Professional Documents

Culture Documents

Safety Manual Full Set

Safety Manual Full Set

Uploaded by

Hariharan MuthukrishananCopyright:

Available Formats

You might also like

- Construction Safety Plan (Template)Document35 pagesConstruction Safety Plan (Template)kanakarao1100% (11)

- BS 6187 Code of Practice For DemolitionDocument58 pagesBS 6187 Code of Practice For Demolitionscg1998100% (4)

- The Boy Who Loved Ice Cream - by Olive SeniorDocument31 pagesThe Boy Who Loved Ice Cream - by Olive Seniorshan69% (16)

- TNB Occupational Safety & Health RequirementDocument48 pagesTNB Occupational Safety & Health RequirementSemifallen95% (19)

- ADH Municipality - Health & Safety Codes of Practice For Construction Projects - Part 1Document116 pagesADH Municipality - Health & Safety Codes of Practice For Construction Projects - Part 1rickymma85% (13)

- ADH Municipality Health Safety Codes of Practice For Construction Projects Part 1 PDFDocument116 pagesADH Municipality Health Safety Codes of Practice For Construction Projects Part 1 PDFjohnknight000100% (1)

- Dubai Construction Safety RegulationsDocument38 pagesDubai Construction Safety Regulationsfannounm100% (4)

- 7.1 Project Health & Safety PlanDocument31 pages7.1 Project Health & Safety PlanGerrit Van HeerdenNo ratings yet

- The National Building Code (Nigeria)Document11 pagesThe National Building Code (Nigeria)Mauton Whenu60% (5)

- Safety ManualDocument180 pagesSafety ManualVijay Jamadar100% (1)

- COP Confined Space Eng 2024Document60 pagesCOP Confined Space Eng 2024Tak Hung CHENGNo ratings yet

- Contractor Safety Handbook: Version No: 1.1Document28 pagesContractor Safety Handbook: Version No: 1.1keroro18No ratings yet

- 37.2 Agreement Between Employer and MandatoryDocument15 pages37.2 Agreement Between Employer and MandatorykkNo ratings yet

- P ACYi Goy 9 IHt RX KDBB XPDocument50 pagesP ACYi Goy 9 IHt RX KDBB XPahmed ibNo ratings yet

- Confined SpaceDocument45 pagesConfined SpaceDeepu Ravikumar100% (1)

- 1.) Client OH&S Specification (Please Only Use The Relevant Sections)Document78 pages1.) Client OH&S Specification (Please Only Use The Relevant Sections)Fadley ValleyNo ratings yet

- Guidelines For Public Safety & Health at Construction SiteDocument32 pagesGuidelines For Public Safety & Health at Construction SitePhaik Sim CheahNo ratings yet

- GL Construction Site BiDocument32 pagesGL Construction Site BiwanazuadiNo ratings yet

- Project Report - Group 6 - OshDocument26 pagesProject Report - Group 6 - OshsyahirabdullahNo ratings yet

- BIS Standard For IlluminationDocument14 pagesBIS Standard For IlluminationbhaskarNo ratings yet

- MS # 00 Method Statement For Repair of Concrete Surface With Cement GroutDocument9 pagesMS # 00 Method Statement For Repair of Concrete Surface With Cement GroutMGNo ratings yet

- Part 2 - EnglishDocument491 pagesPart 2 - EnglishDave Labberton100% (1)

- She Plans and ProceduresDocument14 pagesShe Plans and ProceduresPrince EugoNo ratings yet

- Chemical FactoriesDocument17 pagesChemical FactoriesFinny Jose KNo ratings yet

- Hse-Site Procedure ManualDocument21 pagesHse-Site Procedure ManualAbrar AhmedNo ratings yet

- Method Statement - Hazardous Substances Management and ControlDocument4 pagesMethod Statement - Hazardous Substances Management and ControlaceNo ratings yet

- OutlineDocument11 pagesOutlineKadita RogerNo ratings yet

- HSE Rules For ContractorsDocument39 pagesHSE Rules For ContractorsGihasNo ratings yet

- Site HSE Plan HSE ProcedureDocument56 pagesSite HSE Plan HSE ProcedureMaster22No ratings yet

- SODIC - Safety Plan v.01Document64 pagesSODIC - Safety Plan v.01مصطفىمحمدNo ratings yet

- Specifications and Scope of WorksDocument21 pagesSpecifications and Scope of Works21-06116No ratings yet

- METHOD STATEMENT FOR DemolitionDocument4 pagesMETHOD STATEMENT FOR Demolitionsarifullah khanNo ratings yet

- Construction SafetyDocument61 pagesConstruction SafetyFazli Alias0% (1)

- Indonesia Safety - 1 PDFDocument72 pagesIndonesia Safety - 1 PDFMatt AgonyaNo ratings yet

- Code of Practice ExcavationDocument35 pagesCode of Practice Excavationsrobinson123No ratings yet

- Final Safety ProgramDocument6 pagesFinal Safety ProgramGlaizel MorcillaNo ratings yet

- DO No. 13Document23 pagesDO No. 13Jerome GarganeraNo ratings yet

- MSOSH-Electrical Safety-Day 1 Slide MaterialDocument99 pagesMSOSH-Electrical Safety-Day 1 Slide MaterialMaizatul Akmar ManshorNo ratings yet

