Professional Documents

Culture Documents

Libro Traducido

Libro Traducido

Uploaded by

Kevin AguirreCopyright:

Available Formats

You might also like

- Comminution CourseDocument413 pagesComminution CourseNataniel Linares100% (1)

- Centroid Concept in Pore Pressure PredictionDocument6 pagesCentroid Concept in Pore Pressure PredictionPrasanti Plaban Dash75% (4)

- MP - CH - 1 - Basics - Mineral - Properties and - Primary - CrushersDocument74 pagesMP - CH - 1 - Basics - Mineral - Properties and - Primary - Crusherstatek.anberbirNo ratings yet

- Introduction To Mineral Processing 2010Document24 pagesIntroduction To Mineral Processing 2010elmonemNo ratings yet

- P1 (Intro) & P2Document38 pagesP1 (Intro) & P2Khana Rizki MaulanaNo ratings yet

- zzMINERAL PROCESSINGDocument196 pageszzMINERAL PROCESSINGgulshan100% (1)

- Mineral Processing A DasDocument36 pagesMineral Processing A DasYallarling NagureNo ratings yet

- Process Mineralogy and Application in Mineral Processing and Extractive Metallurgy (Joe Zhou) PDFDocument13 pagesProcess Mineralogy and Application in Mineral Processing and Extractive Metallurgy (Joe Zhou) PDFAldo PabloNo ratings yet

- A Process Mineralogy Approach To Optimize Molybdeniteflotation in CopperDocument10 pagesA Process Mineralogy Approach To Optimize Molybdeniteflotation in CopperCarlos LopezNo ratings yet

- Applications of Ore Microscopy in Mineral TechnologyDocument25 pagesApplications of Ore Microscopy in Mineral TechnologyRobert UribeNo ratings yet

- Mineral Processing Technology-1Document68 pagesMineral Processing Technology-1GC Mahato100% (1)

- Geometallurgy: National University of Moquegua Professional School of Mining EngineeringDocument9 pagesGeometallurgy: National University of Moquegua Professional School of Mining EngineeringAldo Catacora100% (2)

- 2023 Recent Work On The Recovery of Rare Earths Using Ionic Liquids and Deep Eutectic SolventDocument14 pages2023 Recent Work On The Recovery of Rare Earths Using Ionic Liquids and Deep Eutectic SolventHanee Farzana HizaddinNo ratings yet

- Introduction To Mineral ProcessingDocument21 pagesIntroduction To Mineral ProcessingNataniel LinaresNo ratings yet

- Craig Vaughan CHPTR 11 PDFDocument25 pagesCraig Vaughan CHPTR 11 PDFSharon BennyNo ratings yet

- Mineral Beneficiation LectureDocument67 pagesMineral Beneficiation LectureVinay Kumar Sahu0% (1)

- Applied Mineralogy in The Mining IndustryDocument1 pageApplied Mineralogy in The Mining Industrymahapatih_51No ratings yet

- Beneficiation Process Control-1 (Mid Term)Document48 pagesBeneficiation Process Control-1 (Mid Term)Aklilu NegaNo ratings yet

- Guide Processing enDocument18 pagesGuide Processing enMiguel Esteban Ricci ValdesNo ratings yet

- Lecture Notes: Introduction To Mining and Mineral Processing EngineeringDocument91 pagesLecture Notes: Introduction To Mining and Mineral Processing Engineeringfaizalamri2013No ratings yet

- An Investigation of The Factors Affecting The Recovery of Molybdenite in The Kennecott Utah Copper Bulk Flotation CircuitDocument9 pagesAn Investigation of The Factors Affecting The Recovery of Molybdenite in The Kennecott Utah Copper Bulk Flotation CircuitDaniel Ernesto Nauduan FloresNo ratings yet

- Talc in The Processing of Mafic DepositsDocument8 pagesTalc in The Processing of Mafic Depositsgeology1No ratings yet

- Molybdenite Polytypism and Its Implications For Processing and Recovery: A Geometallurgical-Based Case Study From Bingham Canyon Mine, UtahDocument6 pagesMolybdenite Polytypism and Its Implications For Processing and Recovery: A Geometallurgical-Based Case Study From Bingham Canyon Mine, UtahUnurbayar EnkhbaatarNo ratings yet

- Modified Mineral Phases During Clay Ceramic Firing: Clays and Clay Minerals October 2015Document11 pagesModified Mineral Phases During Clay Ceramic Firing: Clays and Clay Minerals October 2015map vitcoNo ratings yet

