Professional Documents

Culture Documents

Final Formülleri2

Final Formülleri2

Uploaded by

Ozan OzgenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Final Formülleri2

Final Formülleri2

Uploaded by

Ozan OzgenCopyright:

Available Formats

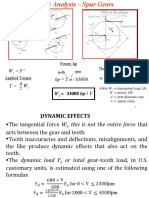

WORM GEAR FLEXIBLE BELTS BEVEL GEAR EXTENSION SPRINGS

Pitch dia.: Flat Belts: Transmitted Power:

Speed range:

If shaft angle and Force Analysis: Transmitted Load:

Without any rotation;

Pitch dia. of worm: ∑

With rotation;

Lead angle:

Pressure angle: table 14-2 syf541

Addendum: table 14-2 syf541

⁄

Dedendum: table 14-2 syf541

Relation between Forces and Friction &

Gear ratio: ⁄ ⁄ (Becareful)

without centrifugal force(Fc):

Effective Face Width: or ⁄

( ) ( ) ( ) or ⁄

Force Analysis with no friction: Torque and Power Transmitted:

Force Analysis with friction: Relation between Forces and Friction &

[ ] with centrifugal force(Fc):

[ ]

mass per unit length of belt(kg/m)

Discussion:If a slight load is added,

some power is transmitted and F1

Efficiency of the Worm: see page 544 increases by and F2 decreases by

same amount. If the load is increased

more and more then eventually F2 will

become zero because belt cannot support

compression load. Then power equation;

and

Max. tension load will be

WORM GEAR(CONTINUE) FLEXIBLE BELTS TORSION SPRINGS

To avoid slippage check; A and m from table 10-2 syf 368

Spring index factor: ⁄

14-17 & If value is not greater ;

- or

Fatique Failure for Bending Stress

Generally the teeth of the worm is stronger - value has to be increased or

than the teeth of the gear in terms of bending. -Use a larger belt section

Thus the bending fatigue failure of worm

gear set is based on the bending stress value Note:F1 from table 17-1 and Fi

of the gear tooth. must be ⁄

Max. tension:

Belt velocity:

&

Note: this formula

for factor of safety (becarefull)

If

Shaft Loads:

( )

Bearing Calculations:

( )

You might also like

- Density GizmoDocument5 pagesDensity Gizmocherichronicles.No ratings yet

- 222 M TC 106 TC Heat ExchangerDocument211 pages222 M TC 106 TC Heat ExchangerpragatheeskNo ratings yet

- HP T N / 63000 T W W F: Transmitted Load, LBDocument35 pagesHP T N / 63000 T W W F: Transmitted Load, LBLayike Alemayehu100% (1)

- 05) Machine Design IDocument23 pages05) Machine Design IStar GlacierNo ratings yet

- 05) Machine Design IDocument23 pages05) Machine Design IM A JomahNo ratings yet

- Calculation of Actual Working Loads and Arrangement of SlingsDocument2 pagesCalculation of Actual Working Loads and Arrangement of SlingsMichael ThaiNo ratings yet

- Machine Design: Flexible Power Transmission: BeltsDocument11 pagesMachine Design: Flexible Power Transmission: Beltsomer1299No ratings yet

- Machine Design: Flexible Power Transmission: BeltsDocument11 pagesMachine Design: Flexible Power Transmission: BeltsSnigdha YadavNo ratings yet

- Machine Design: Flexible Power Transmission: BeltsDocument11 pagesMachine Design: Flexible Power Transmission: Beltsomer1299No ratings yet

- FrictionDocument32 pagesFrictionSa RaNo ratings yet

- Machine Design Formula Sheet (Spring - Fastners and Screws)Document9 pagesMachine Design Formula Sheet (Spring - Fastners and Screws)jadhsaayedNo ratings yet

- Lecture 5Document49 pagesLecture 5JayHatNo ratings yet

- Design of Spur Gear and Helical Gear (Week 05-06)Document74 pagesDesign of Spur Gear and Helical Gear (Week 05-06)Muhammad Zohaib AliNo ratings yet