- Code DemolitionDocument58 pagesCode DemolitionMary John Paul BetontaNo ratings yet

- Health & Safety PlanDocument15 pagesHealth & Safety PlansimoneNo ratings yet

- Factories Works Act - General RegulationsDocument12 pagesFactories Works Act - General Regulationschrissy zee1100% (2)

- Contractor Safety ManualDocument56 pagesContractor Safety ManualGNo ratings yet

- Dish - Schedule of ChemicalsDocument15 pagesDish - Schedule of ChemicalsHimanshu PanchalNo ratings yet

- Method StatementDocument30 pagesMethod StatementSathish KumarNo ratings yet

- Construction Site Safety HandbookDocument217 pagesConstruction Site Safety Handbookjoshappy246No ratings yet

- Construction Safety Manual-EditDocument65 pagesConstruction Safety Manual-Editdreamboy87100% (3)

- Excavation WorkDocument43 pagesExcavation WorkJK AlmaNo ratings yet

- Regulatory Control of Exposure Due to Radionuclides in Building Materials and Construction MaterialsFrom EverandRegulatory Control of Exposure Due to Radionuclides in Building Materials and Construction MaterialsNo ratings yet

- Computer Security Aspects of Design for Instrumentation and Control Systems at Nuclear Power PlantsFrom EverandComputer Security Aspects of Design for Instrumentation and Control Systems at Nuclear Power PlantsNo ratings yet

- The Nuclear Safety and Nuclear Security Interface: Approaches and National ExperiencesFrom EverandThe Nuclear Safety and Nuclear Security Interface: Approaches and National ExperiencesNo ratings yet

- Licensing Process for the Construction, Commissioning and Operation of Nuclear Power PlantsFrom EverandLicensing Process for the Construction, Commissioning and Operation of Nuclear Power PlantsNo ratings yet

- L24 Workplace Health, Safety And Welfare: Workplace (Health, Safety and Welfare) Regulations 1992. Approved Code of Practice and Guidance, L24From EverandL24 Workplace Health, Safety And Welfare: Workplace (Health, Safety and Welfare) Regulations 1992. Approved Code of Practice and Guidance, L24No ratings yet

- Challenges and Approaches for Selecting, Assessing and Qualifying Commercial Industrial Digital Instrumentation and Control Equipment for Use in Nuclear Power Plant ApplicationsFrom EverandChallenges and Approaches for Selecting, Assessing and Qualifying Commercial Industrial Digital Instrumentation and Control Equipment for Use in Nuclear Power Plant ApplicationsNo ratings yet

- Member States’ Experiences and Insights from Maintaining Safety, Security and Reliable Nuclear Industry Operations During the Covid-19 PandemicFrom EverandMember States’ Experiences and Insights from Maintaining Safety, Security and Reliable Nuclear Industry Operations During the Covid-19 PandemicNo ratings yet

- Methodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsFrom EverandMethodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsNo ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- Applicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsFrom EverandApplicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsNo ratings yet

- Regulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsFrom EverandRegulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsNo ratings yet

- Virtual Reality, Artificial Intelligence and Specialized Logistics in HealthcareFrom EverandVirtual Reality, Artificial Intelligence and Specialized Logistics in HealthcareNo ratings yet

- Construction Waste Management Plan Rev000Document10 pagesConstruction Waste Management Plan Rev000Hariharan MuthukrishananNo ratings yet

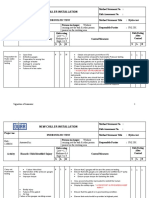

- De-Shuttering PermitDocument1 pageDe-Shuttering PermitHariharan Muthukrishanan100% (1)

- Hazardous SubstanceDocument2 pagesHazardous SubstanceHariharan MuthukrishananNo ratings yet

- Construction WorkersDocument103 pagesConstruction WorkersHariharan MuthukrishananNo ratings yet

- First Aid Log RegisterDocument2 pagesFirst Aid Log RegisterHariharan MuthukrishananNo ratings yet

- Night Work PermitDocument1 pageNight Work PermitHariharan MuthukrishananNo ratings yet

- Rebar Coupler CatalogDocument4 pagesRebar Coupler CatalogHariharan MuthukrishananNo ratings yet

- NAPC - Project HSE PlanDocument55 pagesNAPC - Project HSE PlanHariharan MuthukrishananNo ratings yet

- Dos & Don'ts at WorkDocument28 pagesDos & Don'ts at WorkHariharan MuthukrishananNo ratings yet

- Amendments To The Tamil Nadu Factories Rules. .. .28-12-22Document2 pagesAmendments To The Tamil Nadu Factories Rules. .. .28-12-22Hariharan MuthukrishananNo ratings yet

- Pamphlet On Classification of Fires & Types of Fire ExtinguishersDocument12 pagesPamphlet On Classification of Fires & Types of Fire ExtinguishersHariharan MuthukrishananNo ratings yet

- Spill Prevention and Response Plan Rev000Document9 pagesSpill Prevention and Response Plan Rev000Hariharan MuthukrishananNo ratings yet

