Professional Documents

Culture Documents

Emed Jour 1986 015 048 02

Emed Jour 1986 015 048 02

Uploaded by

vishal bhatCopyright:

Available Formats

You might also like

- Horiba ABX Micros ES60 ESV60 Service Manual PDFDocument214 pagesHoriba ABX Micros ES60 ESV60 Service Manual PDFjorgeluis100% (4)

- Beckman Coulter Chemistry Analyzer: Ise User GuideDocument84 pagesBeckman Coulter Chemistry Analyzer: Ise User GuidePhong Do100% (1)

- OGP Standards For Local Medical SupportDocument36 pagesOGP Standards For Local Medical Supportihwan100% (1)

- Active Projects 2001: 1. Precise Speed HoldingDocument10 pagesActive Projects 2001: 1. Precise Speed HoldingDipmoi PathakNo ratings yet

- DCIM-B01.840.10.01.02 Immulite Com Lis PDFDocument311 pagesDCIM-B01.840.10.01.02 Immulite Com Lis PDFОлександр100% (1)

- Fundamentals of Nursing1Document51 pagesFundamentals of Nursing1Charles Gerard B. BeluanNo ratings yet

- A New Type of Motor - Pneumatic Step MotorDocument9 pagesA New Type of Motor - Pneumatic Step MotorAbbasali AfzaliNo ratings yet

- Statistic-Based Method To Monitor Belt Transmission Looseness Through Motor Phase CurrentsDocument9 pagesStatistic-Based Method To Monitor Belt Transmission Looseness Through Motor Phase CurrentsJOEL EZEQUIEL PACHECO MENANo ratings yet

- Surface Micromachined Electrostatically Actuated Micro Peristaltic PumpDocument7 pagesSurface Micromachined Electrostatically Actuated Micro Peristaltic PumpAman SainiNo ratings yet

- PLC and Hmi For Conveyor Monitoring and Fault DetectionDocument5 pagesPLC and Hmi For Conveyor Monitoring and Fault DetectionIJAR JOURNALNo ratings yet

- Model Based System Identification For Hydraulic Deep Drawing PressesDocument11 pagesModel Based System Identification For Hydraulic Deep Drawing PressesjordanNo ratings yet

- Design and CFD Analysis of Centrifugal Pump IJERTCONV9IS10007Document5 pagesDesign and CFD Analysis of Centrifugal Pump IJERTCONV9IS10007muhammad faisalNo ratings yet

- Aviation Week 1961-03-13Document159 pagesAviation Week 1961-03-13tordo22100% (1)

- Condition-Based Maintenance: Model vs. Statistics A Performance ComparisonDocument7 pagesCondition-Based Maintenance: Model vs. Statistics A Performance ComparisonLourds Egúsquiza EscuderoNo ratings yet

- Design and Development of A Low-Cost Exure-Based Hand-Held Mechanism For MicromanipulationDocument7 pagesDesign and Development of A Low-Cost Exure-Based Hand-Held Mechanism For MicromanipulationDamián Cortina LópezNo ratings yet

- Digital Speed Control of DC Motor For Industrial Automation Using Pulse Width Modulation TechniqueDocument6 pagesDigital Speed Control of DC Motor For Industrial Automation Using Pulse Width Modulation TechniquevendiNo ratings yet

- Sensorless Parameters Estimation of VFD Based CascDocument14 pagesSensorless Parameters Estimation of VFD Based CascAnonymous 1AAjd0No ratings yet

- Researchpaper 1-ElectronicsyringepumpDocument5 pagesResearchpaper 1-ElectronicsyringepumpSidra latifNo ratings yet

- Sciencedirect: Modelling, Simulation and Optimisation of A Piezoelectric Energy HarvesterDocument6 pagesSciencedirect: Modelling, Simulation and Optimisation of A Piezoelectric Energy HarvesterCh AbdullahNo ratings yet

- UIUC 451 Interim PaperDocument13 pagesUIUC 451 Interim Paperanon_996725493No ratings yet

- Design of Fuzzi Pid TrackingDocument12 pagesDesign of Fuzzi Pid Trackingmuhammad shahbazNo ratings yet

- Sensors: Diagnostic of Operation Conditions and Sensor Faults Using Machine Learning in Sucker-Rod Pumping WellsDocument29 pagesSensors: Diagnostic of Operation Conditions and Sensor Faults Using Machine Learning in Sucker-Rod Pumping WellsRodrigo DacolNo ratings yet

- New Sensor Technology For Measuring Torsional Shaft Vibration in Turbine GeneratorsDocument8 pagesNew Sensor Technology For Measuring Torsional Shaft Vibration in Turbine GeneratorssebastianNo ratings yet

- Design of Embedded Microcontroller For Controlling and Monitoring Blood PumpDocument8 pagesDesign of Embedded Microcontroller For Controlling and Monitoring Blood PumpGEORGE MYLONASNo ratings yet

- Dynamic Modeling and Simulation of Control System For Pneumatic Servo Valve Using Piezoelectric ActuatorDocument10 pagesDynamic Modeling and Simulation of Control System For Pneumatic Servo Valve Using Piezoelectric Actuatorkyaw san ooNo ratings yet

