Professional Documents

Culture Documents

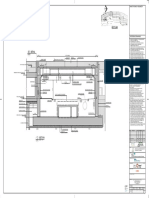

C11' Junction Box Structural Detail

C11' Junction Box Structural Detail

Uploaded by

michael mwaranguCopyright:

Available Formats

You might also like

- Rationale Graphics Redrawn For Clarity, Correct Typo in Table 1, Showing Correct Thread Configuration For Sizes 09 and 18Document2 pagesRationale Graphics Redrawn For Clarity, Correct Typo in Table 1, Showing Correct Thread Configuration For Sizes 09 and 18Larry Hare100% (1)

- 980F Loader (5XJ588 Up)Document2 pages980F Loader (5XJ588 Up)NovakurniawanNo ratings yet

- Sakura Chi IV 19Document72 pagesSakura Chi IV 19Helmi100% (1)

- GAs - BOUNDARY WALL-S77 BOUNDARY WALLSDocument1 pageGAs - BOUNDARY WALL-S77 BOUNDARY WALLSSamitha SoysaNo ratings yet

- Approved Drawing of Boundary WallDocument1 pageApproved Drawing of Boundary WallAnup Singh RajputNo ratings yet

- COM-A-51-ZZ-03-b - STAIRCASE-3 SECTIONAL DETAILSDocument1 pageCOM-A-51-ZZ-03-b - STAIRCASE-3 SECTIONAL DETAILSAkshay SharmaNo ratings yet

- Column Reinforcement Schedule: Good For ConstructionDocument1 pageColumn Reinforcement Schedule: Good For ConstructionZaid HussainNo ratings yet

- t76-R-pp-476562-001 - Rev B Utility Ome Building Elevations & SectionsDocument1 paget76-R-pp-476562-001 - Rev B Utility Ome Building Elevations & SectionsTayyab AchakzaiNo ratings yet

- RaftDocument1 pageRafttmc.roshen.2024No ratings yet

- GAS-TECH Engineering Services LTDDocument1 pageGAS-TECH Engineering Services LTDMustafaNo ratings yet

- 04-R.C.C DETAIL IN R.I.B-ModelDocument1 page04-R.C.C DETAIL IN R.I.B-ModelManvendra Singh RaghuwanshiNo ratings yet

- (Steps Going To Deck Roof) : LegendDocument1 page(Steps Going To Deck Roof) : LegendLowie Torres TonioNo ratings yet

- DHQC Cecb MB Ti Ar DW ML 02 80541Document1 pageDHQC Cecb MB Ti Ar DW ML 02 80541Kumudu PereraNo ratings yet

- D-401 To D-437 Br1 Abutment A1-A2Document37 pagesD-401 To D-437 Br1 Abutment A1-A2Christian MendozaNo ratings yet

- MARK UP Column L1 TO L2Document1 pageMARK UP Column L1 TO L2Emon SahNo ratings yet

- 2.symbol and AbbreviationsDocument1 page2.symbol and Abbreviationshambi1986No ratings yet

- PlumbingDocument14 pagesPlumbingRaizen TanNo ratings yet

- KAAR COW PW IC NTU FZS DWG STR 24637 Rev.01 PDFDocument1 pageKAAR COW PW IC NTU FZS DWG STR 24637 Rev.01 PDFSatyanarayana MukkuNo ratings yet

- AS15001CDocument3 pagesAS15001Cjeniful jenifulNo ratings yet

- 1162-PLOT A-LAYOUT & SCHEDULE OF FIRST FLOORDocument1 page1162-PLOT A-LAYOUT & SCHEDULE OF FIRST FLOORgokulan.pNo ratings yet

- Hac DrawingDocument13 pagesHac Drawingabdulkidwai2009No ratings yet

- 2015 05891 Nmat-Typical Window Bay Details-1584088Document1 page2015 05891 Nmat-Typical Window Bay Details-1584088nextomegagenNo ratings yet

- Ca 477021 002Document1 pageCa 477021 002Sehna SerajNo ratings yet

- CA 352505 001 Rev.00Document1 pageCA 352505 001 Rev.00Muhammad RizwanNo ratings yet

- A.Typical Roadway Section: Pavement Design ParametersDocument1 pageA.Typical Roadway Section: Pavement Design ParametersrickNo ratings yet

- ZX330 Circuit (Electrical and Hydraulic)Document6 pagesZX330 Circuit (Electrical and Hydraulic)Syaiful BahriNo ratings yet

- S2 Structural NotesDocument1 pageS2 Structural NotesRaynz PatronNo ratings yet

- Sae0004-001 (B) - Safe-Away - 2009 Komatsu Power Pack - Electrical SchematicDocument2 pagesSae0004-001 (B) - Safe-Away - 2009 Komatsu Power Pack - Electrical SchematicWagner R.Gomes RodriguesNo ratings yet

- Typ. Detail of Corridor RailingDocument1 pageTyp. Detail of Corridor RailingMNo ratings yet

- 1.air Blower-Tesr - Sludge Sump STR DetailDocument1 page1.air Blower-Tesr - Sludge Sump STR DetailRohit JangidNo ratings yet

- General Construction Notes Design Criteria: Schedule of Minimum Slab Reinforcement Lintels in Block WallsDocument1 pageGeneral Construction Notes Design Criteria: Schedule of Minimum Slab Reinforcement Lintels in Block WallsMItchNo ratings yet

- SD Ec CGC ST 233.1 Rev.1Document1 pageSD Ec CGC ST 233.1 Rev.1Ahmed Salah El DinNo ratings yet

- KAAR COW PW IC NTU FZS DWG STR 24633 Rev.01 PDFDocument1 pageKAAR COW PW IC NTU FZS DWG STR 24633 Rev.01 PDFSatyanarayana MukkuNo ratings yet

- NWPE3 - 4 - 1600kg - 5500MRL - 21so - 2.5mps-General DataDocument1 pageNWPE3 - 4 - 1600kg - 5500MRL - 21so - 2.5mps-General DataBahaa MohamedNo ratings yet