- Permit To WorkDocument13 pagesPermit To WorkHariharan MuthukrishananNo ratings yet

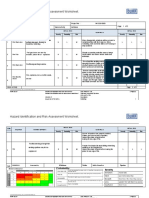

- Hazard Identification and Risk Assessment UnloadingDocument2 pagesHazard Identification and Risk Assessment UnloadingHariharan Muthukrishanan0% (1)

- Cobwebs COVID 19 Workplace Risk AssessmentDocument4 pagesCobwebs COVID 19 Workplace Risk AssessmentHariharan MuthukrishananNo ratings yet

- Hazard Identification and Risk Assessment LiftingDocument2 pagesHazard Identification and Risk Assessment LiftingHariharan Muthukrishanan100% (1)

- Hazard Identification and Risk Assessment Hot WorkDocument2 pagesHazard Identification and Risk Assessment Hot WorkHariharan MuthukrishananNo ratings yet

- Risk Cooling TowerDocument4 pagesRisk Cooling TowerHariharan MuthukrishananNo ratings yet

- DSIN 25.4.4 ScaffoldingDocument3 pagesDSIN 25.4.4 ScaffoldingHariharan MuthukrishananNo ratings yet

- Cleaners and Ground Staff Risk Assesment 3Document52 pagesCleaners and Ground Staff Risk Assesment 3Hariharan MuthukrishananNo ratings yet

- Drug and Alcohol Awareness HSE Presentation HSE FormatsDocument55 pagesDrug and Alcohol Awareness HSE Presentation HSE FormatsHariharan MuthukrishananNo ratings yet

- DSIN 25.4.1 General H&SDocument2 pagesDSIN 25.4.1 General H&SHariharan MuthukrishananNo ratings yet

- Risk Hydro TestDocument4 pagesRisk Hydro TestHariharan MuthukrishananNo ratings yet

- Hazard Identification and Risk Assessment PaintingDocument2 pagesHazard Identification and Risk Assessment PaintingHariharan MuthukrishananNo ratings yet

- Hazard Identification and Risk Assessment Hot & Cool Box InstallationDocument3 pagesHazard Identification and Risk Assessment Hot & Cool Box InstallationHariharan MuthukrishananNo ratings yet

- Fular TricotatDocument3 pagesFular TricotatLisa SukyNo ratings yet

- Textile ActivismDocument23 pagesTextile ActivismJulia UNo ratings yet

- BendyDocument11 pagesBendyRocio RivoltaNo ratings yet

- 75TH NGF Exhibitors List of Kids Wear 08.07.2022Document9 pages75TH NGF Exhibitors List of Kids Wear 08.07.2022Harsh PunmiyaNo ratings yet

- Kick Me - Adventures in Adolescence 2Document8 pagesKick Me - Adventures in Adolescence 2Jared DoschNo ratings yet

- Final 3Document96 pagesFinal 3Triet TruongNo ratings yet

- 1 - Belly of The BeastDocument44 pages1 - Belly of The BeastAlejoNo ratings yet

- Saving MoneyDocument6 pagesSaving MoneySechan HunnieNo ratings yet

- Zipper Pull Strength 80 N: Test Results Buyer RequirementDocument1 pageZipper Pull Strength 80 N: Test Results Buyer Requirementyogesh123789No ratings yet

- Class X - FF 7.1 A Baker From Goa - Notes - DoneDocument3 pagesClass X - FF 7.1 A Baker From Goa - Notes - DoneLEARN JAPANESE WITH MADAN JNo ratings yet

- Understanding The Self Module 2 Lesson 2Document4 pagesUnderstanding The Self Module 2 Lesson 2Marites MancerasNo ratings yet

- Traveler Amer - Elementary A1.2 - Test 7Document4 pagesTraveler Amer - Elementary A1.2 - Test 7Luis SoteloNo ratings yet

- Supply Chain Management and Logistics CollabortionDocument21 pagesSupply Chain Management and Logistics CollabortionSirajus SalekinNo ratings yet

- Sunshine Crop Top: Free Pattern by @crochet.4.daysDocument5 pagesSunshine Crop Top: Free Pattern by @crochet.4.daysTato ColoresNo ratings yet

- Instant Download Test Bank For International Management Culture Strategy and Behavior 11th Edition Fred Luthans Jonathan Doh PDF EbookDocument32 pagesInstant Download Test Bank For International Management Culture Strategy and Behavior 11th Edition Fred Luthans Jonathan Doh PDF Ebooksaginateejoo092udh100% (17)

- Radical Self-Love Companion: by Gala DarlingDocument13 pagesRadical Self-Love Companion: by Gala DarlingKateřina SlezákováNo ratings yet

- Bookmark Crazy GiraffeDocument6 pagesBookmark Crazy GiraffeYasmin Thayse100% (1)

- The ChaosDocument5 pagesThe ChaosMuhammad Arif HassanNo ratings yet

- Reported Speech PDFDocument16 pagesReported Speech PDFLORAINE CAUSADO BARONNo ratings yet

- LESSON-EXEMPLAR-in-EPP-HE 6 CATHERINE CARONONGANDocument11 pagesLESSON-EXEMPLAR-in-EPP-HE 6 CATHERINE CARONONGANVALERIE Y. DIZONNo ratings yet

