Professional Documents

Culture Documents

Bulldog Clip Usage 1

Bulldog Clip Usage 1

Uploaded by

Rajesh NairOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bulldog Clip Usage 1

Bulldog Clip Usage 1

Uploaded by

Rajesh NairCopyright:

Available Formats

BEST PRACTICE:

THE APPLICATION

OF BULLDOG GRIPS

Bulldog grips are commonly used on ships in order to form a loop or “eye” in a wire rope.

The eye can be formed by using a thimble (hard eye) or by a simple wire loop (soft eye).

They are used on ships on mast stays and crane wires, A more common usage is for the securing of project

although swaged connections are now more common. cargo, both under and below deck. The single most

Bulldog grips are not to be used on lifeboat falls (and predominant factor associated with the failure of cargo

for any other purpose where life is at risk) but they are lashings is the incorrect application of bulldog grips.

often found on bowsing tackles and on winch brake

remote release wires.

Damage to project cargoes Failed lashing

The Club’s Risk Assessors often note that bulldog

grips are incorrectly applied both by stevedores and

shipyards.

The right (and wrong) ways are shown in the

diagrams below.

Fig. 1. Right way of applying bulldog grips

Grips reversed

Fig. 2. Wrong way to apply bulldog grips

The saddle part of the bulldog grip should be applied

to the “live” load bearing wire, whereas the U bolt goes

around the “dead” tail.

A useful way to remember this is by using the

mnemonic “never saddle a dead horse”.

Another good “aide memoire” is

Saddle / Stressed, U / Unstressed.

The distance between the grips is important and this

should be about six times the rope diameter; not

Correct way around but grip is too close to the end of tail,

significantly more or less. The length of the tail is also

which is becoming unravelled

important and should be greater than five times the

rope diameter. Also, the tail should be whipped or

Bulldog grips applied over a PVC coating will fail at

bound to prevent it unravelling.

relatively very low slip loads. It is recommended that

plastic coating is stripped away clear of any contact

The number of grips used depends on the diameter of

with bulldog grips.

the wire but at least three should be used for wires up to

19mm, and more for thicker wires as per the table below.

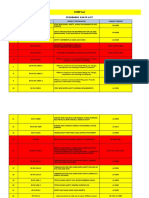

Diameter of wire ropes Bulldog grips

(mm) (Number)

Up to and including 19 3

Over 19: up to and including 32 4

Over 32: up to and including 38 5

Over 38: up to and including 44 6

Over 44: up to and including 56 7

It is important that the tightness of the nuts is checked

periodically as the grips have a flattening effect on the Too few bulldog grips reversely applied over a plastic

wire, resulting in a reduced grip. coating and too far apart

Various tests were carried out several years ago

(financed by Thomas Miller Ltd., Managers of the UK

P&I Club). They showed that a perfectly made up hard

eye around a thimble will hold at 90% to 100% of the

nominal breaking load (NBL) of the wire before slipping

and/or fracturing.

If the grips are reversed, (contrary to the often

expressed opinion that “it makes no difference”) the

wire will fail at around 50% NBL.

By using only two grips (instead of the recommended

three), even correctly applied, the wire would slip at

around 60% NBL reducing to 50% when reversed or

Grips staggered staggered. With one grip, these figures were 25%

(correct way around) and 18% (reversed).

The correct method of fitting bulldog grips is hardly

“rocket science” but the majority of those seen on

board are, in some way, incorrectly fitted.

Proper supervision in the builder’s yard should ensure

that these are initially fitted correctly. Equally,

stevedores / lashing gangs should be supervised and

instructed to correct improper lashings.

Correct way around but insufficient number of grips, too

close together and wire tail too short

Insufficient number of staggered grips, too close together

and wire tail too short

SOURCE OF INFORMATION

Lashing and Securing of Deck Cargoes by John R Knott

(Nautical Institute)

Other related UK P&I Club publications:

Project Cargo Matters and Checklist

www.ukpandi.com/loss-prevention/article/project-cargo-matters-

131532/

Good Practise Poster No. 35 – Bulldog Grips

www.ukpandi.com/loss-prevention/posters/good-practice-

posters/posters-24-47/

For further information, please contact:

Loss Prevention Department, Thomas Miller P&I Ltd

Tel: +44 20 7204 2307 Fax +44 20 7283 6517

Email: lossprevention.ukclub@thomasmiller.com

You might also like

- Basic Book of Knots and LashingsDocument38 pagesBasic Book of Knots and LashingsREBogart93% (40)