- Column Reinforcement Schedule: Good For ConstructionDocument1 pageColumn Reinforcement Schedule: Good For ConstructionZaid HussainNo ratings yet

- PV490-C DrawingDocument15 pagesPV490-C Drawingsajid yaqoobNo ratings yet

- 4217 CSD C 1a 0504 r2 Details Typical Fence Sheet 01Document1 page4217 CSD C 1a 0504 r2 Details Typical Fence Sheet 01Adi PriyapurnatamaNo ratings yet

- As-Inspected Condition Drawing No. Sheet No. CRD-3G Bent 312 Column 3Document5 pagesAs-Inspected Condition Drawing No. Sheet No. CRD-3G Bent 312 Column 3kukadiya127_48673372No ratings yet

- DWC7894 11 02 - 00Document1 pageDWC7894 11 02 - 00nthekkumpuramNo ratings yet

- AS4662CDocument3 pagesAS4662Can NanNo ratings yet

- Zaxis75Ur/135Ur Electrical Circuit Diagram: Attach To Vol. No.: TT1CFE-00Document1 pageZaxis75Ur/135Ur Electrical Circuit Diagram: Attach To Vol. No.: TT1CFE-00Trung LêNo ratings yet

- BVTD LR 210617 Re01Document1 pageBVTD LR 210617 Re01Phú ĐoànNo ratings yet

- Proposed Landscape Design For Shailesh CHS, Nerul: Option-2Document2 pagesProposed Landscape Design For Shailesh CHS, Nerul: Option-2shalmi12No ratings yet

- GCU Consultants (Johor) SDN BHD: General Notes - Typical Rc. Wall Reinforcement DetailDocument1 pageGCU Consultants (Johor) SDN BHD: General Notes - Typical Rc. Wall Reinforcement DetailTOM YEENo ratings yet

- GCU Consultants (Johor) SDN BHD: General Notes and Miscellaneous Detail 3Document1 pageGCU Consultants (Johor) SDN BHD: General Notes and Miscellaneous Detail 3TOM YEENo ratings yet

- S.F Plan & Terrace Block 1Document1 pageS.F Plan & Terrace Block 1VVRAONo ratings yet

- Lay Out Hotel ConjiooDocument1 pageLay Out Hotel Conjiooanes farsaNo ratings yet

- 23-0867.1 - Roof Slab Layout - A1 (Kiloh Comments)Document1 page23-0867.1 - Roof Slab Layout - A1 (Kiloh Comments)NiemNo ratings yet

- 20024-000000u-D005 - Ufd - Ammonia Lines Rev 0Document1 page20024-000000u-D005 - Ufd - Ammonia Lines Rev 0oscar alfredoNo ratings yet

- BR - NO.775 (1X3.00m RCC BOX) 23-08-2019-ModelDocument1 pageBR - NO.775 (1X3.00m RCC BOX) 23-08-2019-Modelgrao vakapalliNo ratings yet

- Pile Cap of Abutment A1 & A2 (Takarma) - 1Document1 pagePile Cap of Abutment A1 & A2 (Takarma) - 1Nilay GandhiNo ratings yet

- 522445-AUR901-DRG-BC-5600-CIVIL TYPICAL UNDERGROUND SERVICES DETAILS SHEET 1 OF 4油罐间Document1 page522445-AUR901-DRG-BC-5600-CIVIL TYPICAL UNDERGROUND SERVICES DETAILS SHEET 1 OF 4油罐间Gibson SitumorangNo ratings yet

- 221627C C2 Drainage PlanDocument3 pages221627C C2 Drainage PlanArash GhaedizadehNo ratings yet

- A005 Stan Deck FRDocument1 pageA005 Stan Deck FRkecalli.restauranteNo ratings yet

- Typical Super T Strand LayoutDocument1 pageTypical Super T Strand LayoutAAMIRNo ratings yet

- 150-25F-2506Document1 page150-25F-2506abbasyalthofNo ratings yet

- Schedule of Member Splice Connection Notes:: F H G E D C B ADocument1 pageSchedule of Member Splice Connection Notes:: F H G E D C B ARajveer SinghNo ratings yet

- Storm Water Forcemain Profile - NishtarDocument1 pageStorm Water Forcemain Profile - NishtarZaheer AbbasNo ratings yet

- L1-2.01b - SectionDocument1 pageL1-2.01b - SectionJiahao LeeNo ratings yet

- La Hot 04 001 02Document1 pageLa Hot 04 001 02Bahaa MohamedNo ratings yet

- I - HRG42N2211 - LPG Device AssemblyDocument7 pagesI - HRG42N2211 - LPG Device AssemblyJOAO BIANCHINI100% (1)

- Instant Download Auditing A Practical Approach Canadian 3rd Edition Moroney Test Bank PDF Full ChapterDocument32 pagesInstant Download Auditing A Practical Approach Canadian 3rd Edition Moroney Test Bank PDF Full ChapterRobertCookdktg100% (9)

- Midliftl Ma enDocument2 pagesMidliftl Ma enStefano SavianNo ratings yet

- The International Style by Kenneth FramptonDocument5 pagesThe International Style by Kenneth FramptonAabidah AliNo ratings yet

- Gas LRe (GTP MP) (011119)Document10 pagesGas LRe (GTP MP) (011119)Bhalvindrakumar MaranNo ratings yet

- A05 Elevations 1 & 2Document1 pageA05 Elevations 1 & 2Daniel EvansNo ratings yet

- Ar 706Document1 pageAr 706Baby SinghNo ratings yet

- Civil Seminar List II-II & III-IIDocument6 pagesCivil Seminar List II-II & III-IIGaneshNo ratings yet

- Code of Practice For The Installation and Inspection of Fire Stopping Systems in BuildingsDocument22 pagesCode of Practice For The Installation and Inspection of Fire Stopping Systems in BuildingsNguyen Trung KienNo ratings yet

