Professional Documents

Culture Documents

Is411 4

Is411 4

Uploaded by

amoghimiCopyright:

Available Formats

You might also like

- LPDocument1,777 pagesLPAccounting Rc MaukNo ratings yet

- Ras Az Zawr Aluminium Smelter Project: Bolt Torque ValueDocument1 pageRas Az Zawr Aluminium Smelter Project: Bolt Torque ValueJayan VKNo ratings yet

- RSS - AprDocument10 pagesRSS - AprRafael BalloriNo ratings yet

- AAICDocument63 pagesAAICJohn wickNo ratings yet

- BV Practical ProblemsDocument18 pagesBV Practical ProblemsSaloni Jain 1820343No ratings yet

- 4 INCH Rotary Table ChartsDocument10 pages4 INCH Rotary Table ChartsSANTERASASANo ratings yet

- Calcular JumboDocument2 pagesCalcular JumboCeliaNo ratings yet

- BẢN VẼ CHI TIẾT GIÓNG ĂNDocument3 pagesBẢN VẼ CHI TIẾT GIÓNG ĂNnguyenbich2893No ratings yet

- 10m1 Textbook AnswersDocument83 pages10m1 Textbook AnswersGertrude RamsbottomNo ratings yet

- UM6WG1 Cylinder BlockDocument6 pagesUM6WG1 Cylinder BlockBurik8No ratings yet

- Nesting Pelambres: UT Indications in PA3 InsertsDocument12 pagesNesting Pelambres: UT Indications in PA3 InsertstobiasNo ratings yet

- Division by 1 DigitDocument3 pagesDivision by 1 DigitNorielle D. V. Naje-PosadasNo ratings yet

- Cutter Prise ListDocument3 pagesCutter Prise ListjgkothavadeNo ratings yet

- Dividing Head Reference Chart - Evolvent DesignDocument1 pageDividing Head Reference Chart - Evolvent DesignpankajhkmnNo ratings yet

- Chart Title: Xi Yi Xi-Xbarra Yi-Ybarra 3 55 - 8 20 12 40 1 5 6 55 - 5 20 20 10 9 - 25 14 15 3 - 20 Media 11 35 SumaDocument3 pagesChart Title: Xi Yi Xi-Xbarra Yi-Ybarra 3 55 - 8 20 12 40 1 5 6 55 - 5 20 20 10 9 - 25 14 15 3 - 20 Media 11 35 SumaJorge Bastidas X.No ratings yet

- Struktur PersDocument13 pagesStruktur PersMochamad Fajar RamdaniNo ratings yet

- SMC TetDocument20 pagesSMC TetQuang Vũ NgọcNo ratings yet

- Contract Labour Report in Works Area As On 31 03 2023Document11 pagesContract Labour Report in Works Area As On 31 03 2023Jhansi PalliNo ratings yet

- Klaten (Klaten)Document92 pagesKlaten (Klaten)Pandu PermanaNo ratings yet

- 777e 171-1232 Cylinder Gp-Hoist - TelescopingDocument2 pages777e 171-1232 Cylinder Gp-Hoist - TelescopingDashzeveg BayrsaikhanNo ratings yet

- PD31GBDocument2 pagesPD31GBNguyễn Văn HưngNo ratings yet

- Massey Ferguson 6499 TRACTOR (TIER 3) ( - R073028 - T198034) Service Parts Catalogue Manual (Part Number 3906077)Document15 pagesMassey Ferguson 6499 TRACTOR (TIER 3) ( - R073028 - T198034) Service Parts Catalogue Manual (Part Number 3906077)bvk2980022No ratings yet

- Gaikindo 2022Document2 pagesGaikindo 2022NoviyatunNo ratings yet

- Tyre Report Oht 21112021Document28 pagesTyre Report Oht 21112021Yulfikatrin Yuyin YuyunNo ratings yet

- Mechanical Data: Frames 63 To 132M/LDocument4 pagesMechanical Data: Frames 63 To 132M/LAnonymous G9t3IVfL4JNo ratings yet

- 260-3903 Case & Frame GP - Waste Handling, LGPDocument2 pages260-3903 Case & Frame GP - Waste Handling, LGPCARLOSNo ratings yet