- F1487-11 PlaygroundsDocument66 pagesF1487-11 PlaygroundsAbdul Maalik Rawasia100% (1)

- Tug Tow Rope Systems and Planned Maintenance Procedures: Robert Underhill, Jeyco Mooring and Rigging Equipment, AustraliaDocument6 pagesTug Tow Rope Systems and Planned Maintenance Procedures: Robert Underhill, Jeyco Mooring and Rigging Equipment, AustraliaDeanna BarrettNo ratings yet

- Seile Taue EnglDocument48 pagesSeile Taue EnglSantiago FalusNo ratings yet

- Brugg HalatDocument8 pagesBrugg HalatsyalmanNo ratings yet

- Knots and LashingDocument13 pagesKnots and LashingMeggy VillanuevaNo ratings yet

- Caving Knots: Nov 2001 Prepared by CCPO S C Milton CSCA Technical Training AdviserDocument12 pagesCaving Knots: Nov 2001 Prepared by CCPO S C Milton CSCA Technical Training AdviserAndi Buftea100% (1)

- Koepe Tail Ropes - HintsDocument15 pagesKoepe Tail Ropes - HintsmosesNo ratings yet

- Knots and LashesDocument5 pagesKnots and LashesMuhammad BabarNo ratings yet

- The Linkage End FittingsDocument2 pagesThe Linkage End FittingsMobile SunNo ratings yet

- Vibration Proof Fasteners - Welding, Bonding & Fastener Engineering - Eng-TipsDocument8 pagesVibration Proof Fasteners - Welding, Bonding & Fastener Engineering - Eng-Tips1339979No ratings yet

- Wireline Advisory Wilco PDFDocument5 pagesWireline Advisory Wilco PDFhesam abbaszadehNo ratings yet

- Guidance On The Use of U-Bolt Type Wire Rope Grips: Document Reference: LEEA-049Document6 pagesGuidance On The Use of U-Bolt Type Wire Rope Grips: Document Reference: LEEA-049Ganiyu100% (1)

- Crosby Thimble Eye Bundle Clips Warning & Application InstructionsDocument1 pageCrosby Thimble Eye Bundle Clips Warning & Application InstructionsMareg Engenharia de SegurançaNo ratings yet

- Knots: An Illustrated Practical Guide to the Essential Knot Types and their UsesFrom EverandKnots: An Illustrated Practical Guide to the Essential Knot Types and their UsesNo ratings yet

- Drogue Instructions PDFDocument10 pagesDrogue Instructions PDFNilson OlympioNo ratings yet

- Wireline Advisory WilcoDocument5 pagesWireline Advisory WilcoWilliam EvansNo ratings yet

- User S Manual Wire RopesDocument13 pagesUser S Manual Wire RopesRajesh NairNo ratings yet

- Crane Drums and CablesDocument4 pagesCrane Drums and Cablesjoe_frangieh100% (1)

- D - D Ratio and The Effect On Sling Capacity - Unirope LTD PDFDocument3 pagesD - D Ratio and The Effect On Sling Capacity - Unirope LTD PDFalphadingNo ratings yet

- LKKKKDocument13 pagesLKKKKyesid caceres morantesNo ratings yet

- Extend Gear Coupling Life: of Can Be ofDocument5 pagesExtend Gear Coupling Life: of Can Be ofUdhayakumar VenkataramanNo ratings yet

- Knots: Bowline KnotDocument12 pagesKnots: Bowline Knotamudha100% (1)

- Satellite TV Repair 4 BeginnersDocument40 pagesSatellite TV Repair 4 Beginnersandrej21120% (2)

- D - D Effect On Sling Capacity - UniropeDocument3 pagesD - D Effect On Sling Capacity - Uniropeanahita romanNo ratings yet

- How To Keep Your Equipment Making Hay.: Agricultural Belt TipsDocument4 pagesHow To Keep Your Equipment Making Hay.: Agricultural Belt TipsKeith VestNo ratings yet

- 048 BMC Ropes - A Guide For Climbers and Mountaineers V7 (SINGLE PAGES)Document32 pages048 BMC Ropes - A Guide For Climbers and Mountaineers V7 (SINGLE PAGES)გაგი ნარტყოშვილიNo ratings yet

- Wire Rop Accessories PDFDocument39 pagesWire Rop Accessories PDFSergio A.S.No ratings yet

- Scout EngineeringDocument32 pagesScout EngineeringRick Gaines100% (4)

- A Few Good KnotsDocument42 pagesA Few Good KnotsDavid Enrique Mendez100% (1)

- Tying Down of Scaffold Boards: GeneralDocument4 pagesTying Down of Scaffold Boards: GeneralJithinNo ratings yet

