Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

6 viewsTime: 3 Hours Max - Marks: 75

Time: 3 Hours Max - Marks: 75

Uploaded by

ApppuThis document provides a model question paper for the Machine Tools course in the Mechanical Engineering program. It contains 3 sections with a total of 75 marks. Section I contains 9 short answer questions worth 1 mark each. Section II contains 8 short answer questions worth 3 marks each. Section III contains 6 long answer questions worth 7 marks each, with options provided for each question. The questions cover topics related to lathe operations, shaper operations, milling operations, grinding operations, cutting tools, and CNC machines.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Fitting and Machining Book by Ron Culley (L341)Document8 pagesFitting and Machining Book by Ron Culley (L341)Mahmud RochyNo ratings yet

- Rong-Fu RF-25 Mill ManualDocument20 pagesRong-Fu RF-25 Mill Manualpowerman450% (4)

- Tacho SystemDocument15 pagesTacho SystemMihir Mishra100% (5)

- TED (21) 2022 QPDocument2 pagesTED (21) 2022 QPshyncsNo ratings yet

- I. Answer All Questions in One Word or One Sentence (9 X 1 9 Marks)Document3 pagesI. Answer All Questions in One Word or One Sentence (9 X 1 9 Marks)Sam JhonsonNo ratings yet

- TED (21) 5021 QPDocument2 pagesTED (21) 5021 QPshyncsNo ratings yet

- Model Question PaperDocument2 pagesModel Question PaperV V DEVADASNo ratings yet

- Valliammai Engineering College SRM Nagar, Kattankulathur - 603 203 Department of Mechanical Engineering Question BankDocument11 pagesValliammai Engineering College SRM Nagar, Kattankulathur - 603 203 Department of Mechanical Engineering Question BankGanthimathi PonnusamyNo ratings yet

- Ted (21) - 5023A Revision 2021 Model Question PaperDocument3 pagesTed (21) - 5023A Revision 2021 Model Question Papermhdajsal52No ratings yet

- ME3493 - Manufacturing TechnologyDocument10 pagesME3493 - Manufacturing TechnologySriram SrinivasanNo ratings yet

- A35c8 MTM R18Document2 pagesA35c8 MTM R18kummarirakesh12No ratings yet

- B-Tech. Mechanical UNIT-1: Bme 206 Manufacturing Technology - 1Document6 pagesB-Tech. Mechanical UNIT-1: Bme 206 Manufacturing Technology - 1Michael ButlerNo ratings yet

- 18 Me 451Document2 pages18 Me 451Karan SNo ratings yet

- Tutorial MP.1 NewDocument4 pagesTutorial MP.1 Newtajap70949No ratings yet

- Assignment 1Document1 pageAssignment 1Aromal ArozNo ratings yet

- Model Question Paper Tool Design: Part ADocument6 pagesModel Question Paper Tool Design: Part ASam JhonsonNo ratings yet

- Machine Tools 3Document4 pagesMachine Tools 3Aaron HarriganNo ratings yet

- Gujarat Technological UniversityDocument4 pagesGujarat Technological Universitynishith ranaNo ratings yet

- UntitledDocument2 pagesUntitledsegarvijay vijayNo ratings yet

- Manufacturing Science-IiDocument5 pagesManufacturing Science-Iiayansiddiqui7700No ratings yet

- 4024Document3 pages4024V V DEVADASNo ratings yet

- Automobile ComponentsDocument6 pagesAutomobile Componentsshincy ARNo ratings yet

- ME6402-Manufacturing Technology-IIDocument10 pagesME6402-Manufacturing Technology-IINIVAS S. SNo ratings yet

- Injection Mold Design Model Question Paper - Set-IDocument6 pagesInjection Mold Design Model Question Paper - Set-ISam JhonsonNo ratings yet

- Mp21 MergedDocument13 pagesMp21 Mergedkuldeep thakorNo ratings yet

- 1616403439362-Subjective Questions On Manufacturing Process MET-03Document4 pages1616403439362-Subjective Questions On Manufacturing Process MET-03Dashmeet SinghNo ratings yet

- MT Question Bank PDFDocument9 pagesMT Question Bank PDFHarish RajaNo ratings yet

