Operating 800 KV DC Converter StationDocument4 pagesMeasurements of Electromagnetic Interference in An Operating 800 KV DC Converter StationVíctor CasadoNo ratings yet

- EE Planning and Progress - SECCO - R1Document2 pagesEE Planning and Progress - SECCO - R1สุภาวดี สุดาบุตรNo ratings yet

- Semicon Talk 2Document38 pagesSemicon Talk 2Jaspreet KaurNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- 1-62305-3-External LPS Design Consideration-TDocument57 pages1-62305-3-External LPS Design Consideration-Tသူ ရိန်No ratings yet

- Presentation Slides On Electrical System StudyDocument119 pagesPresentation Slides On Electrical System Studyသူ ရိန်No ratings yet

- Part II-Site Testing & PDDocument43 pagesPart II-Site Testing & PDသူ ရိန်No ratings yet

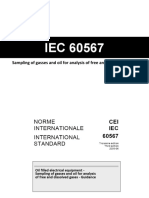

- Rev1-Part III - Iec 60567Document10 pagesRev1-Part III - Iec 60567သူ ရိန်No ratings yet

- Part II - Iec 60599Document28 pagesPart II - Iec 60599သူ ရိန်No ratings yet

- Part Iii - Iec 60567Document10 pagesPart Iii - Iec 60567သူ ရိန်No ratings yet

- Cable Termination I-FundamentalDocument35 pagesCable Termination I-Fundamentalသူ ရိန်No ratings yet

- Dga SeminarDocument98 pagesDga Seminarသူ ရိန်No ratings yet

- IES Articles - As at Oct 2007Document70 pagesIES Articles - As at Oct 2007သူ ရိန်No ratings yet

- Part 1 - Iec 60422Document42 pagesPart 1 - Iec 60422သူ ရိန်No ratings yet

- 4.plambling & SanitryDocument8 pages4.plambling & Sanitryသူ ရိန်No ratings yet

- Reel Tech Catalogue 2018Document24 pagesReel Tech Catalogue 2018သူ ရိန်No ratings yet

- Metering CodeDocument61 pagesMetering Codeသူ ရိန်No ratings yet

- Value Speed DrivesDocument46 pagesValue Speed Drivesသူ ရိန်No ratings yet

- BCA Energy Performance Points CalculatorDocument69 pagesBCA Energy Performance Points Calculatorသူ ရိန်No ratings yet

- Dissolved Gas Analysis Serminal Tutorial Solution 27 June 2013Document15 pagesDissolved Gas Analysis Serminal Tutorial Solution 27 June 2013သူ ရိန်No ratings yet

- 09 HDB SOR - Jul 2014Document238 pages09 HDB SOR - Jul 2014သူ ရိန်No ratings yet

- What Fsms Need To Know About One-Way Emergency Voice Communication (Evc) SystemsDocument45 pagesWhat Fsms Need To Know About One-Way Emergency Voice Communication (Evc) Systemsသူ ရိန်No ratings yet

- McQuay (Plata)Document70 pagesMcQuay (Plata)Ana Gil Pinto Brás100% (2)

- HVACDocument7 pagesHVACJunatan DinglasaNo ratings yet

- Ghid ȘuruburiDocument91 pagesGhid Șuruburireteioan0% (1)

- EWAT-B, EWYT-B - D-EOMHP01301-20 - Operating Manual - EnglishDocument50 pagesEWAT-B, EWYT-B - D-EOMHP01301-20 - Operating Manual - EnglishMANTENCION LA SERENANo ratings yet

- BOQ - SIPIL GI 150 KV RAJAPAKSIDocument14 pagesBOQ - SIPIL GI 150 KV RAJAPAKSIReinhard Jesaya SimbolonNo ratings yet

- S-CLASSIC E SeriesDocument9 pagesS-CLASSIC E SeriesKetut Wahyu WidyanaNo ratings yet

- Fire Protection System: Testing & Commissioning Method StatementDocument14 pagesFire Protection System: Testing & Commissioning Method Statementselcuk peken50% (2)

- Air-Dryer Atlas ASL 2007 03Document22 pagesAir-Dryer Atlas ASL 2007 03Ronaz1981100% (1)

- Design Features Puffer Interrupters: Contact PartingDocument1 pageDesign Features Puffer Interrupters: Contact PartingDoan Anh TuanNo ratings yet

- Papercraft Sloth: Recommended MaterialsDocument16 pagesPapercraft Sloth: Recommended MaterialsccNo ratings yet