- Use and Care of Wire RopeDocument8 pagesUse and Care of Wire RopeAnonymous 7fsk6ZFMNo ratings yet

- D - D Ratio and The Effect On Sling Capacity - Unirope LTD - PDFDocument3 pagesD - D Ratio and The Effect On Sling Capacity - Unirope LTD - PDFRodrigoNo ratings yet

- Fishing Net MakingDocument12 pagesFishing Net MakingTinusAppelgryn100% (1)

- RIGGING SAFETY TrainingDocument43 pagesRIGGING SAFETY TrainingBG REDDYNo ratings yet

- User S Manual Synthetic Mooring TailsDocument13 pagesUser S Manual Synthetic Mooring TailsGökhan UlukuzNo ratings yet

- Rope Inc. Rope Inspection and RetirementDocument4 pagesRope Inc. Rope Inspection and RetirementMr-SmithNo ratings yet

- Quick Lashing Guide: Cargo Securing On Ctus For Transports On Road, Combined Rail and in Sea Area A, B & CDocument56 pagesQuick Lashing Guide: Cargo Securing On Ctus For Transports On Road, Combined Rail and in Sea Area A, B & CJose cedeñoNo ratings yet

- BH64-Instruction Manual COSAIRDocument32 pagesBH64-Instruction Manual COSAIRDougNo ratings yet

- Proper Handling Techniques For Samson 8-Strand High Performance Ropes On H-BittsDocument2 pagesProper Handling Techniques For Samson 8-Strand High Performance Ropes On H-BittsTomash VerbitskyNo ratings yet

- Southwire Cable in Conduit Product CatalogDocument65 pagesSouthwire Cable in Conduit Product Catalogjtb12No ratings yet

- 4 Wire Rope SlingsDocument22 pages4 Wire Rope SlingsMuhammad Shahid MahmoodNo ratings yet

- Sheave Groove InspectionDocument12 pagesSheave Groove Inspectionpaulmann308No ratings yet

- Wire Rope SlingsDocument27 pagesWire Rope Slingsnasirfahim100% (1)

- Rigging TechniquesDocument27 pagesRigging TechniquesDeepak ShettyNo ratings yet

- Section IV (Fishing Tools)Document18 pagesSection IV (Fishing Tools)Pendopo KadipatenNo ratings yet

- AO5 Safety in ClimbingDocument4 pagesAO5 Safety in ClimbingBnoPublicServicesNo ratings yet

- SR Techinfo 06 ENDocument16 pagesSR Techinfo 06 ENÁngel BarrioNo ratings yet

- 12.0 Fishing For WirelineDocument21 pages12.0 Fishing For WirelineSarita100% (1)

- V-Belt Drive Failure AnalysisDocument1 pageV-Belt Drive Failure AnalysisMuhammad afzalNo ratings yet

- Rope Rescue KnotsDocument18 pagesRope Rescue KnotsRNdrei dela Cruz100% (1)

- Rigging KNOTSDocument13 pagesRigging KNOTSDexter FernandezNo ratings yet

- Anchor Chain Locker Volume CalculationDocument8 pagesAnchor Chain Locker Volume CalculationRAMSINGH CHAUHANNo ratings yet

- User's Manual - Synthetic Μooring RopesDocument32 pagesUser's Manual - Synthetic Μooring RopesNikos StratisNo ratings yet

- The Knot Book - Knots, Bends and Hitches - A Guide for Sailors, Adventurers and HobbyistsFrom EverandThe Knot Book - Knots, Bends and Hitches - A Guide for Sailors, Adventurers and HobbyistsNo ratings yet

- Understanding Your Boats Systems and Choices.From EverandUnderstanding Your Boats Systems and Choices.Rating: 3 out of 5 stars3/5 (1)

- Knots and Nets - The Various Types, How to Make them and Practical Uses for themFrom EverandKnots and Nets - The Various Types, How to Make them and Practical Uses for themNo ratings yet

- Per 01 - Enclosed Space Entry PermitDocument3 pagesPer 01 - Enclosed Space Entry PermitRajesh Nair100% (1)

- Per 01a - Cargo Pumproom Entry PermitDocument3 pagesPer 01a - Cargo Pumproom Entry PermitRajesh NairNo ratings yet

- User S Manual Wire RopesDocument13 pagesUser S Manual Wire RopesRajesh NairNo ratings yet

- P&I Pilot Ladder and Portable LadderDocument12 pagesP&I Pilot Ladder and Portable LadderRajesh NairNo ratings yet