- B2 Respuestas Ideales Speaking: B2-OTE 2 Test 2 Answer KeyDocument2 pagesB2 Respuestas Ideales Speaking: B2-OTE 2 Test 2 Answer KeyAndrea Martínez MoralesNo ratings yet

- College of St. John - Roxas: Self-Learning Module and Activity SheetsDocument6 pagesCollege of St. John - Roxas: Self-Learning Module and Activity SheetsJANEL BRIÑOSANo ratings yet

- Script Controllers Tokosepatu - PHPDocument6 pagesScript Controllers Tokosepatu - PHPIndah Putri SuryaningsihNo ratings yet

- Bo de Thi Hoc Ki 1 Mon Anh 9Document30 pagesBo de Thi Hoc Ki 1 Mon Anh 9Thuỷ Trần HươngNo ratings yet

- Life in The Universe 4Th Edition Bennett Test Bank PDFDocument26 pagesLife in The Universe 4Th Edition Bennett Test Bank PDFirma.smith986100% (23)

- Diapo Présentation D'une MarqueDocument5 pagesDiapo Présentation D'une MarqueValentin PsGNo ratings yet

- Mangyan Research 2Document22 pagesMangyan Research 2Ysarra SandovalNo ratings yet

- Healy 2015Document23 pagesHealy 2015Asilatul Hanaa AbdullahNo ratings yet

- XLS295 XLS EngDocument9 pagesXLS295 XLS EngiaiqvNo ratings yet

Safety Manual Full Set

Safety Manual Full Set

Uploaded by

Hariharan MuthukrishananOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety Manual Full Set

Safety Manual Full Set

Uploaded by

Hariharan MuthukrishananCopyright:

Available Formats

SAFETY MANUAL

DRA AADITHYA

DRA Aadithya,

1st Floor, Khivraj Complex II,

No. 480, Anna Salai, Nandanam,

CHENNAI – 600 035.

Ph. No. +91 44 4560 7800

Fax +91 44 2434 1686

Mail id : info@drahomes.in

Web site: www.drahomes.in

SAFETY MANUAL

SAFETY MANUAL PAGE 1

DRA AADITHYA

INDEX

1.0 INTRODUCTION

2.0 GENERAL SITE RULES

2.1 SCOPE

2.2 GENERAL RESPONSIBILITIES

2.3 PERSONAL PROTECTIVE EQUIPMENT

2.4 DRESS REQUIREMENTS

2.5 FALL PROTECTION

2.6 VISITORS

2.7 BARRICADES

2.8 SIGNS AND TAGS

2.9 SCAFFOLDS & PLATFORMS

2.10 LADDERS

2.11 FLOOR, ROOF, WALL AND PLATFORM OPENINGS

2.12 CRANES AND MATERIAL HANDLING / LIFTING APPLIANCES

AND GEAR.

2.13 HAZARDOUS MATERIALS

2.14 FIRE PREVENTION AND PROTECTION

2.15 WELDING AND CUTTING

2.16 CONFINED SPACE PROCEDURES

2.17 “DO NOT OPERATE” TAG PROCEDURE

2.18 LOCK-OUT PROCEDURE

2.19 HAND, AIR AND ELECTRICAL TOOLS

2.20 POWDER-ACTUATED TOOLS

2.21 RADIOGRAPHY

2.22 RADIOS AND ELECTRONIC EQUIPMENT

2.23 HOUSE KEEPING

2.24 HEALTH AND HYGIENE

2.25 PHOTOGRAPHY EQUIPMENT

2.26 SMOKING REGULATIONS

2.27 EMPLOYEE SAFETY MEETINGS

2.28 MEDICAL FACILITIES AND STATUTORY REQUIREMENTS

SAFETY MANUAL PAGE 2

DRA AADITHYA

"IT IS OF PRIME IMPORTANCE THAT ALL INCIDENTS THAT

COULD RESULT IN INJURY OR ILLNESS TO THE EMPLOYEES OF DRA

AADITHYA, SUBCONTRACTOR AND CLIENT ARE PREVENTED.

DRA AADITHYA INTENDS TO FURNISH ITS EMPLOYEES WITH A PLACE OF

WORK WHERE RECOGNISED SAFETY AND HEALTH HAZARDS WILL BE

ELIMINATED BY ADOPTING AND FOLLOWING SAFE PROCEDURES AND

PRACTICES. EMPLOYEES WILL BE INSTRUCTED IN SAFE WORK PRACTICES

PRIOR TO EACH WORK OPERATION AND A TEAM OF PROFESSIONALLY

QUALIFIED ENGINEERS WILL INSPECT THE WORK SITE AT PERIODIC

INTERVALS AND REPORT THEIR FINDINGS TO THE RESIDENT GENERAL

MANAGER AND THE HEAD OF THE CONSTRUCTION DEPARTMENT.