- Dynamic Analysis of Engine Valvetrain and Its Effects On CamshaftDocument5 pagesDynamic Analysis of Engine Valvetrain and Its Effects On CamshaftYuva NNo ratings yet

- Chapter 1c Stress and Strain (Allowable Stress and Bending Stress)Document37 pagesChapter 1c Stress and Strain (Allowable Stress and Bending Stress)sp-ahmadfareedmohdkarimNo ratings yet

- Belting FormulasDocument1 pageBelting Formulasmanoj-kr-dorai-9476No ratings yet

- The Spring CharacteristicDocument4 pagesThe Spring CharacteristicBharatiyulam100% (1)

- Mechanics of Friction ClutchesDocument22 pagesMechanics of Friction ClutchesEDISON OCHIENGNo ratings yet

- The 10xi in The Element Spliced Plus 5 Percent But in Nocase Shouldthe Strength Developed Be Less Than 50percent ofDocument5 pagesThe 10xi in The Element Spliced Plus 5 Percent But in Nocase Shouldthe Strength Developed Be Less Than 50percent ofRaj MeenaNo ratings yet

- Product-Guide3 LNG en JPN 202108Document11 pagesProduct-Guide3 LNG en JPN 202108ThùyNo ratings yet

- Exp # 04Document8 pagesExp # 04Savaiz HannanNo ratings yet

- Power Screws: ME 147P Machine Design IDocument23 pagesPower Screws: ME 147P Machine Design IJohn Karl De BelenNo ratings yet

- Belt DriveDocument29 pagesBelt Drivevuductoan07072003No ratings yet

- Power Screws: Looking at A Square Thread Screw, We Unwind One Turn: WDocument4 pagesPower Screws: Looking at A Square Thread Screw, We Unwind One Turn: WMohammed AlnasharNo ratings yet

- Calculation of Bearing LoadDocument6 pagesCalculation of Bearing LoadKhaled SaadnehNo ratings yet

- Set1-Full Flexible Drives 2020-08-04Document134 pagesSet1-Full Flexible Drives 2020-08-04Vincent SibandaNo ratings yet

- Loads On Gear TeethDocument9 pagesLoads On Gear TeethShivanshu BaranwalNo ratings yet

- Design of ShaftsDocument47 pagesDesign of ShaftsTejas RaoNo ratings yet

- ME-329 - Mechanical Vibrations: Dated: 16 March, 2021Document41 pagesME-329 - Mechanical Vibrations: Dated: 16 March, 2021Muhammad Junaid JahangirNo ratings yet

- Surface Durability of Spur and Helical Gears - KHK GearsDocument16 pagesSurface Durability of Spur and Helical Gears - KHK GearsDiego Teixeira Da Costa Diniz MascarenhasNo ratings yet

- ME311 - Figures - CH4 - Deflection & StiffnessDocument19 pagesME311 - Figures - CH4 - Deflection & StiffnessMertNo ratings yet

- 4 Eng PDFDocument31 pages4 Eng PDFZaYnab IbrahimNo ratings yet

- Railways: Railway IntroductionDocument9 pagesRailways: Railway IntroductionIkram ArifNo ratings yet

- Spring 1999 ME14 Design Project: Estimation of Mechanical Parameters For A Ski Lift DesignDocument3 pagesSpring 1999 ME14 Design Project: Estimation of Mechanical Parameters For A Ski Lift DesignFaisalNo ratings yet

- DMX4306 - Session 5.power ScrewDocument13 pagesDMX4306 - Session 5.power ScrewG.G. PRABHATH CHINTHAKANo ratings yet

- Flexible Power-Transmitting Elements Flat Belts:: e 1 e G V 12 - SDocument6 pagesFlexible Power-Transmitting Elements Flat Belts:: e 1 e G V 12 - Swaar lockNo ratings yet

- Design of Single Plate Clutch System: T T M, E E T, P P MDocument4 pagesDesign of Single Plate Clutch System: T T M, E E T, P P MYudha SitumorangNo ratings yet

- Shaft Analysis - Engineering LibraryDocument15 pagesShaft Analysis - Engineering LibraryDeepak GiriNo ratings yet