- Look Ahead Construction ScheduleDocument1 pageLook Ahead Construction ScheduleJhune AbadNo ratings yet

- Top 50 MENA Contractors - CompressedDocument27 pagesTop 50 MENA Contractors - CompressedSharfuddin TajNo ratings yet

- Working at HeightsDocument11 pagesWorking at HeightsKent Anilom100% (1)

- MOS - Cable InstallationDocument7 pagesMOS - Cable InstallationAzree Mohd NoorNo ratings yet

- Estimate ManualDocument94 pagesEstimate ManualRamilArtatesNo ratings yet

- Tensile Fabric Details 3Document1 pageTensile Fabric Details 3FRANKLYN SPENCERNo ratings yet

- Chainage Side Structure Part of Structure Grade of Concrete Date of Casting Date of TestingDocument48 pagesChainage Side Structure Part of Structure Grade of Concrete Date of Casting Date of TestingAyan DuttaNo ratings yet

- Ficha Tecnica Soportek GralDocument1 pageFicha Tecnica Soportek GralMarlene Treviño RamirezNo ratings yet

- Carpentry Install Formwork ComponentsDocument10 pagesCarpentry Install Formwork ComponentsYuriiNo ratings yet

- Specification For Aluminum DoorsDocument6 pagesSpecification For Aluminum DoorscivilaskarNo ratings yet

- Presentation On Pneumatic TMT Bar Bending MachineDocument12 pagesPresentation On Pneumatic TMT Bar Bending MachineRaja Mane100% (1)

- Dia Grid SlabDocument7 pagesDia Grid Slababhishekp9425% (4)

- General Notes: Submittal For ApprovalDocument6 pagesGeneral Notes: Submittal For ApprovalMyo AungNo ratings yet

- 09.VUP Reinf 35+535Document1 page09.VUP Reinf 35+535Praveen CyssanNo ratings yet

- EN010007-001446-6.4.17 App D1-1-Construction Method Statement (Rev 1.0) PDFDocument76 pagesEN010007-001446-6.4.17 App D1-1-Construction Method Statement (Rev 1.0) PDFHarendra RathnayakeNo ratings yet

- Pi-Typical Masonary Wall Details-5516!10!101aDocument1 pagePi-Typical Masonary Wall Details-5516!10!101akrishanNo ratings yet

- Legend: Cbsc8 Earth Pit: Pig Signaller PTDocument1 pageLegend: Cbsc8 Earth Pit: Pig Signaller PTFinanceAdmin FKSIENo ratings yet

- EIFS-Brochure A4Document32 pagesEIFS-Brochure A4Vaittianathan MahavapillaiNo ratings yet

- The Design and Construction of The New San Francisco-Oakland Bay Bridge (Sfobb) East SpanDocument14 pagesThe Design and Construction of The New San Francisco-Oakland Bay Bridge (Sfobb) East SpanLynx101No ratings yet

- Seminar ReportDocument23 pagesSeminar ReportPramod Kumar HTNo ratings yet

C11' Junction Box Structural Detail

C11' Junction Box Structural Detail

Uploaded by

michael mwaranguOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C11' Junction Box Structural Detail

C11' Junction Box Structural Detail

Uploaded by

michael mwaranguCopyright:

Available Formats

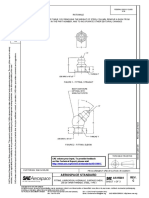

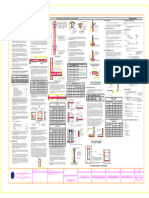

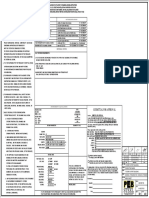

PRECAST CONCRETE NOTES REINFORCEMENT NOTES

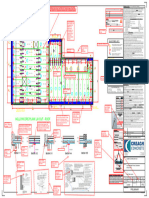

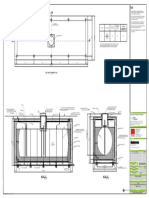

B PIT LID WITH CAST IRON SOLD TOP COVER C B C

P1 ALL PRECAST CONCRETE IS TO COMPLY WITH THE R1 REINFORCEMENT SHOWN ON THE DRAWINGS IS

S01 CLASS D, 200THICK. S01 S01 S01 CONCRETE NOTES ON THESE DRAWINGS, AS 3600 REPRESENTED DIAGRAMMATICALLY AND NOT

AND AS3850. NECESSARILY SHOWN IN TRUE PROJECTION.

150 P2 FOR LOCATIONS AND DIMENSIONS OF PRECAST R2 SPLICES IN REINFORCEMENT SHALL BE MADE

PANELS REFER TO ARCHITECTURAL DRAWINGS. ONLY IN THE POSITION SHOWN ON THE

PANELS NOTED AS SIMILAR ON THESE DRAWINGS DRAWINGS OR AS OTHERWISE APPROVED BY THE

150

ARE ONLY STRUCTURALLY SIMILAR, AND MAY ENGINEER. WHERE THE LAP LENGTH IS NOT

HAVE ARCHITECTURAL DIFFERENCES SUCH AS SHOWN IT SHALL BE SUFFICIENT TO DEVELOP

DIMENSIONS, GROOVES, FERRULES, MINOR THE FULL STRENGTH OF THE REINFORCEMENT.

PENETRATIONS, ETC. REFER TO ARCHITECTS BAR LAPS IN MILLIMETRES ARE TO BE AS SHOWN

DRAWINGS FOR DETAILS. BELOW UNLESS SHOWN OTHERWISE:-

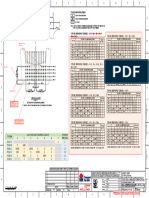

P3 FOR ARCHITECTURAL FIXINGS AND REBATES N12 500 LAP

SL81 CENTRAL. REFER TO ARCHITECTS DRAWINGS. N16 650 LAP

A A P4 ALL PANELS ARE TO BE CONSTRUCTED FROM

900

150 SL81 CENTRAL N20 950 LAP

S01 S01 NORMAL WEIGHT CONCRETE. N24 1100 LAP

P5 SHOP DRAWINGS ARE TO BE DRAWN AND N28 1400 LAP

SUBMITTED AT LEAST 14 DAYS PRIOR TO N32 1700 LAP

N12-250, 500 EACH LEG. N12-250

FABRICATION OF PANELS TO THE ENGINEER TO N36 900 FOR COMPRESSION LAP

ENABLE CHECKING AND ALTERATIONS IF MECHANICAL SPLICE FOR TENSION LAP

NECESSARY TO BE MADE PRIOR TO FABRICATION.