- Beneficiation Manganese Ore FinesDocument3 pagesBeneficiation Manganese Ore Finesyusuf rumbinoNo ratings yet

- Assignment 2 ProcessMineralogyDocument8 pagesAssignment 2 ProcessMineralogyinung84No ratings yet

- Economic GeologyDocument84 pagesEconomic GeologyDeepakNo ratings yet

- Process Mineralogy As A Key Factor AffecDocument10 pagesProcess Mineralogy As A Key Factor AffecJerry TshimonaNo ratings yet

- Acidophile 2Document6 pagesAcidophile 2RITHIK MEHANDIRATTANo ratings yet

- Pengantar Teknik Pengolahan MineralDocument87 pagesPengantar Teknik Pengolahan MineralFajarRizki100% (1)

- A Process Mineralogy Approach To Study The Efficiency of Milling of Molybdenite Circuit ProcessingDocument14 pagesA Process Mineralogy Approach To Study The Efficiency of Milling of Molybdenite Circuit ProcessingNataniel Linares GutiérrezNo ratings yet

- ArticleDocument12 pagesArticletin_tin_tinNo ratings yet

- 1 s2.0 S0956053X15003815 MainDocument8 pages1 s2.0 S0956053X15003815 MainJoan Clotet GarciaNo ratings yet

- Preprint 10-002: SME Annual Meeting Feb. 28-Mar. 03, 2010, Phoenix, AZDocument5 pagesPreprint 10-002: SME Annual Meeting Feb. 28-Mar. 03, 2010, Phoenix, AZEduardo MenaNo ratings yet

- 14impc 932bradshawsubmittedDocument25 pages14impc 932bradshawsubmittedEngineering Office ShahrakNo ratings yet

- BoladeDocument27 pagesBoladeabolade299No ratings yet

- Process Mineralogy PDFDocument4 pagesProcess Mineralogy PDFimran58175100% (1)

- Chemical and Physical Investigations On The Barite of Ain Mimoun Ore Deposit - Khenchela - North-Eastern AlgeriaDocument13 pagesChemical and Physical Investigations On The Barite of Ain Mimoun Ore Deposit - Khenchela - North-Eastern AlgeriaLOUkmen BelNo ratings yet

- Minerals Engineering: P. Hartlieb, M. Toifl, F. Kuchar, R. Meisels, T. AntretterDocument8 pagesMinerals Engineering: P. Hartlieb, M. Toifl, F. Kuchar, R. Meisels, T. AntretterPorfirio Avilez SerranoNo ratings yet

- Minerals 11 00385Document12 pagesMinerals 11 00385Metalurgista SosNo ratings yet

- A Review On The Recovery of Noble Metals From Anode SlimesDocument16 pagesA Review On The Recovery of Noble Metals From Anode SlimesEdon BediNo ratings yet

- Industrial Minerals and Classification: Excavation Material Metal / Ore (Ore), A Mineral That When A ParticularDocument10 pagesIndustrial Minerals and Classification: Excavation Material Metal / Ore (Ore), A Mineral That When A ParticularDayatNo ratings yet

- 18) The Study of Possibilities of Selective Recovery of Palladium (II) From Chlorides Solutions by Ion Exchange Resin Lewatit TP-214Document7 pages18) The Study of Possibilities of Selective Recovery of Palladium (II) From Chlorides Solutions by Ion Exchange Resin Lewatit TP-214SrikanthNo ratings yet

- Modified Mineral Phases During Clay Ceramic Firing: Clays and Clay Minerals October 2015Document11 pagesModified Mineral Phases During Clay Ceramic Firing: Clays and Clay Minerals October 2015duyen nguyen chi luongNo ratings yet

- Bioleaching of Heavy Metals From Mine Tailings by Indigenous Sulfur-Oxidizing Bacteria: Effects of Substrate ConcentrationDocument6 pagesBioleaching of Heavy Metals From Mine Tailings by Indigenous Sulfur-Oxidizing Bacteria: Effects of Substrate ConcentrationJordan Ulloa BelloNo ratings yet

- 14impc 932bradshawsubmitted PDFDocument25 pages14impc 932bradshawsubmitted PDFRUTH MALABANo ratings yet

- A Novel Approach For Preferential Flotation Recovery of Molybdenite From A PorphyryDocument8 pagesA Novel Approach For Preferential Flotation Recovery of Molybdenite From A PorphyrydanisaNo ratings yet

- B. Akash Dissertation ReportDocument19 pagesB. Akash Dissertation Reportbonthuakash005No ratings yet