- Automated Drilling Algorithms ImplementationDocument11 pagesAutomated Drilling Algorithms ImplementationnanlingjigongNo ratings yet

- Machine ToolspindleunitsDocument22 pagesMachine Toolspindleunitsdevmecz2696No ratings yet

- Design of Fuzzi-Pid Tracking Controller For IndustDocument8 pagesDesign of Fuzzi-Pid Tracking Controller For IndustBernadetteNo ratings yet

- SPE 35236 Low Cost Solutions For Well Interventions Through Advanced Slickline ServicesDocument16 pagesSPE 35236 Low Cost Solutions For Well Interventions Through Advanced Slickline ServicesDen YogaNo ratings yet

- Celluveyor 2Document7 pagesCelluveyor 2Paúl TituañaNo ratings yet

- Bi-Directional Control Systems For Microfluids: Cpjen@mail - Ncku.edu - TW Yuclin@mail - Ncku.edu - TWDocument4 pagesBi-Directional Control Systems For Microfluids: Cpjen@mail - Ncku.edu - TW Yuclin@mail - Ncku.edu - TWdenghueiNo ratings yet

- Electric Propulsion System Characterization Through ExperimentsDocument9 pagesElectric Propulsion System Characterization Through Experiments呂文祺No ratings yet

- Eccentric Cam Operated Semi Automatic Gear Shifting System For Two WheelerDocument8 pagesEccentric Cam Operated Semi Automatic Gear Shifting System For Two Wheelerkifle abelNo ratings yet

- Modeling of Heavy Duty Electrohydraulic ManipulatorDocument10 pagesModeling of Heavy Duty Electrohydraulic Manipulatoraenas984363No ratings yet

- Dovermotion AprDocument7 pagesDovermotion Aprfog900No ratings yet

- Design and Assembly of Prototype of Automatic Rail Track Cleaning MachineDocument3 pagesDesign and Assembly of Prototype of Automatic Rail Track Cleaning MachineGirishZopeNo ratings yet

- Modelling and Operational Testing of Pulse-Width Modulation at Injection Time For A Spark-Ignition EngineDocument7 pagesModelling and Operational Testing of Pulse-Width Modulation at Injection Time For A Spark-Ignition EngineAdal VeraNo ratings yet

- Note Law ClassDocument17 pagesNote Law ClassAgung WiranataNo ratings yet

- Application Guideline For Cent Comp Surge ControlDocument75 pagesApplication Guideline For Cent Comp Surge ControlPedro MunizNo ratings yet

- Compressor Operation PDF DocumentDocument28 pagesCompressor Operation PDF DocumentMarian RusuNo ratings yet

- Condition Monitoring of Wind Turbines: Challenges and OpportunitiesDocument12 pagesCondition Monitoring of Wind Turbines: Challenges and OpportunitiesJasonNo ratings yet

- Installation and Operation of Densitometers 2205Document4 pagesInstallation and Operation of Densitometers 2205CRT ServicesNo ratings yet

- Representation of Type 4 Wind Turbine Generator For Steady State Short Circuit Calculations-Wouleye Kamara-UNIVERSITÉ de MONTRÉAL (2013) - TESISDocument89 pagesRepresentation of Type 4 Wind Turbine Generator For Steady State Short Circuit Calculations-Wouleye Kamara-UNIVERSITÉ de MONTRÉAL (2013) - TESISEdgardoKatReyesNo ratings yet

- Wind Turbine Simulator Fault Diagnosis Via Fuzzy Modelling and Identification TechniquesDocument8 pagesWind Turbine Simulator Fault Diagnosis Via Fuzzy Modelling and Identification TechniquesAli AlmisbahNo ratings yet

- GMRC Surge GuidelineDocument75 pagesGMRC Surge Guidelinesbas84No ratings yet

- Bearing Condition Monitoring Using Vibration SignatureDocument7 pagesBearing Condition Monitoring Using Vibration SignaturemarnalaNo ratings yet

- Experimental Investigation of Dynamics Effects On Multiple-Injection Common Rail System PerformanceDocument13 pagesExperimental Investigation of Dynamics Effects On Multiple-Injection Common Rail System PerformancemoaedNo ratings yet

- ConclusionDocument6 pagesConclusionMaria CafeNo ratings yet

- A Review of Condition Monitoring of Motors-May 2017Document45 pagesA Review of Condition Monitoring of Motors-May 2017irfanNo ratings yet

- Clamp-Force Estimation For A Brake-by-Wire System: A Sensor-Fusion ApproachDocument10 pagesClamp-Force Estimation For A Brake-by-Wire System: A Sensor-Fusion ApproachHsan HaddarNo ratings yet

- Ijaer Cmss CNCDocument11 pagesIjaer Cmss CNCDuy TrầnNo ratings yet

- Research Paper 1Document6 pagesResearch Paper 1vishnubaghel40No ratings yet

- Troubleshooting Rotating MachineryDocument5 pagesTroubleshooting Rotating Machineryroberdani12No ratings yet

- Small Wind Turbine Technology: April 2011Document31 pagesSmall Wind Turbine Technology: April 2011NEDALNo ratings yet

- Digital Control of A Three Phase Induction MotorDocument60 pagesDigital Control of A Three Phase Induction MotorKeshavamurthy MurthyNo ratings yet

