Professional Documents

Culture Documents

BA-10A - BA-10AL Bonding Agent 052412

BA-10A - BA-10AL Bonding Agent 052412

Uploaded by

EdgarJimenezNievesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BA-10A - BA-10AL Bonding Agent 052412

BA-10A - BA-10AL Bonding Agent 052412

Uploaded by

EdgarJimenezNievesCopyright:

Available Formats

Overview

BA-10A/BA-10AL Bonding Agents

The Baker Hughes BA-10A and BA-10AL bonding agents are polymeric gas control

additives that provide excellent bonding potential due to their adhesive properties.

The additive’s film-forming tendency limits interparticle flow within the matrix of the

cement to control fluid loss from the slurry to permeable formations. Applications

Foamed cementing operations

Technical Data Lightweight, standard, and densified

BA-10A BA-10AL slurries

agent typical properties agent typical properties

Appearance White powder White liquid Benefits

Typical temperature range 80 to 240°F (27 to 166°C) BHCT 80 to 240°F (27 to 166°C) BHCT Minimizes annular gas migration

Typical slurry density range 12 to 18 ppg (1438 to 2157 kg/m ) 3

12 to 18 ppg (1438 to 2157 kg/m ) 3

Minimizes formation damage

10 to 100 ghs

Typical concentration range 0.5 to 2% BWOC

(0.888 to 8.878 L/100 kg)

Features

Specific gravity 1.30 1.23

E nhances the hydraulic seal between

Bulk density 40.0 lbm/ft3 (640.7 kg/m3) 76.7 lbm/ft3 (1228.6 kg/m3) the cement and casing/wellbore

Absolute volume 0.0922 gal/lb (0.7694 L/kg) 0.0975 gal/lb (0.8137 L/kg)

Nonretarding in nature

Note: One gallon of BA-10AL agent is an aqueous suspension containing 2.55 lb of

Film-forming property limits

BA-10A agent.

interparticle flow within the matrix of

the cement

BA-10A agents are incompatible with products containing borates such as Baker Hughes

R-9 and R-18 retarders, LW-5 and LW-7 extenders, and CD-31 and CD-31L dispersants. Reduces the permeability of the set

cement

The performance of these additives may also be sensitive to systems containing

bentonite or more than 3% salt. Excellent foam stabilizer for foamed

cementing applications

Baker Hughes Gas Flow Model

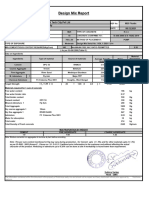

Type III + 3% Salt + 0.8% BA-10A Bonding Agent @ 14.0 ppg

350 1200

Develops good early compressive

strength

300

1000

Improves bonding to the formation

and pipe

Gas Volume cc, Cement Pore Pressure psi

Slurry Temp F, Filtrate Volume cc

250

800

200 Works with virtually all API, ASTM,

600 pozzolan, and lightweight cements

150

400

100

200

50

0 0

3 6 9 12 15 18 21 24

0

Time in hours

Filtrate Volume Slurry Temp Cement Pore Pressure

Safety Precautions

Refer to material safety data sheets (MSDS) for handling, transport, environmental

information, and first aid.

www.bakerhughes.com

Disclaimer of Liability: This information is provided for general information purposes only and is believed to be accurate as of the date hereof; however, Baker Hughes Incorporated and its affiliates do

not make any warranties or representations of any kind regarding the information and disclaim all express and implied warranties or representations to the fullest extent permissible by law, including

those of merchantability, fitness for a particular purpose or use, title, non-infringement, accuracy, correctness or completeness of the information provided herein. All information is furnished “as is”

and without any license to distribute. The user agrees to assume all liabilities related to the use of or reliance on such information. BAKER HUGHES INCORPORATED AND ITS AFFILIATES SHALL NOT BE

LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, PUNITIVE, EXEMPLARY OR CONSEQUENTIAL DAMAGES FROM ANY CAUSE WHATSOEVER INCLUDING BUT NOT LIMITED TO ITS NEGLIGENCE.