- Brake System, Tractor Units Tillv NR 59472 - Old Products Volvo BM Volvo 860 - 861 - Brake Wheel Brake 777partsDocument4 pagesBrake System, Tractor Units Tillv NR 59472 - Old Products Volvo BM Volvo 860 - 861 - Brake Wheel Brake 777partsashraf elsayedNo ratings yet

- BLR TO FTC CAB-001 Rev03Document133 pagesBLR TO FTC CAB-001 Rev03Debaprajnya SahuNo ratings yet

- Mp-In001 - En-P Servomoteur ReférenceDocument26 pagesMp-In001 - En-P Servomoteur ReférenceAbdou DENo ratings yet

- 38 H Gyrasphere Crusher ManualDocument26 pages38 H Gyrasphere Crusher ManualCarl Richter100% (1)

- EPC-PMC HSE Management Safety Walkthrough Close Out Report.26Document5 pagesEPC-PMC HSE Management Safety Walkthrough Close Out Report.26Rickz CabaloNo ratings yet

- Mri MidDocument4 pagesMri Midsarah kilaniNo ratings yet

- Data Cool Brochure (2-3) 10-23-07Document4 pagesData Cool Brochure (2-3) 10-23-07Virg ArtajoNo ratings yet

- Multi Type Room Air Conditioner: Service ManualDocument56 pagesMulti Type Room Air Conditioner: Service ManualCesar Calderon GrNo ratings yet

- V Guard Price List 12 11 2019Document1 pageV Guard Price List 12 11 2019Abhishek RaiNo ratings yet

- Clock ModeDocument2 pagesClock ModeCeleynes RTNo ratings yet

- d3g Lines 2Document4 pagesd3g Lines 2Yudi setiawanNo ratings yet

- Boston Bay AirconDocument3 pagesBoston Bay AirconMichael John Pilota100% (1)

- FPHF 117Document1 pageFPHF 117murugan.ragulNo ratings yet

- Emt 4103 Sensors and Transducers On 17th June Lesson 5Document52 pagesEmt 4103 Sensors and Transducers On 17th June Lesson 5SEAN WALLACENo ratings yet

- Ritter m9 UltraclaveDocument1 pageRitter m9 Ultraclaveelectronico1000No ratings yet

- Cutter HF 2020 LowresDocument1 pageCutter HF 2020 LowresSivaramanNo ratings yet

- Mini Musical Tesla Coil KitDocument6 pagesMini Musical Tesla Coil KitventerhermanjNo ratings yet

Part I-Fundamental

Part I-Fundamental

Uploaded by

သူ ရိန်Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Part I-Fundamental

Part I-Fundamental

Uploaded by

သူ ရိန်Copyright:

Available Formats

FAILURE OF CABLE

TERMINATION

A COMMON CAUSE VOLTAGE DIP

IN SINGAPORE

By

LEE WAI MENG

J.M. PANG & SEAH (PTE) LTD

J.M.PANG & SEAH (PTE) LTD

CONTENTS

• FUNDAMENTAL OF CABLE TERMINATION

• SITE TESTING OF CABLE TERMINATION

• PARTIAL DISCHARGE MEASUREMENT IN

CABLE TERMINATION

• CASE HISTORY OF PREMATURE FAILURE

OF CABLE TERMINATION

JMPS J.M.PANG & SEAH (PTE) LTD CONTENTS

FUNDAMENTAL OF

CABLE TERMINATION

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION

Armour PVC Copper Semi XLPE copper

PVC outer sheath Screen conducting

screen

CONSTRUCTION OF CABLE

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 1

Copper

pp Screen

Cable Insulation

C bl C

Cable Conductor

d t (E (Energized)

i d)

Electric Field

Flux Lines

Uniform distribution of electric field Non uniform distribution of electric field

for screened cable for un-screened cable

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 2

LINES OF ELECTRICAL STRESS WITHOUT STRESS CONTROL

30%

80%

40%

50%

90%

60%

70%

20%

Copper Screen

10%

Copper

XLPE

Semi-conducting Screen

LINES OF ELECTRICAL STRESS WITH STRESS CONTROL

20%

30%

40%

60%

10%

50%

70%

80%

Copper Screen

90%

Copper

XLPE

Semi-conducting Screen Stress Control

S C

Tube

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 3

30%

50%

70%

10%

90%

Insulator 90% Line

Conductor

Electric field in the

shape of a funnel

Copper Screen

30%

50%

70%

10%

connected to earth

90%

LINES OF ELECTRIC FIELD

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION – 4

deep cut

Armour PVC Copper Semi XLPE copper

PVC outer sheath Screen conducting

screen

Deep Cut At XLPE

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 5

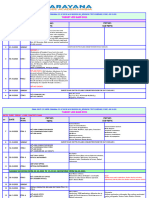

Guideline for Stress Control Tube

Length of Stress Control Tube (mm)