- Day 2A Simplifying Radical ExpressionsDocument9 pagesDay 2A Simplifying Radical ExpressionsLeevan PalomarNo ratings yet

- MF1547Engine PDFDocument83 pagesMF1547Engine PDFAhmad Ali Nursahidin100% (1)

- Data Covid-19 Tahap 6... September 2020Document918 pagesData Covid-19 Tahap 6... September 2020Achmad YaumiNo ratings yet

- Susp Cyl ValveDocument2 pagesSusp Cyl ValvekkyouNo ratings yet

- Kebutuhan Consumable PartDocument65 pagesKebutuhan Consumable Partindro0607No ratings yet

- Result 4Document16 pagesResult 4yanox50047No ratings yet

- Updated Job Card & Process Flow ChecklistDocument10 pagesUpdated Job Card & Process Flow Checklistjustin29600No ratings yet

- IS 1538 1993 Table 22 Double Flanged l/4 Duckfoot Bends (Clailses 9. T and 11.1)Document1 pageIS 1538 1993 Table 22 Double Flanged l/4 Duckfoot Bends (Clailses 9. T and 11.1)Akshat Engineers Private LimitedNo ratings yet

- WP025 Engine CAT 3412C HarnessDocument4 pagesWP025 Engine CAT 3412C HarnessTupai PanderNo ratings yet

- 2-Gaikindo Brand Data Janaug2022-RevDocument2 pages2-Gaikindo Brand Data Janaug2022-RevfahranyNo ratings yet

- Rehabilitation & Modernization of Jinnah Barrage Project (CONTRACT No. JB/ICB-01)Document1 pageRehabilitation & Modernization of Jinnah Barrage Project (CONTRACT No. JB/ICB-01)Samir AhmedNo ratings yet

- BlueDocument1 pageBluesri316831No ratings yet

- 351104894-Monitoring-Serak-Jangkos-converted 2Document22 pages351104894-Monitoring-Serak-Jangkos-converted 2Malik YasinNo ratings yet

- 2 GAIKINDO Brand Data Janapr2024Document2 pages2 GAIKINDO Brand Data Janapr2024fikri.a.nugrohoNo ratings yet

- Motor GP HydraulicDocument2 pagesMotor GP HydraulicFiza IlmiNo ratings yet

- 2 GAIKINDO Brand Data Janmar2024Document2 pages2 GAIKINDO Brand Data Janmar2024Zack RamadhanNo ratings yet

- Beta CasesDocument4 pagesBeta CasesMïçhäêł JãkšîNo ratings yet

- Sebeta G+1 BOQDocument17 pagesSebeta G+1 BOQDave EdgarNo ratings yet

- BW - P12a - RMM - IFC - ST - RF - B2 - R02 - B02 Reinforcement ScheduleDocument71 pagesBW - P12a - RMM - IFC - ST - RF - B2 - R02 - B02 Reinforcement Scheduledusan345No ratings yet

- RR Rto-16908llDocument36 pagesRR Rto-16908llgestada023No ratings yet

- Perkiraan Pasokan Gas Bumi Jawa Timur: UraianDocument4 pagesPerkiraan Pasokan Gas Bumi Jawa Timur: Uraiangundul menawanNo ratings yet

- Catálogo de Peças Z80-60Document119 pagesCatálogo de Peças Z80-60Clovis AlvesNo ratings yet

- 2-Gaikindo Brand Data Janmar2020-RevDocument2 pages2-Gaikindo Brand Data Janmar2020-RevacmunarNo ratings yet

- Alternative Dispute Resolution System in India A SDocument188 pagesAlternative Dispute Resolution System in India A SdhruvkamaliyaNo ratings yet

- Awami National Party Manifesto 2018 (Pashto)Document28 pagesAwami National Party Manifesto 2018 (Pashto)Awami National Party100% (1)

- Royalty District WiseDocument38 pagesRoyalty District Wisegplorr2No ratings yet

- Nascar11 VegasDocument55 pagesNascar11 VegasfclexNo ratings yet

- Report e CasillasDocument3 pagesReport e CasillasEon Oilime ZelaznogNo ratings yet

- Swing Machinery and Motor SwinDocument2 pagesSwing Machinery and Motor SwinBuku DigitalNo ratings yet