- 10.3 Calculation For Cylindrical Worm Gear Pair StrengthDocument7 pages10.3 Calculation For Cylindrical Worm Gear Pair StrengthNandaKumarPNo ratings yet

- Design Calculation of Coil Spring in The Independent Suspension System (Landcruiser)Document5 pagesDesign Calculation of Coil Spring in The Independent Suspension System (Landcruiser)Dr. Aung Ko LattNo ratings yet

- Chapter2 - Principle of ThrustDocument8 pagesChapter2 - Principle of Thrustsh1999No ratings yet

- Friction Devices 19Document36 pagesFriction Devices 19mahaveer dasNo ratings yet

- 7 - Power Screw PDFDocument20 pages7 - Power Screw PDFViven SharmaNo ratings yet

- IDM Basic Training - ModrillDocument30 pagesIDM Basic Training - ModrillThomas Du100% (1)

- Calculation SheetDocument2 pagesCalculation SheetSamwailNo ratings yet

- PulleysDocument16 pagesPulleysFinito TheEndNo ratings yet

- Brake UploadDocument9 pagesBrake UploadPETER PENNo ratings yet

- Beam Pre StressDocument55 pagesBeam Pre StresssurangaNo ratings yet

- Inno2020 T7 Flexible Mechanical ElementsDocument21 pagesInno2020 T7 Flexible Mechanical ElementsGhostNo ratings yet

- SFD BMDDocument44 pagesSFD BMDRakeshAdakaneNo ratings yet

- Chapter 7 Rolling Contact Bearing-2Document33 pagesChapter 7 Rolling Contact Bearing-2Abaziz Mousa OutlawZzNo ratings yet

- Chapter One: (I) Load To Be Lifted., and (Ii) Height of LiftDocument21 pagesChapter One: (I) Load To Be Lifted., and (Ii) Height of Liftmailme_abhishu55100% (2)

- ACME Power Screw Torque CalculationDocument7 pagesACME Power Screw Torque CalculationVarun Sreethar100% (1)

- Power ScrewDocument7 pagesPower ScrewLeiyibot bayot ver.No ratings yet

- Ball Equiv LoadDocument2 pagesBall Equiv LoadBhuqaNo ratings yet

- Gear EfficiencyDocument6 pagesGear EfficiencysohamkoliNo ratings yet

- Power Screws: Prof. Shankar Krishnapillai IitmDocument56 pagesPower Screws: Prof. Shankar Krishnapillai IitmHimanshu agarwalNo ratings yet

- Design of Journal Bearings (Week 9-10)Document54 pagesDesign of Journal Bearings (Week 9-10)Muhammad Zohaib AliNo ratings yet

- Sumitomo Corporation: Checked by Page of Area: Turbine Build. Rev Dept StructuralDocument10 pagesSumitomo Corporation: Checked by Page of Area: Turbine Build. Rev Dept StructuralIbrahim MeharoofNo ratings yet

- Lab Manual DBT 210 PDFDocument19 pagesLab Manual DBT 210 PDFBELAL ALSUBARINo ratings yet

- Midterm 1Document2 pagesMidterm 1Ozan OzgenNo ratings yet

- Dokumen - Tips - Prof Huseyin Filiz Problems of The Design of Machine ElementsDocument115 pagesDokumen - Tips - Prof Huseyin Filiz Problems of The Design of Machine ElementsOzan OzgenNo ratings yet

- ME308 Second Project PDFDocument13 pagesME308 Second Project PDFOzan OzgenNo ratings yet

- Elements of Heat Transfer Yildiz Beyazitoä LuDocument448 pagesElements of Heat Transfer Yildiz Beyazitoä LuOzan OzgenNo ratings yet

- Ac BridgeDocument7 pagesAc BridgeAditiNo ratings yet

- Instalation Proposal Drawing Secador FD410 MetricDocument1 pageInstalation Proposal Drawing Secador FD410 MetricEddo CarrionNo ratings yet

- ME2202 Question BankDocument5 pagesME2202 Question BankStanly ThomasNo ratings yet