© 2012 Baker Hughes Incorporated. All rights reserved. 31613

You might also like

- Productos de CementaciónDocument43 pagesProductos de CementaciónPaola Giron100% (2)

- Concrete Mix Design - Grout Mix (SRC) : Cement Ggbs M.Silica Temp (Fresh Conc-) Mix ClassDocument1 pageConcrete Mix Design - Grout Mix (SRC) : Cement Ggbs M.Silica Temp (Fresh Conc-) Mix ClassAlbert NajjarNo ratings yet

- Design Mix M 25 PPC - CP2659-41Document2 pagesDesign Mix M 25 PPC - CP2659-41Sathish AnandakumarNo ratings yet

- 14 X 28 Extra-Flow Product Data Sheet: Cartridge CharacteristicsDocument2 pages14 X 28 Extra-Flow Product Data Sheet: Cartridge CharacteristicsDmitry BNo ratings yet

- Dowex Upcore Mono C600 LDocument2 pagesDowex Upcore Mono C600 Lengineer.humgNo ratings yet

- Dow DowexhcrsofteningDocument4 pagesDow DowexhcrsofteningdapurayuenNo ratings yet

- M25 - Fluidic Mix Design With Trial MixDocument3 pagesM25 - Fluidic Mix Design With Trial Mixabir senguptaNo ratings yet

- Jacobi TDS Aquasorb 80 A4 Eng C0715Document2 pagesJacobi TDS Aquasorb 80 A4 Eng C0715Hakim BenNo ratings yet

- 6 X 28 Extra-Flow Product Data Sheet: Membrane CharacteristicsDocument2 pages6 X 28 Extra-Flow Product Data Sheet: Membrane CharacteristicsDonatas BertasiusNo ratings yet

- Project:: Type of Concrete: RCC Concrete Confirms To: IS456 Concrete Mix For: Pump / ManualDocument2 pagesProject:: Type of Concrete: RCC Concrete Confirms To: IS456 Concrete Mix For: Pump / ManualKrishnaraj Cnt.No ratings yet

- Hempadur 35760Document4 pagesHempadur 35760aerudzikriNo ratings yet

- En GBDocument3 pagesEn GBAndrea Pamela León AlgarañazNo ratings yet

- Hempalin Enamel 52140Document3 pagesHempalin Enamel 52140Nhien ManNo ratings yet

- Eutalloy 1202Document2 pagesEutalloy 1202Siddharth DasNo ratings yet

- Brexco - Emulinit 2 - TDS - 2023Document1 pageBrexco - Emulinit 2 - TDS - 2023brexcoNo ratings yet

- 1 SOCAR Chemical List - 20151223Document1 page1 SOCAR Chemical List - 20151223Ley LaNo ratings yet

- TDS of AxSorb DDocument1 pageTDS of AxSorb DJohan KhaeriNo ratings yet

- Dowex-Marathon-A RESINA ANIÔNICADocument3 pagesDowex-Marathon-A RESINA ANIÔNICAMarcus FreitasNo ratings yet

- Vinyil Ester GF 3591Document4 pagesVinyil Ester GF 3591irwanNo ratings yet

- DOWEX UPCORE Mono C 600 PDFDocument2 pagesDOWEX UPCORE Mono C 600 PDFlisazulmayetiNo ratings yet

- Stepan Polyester Polyols For Rigid: Polyisocyanurate (PIR) and Polyurethane (PUR Foam)Document4 pagesStepan Polyester Polyols For Rigid: Polyisocyanurate (PIR) and Polyurethane (PUR Foam)s0n1907No ratings yet

- Eutectic 19400: Atomized Martensitic Stainless Steel Alloy PowderDocument2 pagesEutectic 19400: Atomized Martensitic Stainless Steel Alloy PowderYeison Piedrahita PérezNo ratings yet

- Presentation On Biscuit SegmentDocument13 pagesPresentation On Biscuit SegmentSachin KothariNo ratings yet

- Dowex Marathon ADocument2 pagesDowex Marathon Ajuan grasselerNo ratings yet

- (DS - LF - 011 - 0111 Rev. 4A - 01-11) CARBOFLOW MX Filter CartridgesDocument2 pages(DS - LF - 011 - 0111 Rev. 4A - 01-11) CARBOFLOW MX Filter CartridgesRyelfi SessimNo ratings yet

- Silicona Aluminum HempelDocument3 pagesSilicona Aluminum HempelJonathan LugoNo ratings yet

- GCS-830 DSDocument2 pagesGCS-830 DSJose de Jesus Morales MendozaNo ratings yet

- TDS - Tegostab B 8734 LF 2 - 092021Document2 pagesTDS - Tegostab B 8734 LF 2 - 092021NorbertoNo ratings yet

- Design Mix M 30 PPC - CP2659-41Document2 pagesDesign Mix M 30 PPC - CP2659-41Sathish AnandakumarNo ratings yet

- Hempathane 55930Document3 pagesHempathane 55930lobo_hnNo ratings yet

- M-20 MIX DESIGN - PCC (Subject To - Confirmation at Aite) : DistrictDocument3 pagesM-20 MIX DESIGN - PCC (Subject To - Confirmation at Aite) : DistrictAnuraazNo ratings yet

- Dowex Marathon C: Ion Exchange ResinDocument12 pagesDowex Marathon C: Ion Exchange ResinZeeshan TalibNo ratings yet