- Bioleaching of Tungsten-Rich Spent Hydrocracking Catalyst UsingDocument7 pagesBioleaching of Tungsten-Rich Spent Hydrocracking Catalyst Usingsrinandhinisrini62No ratings yet

- Topic 1 (Week 1)Document19 pagesTopic 1 (Week 1)George GomezNo ratings yet

- Sustainability 15 02518Document21 pagesSustainability 15 02518idu054452No ratings yet

- 0 IntroductionDocument104 pages0 IntroductionAbdelrahman NabawyNo ratings yet

- Roasting Followed by MSDocument10 pagesRoasting Followed by MSDEGAGA AMENUNo ratings yet

- Integrating Bulk Ore Sorting Into A Mining Operation: November 2016Document16 pagesIntegrating Bulk Ore Sorting Into A Mining Operation: November 2016Camilo Ignaacio Suazo FigueroaNo ratings yet

- Module 1Document65 pagesModule 1himeNo ratings yet

- Synthesis of Magnetite Nanoparticles From Mineral WasteDocument33 pagesSynthesis of Magnetite Nanoparticles From Mineral WasteMelissa Sonia Yactayo YarangaNo ratings yet

- CH#1Document5 pagesCH#1Rahaf HammadNo ratings yet

- Mineral Liberation by High Voltage Pulses and Conventional Comminution With Same Specific Energy Levels PDFDocument9 pagesMineral Liberation by High Voltage Pulses and Conventional Comminution With Same Specific Energy Levels PDFMonica Ulloa LamasNo ratings yet

- Malaysia REDocument9 pagesMalaysia REyeyintlayNo ratings yet

- Journal of The Taiwan Institute of Chemical Engineers: Morteza Feizi, Mohsen JalaliDocument12 pagesJournal of The Taiwan Institute of Chemical Engineers: Morteza Feizi, Mohsen JalaliZaharia MariusNo ratings yet

- Auxiliary System Charge Air System: Sterling and Wilson Co-Gen SolutionsDocument17 pagesAuxiliary System Charge Air System: Sterling and Wilson Co-Gen SolutionsKeshav Shrivastava KSNo ratings yet

- Chromatography MethodDocument19 pagesChromatography MethodHafiz AzizNo ratings yet

- Flow Through Sampler (FTS) : Kuster CompanyDocument1 pageFlow Through Sampler (FTS) : Kuster CompanyEnrique AssmannNo ratings yet

- Robotics TopicsDocument3 pagesRobotics TopicsSerat RahmanNo ratings yet

- Peskin & Schroeder - The Quantum SpinDocument6 pagesPeskin & Schroeder - The Quantum SpinGiggs SandyNo ratings yet

- MACO CalculationDocument2 pagesMACO CalculationNishit SuvaNo ratings yet

- CH 14 ThermodynamicsDocument46 pagesCH 14 ThermodynamicsHarshad MehtaNo ratings yet

- Synthesis and Applications of Silver Nanoparticles: Arabian Journal of Chemistry July 2010Document7 pagesSynthesis and Applications of Silver Nanoparticles: Arabian Journal of Chemistry July 2010TigerNo ratings yet

- Frabication of An Eco-Friendly Corrosion Inhibitor From Terminalia Catappa Leaf Concrete Reinforcement in SeawaterDocument6 pagesFrabication of An Eco-Friendly Corrosion Inhibitor From Terminalia Catappa Leaf Concrete Reinforcement in SeawaterPoonam KilaniyaNo ratings yet

- Lecture Notes4Document15 pagesLecture Notes4aj_gto30No ratings yet

- 331 Chap1 - Dim AnalysisDocument12 pages331 Chap1 - Dim AnalysisIsaac NjorogeNo ratings yet

- Lab Practice 1-Use of The MicroscopeDocument4 pagesLab Practice 1-Use of The MicroscopeANANo ratings yet

- Fluidized Bed Reactor Design StepsDocument13 pagesFluidized Bed Reactor Design Stepsmalavur50% (2)

- Climate - Change Book PDFDocument283 pagesClimate - Change Book PDFPantulu MurtyNo ratings yet

- Wrapped Thick Cylinder Under Pressure and Thermal LoadingDocument5 pagesWrapped Thick Cylinder Under Pressure and Thermal LoadingDan WolfNo ratings yet

- Concepts of Modern Physics SolutionsDocument166 pagesConcepts of Modern Physics SolutionsKonrad Nied33% (3)

- Method For Determining The Concentration of FLUORIDE in Water SampleDocument4 pagesMethod For Determining The Concentration of FLUORIDE in Water SampleValter NevesNo ratings yet