Operating Voltage (kV) Single Core Cable Multi-Core Cable

22 190 250

11 130 190

6.6 100 130

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 6

SECTION 3: DESIGN & CONSTRUCTION (22kV & 6.6kV TERMINATION KITS)

Design 3.1 The heat shrink, cold shrink or slip over type of Semi-Conductive 3.4 Semi-conductive stress control mastic

t

termination

i ti kits

kit and

d accessoriesi offered

ff d shall

h ll b

be d

designed

i d M ti

Mastic shall

h ll be

b provided

id d ffor th

the iinsulation

l ti semi-

i

for both 185mm² and 300mm² cables described in conducting screen cutback.

Clause 1.1, Section 1 of this specification.

Termination 3.2 To suit the various cable termination heights found in Anti-Track 3.5 The insulation shall be a heat-shrinkable

Height the Company

Company’s s different switchgear and transformer cable Insulation flexible polymeric tubing, easily distinguished

boxes/compartments, the supplier shall provide insulation Sleeve/Tubing by colour from non anti-track material and

sleeves of 800mm and 700mm standard length for the 22kV shall not be coloured black, possessing anti-

and 6.6kV termination kits respectively. track and erosion resistant properties for use

as an external covering of the insulation cable

It shall be possible to cross the cable cores with the

cores.

termination kit installed and for the kit to function normallyy in

this manner. Three-Legged 3.6 Three legged semi-rigid mould glove

Mould Glove shall be provided.

Stress Control 3.3 For heat shrink type of termination, the stress control Earth Braids 3.7 Three lengths of 1000mm tinned copper

g

Tubing tubing

g shall be a flexible p

polymeric

y tubing,

g, p

permanentlyy braids shall be pprovided with each termination

colour black, possessing properties to provide electrical kit for earthing of the metallic tape screen of

stress control over the insulated cable cores. Stress control the cable. The minimum cross-sectional area

tubing incorporating paste like stress-relief compound of each braid shall be 25mm². A copper lug

coated on the inner wall of the tubing will not be accepted. shall be crimped at one end of each braid.

The length of stress control tubing shall not be less than The lug shall be suitable for a bolt size of

250mm and 130mm for 22kV and 6 6.6kV

6kV respectively

respectively. The 12mm

12mm.

stress control tubing shall have the words “Stress Control”

in white printed on it to distinguish it from black coloured LV

heat-shrink tubing.

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 7

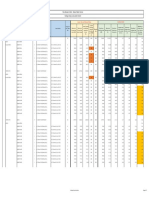

Breakdown Strength of Insulation

Type of Insulation kV/mn

Oil - paper 40

XLPE 70

Air 3

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 8

Method of Air Void Elimination

The following methods can be used to eliminate the air voids

t

tapped

d beneath

b th the

th stress

t control

t l tube

t b att the

th interface

i t f

between the semi conducting screen and the insulation :

• By using mastic tape (new method)

• By using paint (old method)

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 9

Types of Cable Termination

• Heat Shrink Type

• Cold Shrink Type

• Slip Over Type

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 10

Heat Shrink Type Termination

Vendor:Tyco

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 11

Prepare the cable to the required length and

remove the oversheath. The armouring should

be removed according to the dimensions given

or according to the types of glands being used.

used

Remove both the innersheath 75 mm above

armouring or according to the gland type, and

the metal tape shield according to the

dimensions. Then remove the conductive core

screen to 20 mm above the metal tape shield.

The core insulation should be kept clean and

smooth any irregularities should be smoothed

smooth,

out using non-conductive abrasive paper.

Earthing - Fasten the earth braid to the copper

tape screen with one turn of the constant force

spring Fold back the earth braid and wrap the

remaining constant force spring over the earth

braid. Wrap Red HV-adhesive tape SMVA (50%

overlap) for a distance of 90 mm around the

cable jacket and lay the earth tails on top of the

Red HV-adhesive tape SMVA.

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 12

Remove any binders from the end of screen and

remove the release paper from the Stress

control mastic SMCM. Place the point of the

tape at the conductive screen cutback, then

stretching the tape to ½ its original width, tightly

wrap 3 - 4 layers to fill the conductive screen

step and create a smooth transition. The tape

should overlap the screen and insulation by 10

mm on either side.

Slide the Stress control tubing SMCT over

each core with a 50mm overlap onto the

screen. Shrink down the tubing using a torch

working from the bottom upwards.