- Mt-Ii QBDocument10 pagesMt-Ii QBRavi ChandranNo ratings yet

- S4 Instrumentation Engineering: Module Cognitive Outcomes LevelDocument4 pagesS4 Instrumentation Engineering: Module Cognitive Outcomes Levelabhishekash502No ratings yet

- Bmm4243 (Mt2) - TutorialDocument3 pagesBmm4243 (Mt2) - TutorialNajip TalibinNo ratings yet

- Assignment 1Document1 pageAssignment 1Swastik PanchalNo ratings yet

- Production Technology SyllabusDocument9 pagesProduction Technology SyllabusPankaj SharmaNo ratings yet

- MT Assignment 1Document2 pagesMT Assignment 1Ashwini SinghNo ratings yet

- Fourth Semester Diploma Examination in Mechanical Engineering/TechnologyDocument2 pagesFourth Semester Diploma Examination in Mechanical Engineering/TechnologyV V DEVADASNo ratings yet

- MT 2 Terminal Test 1Document1 pageMT 2 Terminal Test 1Rajchandar KannanNo ratings yet

- AssignmentDocument3 pagesAssignmentAviral Sansi0% (1)

- Iae I QB PDFDocument2 pagesIae I QB PDFrubberNo ratings yet

- Metal FormingDocument6 pagesMetal FormingHarish Kumar SNo ratings yet

- Tutorial SheetDocument21 pagesTutorial Sheetankita awasthiNo ratings yet

- Answer Any Five Questions From Section-BDocument1 pageAnswer Any Five Questions From Section-BCharyNo ratings yet

- MCMT AssignmentsDocument2 pagesMCMT AssignmentsSamNihalNo ratings yet

- Code No: 35033Document5 pagesCode No: 35033SRINIVASA RAO GANTANo ratings yet

- JM303 End of Chapter 3 Solenoid Power Diode TransistorDocument1 pageJM303 End of Chapter 3 Solenoid Power Diode Transistorshobanraj1995No ratings yet

- Assignment Unit IV BMEDocument2 pagesAssignment Unit IV BMERoop LalNo ratings yet

- Automobile Engg A23 R21 4023Document2 pagesAutomobile Engg A23 R21 4023muhammadsinane1No ratings yet

- Machine Tools and Digital MFG UQSDocument3 pagesMachine Tools and Digital MFG UQSAnonymous f1UCK4No ratings yet

- Machine Tools Assignments 1 N 2Document3 pagesMachine Tools Assignments 1 N 2Sunkeswaram Deva PrasadNo ratings yet

- Design of Jigs, Fixtures and Press Tools - Department of Mechanical EngineeringDocument8 pagesDesign of Jigs, Fixtures and Press Tools - Department of Mechanical EngineeringLoga Nath100% (2)

- Model Question Paper Wood Products Ii: Module Outcome Cognitive LevelDocument2 pagesModel Question Paper Wood Products Ii: Module Outcome Cognitive LevelSam JhonsonNo ratings yet

- Silibus Baru JJ104Document12 pagesSilibus Baru JJ104limakupang_matNo ratings yet

- Assignment-I-MC &MT PDFDocument2 pagesAssignment-I-MC &MT PDFChadaram JagadishNo ratings yet

- Tools Design Question Paper 2021 CVSRDocument2 pagesTools Design Question Paper 2021 CVSRRadha Krishna100% (1)

- Manufacturing Engineering Guide BookDocument2 pagesManufacturing Engineering Guide BookGiridharan SharmaNo ratings yet

- Semester End Supplementary Examinations (Ar19), Feb - 2023Document1 pageSemester End Supplementary Examinations (Ar19), Feb - 2023Jury.rahulNo ratings yet

- Course ObjectivesDocument5 pagesCourse Objectives75Ujwal TDNo ratings yet

- Ii Mech Mt-IiDocument3 pagesIi Mech Mt-IiRameez FaroukNo ratings yet

- Qid: Model: Module Cognitive Outcome LevelDocument2 pagesQid: Model: Module Cognitive Outcome LevelNithinNo ratings yet