- Rt/Paut Coverage Percentage List Per Piping Class: Date: 10% 25%Document6 pagesRt/Paut Coverage Percentage List Per Piping Class: Date: 10% 25%aakashNo ratings yet

- F, D, D Qty For EnggDocument11 pagesF, D, D Qty For EnggJOHN KEVINNo ratings yet

- Ingersoll Rand 259 Air ImpactoolDocument2 pagesIngersoll Rand 259 Air Impactoolahmad ganiNo ratings yet

- Ezip 500 SparepartsDocument3 pagesEzip 500 SparepartsJorge MartinNo ratings yet

- Is411 7Document1 pageIs411 7amoghimiNo ratings yet

- Is411 9Document1 pageIs411 9amoghimiNo ratings yet

- Is411 12Document1 pageIs411 12amoghimiNo ratings yet

- Is411 10Document1 pageIs411 10amoghimiNo ratings yet

- Is411 1Document1 pageIs411 1amoghimiNo ratings yet

- Is411 6Document1 pageIs411 6amoghimiNo ratings yet

- Is411 8Document1 pageIs411 8amoghimiNo ratings yet

- Is411 5Document1 pageIs411 5amoghimiNo ratings yet

- Is411 3Document1 pageIs411 3amoghimiNo ratings yet

- Petronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 11Document1 pagePetronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 11amoghimiNo ratings yet

- Is411 2Document1 pageIs411 2amoghimiNo ratings yet

- Petronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 7Document1 pagePetronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 7amoghimiNo ratings yet

- Petronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 9Document1 pagePetronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 9amoghimiNo ratings yet

- Petronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 10Document1 pagePetronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 10amoghimiNo ratings yet

- Petronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 1Document1 pagePetronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 1amoghimiNo ratings yet

- Petronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 8Document1 pagePetronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 8amoghimiNo ratings yet

- Petronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 3Document1 pagePetronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 3amoghimiNo ratings yet

- Petronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 5Document1 pagePetronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 5amoghimiNo ratings yet

- Petronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 6Document1 pagePetronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 6amoghimiNo ratings yet

- Petronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 2Document1 pagePetronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 2amoghimiNo ratings yet

- Petronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 4Document1 pagePetronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 4amoghimiNo ratings yet

- 285130056-Unit-Plot-Plan 4Document1 page285130056-Unit-Plot-Plan 4amoghimiNo ratings yet

- 285130056-Unit-Plot-Plan 2Document1 page285130056-Unit-Plot-Plan 2amoghimiNo ratings yet

- 285130056-Unit-Plot-Plan 5Document1 page285130056-Unit-Plot-Plan 5amoghimiNo ratings yet

- 285130056-Unit-Plot-Plan 1Document1 page285130056-Unit-Plot-Plan 1amoghimiNo ratings yet

- 285130056-Unit-Plot-Plan 3Document1 page285130056-Unit-Plot-Plan 3amoghimiNo ratings yet

- Lecture 2 Intro To Ground ImprovementDocument50 pagesLecture 2 Intro To Ground ImprovementAna RozaininaidaNo ratings yet

- CIV 7240 Formula Sheet FinalExamDocument8 pagesCIV 7240 Formula Sheet FinalExamThirojan JayabalasinghamNo ratings yet

- Soil Fertilty Senior EssayDocument12 pagesSoil Fertilty Senior EssayTilahun MikiasNo ratings yet

- Physics of Soil Water and WatershedsDocument4 pagesPhysics of Soil Water and Watershedschrisr310No ratings yet

- Dutch Cone Penetration Test (Data Sheet)Document21 pagesDutch Cone Penetration Test (Data Sheet)lisa montanaNo ratings yet

- Project Work - Biology (Class Ix)Document9 pagesProject Work - Biology (Class Ix)Aarav VermaNo ratings yet

- Rb6164 Elmina West Section B-B (Global) Soil Nailing 15M: Surcharge 10 KpaDocument1 pageRb6164 Elmina West Section B-B (Global) Soil Nailing 15M: Surcharge 10 KpaHoihogo HoiNo ratings yet

- Mikrobiologi Dasar-Pertemuan 2Document22 pagesMikrobiologi Dasar-Pertemuan 2Wahyu Aji SantosoNo ratings yet