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 13

Slide the Breakout SMBH over the cores and

remove any release paper which may be in the

breakout. Pull the breakout out well down into

the crutch and shrink the breakout into place

starting at the centre. First shrink down towards

to the skirt (1), then finally upwards toward the

end of the fingers (2).

(2)

With the cores in the correct position, fit the

connectors

t or lugs.

l Th using

Then i a slight

li ht tension,

t i

wrap the Red H.V. adhesive tape SMVA (50%

overlap) on the lug barrel. Build up the barrel

diameter

d a ete aand

d ooverlap

e ap tthe

e co

core

e insulation

su at o by 20 0

mm.

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 14

Wrap one layer of the Red Adhesive SMVA over

each of the breakout turrets.

Slide the Non-tracking g SMVT onto each

g tubing

core. Start shrinking in an upward direction.

The core tubes can thus be trimmed off on the

cable lugs or connectors.

Up to indoor terminations are now complete.

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 15

Position the Sheds SMVS according to the

specified dimensions and shrink into position.

Hold the edge of the Shed with a pair of pliers and

brush with flame. Only the collar will shrink.

Outdoor and indoor terminations are now

complete.

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 16

Cold Shrink Type Termination

Vendor: 3M

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 17

P

Preparation

i for

f Cable

C bl Termination

T i i

Prepare cable using dimension shown in below figure, be sure to allow for depth of terminal lug

Wrap 2 highly stretched half-lapped layers of semi-conducting tape① over the tape shield and

semi-con extending ½″ (13mm) on to cable insulation. Start and end tapping ¾″(19mm) onto tape

shield. Provide a smooth, even leading edge over cable insulation as shown②. Select one of two

Mastic seal strips, provided in kit and remove white liners. Using light tension , wrap a band of

mastic around the cable jacket ½″(13mm) from cut edge③. Cut off excess

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 18

Position pre-formed Ground Braids④ along opposite sides of cable jacket and secure in place

with binding wire on vinyl tape as shown in below. Ground Braid Legs⑤ over cable tape shield

should be position ¼″ from jacket cut edge. Lay each Ground Braid Legs⑤ around the cable

shield and trim its length to prevent overlap as needed⑥.

needed⑥

Secure Ground Braid Legs to cable

shield using supplied Constant-Force

spring⑦. Start the spring on one braid

folded section⑧ and wrap p Ground Braid

Legs and spring together in a common

direction. Capture both Ground Braid

Legs while wrapping and cinch the

spring after wrapping the final winding

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 19

Select second Mastic Seal Strip from kit and remove white liners. Using light tension, wrap a

band of mastic over the Ground Braids covering the Solder-Blocks and the previously

i t ll d Mastic

installed M ti Seal St i ⑨ Apply

S l Strip⑨. A l one highly-stretched,

hi hl t t h d half-lapped

h lf l d layer

l vinyl

i l tape

t over

Constant Force Spring⑩ and Mastic Seal Strip ⑨. Start tapping ¼″ (½″ Max) over applied

13 Tape⑪, extend over Mastic Seal Strip and finish by covering binding wire or vinyl tape

band⑫ applied in step 1

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 20

Position Jacket Seal PST Assembly① over cable jacket with loose core tab② Direct

away from prepared cable end.

Install Jacket Seal PST by pulling loose core pull tab while unwinding counter-

clockwise②. Silicone rubber tube (not the core) should be align with ridge formed by

previously applied 13 tape③.

tape③

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 21

Cover the edge of the 13 Tape with a liberal coating of Silicone Grease④.

Slide 8-Skirt Termination Body on to the cable and remove core. Pull while unwinding

counter-clockwise

counter clockwise,⑤ ⑤ starting with the loose end.

end Make sure the termination body

(not the core) is aligned as shown⑥ below.

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 22

Position Silicone 4-Skirt Insulator over cable end and install by pulling loose core end

while unwinding counter-clockwise. Align 4-Skirt Insulator (not the core) to overlap

previously installed 8-Skirt

8 Skirt Termination by ¾

¾″(19mm)

(19mm) as shown⑦ below

Install terminal lug per manufacturer’s direction. Wrap 4 half-lapped layers of Silicone

Rubber Tape over the lug and onto the insulator for 1″(25mm)①. If lug is not used,

solder block conductor and wrap 4 half-lapped layers of 70 Tape from the solder block

to 1″(25mm) on to the insulator using “Tapping Hint”