- SELEKhrhhCIJA HIDROTURBINADocument107 pagesSELEKhrhhCIJA HIDROTURBINADalibor-Jelena VlaškiNo ratings yet

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- Practical Control of Electric Machines: Model-Based Design and SimulationFrom EverandPractical Control of Electric Machines: Model-Based Design and SimulationNo ratings yet

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowRating: 2 out of 5 stars2/5 (1)

- Advances in Motion Sensing and Control for Robotic Applications: Selected Papers from the Symposium on Mechatronics, Robotics, and Control (SMRC’18)- CSME International Congress 2018, May 27-30, 2018 Toronto, CanadaFrom EverandAdvances in Motion Sensing and Control for Robotic Applications: Selected Papers from the Symposium on Mechatronics, Robotics, and Control (SMRC’18)- CSME International Congress 2018, May 27-30, 2018 Toronto, CanadaFarrokh Janabi-SharifiNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- NVI Product Catalog 4 1Document40 pagesNVI Product Catalog 4 1Ayele Bizuneh100% (4)

- Using Prepackaged Sterile KitDocument14 pagesUsing Prepackaged Sterile KitHannaNo ratings yet

- Infusion Set Terumo Paed PDFDocument16 pagesInfusion Set Terumo Paed PDFnuryani agustinaNo ratings yet

- PPMP Medical Supplies 2020Document16 pagesPPMP Medical Supplies 2020Jan Oneille Y. VallesNo ratings yet

- McFarlane Shimmy Dampner ManualDocument6 pagesMcFarlane Shimmy Dampner ManualmidunNo ratings yet

- GY Syringe Systems BrochureDocument20 pagesGY Syringe Systems Brochurepushpanjali singhNo ratings yet

- Lecture 3 PharmaceuticsDocument31 pagesLecture 3 PharmaceuticsKC PalattaoNo ratings yet

- Chapter 013Document36 pagesChapter 013Aria LeNo ratings yet

- PDPN 1096 G - RevEDocument1 pagePDPN 1096 G - RevEhienluuduc2011_66877No ratings yet

- Acessories ThermoDocument29 pagesAcessories ThermoValquiria MoraesNo ratings yet

- VycrossDocument33 pagesVycrossJonathan David Contreras InfanteNo ratings yet

- As SuppliesDocument72 pagesAs SuppliesKim HiềnNo ratings yet

- ITC IRMA TRUpoint Operation Manual enDocument170 pagesITC IRMA TRUpoint Operation Manual enAdolfo Kubber ZambranaNo ratings yet

- Pharmacology Checklist - Rationale 02Document30 pagesPharmacology Checklist - Rationale 02Tisha DeiparineNo ratings yet

- Drug Calculation ReviewDocument124 pagesDrug Calculation Reviewhgfree41392100% (1)

- Bag Technique Lecture NotesDocument4 pagesBag Technique Lecture NotesSarahLabadanNo ratings yet

- Astm D5453-93Document6 pagesAstm D5453-93nardeneNo ratings yet

- Medication Administration (Parenteral)Document12 pagesMedication Administration (Parenteral)Akio OzaragaNo ratings yet

- Catalogue Mano Medical en Malte PDFDocument8 pagesCatalogue Mano Medical en Malte PDFE RossouwNo ratings yet

- SOP For Integrity Test of Syringe FilterDocument3 pagesSOP For Integrity Test of Syringe Filter王仁宏No ratings yet

- Aptitud Capitulo 71Document7 pagesAptitud Capitulo 71JuanNo ratings yet

- Ibuprofen Suspension PDFDocument3 pagesIbuprofen Suspension PDFazida59No ratings yet

- Sphera Duo Data SheetDocument2 pagesSphera Duo Data SheetHohoNo ratings yet

- Sharp Safety 3Document8 pagesSharp Safety 3psp710No ratings yet

- Procedure Checklist Chapter 26: Administering Feedings Through Gastric and Enteric TubesDocument3 pagesProcedure Checklist Chapter 26: Administering Feedings Through Gastric and Enteric TubesjthsNo ratings yet

Emed Jour 1986 015 048 02

Emed Jour 1986 015 048 02

Uploaded by

vishal bhatOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Emed Jour 1986 015 048 02

Emed Jour 1986 015 048 02

Uploaded by

vishal bhatCopyright:

Available Formats

Syringe pump design

PAUL WADHAM Vickers Medical, Basingstoke

With the evolution of special care baby, intensive care, and coronary care units over the last decade, there has

developed a need for greater accuracy in the control of increasingly potent infusions.

The design of bedside syringe pump infusers that administer the contents of a syringe to a patient at a constant

and predetermined rate will b e considered in terms of their ergonomics, control, and safety.

Syringe pump design has evolved over the past few years from simple mechanised forms of syringe driving to

very sophisticated and precisely-controlled drive systems capable of high volumetric accuracy over a wide range

of clinical conditions and sustained for long time periods. This has led to the development of new and critical

forms of drug therapy.

In addition, important progress has been made in the safety and reliability aspects of syringe pump design.