- Plate Load Test Problems - PDFDocument5 pagesPlate Load Test Problems - PDFNIKHIL BANDWALNo ratings yet

- Science PPT PresentationDocument38 pagesScience PPT PresentationGiridhar BhandiwadNo ratings yet

- 02 2002csDocument6 pages02 2002csmarc naganoNo ratings yet

- Retaining WallsDocument70 pagesRetaining WallsKhaled Abdelbaky100% (1)

- Borlog RoxiDocument2 pagesBorlog RoxiYanus SNo ratings yet

- The Dirt On SoilDocument2 pagesThe Dirt On Soilapi-251807679No ratings yet

- Pupuk Arenga PinataDocument9 pagesPupuk Arenga PinataHoly WidastraNo ratings yet

- Index Propertis BH 2Document7 pagesIndex Propertis BH 2Andrea AsvaniNo ratings yet

- Brief Retaining Wall Site CalculationDocument9 pagesBrief Retaining Wall Site CalculationHarjo SarjonoNo ratings yet

- Settlement of Pile GroupDocument19 pagesSettlement of Pile Groupdivya rNo ratings yet

- Gatch MaterialDocument7 pagesGatch MaterialamesbNo ratings yet

- ClassificationDocument8 pagesClassificationUsha HeeranandNo ratings yet

- Calculation: Formula For Moisture Content W (Weight of Water/ Weight of Soil) X 100Document8 pagesCalculation: Formula For Moisture Content W (Weight of Water/ Weight of Soil) X 100SilverfangNo ratings yet

- Design of Subsurface Drip Irrigation Base On Soil Hydraulic Conductivity For Horticulture Crop ProductionDocument12 pagesDesign of Subsurface Drip Irrigation Base On Soil Hydraulic Conductivity For Horticulture Crop ProductionSagitan Putra La KimbiNo ratings yet

- Soil ErosionDocument38 pagesSoil ErosionVishalNo ratings yet

- Engineering Borehole Log: Gagasan Teguh Sdn. BHDDocument1 pageEngineering Borehole Log: Gagasan Teguh Sdn. BHDZeYang LeeNo ratings yet

- Is 5510Document30 pagesIs 5510selva_651950No ratings yet

- HYDRODocument18 pagesHYDROEllaine Marie PostradoNo ratings yet

- Geotech QPDocument2 pagesGeotech QPchandrahas reddyNo ratings yet

- Agricultural Science Form 2Document3 pagesAgricultural Science Form 2nehru09No ratings yet

- Quality Control Tests and Their Frequency For Borrow MaterialDocument2 pagesQuality Control Tests and Their Frequency For Borrow Materialgowreesh ys100% (1)

- Effects of Soil and Water Conservation Techniques On Soil Productivity and Bean Grain Yield in Nyamasheke District, RwandaDocument91 pagesEffects of Soil and Water Conservation Techniques On Soil Productivity and Bean Grain Yield in Nyamasheke District, RwandaBishri MohammedNo ratings yet

Is411 4

Is411 4

Uploaded by

amoghimiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Is411 4

Is411 4

Uploaded by

amoghimiCopyright:

Available Formats

portion of the moisture-controlled subgrade not only prevents cementitious material.

(Obviously, this secondary process

volume changes but produces an impermeable layer that will does not occur with clean granular materials or concrete

protect the soil below from seasonable variations in moisture aggregates.) Thus, in spite of the otherwise objectionable

content. The cement-treated layer also provides protection properties of untreated clay, the clay material itself contributes

against subgrade drying between the time the subgrade is somewhat to the strength development of cement-clay

compacted and the subsequent layers of the pavement are placed. mixtures.

Strength and Bearing Tests. The cementitious reaction Examples of the beneficial effect of cement-modification on

between cement and clay takes place as primary and second- compressive strength are given in Table 5 for 9 clay soils.

ary processes. Hydration of the cement is regarded as the These data are from a comprehensive study5 that also investi-

primary reaction and forms the normal cement hydration gated other properties of cement-treated clay such as triaxial

products that bind particles together. In the secondary process, strength, cohesiometer values, plasticity indices, shrinkage

the fresh calcium hydroxide formed in the primary phase reacts limits, and so forth. Similar increases in strength were found in

with the silica and alumina in the clay to form additional the results of triaxial strength tests and cohesiometer tests.