R3 BUNDLED BARS SHALL BE TIED TOGETHER AT 30

P6 THE PANELS HAVE BEEN DESIGNED FOR THE IN BAR DIAMETER CENTRES WITH 3 WRAPS OF TIE

150

PLACE CONDITION (I.E. : LOADS THE PRECAST WIRE.

PANELS ARE SUBJECTED TO AFTER ERECTION ON

500 SITE) AND THE CONTRACTOR MUST MAKE HIS R4 REINFORCEMENT SYMBOLS :

OWN ASSESSMENT AS TO ANY EXTRA N GRADE 500 DEFORMED REINFORCING BARS,

REINFORCEMENT, LIFTING FITTINGS, DUCTILITY CLASS N TO AS 4671.

JUNCTION BOX PLAN VIEW SECTION D STRONGBACKS, ETC., THAT MAY BE REQUIRED TO R GRADE 250 PLAIN REINFORCING BARS TO AS

SCALE 1 : 20 SCALE 1 : 20 S01 SUIT HIS PROPOSED TRANSPORTATION, 1302.

HANDLING AND ERECTION METHODS. ANY SUCH W HARD DRAWN STEEL REINFORCING WIRE,

EXTRA MATERIALS OR OTHER HANDLING GRADE 500 DUCTILITY CLASS L TO AS 4671.

1300 SQ TM HARD DRAWN STEEL TRENCH MESH, GRADE 500

REQUIREMENTS MUST BE ALLOWED FOR IN THE

TENDER. THE CONTRACTOR SHALL SUBMIT FOR DUCTILITY CLASS L TO AS 4671.

50 RL RECTANGULAR RIB MESH, GRADE 500

REVIEW BY THE ENGINEER, FULL DETAILS AND

COMPUTATIONS BY A CHARTERED ENGINEER DUCTILITY CLASS L TO AS 4671.

50 B A A SL SQUARE RIB MESH, GRADE 500

EXPERIENCED IN THIS TYPE OF WORK. THESE

900SQ CLASS D COVER, BY OTHERS. 50mm HIGH STRENGTH, NON-SHRINK GROUT MIN, S01 900SQ CLASS D COVER, BY OTHERS. S01 DUCTILITY CLASS L TO AS 4671.

S01 SHALL COVER THE HANDLING PROCEDURE OF THE

PROVIDE REBATE TO CONCRETE AS PER VARIES. REFER CIVIL DRAWINGS FOR FALL. THE NUMBER FOLLOWING THE BAR SYMBOL IS THE

UNITS THROUGHOUT ALL STAGES INCLUDING

MANUFACTURERS REQUIREMENTS. 1300 NOMINAL BAR DIAMETER IN MILLIMETERS.

STRIPPING, LIFTING, STACKING,

TRANSPORTATION AND ERECTION. CONCRETE R5 REINFORCEMENT ABBREVIATIONS :-

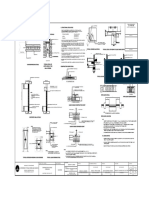

200 EF EACH FACE

C STRESSES THROUGHOUT HANDLING SHALL NOT

200

NF NEAR FACE

400 MAX

S01 CAUSE CRACKING. COMPUTATIONS AND DETAILS

SHALL INCLUDE LOCATION AND SIZE OF INSERTS FF FAR FACE

900 SL81 CENTRAL. EW EACH WAY

N12-250 SL81 CENTRAL. AND TESTS PROVING ANCHORAGE CAPACITY OF

2-N12 PERIMETER LIFTING FERRULES. T TOP

BARS P7 ALL SHOP DRAWINGS ARE TO BE APPROVED BY B or BTM BOTTOM

150

THE MAIN CONTRACTOR PRIOR TO C CENTRAL

CONSTRUCTION COMMENCING. THE LV LENGTH VARIES

CONTRACTOR SHALL BE RESPONSIBLE FOR ALL R6 WELDING OF REINFORCEMENT IS NOT PERMITTED

500 N12-250 N12-250 DIMENSIONAL CHECKS AND CO-ORDINATION OF UNLESS SHOWN ON THE DRAWINGS OR

THE CONTRACT DOCUMENTS AND SITE APPROVED BY THE ENGINEER.

SL81 CENTRAL. SL81 CENTRAL R7 ALL REINFORCING BARS SHALL BE FIRMLY

DIMENSIONS. ANY DISCREPANCY SHALL BE

BROUGHT TO THE ARCHITECT'S ATTENTION SUPPORTED ON PLASTIC CHAIRS OR CONCRETE

PRIOR TO MANUFACTURE COMMENCING. CHAIRS AT SPACING NOT GREATER THAN 60 BAR

SL81 CENTRAL SL81 CENTRAL P8 ALL FERRULES AND CAST -IN ITEM USED SHALL BE DIAMETERS. MESH SHALL BE SUPPORTED ON

2460 MAX

D D D PLASTIC OR CONCRETE CHAIRS AT 750 MAXIMUM

GALVANISED STEEL IN ACCORDANCE WITH

S01 S01 S01 AS4680, MINIMUM COATING THICKNESS 600g/m² OR CENTRES. ALL REINFORCEMENT SHALL BE

OTHERWISE APPROVED, AND FITTED WITH SECURELY TIED WITH WIRE TIES AND ALL TIE

2310 MAX

150 3880 150 150 900 150 ANCHORAGE BARS OF MINIMUM 10mm DIAMETER. ENDS SHALL BE TURNED INWARD CLEAR OF THE

A MINIMUM M20 DIAMETER FERRULE IS TO BE COVER ZONE.