Modern syringe pumps are expected to have fail-safe electronics to protect the patient in the event of a fault

occurring. With the advent of modern microprocessor techniques, future syringe pumps can be expected to

incorporate further sophisticated operational.and safety enhancements, whilst remaining simple to operate.

Typical safety enhancements could include the incorporation of a variable pressure sensor to protect against

unwanted pressure build up in the IV line, the use of absolute linear encoding techniques for control and

monitoring of the infusion, and the increasing use of self-tests and diagnostics to aid the user.

Operational enhancements could include the ability to support pharmacokinetic techniques, as well as closed

loop drug therapy and remote computer control.

Whilst this suggests that infusion therapy might become too sophisticated for day to day use, comprehensive

interactive instructions and diagnostic aids would contribute greatly to ease of use.

Good user training will be of increasing importance to maximize the benefits of the advances in syringe pump

design.

ERGONOMICS THE EVOLUTION OF THE SYRINGE PUMP DRIVE MECHANISM

The phrase ‘good ergonomics’ although overused, is one One of the first claimed designs for a syringe pump was

which is particularly relevant to syringe pump design. the ‘rubber band’ driven pump. This worked on the

Early syringe pumps tended towards engineering exer- simple ‘slingshot’ principle and was evidently unsatis-

cises in the area of fluid delivery, often with the minimum factory for many reasons, not the least of which was the

of patient safety features and controls. As the designs arbitrary rate at which the infusion occurred.

improved, so the products were to be found in the The next generation of syringe pump designs was

broader context of patient care, from general ward use to based around the clockwork mechanism. This type of

critical care environments. pump exhibits the fundamental features of all subsequent

Syringe pumps have developed to the stage where they designs, a drive mechanism which can be divided into

are expected to be used in an increasingly wide range of two parts, the first being the source of motive power for

clinical conditions by an ever broadening staff spectrum. the infusion. Initially it was a simple rubber band and

To achieve this the pump must be simple to operate, later a clock spring. The second feature is a transmission,

ideally even for someone without specific training. The designed to convert the power source into axial move-

controls should be clear and easy to interpret. Setting the ment of the syringe plunger. This combination needs to

rate, for example, should be done in ml/hr and not left to be consistent over a wide range of parameters, most of

the user to calculate in terms of axial travel. which are not pump related: syringe size, friction, fluid

All the pump controls should, ideally, be in view viscosity, and infusion pressure.

during normal use to provide as much information as Whilst clockwork or spring driven pumps were

possible about the infusion. capable of providing sufficient motive power, early

Such a user-friendly philosophy, together with inher- designs were limited in their ability to control accurately

ent simplicity, are important facets for a safe product. A n over the increasingly wide range of clinical conditions.

example of this is the replacement of mechanical rate Designers quickly moved on to exploit small but power-

switches with Light Emitting Diode (LED) or Liquid ful electric motors of which there are two types: the

Crystal Displays (LCDs) linked to a membrane switch stepper motor and the d.c. motor. Modern versions when

panel providing better-disseminated information. This coupled to a reduction gearbox are more than capable of

has been made possible by advances in electronic design providing sufficient motive power whilst affording

coupled to cheaply-available microprocessor power. precise control.

The layout of pumps has also improved. Early designs In the case of the stepper, this control is achieved

were more compromised to meet the packaging needs of through the relationship between one pulse and the angle

the transmission and electronics. With the advent of the motor subtends equating (via the transmission) to a

widely available moulding techniques, and suitable specific movement of the syringe plunger. A d.c. motor,

structural materials, designers may now present the on the other hand, requires some system of encoders to

package in an optimal fashion. ‘Surface mount’ printed allow this relationship between motor revolutions (or

circuit board technology and smaller more powerful fractions of) and plunger movement.

electric motors have combined to allow designs laid out The layout of the drive system is often dictated as

in such a way that all controls and information are much by the constraints of packaging as those of per-

immediately apparent to the user. formance. Two different transmissions have been most

( MEP Ltd 1986 VoI 15. No 4 004&2039/86/00104171 $02.00 171

Downloaded from eim.sagepub.com by guest on July 24, 2015

t

I I

I I

!

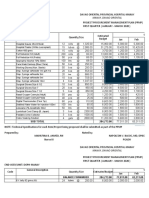

Fig. 3. Corirrol loyicjiw yerirrul purpose syririge prtrnp coritairi-

ultrrnis urid motor driw moniroririg

i r i g i~ornprekeri.sir~c

Early designs utilised conventional circuit boards and

frequently used, the rack and pinion (Fig. l(a))and the discrete component technology to achieve this. As the

leadscrew (Fig. l(b)). The rack and pinion allows the circuit logic became more comprehensive (Fig. 3) so the

motor to be perpendicular to the syringe axis, whilst with layout tended to require complex boards which were

the leadscrew layout the motor is arranged parallel to the large, difficult to package, and expensive t o produce.

syringe axis. Whichever is used. it must be inherently With the advent of the microprocessor, a more sophis-

linear to provide sufficient accuracy for long term infu- ticated network of controls could be built into the design

sions. A method of disengaging the drive must also be on a more simple layout, with the complexity shifting

included to allow syringes to be loaded and unloaded, towards the software. Here risk is associated with the

whilst the drive system must offer the user a wide range way in which software is written, and there is always an

of precise flow rates (typically 0.1-99.9 ml/hr in 0.1 ml/hr oblique chance that the microprocessor may itself be

increments) to meet the increasingly sophisticated drug fa 11It y .