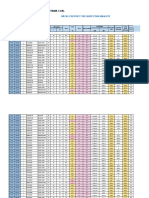

Table 5. Unconfined Compressive Strengths,* psi, of Cement-Treated Clays

No compaction delay 24-hour compaction delay

Cement

AASHTO Content, 7-day 28-day 7-day 28-day

Soil No. Classification percent strength strength strength strength

by wt.

1 A-7-6(20) 0 56 -- -- --

3 98 135 83 128

5 160 233 155 207

2 A-6(8) 0 26 -- -- --

3 316 374 243 324

5 445 495 270 371

4 A7-6(17) 0 29 -- -- --

3 216 277 179 238

5 332 426 256 320

6 A-6(9) 0 28 -- -- --

3 210 269 141 185

5 323 414 234 302

7 A-7-6(19) 0 41 -- -- --

3 124 149 100 133

5 172 232 158 213

8 A-6(6) 0 26 -- -- --

3 234 276 156 267

5 405 452 217 346

9 A-7-6(18) 0 37 -- -- --

3 158 202 135 192

5 243 310 219 283

10 A-6(9) 0 54 -- -- --

3 114 158 84 140

5 174 234 141 205

11 A-7-6(14) 0 38 -- -- --

3 147 186 107 137

5 237 377 204 294

*2.8 x 5.6 in. cylinders kept damp until tested. From Reference 5.

You might also like

- LPDocument1,777 pagesLPAccounting Rc MaukNo ratings yet

- Ras Az Zawr Aluminium Smelter Project: Bolt Torque ValueDocument1 pageRas Az Zawr Aluminium Smelter Project: Bolt Torque ValueJayan VKNo ratings yet

- RSS - AprDocument10 pagesRSS - AprRafael BalloriNo ratings yet

- AAICDocument63 pagesAAICJohn wickNo ratings yet

- BV Practical ProblemsDocument18 pagesBV Practical ProblemsSaloni Jain 1820343No ratings yet

- 4 INCH Rotary Table ChartsDocument10 pages4 INCH Rotary Table ChartsSANTERASASANo ratings yet

- Calcular JumboDocument2 pagesCalcular JumboCeliaNo ratings yet

- BẢN VẼ CHI TIẾT GIÓNG ĂNDocument3 pagesBẢN VẼ CHI TIẾT GIÓNG ĂNnguyenbich2893No ratings yet

- 10m1 Textbook AnswersDocument83 pages10m1 Textbook AnswersGertrude RamsbottomNo ratings yet

- UM6WG1 Cylinder BlockDocument6 pagesUM6WG1 Cylinder BlockBurik8No ratings yet

- Nesting Pelambres: UT Indications in PA3 InsertsDocument12 pagesNesting Pelambres: UT Indications in PA3 InsertstobiasNo ratings yet

- Division by 1 DigitDocument3 pagesDivision by 1 DigitNorielle D. V. Naje-PosadasNo ratings yet

- Cutter Prise ListDocument3 pagesCutter Prise ListjgkothavadeNo ratings yet

- Dividing Head Reference Chart - Evolvent DesignDocument1 pageDividing Head Reference Chart - Evolvent DesignpankajhkmnNo ratings yet

- Chart Title: Xi Yi Xi-Xbarra Yi-Ybarra 3 55 - 8 20 12 40 1 5 6 55 - 5 20 20 10 9 - 25 14 15 3 - 20 Media 11 35 SumaDocument3 pagesChart Title: Xi Yi Xi-Xbarra Yi-Ybarra 3 55 - 8 20 12 40 1 5 6 55 - 5 20 20 10 9 - 25 14 15 3 - 20 Media 11 35 SumaJorge Bastidas X.No ratings yet

- Struktur PersDocument13 pagesStruktur PersMochamad Fajar RamdaniNo ratings yet

- SMC TetDocument20 pagesSMC TetQuang Vũ NgọcNo ratings yet

- Contract Labour Report in Works Area As On 31 03 2023Document11 pagesContract Labour Report in Works Area As On 31 03 2023Jhansi PalliNo ratings yet

- Klaten (Klaten)Document92 pagesKlaten (Klaten)Pandu PermanaNo ratings yet

- 777e 171-1232 Cylinder Gp-Hoist - TelescopingDocument2 pages777e 171-1232 Cylinder Gp-Hoist - TelescopingDashzeveg BayrsaikhanNo ratings yet