THE GOAL OF DRA AADITHYA IS TO INITIATE NECESSARY STEPS DURING

CONSTRUCTION, COMMISSIONING AND START-UP OPERATIONS TO PROTECT

ALL PERSONNEL WORKING ON OR NEAR THE PLANT CONSTRUCTION

COMPLEX FROM HARM. THIS IS INTENDED TO BE ACCOMPLISHED BY

CREATING AWARENESS PROGRAMMES AND ACTIVITIES WHICH LEAD TO

THE UNDERSTANDING THAT ALL OR NEARLY ALL ACCIDENTS ARE

PREVENTABLE."

SAFETY MANUAL PAGE 3

DRA AADITHYA

1.0 INTRODUCTION

1.1 SCOPE AND APPLICABILITY

This document represents the Safety, Health and Environment management system that DRA

Aadithya intended to be put in place during the implementation stage of a project- at a

construction site.

Further, the document provides the plan that DRA Aadithya will adopt to ensure that all

requirements of the governing safety regulations and of the policy statement contained herein is

strictly maintained and to ensure the establishment and continued existence of a healthy

Workforce and of a safe working environment at all sites.

1.2 PURPOSE

The purpose of this document is to ensure that all persons concerned with the project carry out

the effective management of safety and health in all activities in order that people, plant and the

environment is not exposed to any undue hazards or risks. The field standards and procedures

have been developed to promote accident prevention.

1.3 ADMINISTRATION

The Resident General Manager / Project Manager, department heads and supervisory personnel

are responsible for the communication and enforcement of the Field Standards and Procedures.

1.4 REFERENCE DOCUMENTS

The main contractual reference documents are:

1.4.1 Indian Government laws including The Building and Other Construction Workers

(Regulation of Employment and Conditions of Service) Act, 1996 and Central Rules, 1998.

1.4.2 Owners site Safety Regulations.

2.0 GENERAL SITE RULES

2.1 SCOPE

This procedure identifies those safety rules that are applicable to all areas of the site and/or all

employees, subcontractors and visitors.

2.2 GENERAL RESPONSIBILITIES

2.2.1 During the course of work, each person who directs the activities of employees shall

monitor the work activities. The field standards and procedures shall be incorporated into the

planning and execution of work.

SAFETY MANUAL PAGE 4

DRA AADITHYA

Supervisors are responsible for correcting unsafe acts and conditions within their

area of responsibility and administering disciplinary action to employees who fail to follow the

prescribed procedures.

Each employee performing work must know and understand the safety and health requirements

that apply to the work they perform. Employees who receive assignments that are not understood

have an obligation to request additional information and further clarification before they

commence their work activities.

It is essential to take steps to comply with the statutory provisions prescribed under "The

Building and Other Construction Workers (Regulation of Employment and Conditions of

Service) Act, 1996 and "The Building and Other Construction Workers (Regulation of

Employment and Conditions of Service) Central Rules, 1998.

2.2.2 Incident Reporting:

Occurrences which result in injury or property damage or which have potential for injury or

property damage, shall be promptly reported to supervision and the Construction Head Office

and a written report completed. In accordance with Rule 210 [on "Reporting of Accidents"] of

"The Building and Other Construction Workers (Regulation of Employment and Conditions of

Service) Central Rules, 1998, it is a statutory requirement to report accidents.

As per this Rule 210:

"(1) Notice of any accident on the construction site which either -

(a) cause loss of life; or

(b) disables a building worker from working for a period of 48 (forty eight)

hours or more, immediately following the accident, shall forthwith be sent by telegram,

telephone, fax or similar other means including special messenger, within four hours in case of

fatal accidents and seventy-two hours, in case of other accidents involving building worker, to :-

(i) the Regional Labour Commissioner (Central), having jurisdiction in the area in which the

establishment in which such accident or dangerous occurrence took place, is located. Such

Regional Labour Commissioner(Central) shall be the authority appointed under Section 39 of the

Act ;

(ii) Board with which the building worker involved in accident was registered as a beneficiary;

(iii) Director General; and

(iv) The next of kin or other relative of the building worker involved in the accident.

(2) Notice of any accident at a construction site of a building or other construction work which

(a) cause loss of life; or

(b) disables such building worker from work for more than ten days following the accident, shall

also be sent to –

SAFETY MANUAL PAGE 5

DRA AADITHYA

(i) the Officer in-charge of the nearest police station;

(ii) the District Magistrate, or if the District Magistrate, by order, so desires, to the Sub-

Divisional Magistrate.

(3) In the case of an accident falling under clause(b) of sub-rule(1) or clause(b) of sub-rule(2),

the injured building worker shall be given first-aid and immediately thereafter, be transferred to a

hospital or other place for medical treatment."