- Corrosion Studies KitDocument26 pagesCorrosion Studies KitMurphy MofeNo ratings yet

- Lab 3: Solubility of Organic Compounds: ObjectivesDocument12 pagesLab 3: Solubility of Organic Compounds: ObjectivesJAN CAMILLE OLIVARESNo ratings yet

- TLT Febrero 2021Document68 pagesTLT Febrero 2021Rocio RupayNo ratings yet

- Tutorial No: 1 Thermodynamic Properties: Fundamentals of Thermodynamics and Heat TransferDocument3 pagesTutorial No: 1 Thermodynamic Properties: Fundamentals of Thermodynamics and Heat TransferParas gurungNo ratings yet

- IV I and Optical Fiber CommunicationDocument24 pagesIV I and Optical Fiber CommunicationjohnNo ratings yet

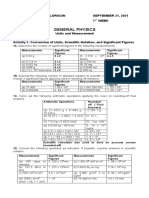

- General Physics: Andrie Jacob G. Doloricon SEPTEMBER 21, 2021 Grade Xii - Stem D 1 WeekDocument6 pagesGeneral Physics: Andrie Jacob G. Doloricon SEPTEMBER 21, 2021 Grade Xii - Stem D 1 WeekReynaldNo ratings yet

- Thermodynamics - Aakash RM Modules (@TEAMFLOOD) - UnlockedDocument38 pagesThermodynamics - Aakash RM Modules (@TEAMFLOOD) - Unlockedbrainly312No ratings yet

- CMC - Chapter 1Document58 pagesCMC - Chapter 1Habete ItfNo ratings yet

- Pengban 11 CeramicsDocument122 pagesPengban 11 CeramicstheoNo ratings yet

- 1.4 Solved ProblemsDocument2 pages1.4 Solved ProblemsMohammad Hussain Raza ShaikNo ratings yet

- Generator Stator Assembly Inspection Sheet PDFDocument32 pagesGenerator Stator Assembly Inspection Sheet PDFPradip RajNo ratings yet

- Lecture 01Document31 pagesLecture 01sivamadhaviyamNo ratings yet

Libro Traducido

Libro Traducido

Uploaded by

Kevin AguirreOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Libro Traducido

Libro Traducido

Uploaded by

Kevin AguirreCopyright:

Available Formats

Introduction

Mineral processing is a branch of science and technology dealing with processing

of natural and synthetic mineral materials as well as accompanying liquids, solutions

and gases to provide them with desired properties. It is a part of technical sciences,

although it contains elements originating from other fields of knowledge, especially

natural sciences. Mineral processing is based on separation processes and is involved

in performing and description of separations, as well as their analysis, evaluation, and

comparison.

Various terms are used in different countries for mineral processing. In English

speaking countries (USA, UK, Canada, Australia, etc.) it is also termed, dressing,

preparation, beneficiation, and recently mineralurgy or minerallurgy. The Poles

mostly use przeróbka kopalin, the Russians obogashchenie poleznykh iskopaemykh,

the Germans Die Aufberaitung, and the Spanish Procesamiento de minerals.

The term mineralurgia becomes more and more popular in Poland, Italy, Portugal,

Spain, Slovakia, Hungry, Czech Republic, Russia, minéralurgie in France, and min-

eralurgy or minerallurgy in Canada and Australia. In spite of the fact that the term

mineralurgy precisely characterizes our branch of knowledge and practice, it finds dif-

ficulties among both scientists and technologists to be commonly applied.

The word minerallurgy is a combination of the word mineral meaning a substance

resulting from geological processes and a Greek word lurgia (streactly speaking lour-

geion) denoting the place of processing.

Miting raw Post-mining Secondary raw

materials raw materials materials

MINERAL PROCESSING

Metallurgy Chemical

Construstion Wastes

industry

materials

Fig. 1. Place of mineral processing in science and practice

10 Introduction

The history of mineral processing is as old as that of a man. Cleaving stones,

sharpening flint stones and sorting were one of the first mineral processing activities

practiced by humans. A considerable development of mineral processing and its phys-

icochemical basis took place within the last hundred years. Processing of useful min-

erals has become a branch of science and technology closely cooperating with mining

and chemical industry as well as other branches of industry. Minerallurgy also deals

with utilization of industrial an municipal wastes. The products manufactured by

minerallurgists are utilized by metallurgical, chemical, civil engineering, and envi-

ronmental protection industries (Fig.1.).