regimes and clinical situations. This then leads to the optimum configuration o f a twin

microprocessor system. in a master and slave configu-

CONTROL TECHNIQUES ration. This, as its name suggests. provides a simple

The control technique for all electrically driven syringe circuit with enormous processing power with one con-

pumps is exceedingly similar. For a given syringe trolling the motor and the second checking for faults.

mounted on the drive system, i t will require a specific Microprocessor faults are avoided by each sending the

number of motor revolutions to provide the correct rate other test routines. To avoid the unlikely event of both

in millilitres per hour. I n the execution of this trans- microprocessors hanging up, a hardware watchdog has

lation, there is only one simple calculation. to be regularly reset, or i t shuts down the motor.

Once the infusion is underway, this converts into a In terms of packaging advances, there are several new

simple closed loop system of measurement, comparison, technologies which can now be utilised to reduce the

and correction. Any error in this continuous process will impact that the control board has on the pump design.

lead to oscillation, requiring the addition of a n integral The advent of surface mount, where components are

term to d a m p this out. smaller due to their interconnection by pad rather than

Whilst motor control is the primary function of the leadwire, has dramatically increased the packing density

pump electronics, patient safety parameters such as of board layout. Often a reduction of four times in area

pumping pressure and end of travel are also monitored can be achieved. Beyond this lies hybrid technology,

(Fig. 2). where components are replaced almost entirely by thick

172 Engineering in Medicine I MEP Ltd 1986

Downloaded from eim.sagepub.com by guest on July 24, 2015

film ‘inks’ of material. This yields greater area savings, All these interrupt the normal course of the infusion

but its financial justification requires high volume pro- and could be potentially harmful. Modern pump designs

duction. Finally, ‘custom chip’ offers the ability to place a feature pressure monitoring methods to detect the high

major part of the circuit ‘into silicon’ offering enormous pumping pressure in the syringe and line under such

space savings but at very high initial cost, coupled to a conditions.

circuit design which must remain fixed. Finally the pump should warn if the power source is

removed or fails. This is particularly relevant to modern

SAFETY AND RELIABILITY a.c. powered designs which feature automatic battery

Syringe pump design has been considered above in terms back up. Here it is imperative that, in the case of a.c.

of ergonomics, the drive system and control techniques, power failure, the user is warned that the pump is contin-

but none of this is useful unless the pump is reliable and uing to infuse on battery power.

safe.

These two facets of the design are closely linked in

FUTURE ENHANCEMENTS

terms of component failure which may not only cause the

pump to stop working, but could cause undesirable The benefits of the technological advances outlined

behaviour. Here, experience guides the designer to avoid above are likely to manifest themselves in terms of oper-

components which are known to be unreliable, but the ational and safety enhancements.

tendency to build fault-tolerant circuits must be meted in To achieve a high degree of volumetric accuracy users

terms of the software being able to detect and act upon have generally been limited to an infusion pump which

such faults. will accept only one manufacturer’s type and size of

Early syringe pumps featured minimal safety systems syringe, a factor which is limiting both in terms of

to protect the patient in the case of a malfunction. As medical and financial constraints. New designs will be

devices have been used in increasingly sophisticated capable of providing this whilst accepting a wide range of

environments, so better and more comprehensive safety syringe makes and sizes with perhaps automatic recogni-

systems have been developed. tion. Similarly, a preset occlusion alarm level is almost

The pump should be ‘tamper-proof’ to avoid acciden- an ‘industry standard’. Again the next generation should

tal interruption or corruption of the patient’s treatment. have the facility to set the alarm level to suit the clinical

This suggests that the drive system should not be capable situation; a feature particularly relevant in the field of

of being disengaged during infusion without alarm. I t intensive and neonatal care where long term site patency

should also not be possible to change the rate during and closer control of pumping pressures are sought.

infusion. All these advantages could be lost as unwanted com-

A n obvious point is that the pump should not be plications unless the ergonomics of new designs do not

capable of being run with a zero rate selected. The keep pace. Multiple character alphanumeric LCDs are

control circuitry should also self monitor to check already in use to provide prompts for assistance in

against internal malfunctions. Some early designs could, setting the infusion up. This usage will expand to providc

under certain conditions, be induced to operate without full assistance, both in setting up, identification of alarm

proper control of the infusion rate. conditions, and in diagnostic help for fault finding.

Other safety systems should minimize the time spent Clinical regimens are advancing in line with infusion

attendant at the pump. An example of this is ‘end of pump technology. Current practice revolves around

infusion’, where early designs had an alarm to warn the constant-rate open-loop infusions (Fig. 4), a concept

user only that the infusion had ended. New designs which fails to account for varying efficacies of drugs and,

feature a ‘keep vein open’ rate where, a few millilitres of course, differing patient conditions. Pharmacokinetics

from the end, the pump alarms and automatically goes are developing into non-constant rate infusions coupled

onto a low rate. This both provides time for the next dose to closed-loop control (Fig. 5). Current technology will

preparation and keeps the site patent. limit new designs to interfaceable solutions, where a

Probably the most important system in a pump design syringe pump is linked to a computer and monitoring

is its capability of detecting the occlusion at the IV site, equipment to close this loop. Inevitably miniaturisation

caused by say, positional IV where the cannula becomes will allow an infusion pump to offer all this within the

misplaced and tissue infiltration occurs, a kinked or confines of one single piece of equipment.

twisted extension line, or clotting. Safety enhancements are likely to be less immediately

apparent to the user. Control circuitry is already

designed to catch single fault failure at component level,

h-

!