Further, as per item(4), " Where any accident causing disablement subsequently results in death

of a building worker, notice in writing of such death shall be communicated to the authorities as

mentioned in sub-rule(1) and sub-rule(2) within seventy-two hours of such death." and, as per

item(5), " The following classes of dangerous occurrences shall be reported to the Inspector

having jurisdiction, whether or not any death or disablement is caused to a building worker, in

the manner prescribed in sub-rule(1), namely:-

(a) collapse or failure of lifting appliances or hoist or conveyors or other similar equipment for

handling building or construction material or breakage or failure of rope, chain or loose gears;

overturning of cranes used in building or other construction work; falling of objects from height;

(b) collapse or subsidence of soil, any wall, floor, gallery, roof or any other part of any structure,

platform, staging, scaffolding or any means of access, including formwork;

(c) contract work; excavation, collapse of transmission;

(d) explosion of receiver or vessel used for storage, at a pressure greater than atmospheric

pressure, of any gas or gases or any liquid or solid used as building material;

(e) fire and explosion causing damage to any place on construction site where building workers

are employed;

(f) spillage or leakage of hazardous substances and damage to their container;

(g) collapse, capsizing, toppling or collision of transport equipment;

(h) leakage or release of harmful toxic gases at the construction site." Further, as per item (6) of

Rule 210, " In case of failure of a lifting appliance, loose gear, hoist or building and other

construction work, machinery and transport equipment at a construction site of a building or

other construction work, such appliances, gear, hoist, machinery or equipment and the site of

such occurrence shall, as far as practicable, be kept undisturbed until inspected by the inspector

having jurisdiction." and as per item (7), "Every notice given under sub-rule(2) or sub-rule(4)

shall be followed by a written report to the Inspector, authority under Section-39 of the Act, the

Board and the Director General in Form XIV under

proper acknowledgement."

(i) [Copy of Form XIV is enclosed as Enclosure-1]

SAFETY MANUAL PAGE 6

DRA AADITHYA

2.2.3 Vehicle Operation: Licensed and authorized drivers will operate motor vehicles. All

(ii) posted speed limits and other traffic signs will be strictly observed. Where weather or

other conditions dictate, additional precautions must be taken.

2.2.4 Seat Belts: When seat belts are provided in automobiles, trucks, and equipment, they shall

be worn. This requirement also applies to off-site travel on company business.

2.2.5 "Horse play", fighting, gambling, possession of firearms, possession or use of alcohol or

unauthorized drugs while on this site may result in being terminated. Jewellery: The wearing of

rings, watches, and bracelets is prohibited, except in office areas.

2.3 PERSONAL PROTECTIVE EQUIPMENT

This section establishes the minimum requirements for personal protective equipment.

Only equipment complying with the standards prescribed by the Bureau of Indian

Standards and having the ISI mark shall be used. Equipment that has been altered in anyway

shall not be worn on the Project. The wearing of protective equipment and/or clothing in

restricted areas of client Facility shall be in conformance with client standards and statutory

requirements.

2.3.1 The wearing of head protection at the project site is mandatory. Hard hats shall meet the

specifications of IS- 2925 published by the Bureau of Indian Standards. Rule 46 of "The

Building and Other Construction Workers (Regulation of Employment and Conditions of

Service) Central Rules, 1998", deals with the subject of "Head Protection and other

protective apparel." As per item(1) of Rule 46, "Every building worker required to pass

through or work within the areas at building or other construction work where there is hazard

of his being struck by falling objects or materials shall be provided by the employer with

Safety Helmets of type and tested in accordance with national standards." Further, as per

item(2), "Every building worker required to work in water or in wet concrete or in other

similar work at a building or other construction work, shall be provided with suitable water-

proof boots by the employer" and as per item(3), "Every building worker required to work in

rain or in similar wet condition at building or other construction work, shall be provided with

water-proof coat with hat by the employer." As per item(4) of Rule 46, "Every building

worker required to use or handle alkalies, acid or other similar corrosive substances at a

building or other construction work shall be provided with appropriate protective equipment

by an employer, in accordance with the accordance with the national standards." and, as per

item(5), "Every building worker engaged in handling sharp objects or materials at a building

or other construction work which may cause hand injury, shall be provided with suitable

hand-gloves by the employer, in accordance with the national standards." Soft caps (Sock

hoods) used for welding or cutting shall be approved by the Resident Construction Manager /

Resident Site Engineer. All personnel on the project are advised to have their company logo

and name displayed prominently on their hard hat. The name shall be applied above the brim

of the hat using block letters.

SAFETY MANUAL PAGE 7

DRA AADITHYA

Hard hats are required at all times while inside the gate with following exceptions:

- Vehicle and Equipment Operators Inside Enclosed Cabs.

- Administration Building (Office Work).

- Lunch and Break periods provided no work is in progress In the immediate

area around the place where the people are having their lunch. Hard hats shall not be altered in

any way, and must be worn with brim to the front.

2.3.2 In cases where employees perform work in restricted/ confined areas of the operations

facility ,where exposure to chemicals is likely, chemical goggles, face shield, and other

protective equipment are required to be worn as defined by client procedures. During grinding

operations, full-face shields shall be worn in addition to required protective eyewear. Welders

will wear appropriate eye protection while welding.

Rule 45 of "The Building and Other Construction Workers (Regulation of Employment and

Conditions of Service) Central Rules, 1998" prescribes the requirements on "Eye Protection". As

per Rule 45, "Suitable personal protective equipment for the protection of eyes shall be provided

by an employer and used by the building worker engaged in operations like welding, cutting,

chipping, grinding or similar operations which may cause hazard to his eyes at a building or

other construction work." Any employee at the construction site shall not wear contact lenses.

2.3.3 Employees shall wear respiratory protection devices of the approved type when

exposed to hazardous concentrations of toxic or noxious dust, fumes, mists or gases

2.3.4 Approved hearing protection devices shall be made available and such devices

shall be worn by all employees exposed to noise levels above 90 decibel, and where

posted within the Operations Facility Area or Project perimeter.