EXTRACTIVE METALLURGY

MINERALLURGY METALLURGY

(MINERAL PROCESSING)

(separations without chemcial changes) (separations with chemcial changes)

feed

grinding concentrate smelting metal

screening leaching

flotation & other electrolysis

oindustr

t ies

tailing

h tailing

e

r

Fig. 2. Mineral processing is a part of extractive metallurgy

Mineral Processing, together with metallurgy, constitute extractive metallurgy

(Fig. 2). Extractive metallurgy is a wide branch of knowledge as it covers many raw

materials and numerous methods of separation.

Mineral processing is sometimes divided into mechanical and physicochemical

parts. Another classification of mineral processing leads to coal preparation and proc-

essing of mineral raw materials. These divisions are frequently the source of misun-

derstanding because there is a tendency to use different terms for the same phenom-

ena, parameters and properties. For example, the fraction of a particular component

which is transferred from the feed to a product of separation can be called recovery,

separation number, release degree, efficiency, transfer probability, and so on. In this

book an attempt was undertaken to treat all mineral processing operations as separa-

tion and four basic terms, yield, recovery, content, and separation feature will be used

for delineation, analysis, assessment, and comparison of separations and their results

Introduction 11

hoping that in the future this will unify all branches of mineral processing as to its phi-

losophy and terminology.

The advances in mineral processing can be noticed in the papers and books pub-

lished in different countries. The best ones, written in English, still full of useful in-

formation are the works by Taggart (Handbook of mineral dressing, Wiley 1945),

Gaudin (Flotation, McGraw-Hill, 1957), Wills (Mineral processing technology, Per-

gamon 1979 and further editions), Kelly and Spottiswood (Introduction to mineral

processing, Wiley 1982), Leja (Surface chemistry of froth flotation, Plenum Press

1982), Wiess (chief ed., SME Mineral processing handbook, AIMME/SME, 1985),

Fuerstenau, Miller, and Kuhn (Chemistry of flotation, AIME/SME, 1985), Tarjan

(Mineral processing, Akademai Kiado 1986), Laskowski (Coal flotation and fine coal

utilization, Elsevier, 2001).

The goal of this book is to present the bases of mineral processing with emphasis

on treating all operations as separation processes having similar structure, which can

be subjected to the same procedure of delineation, analysis, and evaluation. The pre-

sent, most common treatment of mineral processing operations is shown in Fig. 3.

Comminution Upgrading

- flotation

- gravity

- magnetic

Classification - etc.

Final treatment

- drying

- sampling

- portioning

- etc.

Fig. 3. Typical treatment of mineral processing operations

while the treatment used in this book in Fig. 4:

You might also like

- Comminution CourseDocument413 pagesComminution CourseNataniel Linares100% (1)

- Centroid Concept in Pore Pressure PredictionDocument6 pagesCentroid Concept in Pore Pressure PredictionPrasanti Plaban Dash75% (4)

- MP - CH - 1 - Basics - Mineral - Properties and - Primary - CrushersDocument74 pagesMP - CH - 1 - Basics - Mineral - Properties and - Primary - Crusherstatek.anberbirNo ratings yet

- Introduction To Mineral Processing 2010Document24 pagesIntroduction To Mineral Processing 2010elmonemNo ratings yet

- P1 (Intro) & P2Document38 pagesP1 (Intro) & P2Khana Rizki MaulanaNo ratings yet

- zzMINERAL PROCESSINGDocument196 pageszzMINERAL PROCESSINGgulshan100% (1)

- Mineral Processing A DasDocument36 pagesMineral Processing A DasYallarling NagureNo ratings yet

- Process Mineralogy and Application in Mineral Processing and Extractive Metallurgy (Joe Zhou) PDFDocument13 pagesProcess Mineralogy and Application in Mineral Processing and Extractive Metallurgy (Joe Zhou) PDFAldo PabloNo ratings yet

- A Process Mineralogy Approach To Optimize Molybdeniteflotation in CopperDocument10 pagesA Process Mineralogy Approach To Optimize Molybdeniteflotation in CopperCarlos LopezNo ratings yet

- Applications of Ore Microscopy in Mineral TechnologyDocument25 pagesApplications of Ore Microscopy in Mineral TechnologyRobert UribeNo ratings yet

- Mineral Processing Technology-1Document68 pagesMineral Processing Technology-1GC Mahato100% (1)

- Geometallurgy: National University of Moquegua Professional School of Mining EngineeringDocument9 pagesGeometallurgy: National University of Moquegua Professional School of Mining EngineeringAldo Catacora100% (2)