‘1

I

!

t

c---

F i g . 4 . Open-loop systemfor programmed injiisions Fiy. 5 . Integrated closed-loop injiision system

( MEP Ltd 1986 Vol 15, No 4 173

Downloaded from eim.sagepub.com by guest on July 24, 2015

and, as previously discussed, the advent of cheap micro- Future work is likely to concentrate in the areas

processor power has produced powerful and capable associated with pump safety and control circuitry. Par-

control circuits. The associated software, whilst signifi- ticular emphasis will be placed on the rate and syringe

cantly more important, is already heavily scrutinized for travel monitoring, coupled to more sophisticated alarm

most internationally recognized standards approvals. protection.

174 Engineering in Medicine ( MEP Ltd 1986

Downloaded from eim.sagepub.com by guest on July 24, 2015

You might also like

- Horiba ABX Micros ES60 ESV60 Service Manual PDFDocument214 pagesHoriba ABX Micros ES60 ESV60 Service Manual PDFjorgeluis100% (4)

- Beckman Coulter Chemistry Analyzer: Ise User GuideDocument84 pagesBeckman Coulter Chemistry Analyzer: Ise User GuidePhong Do100% (1)

- OGP Standards For Local Medical SupportDocument36 pagesOGP Standards For Local Medical Supportihwan100% (1)

- Active Projects 2001: 1. Precise Speed HoldingDocument10 pagesActive Projects 2001: 1. Precise Speed HoldingDipmoi PathakNo ratings yet

- DCIM-B01.840.10.01.02 Immulite Com Lis PDFDocument311 pagesDCIM-B01.840.10.01.02 Immulite Com Lis PDFОлександр100% (1)

- Fundamentals of Nursing1Document51 pagesFundamentals of Nursing1Charles Gerard B. BeluanNo ratings yet

- A New Type of Motor - Pneumatic Step MotorDocument9 pagesA New Type of Motor - Pneumatic Step MotorAbbasali AfzaliNo ratings yet

- Statistic-Based Method To Monitor Belt Transmission Looseness Through Motor Phase CurrentsDocument9 pagesStatistic-Based Method To Monitor Belt Transmission Looseness Through Motor Phase CurrentsJOEL EZEQUIEL PACHECO MENANo ratings yet

- Surface Micromachined Electrostatically Actuated Micro Peristaltic PumpDocument7 pagesSurface Micromachined Electrostatically Actuated Micro Peristaltic PumpAman SainiNo ratings yet

- PLC and Hmi For Conveyor Monitoring and Fault DetectionDocument5 pagesPLC and Hmi For Conveyor Monitoring and Fault DetectionIJAR JOURNALNo ratings yet

- Model Based System Identification For Hydraulic Deep Drawing PressesDocument11 pagesModel Based System Identification For Hydraulic Deep Drawing PressesjordanNo ratings yet

- Design and CFD Analysis of Centrifugal Pump IJERTCONV9IS10007Document5 pagesDesign and CFD Analysis of Centrifugal Pump IJERTCONV9IS10007muhammad faisalNo ratings yet

- Aviation Week 1961-03-13Document159 pagesAviation Week 1961-03-13tordo22100% (1)

- Condition-Based Maintenance: Model vs. Statistics A Performance ComparisonDocument7 pagesCondition-Based Maintenance: Model vs. Statistics A Performance ComparisonLourds Egúsquiza EscuderoNo ratings yet

- Design and Development of A Low-Cost Exure-Based Hand-Held Mechanism For MicromanipulationDocument7 pagesDesign and Development of A Low-Cost Exure-Based Hand-Held Mechanism For MicromanipulationDamián Cortina LópezNo ratings yet

- Digital Speed Control of DC Motor For Industrial Automation Using Pulse Width Modulation TechniqueDocument6 pagesDigital Speed Control of DC Motor For Industrial Automation Using Pulse Width Modulation TechniquevendiNo ratings yet

- Sensorless Parameters Estimation of VFD Based CascDocument14 pagesSensorless Parameters Estimation of VFD Based CascAnonymous 1AAjd0No ratings yet

- Researchpaper 1-ElectronicsyringepumpDocument5 pagesResearchpaper 1-ElectronicsyringepumpSidra latifNo ratings yet

- Sciencedirect: Modelling, Simulation and Optimisation of A Piezoelectric Energy HarvesterDocument6 pagesSciencedirect: Modelling, Simulation and Optimisation of A Piezoelectric Energy HarvesterCh AbdullahNo ratings yet

- UIUC 451 Interim PaperDocument13 pagesUIUC 451 Interim Paperanon_996725493No ratings yet

- Design of Fuzzi Pid TrackingDocument12 pagesDesign of Fuzzi Pid Trackingmuhammad shahbazNo ratings yet