- Pillared Metal-Organic Frameworks: Properties and ApplicationsFrom EverandPillared Metal-Organic Frameworks: Properties and ApplicationsNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

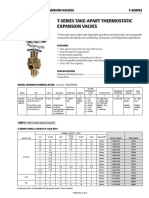

- T Series Take Apart Thermostatic Expansion Valves Catalog en Us 1569686Document5 pagesT Series Take Apart Thermostatic Expansion Valves Catalog en Us 1569686Jak JoniNo ratings yet

- 30x173mm Ammunition Suite MK44 Cannon Version 3 PDFDocument2 pages30x173mm Ammunition Suite MK44 Cannon Version 3 PDFcacak283No ratings yet

- Data Spare Part DatangDocument7 pagesData Spare Part DatangThaufan WijayaNo ratings yet

- Argos FD 700Document20 pagesArgos FD 700Tony Humberto Gutierrez100% (1)

- Scroll Saw 40-100 16 1246Document8 pagesScroll Saw 40-100 16 1246Theodor EikeNo ratings yet

- Climate Control OverviewDocument35 pagesClimate Control OverviewZM OhnNo ratings yet

- Chuck SPANNTOP Nova Pull BackDocument8 pagesChuck SPANNTOP Nova Pull BackhungNo ratings yet

- SAE-J1926 Port Reference DimensionsDocument1 pageSAE-J1926 Port Reference DimensionsSamuel RochetteNo ratings yet

- DME-MEC 604 - 6th Sem 2nd Internal QuestionDocument2 pagesDME-MEC 604 - 6th Sem 2nd Internal QuestionMithilesh kumarNo ratings yet

- Liangchew CatalogueDocument48 pagesLiangchew CatalogueKyaw Naing AungNo ratings yet

- Design and Fabrication of Self Centering Vice Ppt-1Document36 pagesDesign and Fabrication of Self Centering Vice Ppt-1KarthickNo ratings yet

- ManBay-CP20 - GenCon-Bid Form PL & FRDocument40 pagesManBay-CP20 - GenCon-Bid Form PL & FRCamille Mojares BoñonNo ratings yet

- Upright Flying Lead Orientation Tool: ROV ToolsDocument2 pagesUpright Flying Lead Orientation Tool: ROV Toolsdodo salahNo ratings yet

- JACMOR - Scetional Screw Flights Form 123-1Document1 pageJACMOR - Scetional Screw Flights Form 123-1022freeNo ratings yet

- Engine Assembly-Repair ProcedurDocument24 pagesEngine Assembly-Repair Procedurfebri yuliantoNo ratings yet

- Daftar Pekerjaan HidrantDocument1 pageDaftar Pekerjaan Hidrantjabriklaksono489No ratings yet

- 2021 Holi Retail Offer Document Ver 1.03Document25 pages2021 Holi Retail Offer Document Ver 1.03Sri Harsha KNo ratings yet

- Sleipner E400 Part List 175 001Document27 pagesSleipner E400 Part List 175 001Susilo purwanggi100% (1)

- PPM Check List: Floor: Wing: Room No: DateDocument3 pagesPPM Check List: Floor: Wing: Room No: DateMdrahaman MithuNo ratings yet

- Advanced Tool SharpeningDocument10 pagesAdvanced Tool SharpeningjenrocoNo ratings yet

- Parts Book PC300-8Document112 pagesParts Book PC300-8varo100% (1)

- Sandvik Versatile Tools 2018Document153 pagesSandvik Versatile Tools 2018jaajaNo ratings yet

- W3I0003XQ M240B Medium MachinegunDocument47 pagesW3I0003XQ M240B Medium Machinegunakms1982No ratings yet

- Refrigerator: Service ManualDocument99 pagesRefrigerator: Service ManualUbaldo BritoNo ratings yet

- LIFESTYLE INTERNATIONAL Private Limited - My Colourful Kitchen 2021-22Document49 pagesLIFESTYLE INTERNATIONAL Private Limited - My Colourful Kitchen 2021-22chaitanya.maisaNo ratings yet

- Brake System InspectionDocument6 pagesBrake System Inspectioncarlos pilcoNo ratings yet