- 2023 Recent Work On The Recovery of Rare Earths Using Ionic Liquids and Deep Eutectic SolventDocument14 pages2023 Recent Work On The Recovery of Rare Earths Using Ionic Liquids and Deep Eutectic SolventHanee Farzana HizaddinNo ratings yet

- Introduction To Mineral ProcessingDocument21 pagesIntroduction To Mineral ProcessingNataniel LinaresNo ratings yet

- Craig Vaughan CHPTR 11 PDFDocument25 pagesCraig Vaughan CHPTR 11 PDFSharon BennyNo ratings yet

- Mineral Beneficiation LectureDocument67 pagesMineral Beneficiation LectureVinay Kumar Sahu0% (1)

- Applied Mineralogy in The Mining IndustryDocument1 pageApplied Mineralogy in The Mining Industrymahapatih_51No ratings yet

- Beneficiation Process Control-1 (Mid Term)Document48 pagesBeneficiation Process Control-1 (Mid Term)Aklilu NegaNo ratings yet

- Guide Processing enDocument18 pagesGuide Processing enMiguel Esteban Ricci ValdesNo ratings yet

- Lecture Notes: Introduction To Mining and Mineral Processing EngineeringDocument91 pagesLecture Notes: Introduction To Mining and Mineral Processing Engineeringfaizalamri2013No ratings yet

- An Investigation of The Factors Affecting The Recovery of Molybdenite in The Kennecott Utah Copper Bulk Flotation CircuitDocument9 pagesAn Investigation of The Factors Affecting The Recovery of Molybdenite in The Kennecott Utah Copper Bulk Flotation CircuitDaniel Ernesto Nauduan FloresNo ratings yet

- Talc in The Processing of Mafic DepositsDocument8 pagesTalc in The Processing of Mafic Depositsgeology1No ratings yet

- Molybdenite Polytypism and Its Implications For Processing and Recovery: A Geometallurgical-Based Case Study From Bingham Canyon Mine, UtahDocument6 pagesMolybdenite Polytypism and Its Implications For Processing and Recovery: A Geometallurgical-Based Case Study From Bingham Canyon Mine, UtahUnurbayar EnkhbaatarNo ratings yet

- Modified Mineral Phases During Clay Ceramic Firing: Clays and Clay Minerals October 2015Document11 pagesModified Mineral Phases During Clay Ceramic Firing: Clays and Clay Minerals October 2015map vitcoNo ratings yet

- Beneficiation Manganese Ore FinesDocument3 pagesBeneficiation Manganese Ore Finesyusuf rumbinoNo ratings yet

- Assignment 2 ProcessMineralogyDocument8 pagesAssignment 2 ProcessMineralogyinung84No ratings yet

- Economic GeologyDocument84 pagesEconomic GeologyDeepakNo ratings yet

- Process Mineralogy As A Key Factor AffecDocument10 pagesProcess Mineralogy As A Key Factor AffecJerry TshimonaNo ratings yet

- Acidophile 2Document6 pagesAcidophile 2RITHIK MEHANDIRATTANo ratings yet

- Pengantar Teknik Pengolahan MineralDocument87 pagesPengantar Teknik Pengolahan MineralFajarRizki100% (1)

- A Process Mineralogy Approach To Study The Efficiency of Milling of Molybdenite Circuit ProcessingDocument14 pagesA Process Mineralogy Approach To Study The Efficiency of Milling of Molybdenite Circuit ProcessingNataniel Linares GutiérrezNo ratings yet

- ArticleDocument12 pagesArticletin_tin_tinNo ratings yet

- 1 s2.0 S0956053X15003815 MainDocument8 pages1 s2.0 S0956053X15003815 MainJoan Clotet GarciaNo ratings yet

- Preprint 10-002: SME Annual Meeting Feb. 28-Mar. 03, 2010, Phoenix, AZDocument5 pagesPreprint 10-002: SME Annual Meeting Feb. 28-Mar. 03, 2010, Phoenix, AZEduardo MenaNo ratings yet

- 14impc 932bradshawsubmittedDocument25 pages14impc 932bradshawsubmittedEngineering Office ShahrakNo ratings yet

- BoladeDocument27 pagesBoladeabolade299No ratings yet

- Process Mineralogy PDFDocument4 pagesProcess Mineralogy PDFimran58175100% (1)

- Chemical and Physical Investigations On The Barite of Ain Mimoun Ore Deposit - Khenchela - North-Eastern AlgeriaDocument13 pagesChemical and Physical Investigations On The Barite of Ain Mimoun Ore Deposit - Khenchela - North-Eastern AlgeriaLOUkmen BelNo ratings yet