- PD31GBDocument2 pagesPD31GBNguyễn Văn HưngNo ratings yet

- Massey Ferguson 6499 TRACTOR (TIER 3) ( - R073028 - T198034) Service Parts Catalogue Manual (Part Number 3906077)Document15 pagesMassey Ferguson 6499 TRACTOR (TIER 3) ( - R073028 - T198034) Service Parts Catalogue Manual (Part Number 3906077)bvk2980022No ratings yet

- Gaikindo 2022Document2 pagesGaikindo 2022NoviyatunNo ratings yet

- Tyre Report Oht 21112021Document28 pagesTyre Report Oht 21112021Yulfikatrin Yuyin YuyunNo ratings yet

- Mechanical Data: Frames 63 To 132M/LDocument4 pagesMechanical Data: Frames 63 To 132M/LAnonymous G9t3IVfL4JNo ratings yet

- 260-3903 Case & Frame GP - Waste Handling, LGPDocument2 pages260-3903 Case & Frame GP - Waste Handling, LGPCARLOSNo ratings yet

- Day 2A Simplifying Radical ExpressionsDocument9 pagesDay 2A Simplifying Radical ExpressionsLeevan PalomarNo ratings yet

- MF1547Engine PDFDocument83 pagesMF1547Engine PDFAhmad Ali Nursahidin100% (1)

- Data Covid-19 Tahap 6... September 2020Document918 pagesData Covid-19 Tahap 6... September 2020Achmad YaumiNo ratings yet

- Susp Cyl ValveDocument2 pagesSusp Cyl ValvekkyouNo ratings yet

- Kebutuhan Consumable PartDocument65 pagesKebutuhan Consumable Partindro0607No ratings yet

- Result 4Document16 pagesResult 4yanox50047No ratings yet

- Updated Job Card & Process Flow ChecklistDocument10 pagesUpdated Job Card & Process Flow Checklistjustin29600No ratings yet

- IS 1538 1993 Table 22 Double Flanged l/4 Duckfoot Bends (Clailses 9. T and 11.1)Document1 pageIS 1538 1993 Table 22 Double Flanged l/4 Duckfoot Bends (Clailses 9. T and 11.1)Akshat Engineers Private LimitedNo ratings yet

- WP025 Engine CAT 3412C HarnessDocument4 pagesWP025 Engine CAT 3412C HarnessTupai PanderNo ratings yet

- 2-Gaikindo Brand Data Janaug2022-RevDocument2 pages2-Gaikindo Brand Data Janaug2022-RevfahranyNo ratings yet

- Rehabilitation & Modernization of Jinnah Barrage Project (CONTRACT No. JB/ICB-01)Document1 pageRehabilitation & Modernization of Jinnah Barrage Project (CONTRACT No. JB/ICB-01)Samir AhmedNo ratings yet

- BlueDocument1 pageBluesri316831No ratings yet

- 351104894-Monitoring-Serak-Jangkos-converted 2Document22 pages351104894-Monitoring-Serak-Jangkos-converted 2Malik YasinNo ratings yet

- 2 GAIKINDO Brand Data Janapr2024Document2 pages2 GAIKINDO Brand Data Janapr2024fikri.a.nugrohoNo ratings yet

- Motor GP HydraulicDocument2 pagesMotor GP HydraulicFiza IlmiNo ratings yet

- 2 GAIKINDO Brand Data Janmar2024Document2 pages2 GAIKINDO Brand Data Janmar2024Zack RamadhanNo ratings yet

- Beta CasesDocument4 pagesBeta CasesMïçhäêł JãkšîNo ratings yet

- Sebeta G+1 BOQDocument17 pagesSebeta G+1 BOQDave EdgarNo ratings yet

- BW - P12a - RMM - IFC - ST - RF - B2 - R02 - B02 Reinforcement ScheduleDocument71 pagesBW - P12a - RMM - IFC - ST - RF - B2 - R02 - B02 Reinforcement Scheduledusan345No ratings yet