- SKVJ-M Replacing Preheater Components: 1.1 Replacing The Controller (With Display) of The Control BoxDocument3 pagesSKVJ-M Replacing Preheater Components: 1.1 Replacing The Controller (With Display) of The Control Box徐玉坤No ratings yet

Time: 3 Hours Max - Marks: 75

Time: 3 Hours Max - Marks: 75

Uploaded by

Apppu0 ratings0% found this document useful (0 votes)

6 views3 pagesThis document provides a model question paper for the Machine Tools course in the Mechanical Engineering program. It contains 3 sections with a total of 75 marks. Section I contains 9 short answer questions worth 1 mark each. Section II contains 8 short answer questions worth 3 marks each. Section III contains 6 long answer questions worth 7 marks each, with options provided for each question. The questions cover topics related to lathe operations, shaper operations, milling operations, grinding operations, cutting tools, and CNC machines.

Original Description:

My aadhar

Original Title

3023 (2)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a model question paper for the Machine Tools course in the Mechanical Engineering program. It contains 3 sections with a total of 75 marks. Section I contains 9 short answer questions worth 1 mark each. Section II contains 8 short answer questions worth 3 marks each. Section III contains 6 long answer questions worth 7 marks each, with options provided for each question. The questions cover topics related to lathe operations, shaper operations, milling operations, grinding operations, cutting tools, and CNC machines.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

6 views3 pagesTime: 3 Hours Max - Marks: 75

Time: 3 Hours Max - Marks: 75

Uploaded by

ApppuThis document provides a model question paper for the Machine Tools course in the Mechanical Engineering program. It contains 3 sections with a total of 75 marks. Section I contains 9 short answer questions worth 1 mark each. Section II contains 8 short answer questions worth 3 marks each. Section III contains 6 long answer questions worth 7 marks each, with options provided for each question. The questions cover topics related to lathe operations, shaper operations, milling operations, grinding operations, cutting tools, and CNC machines.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

MODEL QUESTION PAPER

Programme name: Mechanical Engineering Semester : 3

Course code: 3023 Course name: MACHINE TOOLS

Time : 3 Hours Max.Marks : 75

I. Answer all the following questions (9 x 1 = 9 Marks)

1 Define Machinability. MO 1.01 R

2 Write Taylors equation for tool life. MO 1.03 U

3 What is the use of a clapper box in a shaper? MO 2.01 U

4 List the operations that can be performed in a drilling machine. MO 2.04 U

5 List the different types of milling machine. MO 3.01 R

6 Define indexing MO 3.02 U

7 Name a suitable cutting fluid for drilling cast iron block MO 4.04 A

8 Define tool magazine MO 4.02 R

9 List the natural abrasives used in grinding wheel MO 3.04 U

II. Answer any Eight questions from the following 8 x 3= 24

Marks)

1 Describe speed, feed, and depth of cut in turning operation MO 1.05 U

2 Illustrate the nomenclature of a single point cutting tool with details MO 1.02 U

3 Explain crank and slotted lever mechanism in a shaper. MO 2.01 U

4 Draw and explain any two work holding devices in a shaper. MO 2.03 U

5 Draw a neat sketch of an arbor and give its function. MO 3.03 U

6 Give the principle of centerless grinding. What are the limitations of centerless

MO 3.04 U

grinding?

7 Write the differences between NC and CNC machines. MO 4.01 U

8 Explain the classification of lubricants. MO4.05 R

9 Differentiate between orthogonal and oblique cutting.

MO 1.01 U

10 Explain any three shaper operations. MO 2.01 R

III. Answer all questions from the following (6x 7 = 42 Marks)

1 Draw the figure of a center lathe and list its parts MO 1.04 R

OR

2 List the properties required for a good cutting tool material MO 1.02 U

3 Draw a neat figure of radial drilling machine and list its parts MO 2.04 R

OR

4 List the main parts of a shaper and explain their functions MO 2.01 U

5 Differentiate between Upmilling and Downmilling MO 3.01 U

OR

6 Write short note on abrasives and bonding materials used in grinding wheel MO 3.04 R

7 List and explain the main parts of a NC machine. MO 4.02 U

OR

8 List the factors considered for the selection of cutting fluids. MO 4.04 U

9 Explain taper turning by tailstock set over method in a lathe. MO 1.05 U

OR

10 Explain the different types of chips formed during metal cutting operation MO1.01 U

11 Explain the nomenclature of a milling cutter. List the different types of milling

MO3.02 U

cutters

OR

12 Explain Lapping and Honing with suitable figures MO 3.01 U

You might also like

- Fitting and Machining Book by Ron Culley (L341)Document8 pagesFitting and Machining Book by Ron Culley (L341)Mahmud RochyNo ratings yet