- Minerals Engineering: P. Hartlieb, M. Toifl, F. Kuchar, R. Meisels, T. AntretterDocument8 pagesMinerals Engineering: P. Hartlieb, M. Toifl, F. Kuchar, R. Meisels, T. AntretterPorfirio Avilez SerranoNo ratings yet

- Minerals 11 00385Document12 pagesMinerals 11 00385Metalurgista SosNo ratings yet

- A Review On The Recovery of Noble Metals From Anode SlimesDocument16 pagesA Review On The Recovery of Noble Metals From Anode SlimesEdon BediNo ratings yet

- Industrial Minerals and Classification: Excavation Material Metal / Ore (Ore), A Mineral That When A ParticularDocument10 pagesIndustrial Minerals and Classification: Excavation Material Metal / Ore (Ore), A Mineral That When A ParticularDayatNo ratings yet

- 18) The Study of Possibilities of Selective Recovery of Palladium (II) From Chlorides Solutions by Ion Exchange Resin Lewatit TP-214Document7 pages18) The Study of Possibilities of Selective Recovery of Palladium (II) From Chlorides Solutions by Ion Exchange Resin Lewatit TP-214SrikanthNo ratings yet

- Modified Mineral Phases During Clay Ceramic Firing: Clays and Clay Minerals October 2015Document11 pagesModified Mineral Phases During Clay Ceramic Firing: Clays and Clay Minerals October 2015duyen nguyen chi luongNo ratings yet

- Bioleaching of Heavy Metals From Mine Tailings by Indigenous Sulfur-Oxidizing Bacteria: Effects of Substrate ConcentrationDocument6 pagesBioleaching of Heavy Metals From Mine Tailings by Indigenous Sulfur-Oxidizing Bacteria: Effects of Substrate ConcentrationJordan Ulloa BelloNo ratings yet

- 14impc 932bradshawsubmitted PDFDocument25 pages14impc 932bradshawsubmitted PDFRUTH MALABANo ratings yet

- A Novel Approach For Preferential Flotation Recovery of Molybdenite From A PorphyryDocument8 pagesA Novel Approach For Preferential Flotation Recovery of Molybdenite From A PorphyrydanisaNo ratings yet

- B. Akash Dissertation ReportDocument19 pagesB. Akash Dissertation Reportbonthuakash005No ratings yet

- Bioleaching of Tungsten-Rich Spent Hydrocracking Catalyst UsingDocument7 pagesBioleaching of Tungsten-Rich Spent Hydrocracking Catalyst Usingsrinandhinisrini62No ratings yet

- Topic 1 (Week 1)Document19 pagesTopic 1 (Week 1)George GomezNo ratings yet

- Sustainability 15 02518Document21 pagesSustainability 15 02518idu054452No ratings yet

- 0 IntroductionDocument104 pages0 IntroductionAbdelrahman NabawyNo ratings yet

- Roasting Followed by MSDocument10 pagesRoasting Followed by MSDEGAGA AMENUNo ratings yet

- Integrating Bulk Ore Sorting Into A Mining Operation: November 2016Document16 pagesIntegrating Bulk Ore Sorting Into A Mining Operation: November 2016Camilo Ignaacio Suazo FigueroaNo ratings yet

- Module 1Document65 pagesModule 1himeNo ratings yet

- Synthesis of Magnetite Nanoparticles From Mineral WasteDocument33 pagesSynthesis of Magnetite Nanoparticles From Mineral WasteMelissa Sonia Yactayo YarangaNo ratings yet

- CH#1Document5 pagesCH#1Rahaf HammadNo ratings yet

- Mineral Liberation by High Voltage Pulses and Conventional Comminution With Same Specific Energy Levels PDFDocument9 pagesMineral Liberation by High Voltage Pulses and Conventional Comminution With Same Specific Energy Levels PDFMonica Ulloa LamasNo ratings yet

- Malaysia REDocument9 pagesMalaysia REyeyintlayNo ratings yet

- Journal of The Taiwan Institute of Chemical Engineers: Morteza Feizi, Mohsen JalaliDocument12 pagesJournal of The Taiwan Institute of Chemical Engineers: Morteza Feizi, Mohsen JalaliZaharia MariusNo ratings yet

- Auxiliary System Charge Air System: Sterling and Wilson Co-Gen SolutionsDocument17 pagesAuxiliary System Charge Air System: Sterling and Wilson Co-Gen SolutionsKeshav Shrivastava KSNo ratings yet