- RR Rto-16908llDocument36 pagesRR Rto-16908llgestada023No ratings yet

- Perkiraan Pasokan Gas Bumi Jawa Timur: UraianDocument4 pagesPerkiraan Pasokan Gas Bumi Jawa Timur: Uraiangundul menawanNo ratings yet

- Catálogo de Peças Z80-60Document119 pagesCatálogo de Peças Z80-60Clovis AlvesNo ratings yet

- 2-Gaikindo Brand Data Janmar2020-RevDocument2 pages2-Gaikindo Brand Data Janmar2020-RevacmunarNo ratings yet

- Alternative Dispute Resolution System in India A SDocument188 pagesAlternative Dispute Resolution System in India A SdhruvkamaliyaNo ratings yet

- Awami National Party Manifesto 2018 (Pashto)Document28 pagesAwami National Party Manifesto 2018 (Pashto)Awami National Party100% (1)

- Royalty District WiseDocument38 pagesRoyalty District Wisegplorr2No ratings yet

- Nascar11 VegasDocument55 pagesNascar11 VegasfclexNo ratings yet

- Report e CasillasDocument3 pagesReport e CasillasEon Oilime ZelaznogNo ratings yet

- Swing Machinery and Motor SwinDocument2 pagesSwing Machinery and Motor SwinBuku DigitalNo ratings yet

- Rt/Paut Coverage Percentage List Per Piping Class: Date: 10% 25%Document6 pagesRt/Paut Coverage Percentage List Per Piping Class: Date: 10% 25%aakashNo ratings yet

- F, D, D Qty For EnggDocument11 pagesF, D, D Qty For EnggJOHN KEVINNo ratings yet

- Ingersoll Rand 259 Air ImpactoolDocument2 pagesIngersoll Rand 259 Air Impactoolahmad ganiNo ratings yet

- Ezip 500 SparepartsDocument3 pagesEzip 500 SparepartsJorge MartinNo ratings yet

- Is411 7Document1 pageIs411 7amoghimiNo ratings yet

- Is411 9Document1 pageIs411 9amoghimiNo ratings yet

- Is411 12Document1 pageIs411 12amoghimiNo ratings yet

- Is411 10Document1 pageIs411 10amoghimiNo ratings yet

- Is411 1Document1 pageIs411 1amoghimiNo ratings yet

- Is411 6Document1 pageIs411 6amoghimiNo ratings yet

- Is411 8Document1 pageIs411 8amoghimiNo ratings yet

- Is411 5Document1 pageIs411 5amoghimiNo ratings yet

- Is411 3Document1 pageIs411 3amoghimiNo ratings yet

- Petronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 11Document1 pagePetronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 11amoghimiNo ratings yet

- Is411 2Document1 pageIs411 2amoghimiNo ratings yet

- Petronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 7Document1 pagePetronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 7amoghimiNo ratings yet

- Petronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 9Document1 pagePetronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 9amoghimiNo ratings yet

- Petronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 10Document1 pagePetronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 10amoghimiNo ratings yet

- Petronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 1Document1 pagePetronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 1amoghimiNo ratings yet

- Petronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 8Document1 pagePetronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 8amoghimiNo ratings yet

- Petronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 3Document1 pagePetronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 3amoghimiNo ratings yet

- Petronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 5Document1 pagePetronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 5amoghimiNo ratings yet

- Petronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 6Document1 pagePetronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 6amoghimiNo ratings yet

- Petronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 2Document1 pagePetronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 2amoghimiNo ratings yet

- Petronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 4Document1 pagePetronas-PTS 32.37.20.10-Sep. 2008-Instrument Signal Lines 4amoghimiNo ratings yet

- 285130056-Unit-Plot-Plan 4Document1 page285130056-Unit-Plot-Plan 4amoghimiNo ratings yet

- 285130056-Unit-Plot-Plan 2Document1 page285130056-Unit-Plot-Plan 2amoghimiNo ratings yet

- 285130056-Unit-Plot-Plan 5Document1 page285130056-Unit-Plot-Plan 5amoghimiNo ratings yet

- 285130056-Unit-Plot-Plan 1Document1 page285130056-Unit-Plot-Plan 1amoghimiNo ratings yet

- 285130056-Unit-Plot-Plan 3Document1 page285130056-Unit-Plot-Plan 3amoghimiNo ratings yet