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 23

Slip Over Type Termination

Vendor: ABB

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 24

Single Core Cable with Copper Tape Screen

• Remove the oversheath,

oversheath according

to dimension A+X below

• Cut of excess length of the core

Size mm2 A

Cu<70 205

Others 185

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 25

Remove the copper tape until dimension B+X mm from the edge of the

oversheath

Size mm2 B

Cu<70 175

Others 155

St i back

Strip b k the

th insulation

i l ti and

d XLPE-insulation

XLPE i l ti according

di tot dimensions

di i C+X

Size mm2 C

Cu<70 135

Others 115

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 26

• Cut the earth braid in three pieces 0.5m each

• Fasten the earth braid to the copper

pp tape

p screen with one turn of the

constant force spring

• Fold back the earth braid and wrap the remaining constant force spring

over the earth braid

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 27

• Apply one layer of filling tape (FT) on the

edge

d off the

h over sheath

h h

• Put the earth braid over and wind remaining

FT tape over all

• Apply two layer of Electrical tape (ET) with

50% over lap

p

• Start 10mm below the FT tape, continue

over the edge of the copper tape screen

and

d 10mm

10 up on the

h insulation

i l i screen off

the cable and back again

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 28

• Confirm 30mm

• Make a tape mark 75 mm from the end of the insulation screen

• Apply one of FT tape at the center of the taping

• Wind one layer of ET tape

• Start on the insulation and wind

towards the end of the conductor

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 29

• Apply grease over the insulation and spread it by means of the

brush included.

• Use half the g

grease content in tube

• Apply remaining grease on the black

layer inside the bottom end of the

termination.

• Spread the grease by squeezing the

termination

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 30

• Push and twist the termination over the cable and the FT tape down

to the tape marking

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 31

• Fold

F ld down

d th end

the d off the

th termination

t i ti andd remove the

th tape

t

• Crimp the cable lug on the cable

• M

Make

k a seall by

b wrapping

i a few

f t

turns off the

th FT tape

t over the

th

cable lug

• Fold

F ld back

b k the

h end

d off the

h termination

i i

JMPS J.M.PANG & SEAH (PTE) LTD FUNDAMENTAL OF CABLE TERMINATION - 32

You might also like

- TD2310-02EN Troubleshooting Manual 3000 - 4000 5th GenDocument1,113 pagesTD2310-02EN Troubleshooting Manual 3000 - 4000 5th Genabdelhadi houssinNo ratings yet

- Kompakt Recu: Series Air Handling Units With C2 Control System Electrical Installation and Operation ManualDocument20 pagesKompakt Recu: Series Air Handling Units With C2 Control System Electrical Installation and Operation ManualRamoNo ratings yet

- Voltage Drop Calculation: Riyadh Cable Group CompanyDocument1 pageVoltage Drop Calculation: Riyadh Cable Group CompanyKhizer Amin100% (1)

- BNWAS Flyer ROCKSON-GuardianV11Document6 pagesBNWAS Flyer ROCKSON-GuardianV11djoko susantoNo ratings yet

- Cable Termination 291209 PDFDocument110 pagesCable Termination 291209 PDFzarchiwin05100% (1)

- Cable Termination I-FundamentalDocument35 pagesCable Termination I-Fundamentalသူ ရိန်No ratings yet

- Optimizer2008 2Document99 pagesOptimizer2008 2Victor Hugo RojasNo ratings yet

- Schematic Diagram CWQMDocument1 pageSchematic Diagram CWQMAhyar Bin IdrisNo ratings yet

- CuS Chalcogenide Letters 2017Document6 pagesCuS Chalcogenide Letters 2017JOAM MANUEL RINCÓN ZULUAGANo ratings yet

- Attachment 11.2 LFDocument5,716 pagesAttachment 11.2 LFGeetha BirudalaNo ratings yet

- 1.1 KV Cable Voltage Drope CalculationDocument3 pages1.1 KV Cable Voltage Drope CalculationParmod SainiNo ratings yet

- A Power Line Communication Tutorial Challenges andDocument17 pagesA Power Line Communication Tutorial Challenges andzeeshanmianNo ratings yet

- 2 FIGURE1 1 Model PDFDocument1 page2 FIGURE1 1 Model PDFdeyanshu7No ratings yet

- 1 LongDocument1 page1 Longjohn02 deanNo ratings yet

- Elmeasure Split Core CT CatalogDocument1 pageElmeasure Split Core CT CatalogManikandan BNo ratings yet

- Remote Field Eddy CurrentDocument4 pagesRemote Field Eddy CurrentExsan OthmanNo ratings yet

- Relay Test Set: MOT - RTS: FeaturesDocument2 pagesRelay Test Set: MOT - RTS: Featuresamiya_driemsNo ratings yet