- Rong-Fu RF-25 Mill ManualDocument20 pagesRong-Fu RF-25 Mill Manualpowerman450% (4)

- Tacho SystemDocument15 pagesTacho SystemMihir Mishra100% (5)

- TED (21) 2022 QPDocument2 pagesTED (21) 2022 QPshyncsNo ratings yet

- I. Answer All Questions in One Word or One Sentence (9 X 1 9 Marks)Document3 pagesI. Answer All Questions in One Word or One Sentence (9 X 1 9 Marks)Sam JhonsonNo ratings yet

- TED (21) 5021 QPDocument2 pagesTED (21) 5021 QPshyncsNo ratings yet

- Model Question PaperDocument2 pagesModel Question PaperV V DEVADASNo ratings yet

- Valliammai Engineering College SRM Nagar, Kattankulathur - 603 203 Department of Mechanical Engineering Question BankDocument11 pagesValliammai Engineering College SRM Nagar, Kattankulathur - 603 203 Department of Mechanical Engineering Question BankGanthimathi PonnusamyNo ratings yet

- Ted (21) - 5023A Revision 2021 Model Question PaperDocument3 pagesTed (21) - 5023A Revision 2021 Model Question Papermhdajsal52No ratings yet

- ME3493 - Manufacturing TechnologyDocument10 pagesME3493 - Manufacturing TechnologySriram SrinivasanNo ratings yet

- A35c8 MTM R18Document2 pagesA35c8 MTM R18kummarirakesh12No ratings yet

- B-Tech. Mechanical UNIT-1: Bme 206 Manufacturing Technology - 1Document6 pagesB-Tech. Mechanical UNIT-1: Bme 206 Manufacturing Technology - 1Michael ButlerNo ratings yet

- 18 Me 451Document2 pages18 Me 451Karan SNo ratings yet

- Tutorial MP.1 NewDocument4 pagesTutorial MP.1 Newtajap70949No ratings yet

- Assignment 1Document1 pageAssignment 1Aromal ArozNo ratings yet

- Model Question Paper Tool Design: Part ADocument6 pagesModel Question Paper Tool Design: Part ASam JhonsonNo ratings yet

- Machine Tools 3Document4 pagesMachine Tools 3Aaron HarriganNo ratings yet

- Gujarat Technological UniversityDocument4 pagesGujarat Technological Universitynishith ranaNo ratings yet

- UntitledDocument2 pagesUntitledsegarvijay vijayNo ratings yet

- Manufacturing Science-IiDocument5 pagesManufacturing Science-Iiayansiddiqui7700No ratings yet

- 4024Document3 pages4024V V DEVADASNo ratings yet

- Automobile ComponentsDocument6 pagesAutomobile Componentsshincy ARNo ratings yet

- ME6402-Manufacturing Technology-IIDocument10 pagesME6402-Manufacturing Technology-IINIVAS S. SNo ratings yet

- Injection Mold Design Model Question Paper - Set-IDocument6 pagesInjection Mold Design Model Question Paper - Set-ISam JhonsonNo ratings yet

- Mp21 MergedDocument13 pagesMp21 Mergedkuldeep thakorNo ratings yet

- 1616403439362-Subjective Questions On Manufacturing Process MET-03Document4 pages1616403439362-Subjective Questions On Manufacturing Process MET-03Dashmeet SinghNo ratings yet

- MT Question Bank PDFDocument9 pagesMT Question Bank PDFHarish RajaNo ratings yet