- Framo PurgingDocument8 pagesFramo PurgingRajesh NairNo ratings yet

- xs-5487-1 2800xpc DC BroDocument5 pagesxs-5487-1 2800xpc DC BrojohnNo ratings yet

- Method Statement-MV Cable (132) Laying & TerminationDocument9 pagesMethod Statement-MV Cable (132) Laying & TerminationSriram VNo ratings yet

- QD-181 211 - Main - en C 1Document32 pagesQD-181 211 - Main - en C 1Huy Nhut Ele VatorNo ratings yet

- Industrial Training at Traco Cables Company Limited: Cochin University College of Engineering KUTTANADU-637215Document30 pagesIndustrial Training at Traco Cables Company Limited: Cochin University College of Engineering KUTTANADU-637215Vimal SudhakaranNo ratings yet

- D04 BLE2 Brushless Motors AC InputDocument20 pagesD04 BLE2 Brushless Motors AC InputmakanakiliNo ratings yet

- Dxap5004 Idxa External Options Installation Instructions DPN Dxap5004preDocument20 pagesDxap5004 Idxa External Options Installation Instructions DPN Dxap5004preOtávio PagnoncelliNo ratings yet

- BROOKLINDocument11 pagesBROOKLINsandeep tanavadekarNo ratings yet

- TIP A 03 D Splicing A Steel Wire DefDocument7 pagesTIP A 03 D Splicing A Steel Wire DefwileNo ratings yet

- Model Pl8 Service ManualDocument32 pagesModel Pl8 Service ManualEd CalheNo ratings yet

- TW-GJS-M7 Dome Splice Closure: Description 1. ApplicationDocument4 pagesTW-GJS-M7 Dome Splice Closure: Description 1. ApplicationAung Thein OoNo ratings yet

- Itron - Option Board Mounting and Operating InstructionsDocument4 pagesItron - Option Board Mounting and Operating InstructionsIzak HeyNo ratings yet

- 2.0 Components of Drilling RigDocument81 pages2.0 Components of Drilling RigConnor Whiltshire100% (1)

- STRATUS Elevator Installation Manual Feb6 2015Document46 pagesSTRATUS Elevator Installation Manual Feb6 2015Mohd Abu AjajNo ratings yet

- Drilling Line - Ton MileDocument28 pagesDrilling Line - Ton MileShussan100% (3)

- 2维修手册 Chapter 2 - CHAPTER 3Document36 pages2维修手册 Chapter 2 - CHAPTER 3Frank Ch Ccaico100% (1)

- Flexiguard Portable C Frame Rail Fall Arrest System Manual PDFDocument24 pagesFlexiguard Portable C Frame Rail Fall Arrest System Manual PDFbetokarNo ratings yet

- VocabulárioTécnico InglêsDocument80 pagesVocabulárioTécnico InglêsEvandro Cesário da SilvaNo ratings yet

- Specification Cabeceira 16 TonDocument9 pagesSpecification Cabeceira 16 TonDouglas GuarizNo ratings yet

- Tirak Full SpecsDocument28 pagesTirak Full SpecsjusufNo ratings yet

- Bridon Crane and IndustrialDocument91 pagesBridon Crane and IndustrialmatiasNo ratings yet

- Copie de Standards Check ListDocument7 pagesCopie de Standards Check ListAbakar MahamatNo ratings yet

- Glands: Comet Single Compression Type Heavy Duty Cable Gland (Sibg)Document2 pagesGlands: Comet Single Compression Type Heavy Duty Cable Gland (Sibg)dip461No ratings yet

- KL Saltfjord 300812Document12 pagesKL Saltfjord 300812hihihiNo ratings yet

- Arcelor Mital Wire RopesDocument32 pagesArcelor Mital Wire Ropesdsn_sarmaNo ratings yet

- Intelligent Positioner: ConstructionDocument16 pagesIntelligent Positioner: ConstructionSanjay MaheshNo ratings yet

- Tower Crane-Inspections-ListDocument3 pagesTower Crane-Inspections-ListLuffy11No ratings yet

- RTN 320 V100R008 Quick Installation Guide: Issue: 03 Date: 2018-03-10Document37 pagesRTN 320 V100R008 Quick Installation Guide: Issue: 03 Date: 2018-03-10Lubo PicturesMakerNo ratings yet

- 8 PRO Feed Systems ENDocument6 pages8 PRO Feed Systems ENEngels RamírezNo ratings yet

- Dropped Object Survey and Inspection StandardDocument92 pagesDropped Object Survey and Inspection StandardnoormanmubarakNo ratings yet