R8 MINIMUM LAPS IN MESH SHALL BE THE LARGER

ADOPTED UNLESS NOTED OTHERWISE.

SPACING OF TRANSVERSE WIRES UNLESS

P9 FERRULES THAT WILL BE EXPOSED AFTER

SHOWN OTHERWISE.

COMPLETION OF ERECTION ARE TO BE

N12-250 PIPE BY OTHERS OMITTED RECESSED 30mm BELOW THE CONCRETE R9 MESH SHALL NOT BE LAID ON THE GROUND AND

PULLED INTO POSITION THROUGH THE

SURFACE AND ARE TO BE GROUTED ON

COMPLETION. CONCRETE.

P10 PROVIDE 20mm LOCATING DOWELS TO THE BASE R10 CLEAR COVER TO REINFORCEMENT SHALL BE AS

OF ALL WALLS, WITH A MINIMUM OF 2 PER PANEL, SHOWN ON THE DRAWINGS.

500

SL81 CENTRAL N12-250 R11 REINFORCEMENT DEVELOPMENT LENGTHS SHALL

SL81 CENTRAL. UNLESS NOTED OTHERWISE.

P11 ALL CORBELS TO THE PRECAST PANELS TO BE EQUAL LAP LENGTHS.

POURED MONOLITHICALLY WITH THE PANEL.

150

P12 ALL EXPOSED AND BUTTING EDGES OF PANELS

SHALL HAVE A 15mm CHAMFER. R12 WHERE DISTRIBUTION BARS TO MAIN

REINFORCEMENT ARE NOT SHOWN ON THE

P13 ALL PANELS SHALL BE CAST ON A BOND BREAKER

DRAWINGS, PROVIDE MINIMUM N12-300, LAPPED

500

N12-250

CENTRAL.

SECTION A

N12-250

CENTRAL.

SECTION B SECTION C APPLIED IN STRICT ACCORDANCE WITH THE

MANUFACTURER'S RECOMMENDED PROCEDURE.

500mm AT SPLICES.

SCALE 1 : 20 S01 SCALE 1 : 20 S01 SCALE 1 : 20 S01 R13 ALL RE-ENTRANT CORNERS OF PENETRATIONS

THE BOND BREAKER SHALL REDUCE ADHESION

THROUGH WALLS AND SLABS SHALL BE TRIMMED

TO A LEVEL LESS THAN 50 % OF THE PANEL

USING MINIMUM 3-N12 DIAGONAL CORNER BARS

DEAD LOAD.

2000mm LONG.

P14 THE PANELS MUST BE STACKED IN SUCH A WAY

R14 REINFORCEMENT SET-OUT DIMENSION ARE

THAT :

SHOWN IN RELATION TO COLUMN CENTRELINES,

A) CRACKING WILL NOT OCCUR;

QUARTER SPAN POINTS OR WALL / BEAM EDGES

B) WARPING IN EXCESS OF THAT GIVEN IN THE

U.N.O.

RELEVANT CODES WILL NOT OCCUR

P15 THE CONTRACTOR SHALL TRANSPORT, ERECT ON R15 REINFORCING BARS SHALL BE EVENLY

SITE, AND PROP THE PANELS USING A MINIMUM DISTRIBUTED THROUGH THE WIDTH OF THE STRIP

OF TWO PROPS PER PANEL. U.N.O.

1300 P16 PROPS SHALL BE USED IN ACCORDANCE WITH R16 REINFORCEMENT SHALL NOT BE CUT OR BENT ON

THE SUPPLIER'S OR MANUFACTURER'S SITE UNLESS APPROVED BY THE ENGINEER. THE

B RECOMMENDATIONS AND LOAD LIMITS, AND REINFORCEMENT CAN ONLY BE HEATED IF

S01 SHALL BE FIXED TO FOOTINGS DESIGNED BY THE APPROVED IN WRITING BY THE ENGINEER.

CONTRACTOR. R17 AT SLAB EDGES INCLUDING CONSTRUCTION AND

P17 HIGH-STRENGTH PLASTIC PACKERS USED FOR OTHER JOINTS, AT LEAST ONE REINFORCING BAR

C LEVELLING UNDER SUPPORT POINTS OF LOAD- OR FABRIC WIRE SHALL BE LOCATED PARALLEL

S01 BEARING PRECAST PANELS MAY BE LEFT TO AND WITHIN 75mm OF THE SLAB EDGE.

PERMANENTLY PROVIDED THEY ARE CENTRALLY R18 AT PENETRATIONS WITH DIMENSIONS LESS THAN

900 SQ LOCATED BETWEEN THE FACES OF THE PANELS, 400mm DO NOT CUT REINFORCEMENT, RATHER

HAVE A MINIMUM OF 50mm GROUT COVER AND A GATHER REINFORCEMENT TO EACH SIDE OF

BEARING PRESSURE OF LESS THAN 7MPa. PENETRATION U.N.O. ON THE PLANS. AT

PACKERS USED BETWEEN NON-LOAD BEARING PENETRATIONS WITH DIMENSIONS LESS THAN

PANELS SHALL BE REMOVED IMMEDIATELY 600mm LAY REINFORCEMENT IN REQUIRED

2-N12 CRACK BARS EACH FACE 2-N12 CRACK BARS EACH FACE FOLLOWING THE INSTALLATION OF THE PANELS. POSITION AND CUT OUT TO SUIT PENETRATION.

BOTH SIDES OF JUNCTION BOX. BOTH SIDES OF JUNCTION BOX. P18 CONNECT ALL PANELS AT BUTT JOINTS AND PROVIDE ADDITIONAL BARS TO MATCH THE SIZE,

3-N12 @ 100 CTS LENGTH AND NUMBER OF BARS CUT, AND PLACE

CRACK BARS EACH INTERSECTIONS AS INDICATED. WHERE BOLTED

300

CONNECTIONS ARE USED AS PANEL-TO-PANEL EQUALLY ON EACH SIDE OF THE PENETRATION

FACE BOTH SIDES U.N.O. ON PLANS.