- Mt-Ii QBDocument10 pagesMt-Ii QBRavi ChandranNo ratings yet

- S4 Instrumentation Engineering: Module Cognitive Outcomes LevelDocument4 pagesS4 Instrumentation Engineering: Module Cognitive Outcomes Levelabhishekash502No ratings yet

- Bmm4243 (Mt2) - TutorialDocument3 pagesBmm4243 (Mt2) - TutorialNajip TalibinNo ratings yet

- Assignment 1Document1 pageAssignment 1Swastik PanchalNo ratings yet

- Production Technology SyllabusDocument9 pagesProduction Technology SyllabusPankaj SharmaNo ratings yet

- MT Assignment 1Document2 pagesMT Assignment 1Ashwini SinghNo ratings yet

- Fourth Semester Diploma Examination in Mechanical Engineering/TechnologyDocument2 pagesFourth Semester Diploma Examination in Mechanical Engineering/TechnologyV V DEVADASNo ratings yet

- MT 2 Terminal Test 1Document1 pageMT 2 Terminal Test 1Rajchandar KannanNo ratings yet

- AssignmentDocument3 pagesAssignmentAviral Sansi0% (1)

- Iae I QB PDFDocument2 pagesIae I QB PDFrubberNo ratings yet

- Metal FormingDocument6 pagesMetal FormingHarish Kumar SNo ratings yet

- Tutorial SheetDocument21 pagesTutorial Sheetankita awasthiNo ratings yet

- Answer Any Five Questions From Section-BDocument1 pageAnswer Any Five Questions From Section-BCharyNo ratings yet

- MCMT AssignmentsDocument2 pagesMCMT AssignmentsSamNihalNo ratings yet

- Code No: 35033Document5 pagesCode No: 35033SRINIVASA RAO GANTANo ratings yet

- JM303 End of Chapter 3 Solenoid Power Diode TransistorDocument1 pageJM303 End of Chapter 3 Solenoid Power Diode Transistorshobanraj1995No ratings yet

- Assignment Unit IV BMEDocument2 pagesAssignment Unit IV BMERoop LalNo ratings yet

- Automobile Engg A23 R21 4023Document2 pagesAutomobile Engg A23 R21 4023muhammadsinane1No ratings yet

- Machine Tools and Digital MFG UQSDocument3 pagesMachine Tools and Digital MFG UQSAnonymous f1UCK4No ratings yet

- Machine Tools Assignments 1 N 2Document3 pagesMachine Tools Assignments 1 N 2Sunkeswaram Deva PrasadNo ratings yet

- Design of Jigs, Fixtures and Press Tools - Department of Mechanical EngineeringDocument8 pagesDesign of Jigs, Fixtures and Press Tools - Department of Mechanical EngineeringLoga Nath100% (2)

- Model Question Paper Wood Products Ii: Module Outcome Cognitive LevelDocument2 pagesModel Question Paper Wood Products Ii: Module Outcome Cognitive LevelSam JhonsonNo ratings yet

- Silibus Baru JJ104Document12 pagesSilibus Baru JJ104limakupang_matNo ratings yet

- Assignment-I-MC &MT PDFDocument2 pagesAssignment-I-MC &MT PDFChadaram JagadishNo ratings yet

- Tools Design Question Paper 2021 CVSRDocument2 pagesTools Design Question Paper 2021 CVSRRadha Krishna100% (1)

- Manufacturing Engineering Guide BookDocument2 pagesManufacturing Engineering Guide BookGiridharan SharmaNo ratings yet

- Semester End Supplementary Examinations (Ar19), Feb - 2023Document1 pageSemester End Supplementary Examinations (Ar19), Feb - 2023Jury.rahulNo ratings yet

- Course ObjectivesDocument5 pagesCourse Objectives75Ujwal TDNo ratings yet

- Ii Mech Mt-IiDocument3 pagesIi Mech Mt-IiRameez FaroukNo ratings yet

- Qid: Model: Module Cognitive Outcome LevelDocument2 pagesQid: Model: Module Cognitive Outcome LevelNithinNo ratings yet