- Sensors: Diagnostic of Operation Conditions and Sensor Faults Using Machine Learning in Sucker-Rod Pumping WellsDocument29 pagesSensors: Diagnostic of Operation Conditions and Sensor Faults Using Machine Learning in Sucker-Rod Pumping WellsRodrigo DacolNo ratings yet

- New Sensor Technology For Measuring Torsional Shaft Vibration in Turbine GeneratorsDocument8 pagesNew Sensor Technology For Measuring Torsional Shaft Vibration in Turbine GeneratorssebastianNo ratings yet

- Design of Embedded Microcontroller For Controlling and Monitoring Blood PumpDocument8 pagesDesign of Embedded Microcontroller For Controlling and Monitoring Blood PumpGEORGE MYLONASNo ratings yet

- Dynamic Modeling and Simulation of Control System For Pneumatic Servo Valve Using Piezoelectric ActuatorDocument10 pagesDynamic Modeling and Simulation of Control System For Pneumatic Servo Valve Using Piezoelectric Actuatorkyaw san ooNo ratings yet

- Automated Drilling Algorithms ImplementationDocument11 pagesAutomated Drilling Algorithms ImplementationnanlingjigongNo ratings yet

- Machine ToolspindleunitsDocument22 pagesMachine Toolspindleunitsdevmecz2696No ratings yet

- Design of Fuzzi-Pid Tracking Controller For IndustDocument8 pagesDesign of Fuzzi-Pid Tracking Controller For IndustBernadetteNo ratings yet

- SPE 35236 Low Cost Solutions For Well Interventions Through Advanced Slickline ServicesDocument16 pagesSPE 35236 Low Cost Solutions For Well Interventions Through Advanced Slickline ServicesDen YogaNo ratings yet

- Celluveyor 2Document7 pagesCelluveyor 2Paúl TituañaNo ratings yet

- Bi-Directional Control Systems For Microfluids: Cpjen@mail - Ncku.edu - TW Yuclin@mail - Ncku.edu - TWDocument4 pagesBi-Directional Control Systems For Microfluids: Cpjen@mail - Ncku.edu - TW Yuclin@mail - Ncku.edu - TWdenghueiNo ratings yet

- Electric Propulsion System Characterization Through ExperimentsDocument9 pagesElectric Propulsion System Characterization Through Experiments呂文祺No ratings yet

- Eccentric Cam Operated Semi Automatic Gear Shifting System For Two WheelerDocument8 pagesEccentric Cam Operated Semi Automatic Gear Shifting System For Two Wheelerkifle abelNo ratings yet

- Modeling of Heavy Duty Electrohydraulic ManipulatorDocument10 pagesModeling of Heavy Duty Electrohydraulic Manipulatoraenas984363No ratings yet

- Dovermotion AprDocument7 pagesDovermotion Aprfog900No ratings yet

- Design and Assembly of Prototype of Automatic Rail Track Cleaning MachineDocument3 pagesDesign and Assembly of Prototype of Automatic Rail Track Cleaning MachineGirishZopeNo ratings yet

- Modelling and Operational Testing of Pulse-Width Modulation at Injection Time For A Spark-Ignition EngineDocument7 pagesModelling and Operational Testing of Pulse-Width Modulation at Injection Time For A Spark-Ignition EngineAdal VeraNo ratings yet

- Note Law ClassDocument17 pagesNote Law ClassAgung WiranataNo ratings yet

- Application Guideline For Cent Comp Surge ControlDocument75 pagesApplication Guideline For Cent Comp Surge ControlPedro MunizNo ratings yet

- Compressor Operation PDF DocumentDocument28 pagesCompressor Operation PDF DocumentMarian RusuNo ratings yet

- Condition Monitoring of Wind Turbines: Challenges and OpportunitiesDocument12 pagesCondition Monitoring of Wind Turbines: Challenges and OpportunitiesJasonNo ratings yet

- Installation and Operation of Densitometers 2205Document4 pagesInstallation and Operation of Densitometers 2205CRT ServicesNo ratings yet

- Representation of Type 4 Wind Turbine Generator For Steady State Short Circuit Calculations-Wouleye Kamara-UNIVERSITÉ de MONTRÉAL (2013) - TESISDocument89 pagesRepresentation of Type 4 Wind Turbine Generator For Steady State Short Circuit Calculations-Wouleye Kamara-UNIVERSITÉ de MONTRÉAL (2013) - TESISEdgardoKatReyesNo ratings yet

- Wind Turbine Simulator Fault Diagnosis Via Fuzzy Modelling and Identification TechniquesDocument8 pagesWind Turbine Simulator Fault Diagnosis Via Fuzzy Modelling and Identification TechniquesAli AlmisbahNo ratings yet

- GMRC Surge GuidelineDocument75 pagesGMRC Surge Guidelinesbas84No ratings yet

- Bearing Condition Monitoring Using Vibration SignatureDocument7 pagesBearing Condition Monitoring Using Vibration SignaturemarnalaNo ratings yet

- Experimental Investigation of Dynamics Effects On Multiple-Injection Common Rail System PerformanceDocument13 pagesExperimental Investigation of Dynamics Effects On Multiple-Injection Common Rail System PerformancemoaedNo ratings yet