- EMI RFI Suppression Capacitors Film IEC 60384-14 International StandardDocument1 pageEMI RFI Suppression Capacitors Film IEC 60384-14 International StandardmubafawNo ratings yet

- R E5 L3+MC+Volumetric+Assessment - XLSMDocument92 pagesR E5 L3+MC+Volumetric+Assessment - XLSMokonuttynineNo ratings yet

- Synopsis SumitDocument10 pagesSynopsis SumitKamal ChapagainNo ratings yet

- Sample Electrical LayoutDocument1 pageSample Electrical LayoutBentesais Bente UnoNo ratings yet

- EMD Power Utilities Termination Whitepaper - USDocument12 pagesEMD Power Utilities Termination Whitepaper - USfaisalardy20No ratings yet

- (Physics) - FINAL - SR IIT CO SUPER CHAINA& CO SC N120& N1202023-24) - REVISION TEST SCHEDULE (CODE - 09-10-2023)Document22 pages(Physics) - FINAL - SR IIT CO SUPER CHAINA& CO SC N120& N1202023-24) - REVISION TEST SCHEDULE (CODE - 09-10-2023)avinash.aa4623No ratings yet

- Fiche Technique Alpha-N-2Document1 pageFiche Technique Alpha-N-2Anis MeftehNo ratings yet

- Energy StorageDocument16 pagesEnergy StorageRaed Al-HajNo ratings yet

- Fiche Technique Alpha-NDocument1 pageFiche Technique Alpha-NHaifa MabroukNo ratings yet

- Electrical Works 35 ReportDocument6 pagesElectrical Works 35 ReportMohamad Aboelsoud HessenNo ratings yet

- Activity 2Document3 pagesActivity 2Om SinghNo ratings yet

- 7 Schedule of Loads PDFDocument1 page7 Schedule of Loads PDFLeonardo YenNo ratings yet

- Typical 33kV GTPDocument9 pagesTypical 33kV GTPsridhar_gandra1253No ratings yet

- Cigre 2014: 21, Rue D'artois, F-75008 PARISDocument9 pagesCigre 2014: 21, Rue D'artois, F-75008 PARISNamLeNo ratings yet

- Short Circuit Withstand of Power Cables A Calculation ExampleDocument59 pagesShort Circuit Withstand of Power Cables A Calculation Exampleramadani bimaNo ratings yet

- HướNg DẫN Thông Số Chung Và CáC TrườNg HợP ThườNg XảY Ra Khi Driving Test 3GDocument41 pagesHướNg DẫN Thông Số Chung Và CáC TrườNg HợP ThườNg XảY Ra Khi Driving Test 3GThong LaoNo ratings yet

- Re Revised - SR Iit .Co-Super Chaina Star-II (2023-24) Revision Test Schedule With QP Allotment (Code - Diwali - 11!11!23)Document4 pagesRe Revised - SR Iit .Co-Super Chaina Star-II (2023-24) Revision Test Schedule With QP Allotment (Code - Diwali - 11!11!23)5409627.kag.tejesh.lNo ratings yet

- Four Season Hotel - Dubai Water Canal Voltage Drop Calculation SheetDocument1 pageFour Season Hotel - Dubai Water Canal Voltage Drop Calculation SheetSha Sameer NizamiNo ratings yet

- Unit Sub-Station 160kvaDocument2 pagesUnit Sub-Station 160kvaasifaliabidNo ratings yet

- Bee Fuse2 (Nishant Sir)Document2 pagesBee Fuse2 (Nishant Sir)Md Ali AhmadNo ratings yet

- OKI Reed Switch ORD213Document8 pagesOKI Reed Switch ORD213Daniel HilachoqueNo ratings yet

- 2022 - Heapleach Pad C Stage 1 - Lev 1 Project Milestone (W3-Apr-22)Document4 pages2022 - Heapleach Pad C Stage 1 - Lev 1 Project Milestone (W3-Apr-22)rony 2222No ratings yet

- Harmonic Analysis Hand Calculation For THDDocument3 pagesHarmonic Analysis Hand Calculation For THDFabian Andres Calderon HernandezNo ratings yet

- SPM6-60L 310-330 Watt: Mono Crystalline ModuleDocument2 pagesSPM6-60L 310-330 Watt: Mono Crystalline Modulesami ullahNo ratings yet

- Short - Circuit - Resistance - Diagram - EN - Rittal BusbarsDocument7 pagesShort - Circuit - Resistance - Diagram - EN - Rittal BusbarsR r r H h hNo ratings yet