- Pillared Metal-Organic Frameworks: Properties and ApplicationsFrom EverandPillared Metal-Organic Frameworks: Properties and ApplicationsNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- T Series Take Apart Thermostatic Expansion Valves Catalog en Us 1569686Document5 pagesT Series Take Apart Thermostatic Expansion Valves Catalog en Us 1569686Jak JoniNo ratings yet

- 30x173mm Ammunition Suite MK44 Cannon Version 3 PDFDocument2 pages30x173mm Ammunition Suite MK44 Cannon Version 3 PDFcacak283No ratings yet

- Data Spare Part DatangDocument7 pagesData Spare Part DatangThaufan WijayaNo ratings yet

- Argos FD 700Document20 pagesArgos FD 700Tony Humberto Gutierrez100% (1)

- Scroll Saw 40-100 16 1246Document8 pagesScroll Saw 40-100 16 1246Theodor EikeNo ratings yet

- Climate Control OverviewDocument35 pagesClimate Control OverviewZM OhnNo ratings yet

- Chuck SPANNTOP Nova Pull BackDocument8 pagesChuck SPANNTOP Nova Pull BackhungNo ratings yet

- SAE-J1926 Port Reference DimensionsDocument1 pageSAE-J1926 Port Reference DimensionsSamuel RochetteNo ratings yet

- DME-MEC 604 - 6th Sem 2nd Internal QuestionDocument2 pagesDME-MEC 604 - 6th Sem 2nd Internal QuestionMithilesh kumarNo ratings yet

- Liangchew CatalogueDocument48 pagesLiangchew CatalogueKyaw Naing AungNo ratings yet

- Design and Fabrication of Self Centering Vice Ppt-1Document36 pagesDesign and Fabrication of Self Centering Vice Ppt-1KarthickNo ratings yet

- ManBay-CP20 - GenCon-Bid Form PL & FRDocument40 pagesManBay-CP20 - GenCon-Bid Form PL & FRCamille Mojares BoñonNo ratings yet

- Upright Flying Lead Orientation Tool: ROV ToolsDocument2 pagesUpright Flying Lead Orientation Tool: ROV Toolsdodo salahNo ratings yet

- JACMOR - Scetional Screw Flights Form 123-1Document1 pageJACMOR - Scetional Screw Flights Form 123-1022freeNo ratings yet

- Engine Assembly-Repair ProcedurDocument24 pagesEngine Assembly-Repair Procedurfebri yuliantoNo ratings yet

- Daftar Pekerjaan HidrantDocument1 pageDaftar Pekerjaan Hidrantjabriklaksono489No ratings yet

- 2021 Holi Retail Offer Document Ver 1.03Document25 pages2021 Holi Retail Offer Document Ver 1.03Sri Harsha KNo ratings yet

- Sleipner E400 Part List 175 001Document27 pagesSleipner E400 Part List 175 001Susilo purwanggi100% (1)

- PPM Check List: Floor: Wing: Room No: DateDocument3 pagesPPM Check List: Floor: Wing: Room No: DateMdrahaman MithuNo ratings yet

- Advanced Tool SharpeningDocument10 pagesAdvanced Tool SharpeningjenrocoNo ratings yet

- Parts Book PC300-8Document112 pagesParts Book PC300-8varo100% (1)

- Sandvik Versatile Tools 2018Document153 pagesSandvik Versatile Tools 2018jaajaNo ratings yet

- W3I0003XQ M240B Medium MachinegunDocument47 pagesW3I0003XQ M240B Medium Machinegunakms1982No ratings yet

- Refrigerator: Service ManualDocument99 pagesRefrigerator: Service ManualUbaldo BritoNo ratings yet

- LIFESTYLE INTERNATIONAL Private Limited - My Colourful Kitchen 2021-22Document49 pagesLIFESTYLE INTERNATIONAL Private Limited - My Colourful Kitchen 2021-22chaitanya.maisaNo ratings yet

- Brake System InspectionDocument6 pagesBrake System Inspectioncarlos pilcoNo ratings yet

- SKVJ-M Replacing Preheater Components: 1.1 Replacing The Controller (With Display) of The Control BoxDocument3 pagesSKVJ-M Replacing Preheater Components: 1.1 Replacing The Controller (With Display) of The Control Box徐玉坤No ratings yet