- Evo Filters 174004403 - ENDocument4 pagesEvo Filters 174004403 - ENandre_silva_camposNo ratings yet

- Concrete Mixed Design For 60MPaDocument1 pageConcrete Mixed Design For 60MParaju_420034520No ratings yet

- Mix DesignDocument4 pagesMix DesignraheelNo ratings yet

- Mix Composition Contractor: Project: Attn To: Thong Huat Brothers Pte LTDDocument1 pageMix Composition Contractor: Project: Attn To: Thong Huat Brothers Pte LTDKoh Jia JieNo ratings yet

- Dowex Monosphere 650C (H)Document2 pagesDowex Monosphere 650C (H)agnarindra01_8550147No ratings yet

- 1632 - Pbt-Pet Valox 815Document5 pages1632 - Pbt-Pet Valox 815Vinoth SekarNo ratings yet

- PDS Uracron CS113 S1G-60 Vs 1.1Document1 pagePDS Uracron CS113 S1G-60 Vs 1.1DJOUHRINo ratings yet

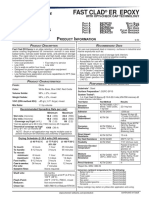

- Fast Clad Er Epoxy: Protective & Marine CoatingsDocument4 pagesFast Clad Er Epoxy: Protective & Marine CoatingsCarlangasPardoNo ratings yet

- LG Abs Hi121hDocument1 pageLG Abs Hi121hChu ChuNo ratings yet

- Ds - TECHDRAIN GTG 720 - enDocument1 pageDs - TECHDRAIN GTG 720 - enThameem SharaafNo ratings yet

- Multiprime P940: Multi Purpose Epoxy Prime Sealer (Anti-Abrasion, Anti-Dust)Document1 pageMultiprime P940: Multi Purpose Epoxy Prime Sealer (Anti-Abrasion, Anti-Dust)Helen ChoiNo ratings yet

- Waterborne PVAc Roof Coating and AdhesiveDocument1 pageWaterborne PVAc Roof Coating and AdhesiveFacundo SepulvedaNo ratings yet

- Mix ACI by Volume Buat ArdiDocument1 pageMix ACI by Volume Buat ArdiBengkulu BetonNo ratings yet

- Shellac Varnishes: Standard Specification ForDocument2 pagesShellac Varnishes: Standard Specification ForLito EstimosNo ratings yet

- Basf Masterseal Below Grade 5500 TdsDocument2 pagesBasf Masterseal Below Grade 5500 Tdsyuva_86No ratings yet

- Hempalin Enamel 52140: Product CharacteristicsDocument3 pagesHempalin Enamel 52140: Product CharacteristicsMohamed FarhanNo ratings yet

- Ficha Tecnica Resina Marathon CDocument2 pagesFicha Tecnica Resina Marathon CDaryl Barrios LamedaNo ratings yet

- Tds - BariteDocument1 pageTds - Bariteaditya imansyahNo ratings yet

- Img 20200831 0005Document1 pageImg 20200831 0005Aung Naing Latt AungNo ratings yet

- Emission CalculationsDocument19 pagesEmission CalculationsJames Daniel BaduriaNo ratings yet

- Ruspetro PI 413 P41 05 EOWDocument15 pagesRuspetro PI 413 P41 05 EOWOleg MalkovNo ratings yet

- PROPOSALDocument3 pagesPROPOSALNidhal KahouliNo ratings yet

- Pds-Bc-Gard WB OgsDocument2 pagesPds-Bc-Gard WB OgsKenji TanNo ratings yet

- JP Carbon Footprint UploadDocument1 pageJP Carbon Footprint Uploadparf1971No ratings yet

- General Information: Shimrin® KBC & C2C-Kbc Classic & Coast 2 Coast Compliant Kandy Basecoat Factory PacksDocument3 pagesGeneral Information: Shimrin® KBC & C2C-Kbc Classic & Coast 2 Coast Compliant Kandy Basecoat Factory PacksrobertoNo ratings yet

- Cost-Effective Solutions For Heavy Layer Mats With Lower Odor and Excellent FlexibilityDocument2 pagesCost-Effective Solutions For Heavy Layer Mats With Lower Odor and Excellent FlexibilityMohitNo ratings yet

- Pages From (ASHRAE) - 2009 - ASHRAE - Handbook - Fundamentals - (SI)Document2 pagesPages From (ASHRAE) - 2009 - ASHRAE - Handbook - Fundamentals - (SI)Tran Canh HoanNo ratings yet

- Design of 200m3 TankDocument4 pagesDesign of 200m3 TankMiko AbiNo ratings yet

- Lumen/Flux/Zonal Cavity MethodDocument4 pagesLumen/Flux/Zonal Cavity MethodVeb GreyNo ratings yet