- Electrical-Dap Report June 20, 2023Document13 pagesElectrical-Dap Report June 20, 2023Rachelle RemigioNo ratings yet

- Power Transformer ProtectionDocument53 pagesPower Transformer ProtectionVasudevan KunjithapathamNo ratings yet

- TG-4033 Dubai Metro - Cables - R70Document18 pagesTG-4033 Dubai Metro - Cables - R70Jason SecretNo ratings yet

- TG-4033 Dubai Metro - Cables - NHT - NewDocument17 pagesTG-4033 Dubai Metro - Cables - NHT - NewJason SecretNo ratings yet

- Philips Master: Ledtube 600 MM High Output T8Document8 pagesPhilips Master: Ledtube 600 MM High Output T8ณัฐดนัย ธนพัชร์อมรกุลNo ratings yet

- Mono P-Type 490-510W 1500VDocument2 pagesMono P-Type 490-510W 1500Vfernando fernandezNo ratings yet

- Column ReportDocument20 pagesColumn ReportChhour CENo ratings yet

- GW122019 CLiP SGLPG - FINAL WebDocument6 pagesGW122019 CLiP SGLPG - FINAL WebMartin CarrascoNo ratings yet

- Work Activity Report-23-2-2022Document4 pagesWork Activity Report-23-2-2022Mohammed ImthiazNo ratings yet

- MCCB Abh403cDocument3 pagesMCCB Abh403chakiman.irecNo ratings yet

- Philips CorePro LEDtube T5 - 180531Document8 pagesPhilips CorePro LEDtube T5 - 180531Deco DluxeNo ratings yet

- M1000230AC5MDocument1 pageM1000230AC5MPlant Site KMI-KJANo ratings yet

- Link - Tanah Tinggi To BTS Tanah Datar - Installation - ReportDocument6 pagesLink - Tanah Tinggi To BTS Tanah Datar - Installation - ReportJuple RipunNo ratings yet

- Schematic DiagramDocument1 pageSchematic DiagramJoenyl Fernand CaingcoyNo ratings yet

- Revision of The CBEMA CurveDocument39 pagesRevision of The CBEMA Curveyasir_639No ratings yet

- Selection of CT & PTDocument4 pagesSelection of CT & PTSwagat PradhanNo ratings yet

- Measurements of Electromagnetic Interference in An Operating 800 KV DC Converter StationDocument4 pagesMeasurements of Electromagnetic Interference in An Operating 800 KV DC Converter StationVíctor CasadoNo ratings yet

- EE Planning and Progress - SECCO - R1Document2 pagesEE Planning and Progress - SECCO - R1สุภาวดี สุดาบุตรNo ratings yet

- Semicon Talk 2Document38 pagesSemicon Talk 2Jaspreet KaurNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- 1-62305-3-External LPS Design Consideration-TDocument57 pages1-62305-3-External LPS Design Consideration-Tသူ ရိန်No ratings yet

- Presentation Slides On Electrical System StudyDocument119 pagesPresentation Slides On Electrical System Studyသူ ရိန်No ratings yet

- Part II-Site Testing & PDDocument43 pagesPart II-Site Testing & PDသူ ရိန်No ratings yet

- Rev1-Part III - Iec 60567Document10 pagesRev1-Part III - Iec 60567သူ ရိန်No ratings yet

- Part II - Iec 60599Document28 pagesPart II - Iec 60599သူ ရိန်No ratings yet

- Part Iii - Iec 60567Document10 pagesPart Iii - Iec 60567သူ ရိန်No ratings yet

- Cable Termination I-FundamentalDocument35 pagesCable Termination I-Fundamentalသူ ရိန်No ratings yet

- Dga SeminarDocument98 pagesDga Seminarသူ ရိန်No ratings yet

- IES Articles - As at Oct 2007Document70 pagesIES Articles - As at Oct 2007သူ ရိန်No ratings yet

- Part 1 - Iec 60422Document42 pagesPart 1 - Iec 60422သူ ရိန်No ratings yet

- 4.plambling & SanitryDocument8 pages4.plambling & Sanitryသူ ရိန်No ratings yet

- Reel Tech Catalogue 2018Document24 pagesReel Tech Catalogue 2018သူ ရိန်No ratings yet

- Metering CodeDocument61 pagesMetering Codeသူ ရိန်No ratings yet

- Value Speed DrivesDocument46 pagesValue Speed Drivesသူ ရိန်No ratings yet

- BCA Energy Performance Points CalculatorDocument69 pagesBCA Energy Performance Points Calculatorသူ ရိန်No ratings yet