- ConclusionDocument6 pagesConclusionMaria CafeNo ratings yet

- A Review of Condition Monitoring of Motors-May 2017Document45 pagesA Review of Condition Monitoring of Motors-May 2017irfanNo ratings yet

- Clamp-Force Estimation For A Brake-by-Wire System: A Sensor-Fusion ApproachDocument10 pagesClamp-Force Estimation For A Brake-by-Wire System: A Sensor-Fusion ApproachHsan HaddarNo ratings yet

- Ijaer Cmss CNCDocument11 pagesIjaer Cmss CNCDuy TrầnNo ratings yet

- Research Paper 1Document6 pagesResearch Paper 1vishnubaghel40No ratings yet

- Troubleshooting Rotating MachineryDocument5 pagesTroubleshooting Rotating Machineryroberdani12No ratings yet

- Small Wind Turbine Technology: April 2011Document31 pagesSmall Wind Turbine Technology: April 2011NEDALNo ratings yet

- Digital Control of A Three Phase Induction MotorDocument60 pagesDigital Control of A Three Phase Induction MotorKeshavamurthy MurthyNo ratings yet

- SELEKhrhhCIJA HIDROTURBINADocument107 pagesSELEKhrhhCIJA HIDROTURBINADalibor-Jelena VlaškiNo ratings yet

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- Practical Control of Electric Machines: Model-Based Design and SimulationFrom EverandPractical Control of Electric Machines: Model-Based Design and SimulationNo ratings yet

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowRating: 2 out of 5 stars2/5 (1)

- Advances in Motion Sensing and Control for Robotic Applications: Selected Papers from the Symposium on Mechatronics, Robotics, and Control (SMRC’18)- CSME International Congress 2018, May 27-30, 2018 Toronto, CanadaFrom EverandAdvances in Motion Sensing and Control for Robotic Applications: Selected Papers from the Symposium on Mechatronics, Robotics, and Control (SMRC’18)- CSME International Congress 2018, May 27-30, 2018 Toronto, CanadaFarrokh Janabi-SharifiNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- NVI Product Catalog 4 1Document40 pagesNVI Product Catalog 4 1Ayele Bizuneh100% (4)

- Using Prepackaged Sterile KitDocument14 pagesUsing Prepackaged Sterile KitHannaNo ratings yet

- Infusion Set Terumo Paed PDFDocument16 pagesInfusion Set Terumo Paed PDFnuryani agustinaNo ratings yet

- PPMP Medical Supplies 2020Document16 pagesPPMP Medical Supplies 2020Jan Oneille Y. VallesNo ratings yet

- McFarlane Shimmy Dampner ManualDocument6 pagesMcFarlane Shimmy Dampner ManualmidunNo ratings yet

- GY Syringe Systems BrochureDocument20 pagesGY Syringe Systems Brochurepushpanjali singhNo ratings yet

- Lecture 3 PharmaceuticsDocument31 pagesLecture 3 PharmaceuticsKC PalattaoNo ratings yet

- Chapter 013Document36 pagesChapter 013Aria LeNo ratings yet

- PDPN 1096 G - RevEDocument1 pagePDPN 1096 G - RevEhienluuduc2011_66877No ratings yet

- Acessories ThermoDocument29 pagesAcessories ThermoValquiria MoraesNo ratings yet

- VycrossDocument33 pagesVycrossJonathan David Contreras InfanteNo ratings yet

- As SuppliesDocument72 pagesAs SuppliesKim HiềnNo ratings yet

- ITC IRMA TRUpoint Operation Manual enDocument170 pagesITC IRMA TRUpoint Operation Manual enAdolfo Kubber ZambranaNo ratings yet

- Pharmacology Checklist - Rationale 02Document30 pagesPharmacology Checklist - Rationale 02Tisha DeiparineNo ratings yet

- Drug Calculation ReviewDocument124 pagesDrug Calculation Reviewhgfree41392100% (1)

- Bag Technique Lecture NotesDocument4 pagesBag Technique Lecture NotesSarahLabadanNo ratings yet

- Astm D5453-93Document6 pagesAstm D5453-93nardeneNo ratings yet

- Medication Administration (Parenteral)Document12 pagesMedication Administration (Parenteral)Akio OzaragaNo ratings yet

- Catalogue Mano Medical en Malte PDFDocument8 pagesCatalogue Mano Medical en Malte PDFE RossouwNo ratings yet

- SOP For Integrity Test of Syringe FilterDocument3 pagesSOP For Integrity Test of Syringe Filter王仁宏No ratings yet

- Aptitud Capitulo 71Document7 pagesAptitud Capitulo 71JuanNo ratings yet

- Ibuprofen Suspension PDFDocument3 pagesIbuprofen Suspension PDFazida59No ratings yet

- Sphera Duo Data SheetDocument2 pagesSphera Duo Data SheetHohoNo ratings yet

- Sharp Safety 3Document8 pagesSharp Safety 3psp710No ratings yet

- Procedure Checklist Chapter 26: Administering Feedings Through Gastric and Enteric TubesDocument3 pagesProcedure Checklist Chapter 26: Administering Feedings Through Gastric and Enteric TubesjthsNo ratings yet