- Solucionario - Groover Ejercicios ForjaDocument6 pagesSolucionario - Groover Ejercicios ForjaEdgard López BriceñoNo ratings yet

- RC From BigBook by GRE Center PDFDocument240 pagesRC From BigBook by GRE Center PDFAriful HoqueNo ratings yet

- Power Transmission Lec#8Document6 pagesPower Transmission Lec#8Rana AtharNo ratings yet

- Industrial Plant Engineering Elements Review PDF FreeDocument4 pagesIndustrial Plant Engineering Elements Review PDF FreeRoss AlteaNo ratings yet

- Characterizing Organic Compounds: Structural Effects in Ultra-Violet SpectrosDocument16 pagesCharacterizing Organic Compounds: Structural Effects in Ultra-Violet SpectrosKrizzi Dizon GarciaNo ratings yet

- Evaluation of Gas in Place, Drainage EfficienyDocument76 pagesEvaluation of Gas in Place, Drainage EfficienytahaNo ratings yet

- Prediction and Analysis of Gear Rattle: Development TransmissionsDocument5 pagesPrediction and Analysis of Gear Rattle: Development TransmissionssmsnvhNo ratings yet

- Centrifuge HERMLE Z326K V2.21 EngDocument56 pagesCentrifuge HERMLE Z326K V2.21 EngIMEEDCO SRLNo ratings yet

- Nitrogen Gas Booster System: MODEL J24366Document2 pagesNitrogen Gas Booster System: MODEL J24366Titus FelixNo ratings yet

- Predmet: Ponuda Za Vršenje Laboratorijskih IspitivanjaDocument2 pagesPredmet: Ponuda Za Vršenje Laboratorijskih IspitivanjaAnonymous iWaBM6P9V6No ratings yet

- Lecture - 9 Fettling and Casting DefectsDocument43 pagesLecture - 9 Fettling and Casting DefectsSara KiNo ratings yet

- Modelling of Gas Foil Bearings Towards Controllable Operation Multi-Domain AnalysisDocument295 pagesModelling of Gas Foil Bearings Towards Controllable Operation Multi-Domain AnalysiswataruNo ratings yet

- Steeper and Servo MotorsDocument3 pagesSteeper and Servo MotorsIan Justine JornalesNo ratings yet

- Civil Engineering Lab 2: Faculty of Engineering and Built EnvironmentDocument7 pagesCivil Engineering Lab 2: Faculty of Engineering and Built EnvironmentAdel MoflhiNo ratings yet

- Ultrasensitive Fluorescence Detection of Peroxymonosulfate Based On A Sulfate Radical-Mediated Aromatic Hydroxylation - SuppDocument15 pagesUltrasensitive Fluorescence Detection of Peroxymonosulfate Based On A Sulfate Radical-Mediated Aromatic Hydroxylation - SuppSantosh Srinivas NNo ratings yet

- CV of Globe Valves Gate Valves and Check ValvesDocument2 pagesCV of Globe Valves Gate Valves and Check ValvesFred Faber100% (3)

- Standing WaveDocument31 pagesStanding WaveJeff GicharuNo ratings yet

- Department of Mathematics Faculty of Science Jagannath University, DhakaDocument129 pagesDepartment of Mathematics Faculty of Science Jagannath University, DhakaRockSamNo ratings yet

- Volkmann CTwisterDocument20 pagesVolkmann CTwisterimma coverNo ratings yet

- ATS Lineman NSQF 4Document44 pagesATS Lineman NSQF 4Mohamoud MuseNo ratings yet

- Agril - Engg.syllbus DetailsDocument55 pagesAgril - Engg.syllbus DetailsVikas VikkiNo ratings yet

- Iso 2954 2012 en PDFDocument8 pagesIso 2954 2012 en PDFJulio Castillo100% (1)

- Light and Shadow Quiz NameDocument4 pagesLight and Shadow Quiz Nameapi-490528795100% (1)

- Chapter 8 Review and Test SolutionsDocument15 pagesChapter 8 Review and Test SolutionsIrfanKhanNo ratings yet

- Donald A. Neumann - Kinesiology of The Musculoskeletal System 3rd Edition (2018, ELSEVIER) - Libgen - Li-P Íginas-6Document42 pagesDonald A. Neumann - Kinesiology of The Musculoskeletal System 3rd Edition (2018, ELSEVIER) - Libgen - Li-P Íginas-6ritaalmeida98No ratings yet

- Optiglaze Over Bleech Shade C&B MFH PDFDocument8 pagesOptiglaze Over Bleech Shade C&B MFH PDFDavid CNo ratings yet

- Problems and SolutionsDocument67 pagesProblems and SolutionsahoaseoNo ratings yet