2.3.5 The Resident Construction Manager is responsible for establishing areas under

control of the Construction Group where hearing protection may be required to be worn.

Employees in the locations identified below shall use hearing protection:

- Designated plant areas.

- Operating or working near chipping hammers.

- Operating or working near power saws cutting metal, concrete or other hard materials.

- Grinding.

2.3.5 Safety shoes are required in the field locations where construction work is in progress.

All personnel on the Project are required to wear construction type footwear. As a

minimum, Project personnel are required to wear approved steel toe work shoes or boots

made of leather material which is commonly referred to as "safety shoes". Shoes made of

synthetic material, open toe shoes, high heel shoes, sandals, hush puppies, tennis shoes,

jogging or athletic shoes, and other such footwear is prohibited on the Project. This rule also

applies to personnel who perform work within the confines of an office and will from time

to time leave their work area and visit the site locations where field activities are taking

place. Rule 54 of "The Building and Other Construction Workers (Regulation of

Employment and Conditions of Service) Central Rules, 1998" deals with the subject of "use

SAFETY MANUAL PAGE 8

DRA AADITHYA

of safety helmets and shoes." According to Rule 54, "The employer shall ensure

that all persons who are performing any work or services at a building or other construction

work, wear safety shoes and helmets conforming to the

national standards."

2.3.6 Maintenance Of Personal Protective Equipment

Personal protective equipment that has been altered in any manner so as to reduce its

effectiveness shall be collected back and repaired or replaced with a new one.

2.4 DRESS REQUIREMENTS

2.4.1 Project personnel are required to wear clothing appropriate for the work being

performed.

2.4.2 Personnel shall wear ankle length pants. Shorts, skirts, dresses or other such

clothing is not allowed.

2.4.3 Full-length shirts with long sleeves and a collar are required to be worn. Knit

shirts, sleeveless shirts, sleeves rolled up onto the ball of the shoulder & other

such apparel or practices are prohibited. Shirts shall be worn tucked into

pants or trousers.

2.4.4 Persons working near moving machinery must wear clothing which cannot be

readily be caught by moving machinery.

2.4.5 In instances involving exposure to extreme heat, cold, chemicals or other such

hazards, protective clothing such as coveralls, chemical suits shall be worn in

accordance with the client safety & health standards and statutory requirements,

Indian Standards and codes of practice.

2.4.6 Clothing soaked with grease, paint, thinners, solvents or similar materials should

not be worn where exposed to a heat source.

2.4.7 The wearing of jewellery during work hours is prohibited. This includes watches,

bracelets, earrings and necklaces. Necklaces can be worn only if contained inside

of shirts. Earrings of the post type may be worn if they are not dangling and/or

hung below or completely cover the earlobe.

2.4.8 Hair that extends beyond the collar of the shirt must be contained under the hard

hat or with a hair net. Ponytails and braids are not permitted. Beards that extend

more than two (2) inches from the face shall be contained in a beard net.

SAFETY MANUAL PAGE 9

DRA AADITHYA

2.5 FALL PROTECTION

2.5.1 The use of fall protection equipment shall be in compliance with applicable

regulatory standards.

2.5.2 Persons who are performing work in unguarded areas and exposed to a potential

fall of two meters or more shall be provided with and utilise fall protection equipment.

2.5.3 In situations where a fall could result in impalement, fall protection equipment shall

be utilised regardless of the potential falling distance.

2.5.4 Vertical impaling objects such as rebar, shall have the ends capped with an article

such as a block of 2 inch and 4 inch piece of wood, rebar cap, or other item which

adequately covers the impaling end of the object.

2.5.5 Personal fall prevention equipment must be inspected daily prior to use by the user.

2.5.6 Safety Belts, Body harness assemblies, lanyards, and other personal equipment

shall be inspected bi-annually by a competent person designated by the Resident

Construction Manager.

2.5.7 Auxiliary fall protection equipment, such as static lines and perimeter guards shall

be utilised by personnel travelling from one location to another in elevated

positions.

2.5.8 Access ways, such as ladders, shall be provided for personnel who need to

perform work in elevated areas.

2.5.9 Persons who are noted to be not utilising fall protection equipment will be identified

and the appropriate supervisor or subcontractor will be notified. If a second

offence occurs, the person is subject to disciplinary action including termination, or

expulsion from the project site premises. A third offence requires immediate

termination or expulsion from the project site, and re-entry upon the project

premises will be precluded.

2.6 VISITORS

2.6.1 All visitors will be issued a hard hat prior to entering any construction work area

outside of office areas.

2.6.2 Persons escorting or allowing a visitor into the field are responsible to ensure that

the visitor is wearing the proper PPE and has received a safety orientation.

SAFETY MANUAL PAGE 10

DRA AADITHYA

2.7 BARRICADES

2.7.1 Supervisors are responsible for erecting and maintaining barricades that are

required for employee protection and establishing boundaries around equipment or

materials to protect them from potential damage.

2.7.2 Barricades must be kept at least two feet (2') from the edge of an open trench or

excavation.