OF JUNCTION BOX. FIXINGS PLACE BOLTS CENTRALLY IN BOLT HOLE

TO GIVE MAXIMUM TOLERANCE IN ALL R19 CONCRETE SHALL NOT BE DELIVERED UNTIL FINAL

APPROVAL FOR REINFORCEMENT INSPECTION IS

2700 MAX

D DIRECTIONS.

P19 ALL GAPS SHALL BE PROPERLY SEALED WHEN OBTAINED.

S01

GROUTING UP THE PRECAST CONNECTIONS TO

2400 MAX

AVOID THE GROUT FILLING THE GAP BETWEEN

THE PANEL AND THE STRUCTURE AND TO AVOID

GROUT SPOILING THE FACE OF THE PANELS.

1500

P20 GROUT TO BE USED SHALL BE NON-SHRINK, AND

SHALL HAVE A 28 DAY CHARACTERISTIC

ø9 ø ø STRENGTH OF 40 MPa. DETAILS OF THE

00 90 90

0 0 PROPOSED GROUT TO BE SUBMITTED TO THE

ENGINEER FOR APPROVAL.

P21 ALL JOINTS SHALL BE PROPERLY CAULKED AND

SEALED AS REQUIRED AND FIRE-RATED WHERE

NECESSARY. TO ARCHITECTURAL

SPECIFICATIONS. ACID ETCHING AND ACID

CLEANING OF PANELS IS NOT ALLOWED.

P22 DETAILS OF SURFACE TREATMENT ARE TO BE

SUBMITTED TO THE ENGINEER FOR APPROVAL

PRIOR TO MANUFACTURE.

P23 VENEERED CONSTRUCTION AND USE OF

DIFFERENT MIXES AND MIXES FROM DIFFERENT

150 3880 150

SUPPLIERS ARE NOT ALLOWED.

JUNCTION BOX ELEVATION ADDITIONAL REINFORCEMENT ISO VIEW OF JUNCTION BOX

SCALE 1 : 20

EARTHWORKS OMITTED FOR CLARITY, REFER CIVIL DRAWINGS FOR LEVELS AND LAYOUT

ISSUE DATE DESCRIPTION CHECKER INITIAL CLIENT PROJECT DRAWING TITLE

A 20/12/22 ISSUED FOR

ISSUED CERTIFICATION

FOR CONSTRUCTION RT SGP ISSUED FOR CERTIFICATION DECHELLIS HOMES 43 AVNUE ROAD, PARADISE JUNCTION BOX DETAILS AND

NOT FOR CONSTRUCTION

NOTES

CONSULTING ENGINEERS

Level 14, Suite 2, 276 Flinders Street Melbourne VIC 3000

03 9923 7455 www.mlei.com.au

DATE PROJECT NUMBER DRAWING SCALE DRAWING NUMBER SIZE REV

DRAFTER DESIGN ENGINEER REVIEWER PROJECT MANAGER DEC 22 A2021-11772 As indicated

SGP MM RT RT DO NOT SCALE FROM THIS DRAWING S01 A1 A

You might also like

- Rationale Graphics Redrawn For Clarity, Correct Typo in Table 1, Showing Correct Thread Configuration For Sizes 09 and 18Document2 pagesRationale Graphics Redrawn For Clarity, Correct Typo in Table 1, Showing Correct Thread Configuration For Sizes 09 and 18Larry Hare100% (1)

- 980F Loader (5XJ588 Up)Document2 pages980F Loader (5XJ588 Up)NovakurniawanNo ratings yet

- Sakura Chi IV 19Document72 pagesSakura Chi IV 19Helmi100% (1)

- GAs - BOUNDARY WALL-S77 BOUNDARY WALLSDocument1 pageGAs - BOUNDARY WALL-S77 BOUNDARY WALLSSamitha SoysaNo ratings yet

- Approved Drawing of Boundary WallDocument1 pageApproved Drawing of Boundary WallAnup Singh RajputNo ratings yet

- COM-A-51-ZZ-03-b - STAIRCASE-3 SECTIONAL DETAILSDocument1 pageCOM-A-51-ZZ-03-b - STAIRCASE-3 SECTIONAL DETAILSAkshay SharmaNo ratings yet

- Column Reinforcement Schedule: Good For ConstructionDocument1 pageColumn Reinforcement Schedule: Good For ConstructionZaid HussainNo ratings yet

- t76-R-pp-476562-001 - Rev B Utility Ome Building Elevations & SectionsDocument1 paget76-R-pp-476562-001 - Rev B Utility Ome Building Elevations & SectionsTayyab AchakzaiNo ratings yet

- RaftDocument1 pageRafttmc.roshen.2024No ratings yet

- GAS-TECH Engineering Services LTDDocument1 pageGAS-TECH Engineering Services LTDMustafaNo ratings yet

- 04-R.C.C DETAIL IN R.I.B-ModelDocument1 page04-R.C.C DETAIL IN R.I.B-ModelManvendra Singh RaghuwanshiNo ratings yet

- (Steps Going To Deck Roof) : LegendDocument1 page(Steps Going To Deck Roof) : LegendLowie Torres TonioNo ratings yet

- DHQC Cecb MB Ti Ar DW ML 02 80541Document1 pageDHQC Cecb MB Ti Ar DW ML 02 80541Kumudu PereraNo ratings yet

- D-401 To D-437 Br1 Abutment A1-A2Document37 pagesD-401 To D-437 Br1 Abutment A1-A2Christian MendozaNo ratings yet

- MARK UP Column L1 TO L2Document1 pageMARK UP Column L1 TO L2Emon SahNo ratings yet

- 2.symbol and AbbreviationsDocument1 page2.symbol and Abbreviationshambi1986No ratings yet