- Chromatography MethodDocument19 pagesChromatography MethodHafiz AzizNo ratings yet

- Flow Through Sampler (FTS) : Kuster CompanyDocument1 pageFlow Through Sampler (FTS) : Kuster CompanyEnrique AssmannNo ratings yet

- Robotics TopicsDocument3 pagesRobotics TopicsSerat RahmanNo ratings yet

- Peskin & Schroeder - The Quantum SpinDocument6 pagesPeskin & Schroeder - The Quantum SpinGiggs SandyNo ratings yet

- MACO CalculationDocument2 pagesMACO CalculationNishit SuvaNo ratings yet

- CH 14 ThermodynamicsDocument46 pagesCH 14 ThermodynamicsHarshad MehtaNo ratings yet

- Synthesis and Applications of Silver Nanoparticles: Arabian Journal of Chemistry July 2010Document7 pagesSynthesis and Applications of Silver Nanoparticles: Arabian Journal of Chemistry July 2010TigerNo ratings yet

- Frabication of An Eco-Friendly Corrosion Inhibitor From Terminalia Catappa Leaf Concrete Reinforcement in SeawaterDocument6 pagesFrabication of An Eco-Friendly Corrosion Inhibitor From Terminalia Catappa Leaf Concrete Reinforcement in SeawaterPoonam KilaniyaNo ratings yet

- Lecture Notes4Document15 pagesLecture Notes4aj_gto30No ratings yet

- 331 Chap1 - Dim AnalysisDocument12 pages331 Chap1 - Dim AnalysisIsaac NjorogeNo ratings yet

- Lab Practice 1-Use of The MicroscopeDocument4 pagesLab Practice 1-Use of The MicroscopeANANo ratings yet

- Fluidized Bed Reactor Design StepsDocument13 pagesFluidized Bed Reactor Design Stepsmalavur50% (2)

- Climate - Change Book PDFDocument283 pagesClimate - Change Book PDFPantulu MurtyNo ratings yet

- Wrapped Thick Cylinder Under Pressure and Thermal LoadingDocument5 pagesWrapped Thick Cylinder Under Pressure and Thermal LoadingDan WolfNo ratings yet

- Concepts of Modern Physics SolutionsDocument166 pagesConcepts of Modern Physics SolutionsKonrad Nied33% (3)

- Method For Determining The Concentration of FLUORIDE in Water SampleDocument4 pagesMethod For Determining The Concentration of FLUORIDE in Water SampleValter NevesNo ratings yet

- Corrosion Studies KitDocument26 pagesCorrosion Studies KitMurphy MofeNo ratings yet

- Lab 3: Solubility of Organic Compounds: ObjectivesDocument12 pagesLab 3: Solubility of Organic Compounds: ObjectivesJAN CAMILLE OLIVARESNo ratings yet

- TLT Febrero 2021Document68 pagesTLT Febrero 2021Rocio RupayNo ratings yet

- Tutorial No: 1 Thermodynamic Properties: Fundamentals of Thermodynamics and Heat TransferDocument3 pagesTutorial No: 1 Thermodynamic Properties: Fundamentals of Thermodynamics and Heat TransferParas gurungNo ratings yet

- IV I and Optical Fiber CommunicationDocument24 pagesIV I and Optical Fiber CommunicationjohnNo ratings yet

- General Physics: Andrie Jacob G. Doloricon SEPTEMBER 21, 2021 Grade Xii - Stem D 1 WeekDocument6 pagesGeneral Physics: Andrie Jacob G. Doloricon SEPTEMBER 21, 2021 Grade Xii - Stem D 1 WeekReynaldNo ratings yet

- Thermodynamics - Aakash RM Modules (@TEAMFLOOD) - UnlockedDocument38 pagesThermodynamics - Aakash RM Modules (@TEAMFLOOD) - Unlockedbrainly312No ratings yet

- CMC - Chapter 1Document58 pagesCMC - Chapter 1Habete ItfNo ratings yet

- Pengban 11 CeramicsDocument122 pagesPengban 11 CeramicstheoNo ratings yet

- 1.4 Solved ProblemsDocument2 pages1.4 Solved ProblemsMohammad Hussain Raza ShaikNo ratings yet

- Generator Stator Assembly Inspection Sheet PDFDocument32 pagesGenerator Stator Assembly Inspection Sheet PDFPradip RajNo ratings yet

- Lecture 01Document31 pagesLecture 01sivamadhaviyamNo ratings yet