- Dissolved Gas Analysis Serminal Tutorial Solution 27 June 2013Document15 pagesDissolved Gas Analysis Serminal Tutorial Solution 27 June 2013သူ ရိန်No ratings yet

- 09 HDB SOR - Jul 2014Document238 pages09 HDB SOR - Jul 2014သူ ရိန်No ratings yet

- What Fsms Need To Know About One-Way Emergency Voice Communication (Evc) SystemsDocument45 pagesWhat Fsms Need To Know About One-Way Emergency Voice Communication (Evc) Systemsသူ ရိန်No ratings yet

- McQuay (Plata)Document70 pagesMcQuay (Plata)Ana Gil Pinto Brás100% (2)

- HVACDocument7 pagesHVACJunatan DinglasaNo ratings yet

- Ghid ȘuruburiDocument91 pagesGhid Șuruburireteioan0% (1)

- EWAT-B, EWYT-B - D-EOMHP01301-20 - Operating Manual - EnglishDocument50 pagesEWAT-B, EWYT-B - D-EOMHP01301-20 - Operating Manual - EnglishMANTENCION LA SERENANo ratings yet

- BOQ - SIPIL GI 150 KV RAJAPAKSIDocument14 pagesBOQ - SIPIL GI 150 KV RAJAPAKSIReinhard Jesaya SimbolonNo ratings yet

- S-CLASSIC E SeriesDocument9 pagesS-CLASSIC E SeriesKetut Wahyu WidyanaNo ratings yet

- Fire Protection System: Testing & Commissioning Method StatementDocument14 pagesFire Protection System: Testing & Commissioning Method Statementselcuk peken50% (2)

- Air-Dryer Atlas ASL 2007 03Document22 pagesAir-Dryer Atlas ASL 2007 03Ronaz1981100% (1)

- Design Features Puffer Interrupters: Contact PartingDocument1 pageDesign Features Puffer Interrupters: Contact PartingDoan Anh TuanNo ratings yet

- Papercraft Sloth: Recommended MaterialsDocument16 pagesPapercraft Sloth: Recommended MaterialsccNo ratings yet

- Brake System, Tractor Units Tillv NR 59472 - Old Products Volvo BM Volvo 860 - 861 - Brake Wheel Brake 777partsDocument4 pagesBrake System, Tractor Units Tillv NR 59472 - Old Products Volvo BM Volvo 860 - 861 - Brake Wheel Brake 777partsashraf elsayedNo ratings yet

- BLR TO FTC CAB-001 Rev03Document133 pagesBLR TO FTC CAB-001 Rev03Debaprajnya SahuNo ratings yet

- Mp-In001 - En-P Servomoteur ReférenceDocument26 pagesMp-In001 - En-P Servomoteur ReférenceAbdou DENo ratings yet

- 38 H Gyrasphere Crusher ManualDocument26 pages38 H Gyrasphere Crusher ManualCarl Richter100% (1)

- EPC-PMC HSE Management Safety Walkthrough Close Out Report.26Document5 pagesEPC-PMC HSE Management Safety Walkthrough Close Out Report.26Rickz CabaloNo ratings yet

- Mri MidDocument4 pagesMri Midsarah kilaniNo ratings yet

- Data Cool Brochure (2-3) 10-23-07Document4 pagesData Cool Brochure (2-3) 10-23-07Virg ArtajoNo ratings yet

- Multi Type Room Air Conditioner: Service ManualDocument56 pagesMulti Type Room Air Conditioner: Service ManualCesar Calderon GrNo ratings yet

- V Guard Price List 12 11 2019Document1 pageV Guard Price List 12 11 2019Abhishek RaiNo ratings yet

- Clock ModeDocument2 pagesClock ModeCeleynes RTNo ratings yet

- d3g Lines 2Document4 pagesd3g Lines 2Yudi setiawanNo ratings yet

- Boston Bay AirconDocument3 pagesBoston Bay AirconMichael John Pilota100% (1)

- FPHF 117Document1 pageFPHF 117murugan.ragulNo ratings yet

- Emt 4103 Sensors and Transducers On 17th June Lesson 5Document52 pagesEmt 4103 Sensors and Transducers On 17th June Lesson 5SEAN WALLACENo ratings yet

- Ritter m9 UltraclaveDocument1 pageRitter m9 Ultraclaveelectronico1000No ratings yet

- Cutter HF 2020 LowresDocument1 pageCutter HF 2020 LowresSivaramanNo ratings yet

- Mini Musical Tesla Coil KitDocument6 pagesMini Musical Tesla Coil KitventerhermanjNo ratings yet