- PlumbingDocument14 pagesPlumbingRaizen TanNo ratings yet

- KAAR COW PW IC NTU FZS DWG STR 24637 Rev.01 PDFDocument1 pageKAAR COW PW IC NTU FZS DWG STR 24637 Rev.01 PDFSatyanarayana MukkuNo ratings yet

- AS15001CDocument3 pagesAS15001Cjeniful jenifulNo ratings yet

- 1162-PLOT A-LAYOUT & SCHEDULE OF FIRST FLOORDocument1 page1162-PLOT A-LAYOUT & SCHEDULE OF FIRST FLOORgokulan.pNo ratings yet

- Hac DrawingDocument13 pagesHac Drawingabdulkidwai2009No ratings yet

- 2015 05891 Nmat-Typical Window Bay Details-1584088Document1 page2015 05891 Nmat-Typical Window Bay Details-1584088nextomegagenNo ratings yet

- Ca 477021 002Document1 pageCa 477021 002Sehna SerajNo ratings yet

- CA 352505 001 Rev.00Document1 pageCA 352505 001 Rev.00Muhammad RizwanNo ratings yet

- A.Typical Roadway Section: Pavement Design ParametersDocument1 pageA.Typical Roadway Section: Pavement Design ParametersrickNo ratings yet

- ZX330 Circuit (Electrical and Hydraulic)Document6 pagesZX330 Circuit (Electrical and Hydraulic)Syaiful BahriNo ratings yet

- S2 Structural NotesDocument1 pageS2 Structural NotesRaynz PatronNo ratings yet

- Sae0004-001 (B) - Safe-Away - 2009 Komatsu Power Pack - Electrical SchematicDocument2 pagesSae0004-001 (B) - Safe-Away - 2009 Komatsu Power Pack - Electrical SchematicWagner R.Gomes RodriguesNo ratings yet

- Typ. Detail of Corridor RailingDocument1 pageTyp. Detail of Corridor RailingMNo ratings yet

- 1.air Blower-Tesr - Sludge Sump STR DetailDocument1 page1.air Blower-Tesr - Sludge Sump STR DetailRohit JangidNo ratings yet

- General Construction Notes Design Criteria: Schedule of Minimum Slab Reinforcement Lintels in Block WallsDocument1 pageGeneral Construction Notes Design Criteria: Schedule of Minimum Slab Reinforcement Lintels in Block WallsMItchNo ratings yet

- SD Ec CGC ST 233.1 Rev.1Document1 pageSD Ec CGC ST 233.1 Rev.1Ahmed Salah El DinNo ratings yet

- KAAR COW PW IC NTU FZS DWG STR 24633 Rev.01 PDFDocument1 pageKAAR COW PW IC NTU FZS DWG STR 24633 Rev.01 PDFSatyanarayana MukkuNo ratings yet

- NWPE3 - 4 - 1600kg - 5500MRL - 21so - 2.5mps-General DataDocument1 pageNWPE3 - 4 - 1600kg - 5500MRL - 21so - 2.5mps-General DataBahaa MohamedNo ratings yet

- Column Reinforcement Schedule: Good For ConstructionDocument1 pageColumn Reinforcement Schedule: Good For ConstructionZaid HussainNo ratings yet

- PV490-C DrawingDocument15 pagesPV490-C Drawingsajid yaqoobNo ratings yet

- 4217 CSD C 1a 0504 r2 Details Typical Fence Sheet 01Document1 page4217 CSD C 1a 0504 r2 Details Typical Fence Sheet 01Adi PriyapurnatamaNo ratings yet

- As-Inspected Condition Drawing No. Sheet No. CRD-3G Bent 312 Column 3Document5 pagesAs-Inspected Condition Drawing No. Sheet No. CRD-3G Bent 312 Column 3kukadiya127_48673372No ratings yet

- DWC7894 11 02 - 00Document1 pageDWC7894 11 02 - 00nthekkumpuramNo ratings yet

- AS4662CDocument3 pagesAS4662Can NanNo ratings yet

- Zaxis75Ur/135Ur Electrical Circuit Diagram: Attach To Vol. No.: TT1CFE-00Document1 pageZaxis75Ur/135Ur Electrical Circuit Diagram: Attach To Vol. No.: TT1CFE-00Trung LêNo ratings yet

- BVTD LR 210617 Re01Document1 pageBVTD LR 210617 Re01Phú ĐoànNo ratings yet

- Proposed Landscape Design For Shailesh CHS, Nerul: Option-2Document2 pagesProposed Landscape Design For Shailesh CHS, Nerul: Option-2shalmi12No ratings yet

- GCU Consultants (Johor) SDN BHD: General Notes - Typical Rc. Wall Reinforcement DetailDocument1 pageGCU Consultants (Johor) SDN BHD: General Notes - Typical Rc. Wall Reinforcement DetailTOM YEENo ratings yet

- GCU Consultants (Johor) SDN BHD: General Notes and Miscellaneous Detail 3Document1 pageGCU Consultants (Johor) SDN BHD: General Notes and Miscellaneous Detail 3TOM YEENo ratings yet

- S.F Plan & Terrace Block 1Document1 pageS.F Plan & Terrace Block 1VVRAONo ratings yet

- Lay Out Hotel ConjiooDocument1 pageLay Out Hotel Conjiooanes farsaNo ratings yet

- 23-0867.1 - Roof Slab Layout - A1 (Kiloh Comments)Document1 page23-0867.1 - Roof Slab Layout - A1 (Kiloh Comments)NiemNo ratings yet

- 20024-000000u-D005 - Ufd - Ammonia Lines Rev 0Document1 page20024-000000u-D005 - Ufd - Ammonia Lines Rev 0oscar alfredoNo ratings yet

- BR - NO.775 (1X3.00m RCC BOX) 23-08-2019-ModelDocument1 pageBR - NO.775 (1X3.00m RCC BOX) 23-08-2019-Modelgrao vakapalliNo ratings yet