- Lecture 2 Intro To Ground ImprovementDocument50 pagesLecture 2 Intro To Ground ImprovementAna RozaininaidaNo ratings yet

- CIV 7240 Formula Sheet FinalExamDocument8 pagesCIV 7240 Formula Sheet FinalExamThirojan JayabalasinghamNo ratings yet

- Soil Fertilty Senior EssayDocument12 pagesSoil Fertilty Senior EssayTilahun MikiasNo ratings yet

- Physics of Soil Water and WatershedsDocument4 pagesPhysics of Soil Water and Watershedschrisr310No ratings yet

- Dutch Cone Penetration Test (Data Sheet)Document21 pagesDutch Cone Penetration Test (Data Sheet)lisa montanaNo ratings yet

- Project Work - Biology (Class Ix)Document9 pagesProject Work - Biology (Class Ix)Aarav VermaNo ratings yet

- Rb6164 Elmina West Section B-B (Global) Soil Nailing 15M: Surcharge 10 KpaDocument1 pageRb6164 Elmina West Section B-B (Global) Soil Nailing 15M: Surcharge 10 KpaHoihogo HoiNo ratings yet

- Mikrobiologi Dasar-Pertemuan 2Document22 pagesMikrobiologi Dasar-Pertemuan 2Wahyu Aji SantosoNo ratings yet

- Plate Load Test Problems - PDFDocument5 pagesPlate Load Test Problems - PDFNIKHIL BANDWALNo ratings yet

- Science PPT PresentationDocument38 pagesScience PPT PresentationGiridhar BhandiwadNo ratings yet

- 02 2002csDocument6 pages02 2002csmarc naganoNo ratings yet

- Retaining WallsDocument70 pagesRetaining WallsKhaled Abdelbaky100% (1)

- Borlog RoxiDocument2 pagesBorlog RoxiYanus SNo ratings yet

- The Dirt On SoilDocument2 pagesThe Dirt On Soilapi-251807679No ratings yet

- Pupuk Arenga PinataDocument9 pagesPupuk Arenga PinataHoly WidastraNo ratings yet

- Index Propertis BH 2Document7 pagesIndex Propertis BH 2Andrea AsvaniNo ratings yet

- Brief Retaining Wall Site CalculationDocument9 pagesBrief Retaining Wall Site CalculationHarjo SarjonoNo ratings yet

- Settlement of Pile GroupDocument19 pagesSettlement of Pile Groupdivya rNo ratings yet

- Gatch MaterialDocument7 pagesGatch MaterialamesbNo ratings yet

- ClassificationDocument8 pagesClassificationUsha HeeranandNo ratings yet

- Calculation: Formula For Moisture Content W (Weight of Water/ Weight of Soil) X 100Document8 pagesCalculation: Formula For Moisture Content W (Weight of Water/ Weight of Soil) X 100SilverfangNo ratings yet

- Design of Subsurface Drip Irrigation Base On Soil Hydraulic Conductivity For Horticulture Crop ProductionDocument12 pagesDesign of Subsurface Drip Irrigation Base On Soil Hydraulic Conductivity For Horticulture Crop ProductionSagitan Putra La KimbiNo ratings yet

- Soil ErosionDocument38 pagesSoil ErosionVishalNo ratings yet

- Engineering Borehole Log: Gagasan Teguh Sdn. BHDDocument1 pageEngineering Borehole Log: Gagasan Teguh Sdn. BHDZeYang LeeNo ratings yet

- Is 5510Document30 pagesIs 5510selva_651950No ratings yet

- HYDRODocument18 pagesHYDROEllaine Marie PostradoNo ratings yet

- Geotech QPDocument2 pagesGeotech QPchandrahas reddyNo ratings yet

- Agricultural Science Form 2Document3 pagesAgricultural Science Form 2nehru09No ratings yet

- Quality Control Tests and Their Frequency For Borrow MaterialDocument2 pagesQuality Control Tests and Their Frequency For Borrow Materialgowreesh ys100% (1)

- Effects of Soil and Water Conservation Techniques On Soil Productivity and Bean Grain Yield in Nyamasheke District, RwandaDocument91 pagesEffects of Soil and Water Conservation Techniques On Soil Productivity and Bean Grain Yield in Nyamasheke District, RwandaBishri MohammedNo ratings yet