- MCD1200 - Tut 1 - Modern Physics - QuestionsDocument3 pagesMCD1200 - Tut 1 - Modern Physics - Questionshyeon님No ratings yet

- Solution Assignment MENG580 Chapter 11Document4 pagesSolution Assignment MENG580 Chapter 11ahmadNo ratings yet

- Technical - Datasheet - 3EK7 420-4CH4Document1 pageTechnical - Datasheet - 3EK7 420-4CH4Nam NguyễnNo ratings yet

- Lab 1: The Digital Multimeter: 1.1 ObjectiveDocument50 pagesLab 1: The Digital Multimeter: 1.1 ObjectiveWarishaNo ratings yet

- Silicon NPN Darlington Power Transistor BDW93C: DescriptionDocument2 pagesSilicon NPN Darlington Power Transistor BDW93C: DescriptionSergio Brida100% (1)

- Waves and Optics - ReviewerDocument15 pagesWaves and Optics - ReviewerJoshua QuimsonNo ratings yet

- R452A TABLA Presión-TemperaturaDocument5 pagesR452A TABLA Presión-TemperaturaJose Ortuño MartínNo ratings yet

- Electric Heat Tracing: Installation ProceduresDocument8 pagesElectric Heat Tracing: Installation ProceduresDavid Luna MolinaNo ratings yet

- Chapter R10Document67 pagesChapter R10Kevin TranNo ratings yet

- AE 301 - Aerodynamics I - Spring 2015 Problem Set 2: Assigned: Friday, January 23, 2015 Due: Friday, January 30, 2015Document2 pagesAE 301 - Aerodynamics I - Spring 2015 Problem Set 2: Assigned: Friday, January 23, 2015 Due: Friday, January 30, 2015TheTannedFishNo ratings yet

- Thermal Properties of Matter PDFDocument33 pagesThermal Properties of Matter PDFGAMES TECHNo ratings yet

- Engineering Data Book Toshiba RAS 3M26UAV EDocument40 pagesEngineering Data Book Toshiba RAS 3M26UAV EMatija MihalkovićNo ratings yet

- Tech Spec 7477Document6 pagesTech Spec 7477Dharmesh ChanawalaNo ratings yet

- Seminar Report-2Document17 pagesSeminar Report-2Appu AppuNo ratings yet

- 100 Questions 100 Min. Capacitance NEET-2017/IIT MAINS 2017Document11 pages100 Questions 100 Min. Capacitance NEET-2017/IIT MAINS 2017umved singh yadav100% (9)

- Reyrolle High Speed Trip Relay: Catalog Reyrolle 7PJ15 Edition 3Document18 pagesReyrolle High Speed Trip Relay: Catalog Reyrolle 7PJ15 Edition 3Rajesh sawaleNo ratings yet

- Stycast 2850FTDocument4 pagesStycast 2850FTKhôi NguyênNo ratings yet

- METSIMDocument4 pagesMETSIMCharles JlNo ratings yet

- Electrical Drive Unit-Ii: Vii Semester ETEE-401Document100 pagesElectrical Drive Unit-Ii: Vii Semester ETEE-401Jeet DattaNo ratings yet

- Ee301 - Capacitors and InductorsDocument3 pagesEe301 - Capacitors and InductorsShahid RanaNo ratings yet

- Ixfk100n65x2 100a 650v N Kanal Mosfet To264 DatasheetDocument6 pagesIxfk100n65x2 100a 650v N Kanal Mosfet To264 Datasheetbasheer almetwakelNo ratings yet

- Magnetism TestDocument4 pagesMagnetism TestRyan AllanNo ratings yet

- Autonics Psan Series ManualDocument1 pageAutonics Psan Series ManualResaKandhyNo ratings yet

- Proyecto FLM Movistar: Entrenamiento Basico en Sistemas de Energia Y PotenciaDocument12 pagesProyecto FLM Movistar: Entrenamiento Basico en Sistemas de Energia Y PotenciaJoan SebastianNo ratings yet

- Pre-Lab.: Experiment 2Document4 pagesPre-Lab.: Experiment 2Waseem HaiderNo ratings yet