- Pile Cap of Abutment A1 & A2 (Takarma) - 1Document1 pagePile Cap of Abutment A1 & A2 (Takarma) - 1Nilay GandhiNo ratings yet

- 522445-AUR901-DRG-BC-5600-CIVIL TYPICAL UNDERGROUND SERVICES DETAILS SHEET 1 OF 4油罐间Document1 page522445-AUR901-DRG-BC-5600-CIVIL TYPICAL UNDERGROUND SERVICES DETAILS SHEET 1 OF 4油罐间Gibson SitumorangNo ratings yet

- 221627C C2 Drainage PlanDocument3 pages221627C C2 Drainage PlanArash GhaedizadehNo ratings yet

- A005 Stan Deck FRDocument1 pageA005 Stan Deck FRkecalli.restauranteNo ratings yet

- Typical Super T Strand LayoutDocument1 pageTypical Super T Strand LayoutAAMIRNo ratings yet

- 150-25F-2506Document1 page150-25F-2506abbasyalthofNo ratings yet

- Schedule of Member Splice Connection Notes:: F H G E D C B ADocument1 pageSchedule of Member Splice Connection Notes:: F H G E D C B ARajveer SinghNo ratings yet

- Storm Water Forcemain Profile - NishtarDocument1 pageStorm Water Forcemain Profile - NishtarZaheer AbbasNo ratings yet

- L1-2.01b - SectionDocument1 pageL1-2.01b - SectionJiahao LeeNo ratings yet

- La Hot 04 001 02Document1 pageLa Hot 04 001 02Bahaa MohamedNo ratings yet

- I - HRG42N2211 - LPG Device AssemblyDocument7 pagesI - HRG42N2211 - LPG Device AssemblyJOAO BIANCHINI100% (1)

- Instant Download Auditing A Practical Approach Canadian 3rd Edition Moroney Test Bank PDF Full ChapterDocument32 pagesInstant Download Auditing A Practical Approach Canadian 3rd Edition Moroney Test Bank PDF Full ChapterRobertCookdktg100% (9)

- Midliftl Ma enDocument2 pagesMidliftl Ma enStefano SavianNo ratings yet

- The International Style by Kenneth FramptonDocument5 pagesThe International Style by Kenneth FramptonAabidah AliNo ratings yet

- Gas LRe (GTP MP) (011119)Document10 pagesGas LRe (GTP MP) (011119)Bhalvindrakumar MaranNo ratings yet

- A05 Elevations 1 & 2Document1 pageA05 Elevations 1 & 2Daniel EvansNo ratings yet

- Ar 706Document1 pageAr 706Baby SinghNo ratings yet

- Civil Seminar List II-II & III-IIDocument6 pagesCivil Seminar List II-II & III-IIGaneshNo ratings yet

- Code of Practice For The Installation and Inspection of Fire Stopping Systems in BuildingsDocument22 pagesCode of Practice For The Installation and Inspection of Fire Stopping Systems in BuildingsNguyen Trung KienNo ratings yet

- Look Ahead Construction ScheduleDocument1 pageLook Ahead Construction ScheduleJhune AbadNo ratings yet

- Top 50 MENA Contractors - CompressedDocument27 pagesTop 50 MENA Contractors - CompressedSharfuddin TajNo ratings yet

- Working at HeightsDocument11 pagesWorking at HeightsKent Anilom100% (1)

- MOS - Cable InstallationDocument7 pagesMOS - Cable InstallationAzree Mohd NoorNo ratings yet

- Estimate ManualDocument94 pagesEstimate ManualRamilArtatesNo ratings yet

- Tensile Fabric Details 3Document1 pageTensile Fabric Details 3FRANKLYN SPENCERNo ratings yet

- Chainage Side Structure Part of Structure Grade of Concrete Date of Casting Date of TestingDocument48 pagesChainage Side Structure Part of Structure Grade of Concrete Date of Casting Date of TestingAyan DuttaNo ratings yet

- Ficha Tecnica Soportek GralDocument1 pageFicha Tecnica Soportek GralMarlene Treviño RamirezNo ratings yet

- Carpentry Install Formwork ComponentsDocument10 pagesCarpentry Install Formwork ComponentsYuriiNo ratings yet

- Specification For Aluminum DoorsDocument6 pagesSpecification For Aluminum DoorscivilaskarNo ratings yet

- Presentation On Pneumatic TMT Bar Bending MachineDocument12 pagesPresentation On Pneumatic TMT Bar Bending MachineRaja Mane100% (1)

- Dia Grid SlabDocument7 pagesDia Grid Slababhishekp9425% (4)

- General Notes: Submittal For ApprovalDocument6 pagesGeneral Notes: Submittal For ApprovalMyo AungNo ratings yet

- 09.VUP Reinf 35+535Document1 page09.VUP Reinf 35+535Praveen CyssanNo ratings yet

- EN010007-001446-6.4.17 App D1-1-Construction Method Statement (Rev 1.0) PDFDocument76 pagesEN010007-001446-6.4.17 App D1-1-Construction Method Statement (Rev 1.0) PDFHarendra RathnayakeNo ratings yet

- Pi-Typical Masonary Wall Details-5516!10!101aDocument1 pagePi-Typical Masonary Wall Details-5516!10!101akrishanNo ratings yet

- Legend: Cbsc8 Earth Pit: Pig Signaller PTDocument1 pageLegend: Cbsc8 Earth Pit: Pig Signaller PTFinanceAdmin FKSIENo ratings yet

- EIFS-Brochure A4Document32 pagesEIFS-Brochure A4Vaittianathan MahavapillaiNo ratings yet

- The Design and Construction of The New San Francisco-Oakland Bay Bridge (Sfobb) East SpanDocument14 pagesThe Design and Construction of The New San Francisco-Oakland Bay Bridge (Sfobb) East SpanLynx101No ratings yet

- Seminar ReportDocument23 pagesSeminar ReportPramod Kumar HTNo ratings yet