2.7.3 Barricade tape shall be used for its intended purpose according to approved

methods. Upon installation, a tag must be affixed to the barricade indicating when

it was installed and by whom. Upon completion of the work being performed, the

Supervisor who originally installed the barricade must remove the barricade.

2.7.4 Unauthorised persons who enter red barricaded areas are subject to expulsion

from the project premises.

2.7.5 Yellow barricade tape shall be used in areas where caution is required.

2.7.6 Red barricades, signs, detours, & other traffic control systems must be in

conformance with Project site regulations and client requirements.

2.7.7 Areas where asbestos abatement or other remedial work is in process shall be

barricaded and entry shall be restricted to authorised personnel by the employer

responsible for performing the work.

2.8 SIGNS AND TAGS

2.8.1 Signs & tags shall be in conformance with regulations as to use, colours, posting,

wording, size & Safety & Health procedures, restrictions & requirements.

2.8.2 The Site Manager for the project is responsible for authorising the general posting

of signs on the project relative to warnings, precautions, notices and other

information pertinent to employees, and road access ways, and closures.

2.8.3 Signs shall be posted only upon the approval of a client representative and the Site

Manager.

2.8.4 Subcontractors are responsible for posting or displaying signs relative to their

scope of work. For example: Signs required at a compressed gas cylinder

storage area.

SAFETY MANUAL PAGE 11

DRA AADITHYA

2.9 SCAFFOLDS AND PLATFORMS

2.9.1 All scaffolding shall be erected in conformance with the relevant IS code viz. IS

4014. A competent person must inspect each scaffold.

2.9.2 All scaffolding shall be equipped with toe boards, mid-rails, top rails; and access

ladders.

2.9.3 Personnel who are conversant with and competent to perform this work shall erect

scaffolding.

2.9.4 Scaffolding shall be removed according to construction requirements and when

work has been completed.

2.9.5 Chapter XIX of "The Building and Other Construction Workers (Regulation of

Employment and Conditions of Service) Central Rules, 1998" deals with the

subject of "SCAFFOLD".

2.9.5.1 Rule No. 188 of Chapter XIX is titled "Scaffold construction". As per Rule

188, "The employer shall ensure at a construction site of a building or

other construction work that –

(a) every scaffold and every component thereof is of adequate construction, made of

sound material and free from defects and is safe for the purposes for which it is intended

for use;

(b) in case bamboo is used for scaffolding, such bamboo is of suitable quality, good

condition, free from protruding knots and stripped off to avoid any injury to building

workers during handling such bamboo;

(c) all metal scaffolds used in building or other construction work conform to the relevant

national standards."

2.9.5.2 Rule No. 189 of Chapter XIX is titled, "Supervision by a responsible person".

As per Rule 189, "The employer shall ensure at a construction site of a building or other

construction work that no scaffold is erected, added, altered or dismantled except under

the supervision of a responsible person for such erection, addition, alteration or

dismantling."

2.9.5.3 Rule No.190 of Chapter XIX is titled, "Maintenance". As per Rule 190,

"The employer shall ensure at a construction site of a building or other

construction work that -

(a) the scaffold used in building or other construction work is maintained in good repairs

and the measures are taken against its accidental displacement or any other hazard;

(b) no scaffold or part thereof is partly dismantled and allowed to remain in such a

condition unless -

(i) the stability or safety of the remaining portion of such scaffold has been ensured by a

responsible person for the safety of such scaffolds;

SAFETY MANUAL PAGE 12

DRA AADITHYA

(ii) in case the remaining part of such scaffold cannot be used by the building

workers, necessary warning notice written in Hindi and in a language understood by the

majority of the building workers that such scaffold is unfit for use, is displayed at the

place where such scaffold is erected. "

2.9.5.4 Rule No. 191 of Chapter XIX is on the subject of "Standards, ledger, putlogs".

As per Rule 191, "The employer shall ensure at a construction site of a building or other

construction work that, -

(a) standards of a scaffold are -

(i) plumb, where practicable;

(ii) fixed sufficiently close together to secure the stability of such scaffold having regard

to all the possible working situations and conditions for the intended use of such scaffold;

(iii) spaced, as close as practicable, to ensure safety and stability of such scaffold;

(b) adequate measures are taken to prevent displacement of a standard of a scaffold either

by providing sole plate or a base plate, as necessary;

(c) ledgers of metal scaffold are placed at vertical intervals with due regard to safety and

stability of such scaffold;

(d) bamboo ledgers are kept as nearly as possible and are placed and fastened to the

standards of a scaffold with due regard to the stability of such scaffold."

2.9.5.5. Rule No. 192 of Chapter XIX is on the subject of "Working platform."

As per Rule No. 192, "The employer shall ensure at a construction site of

a building or other construction work that -

(a) working platform is provided around the face or edge of a building adjoining at every

upper most permanent floor of such building under construction and at any level where

construction work of such building is carried out;

(b) a platform is designed to suit the number of building workers to be employed on each

bay of a scaffold work on such platform and the materials or articles and tools to be

carried with them in such bay;

(c) the safe working load and the number of building workers to be employed in each bay

of a scaffold are displayed for the information of all the building workers employed at

such construction site."

2.9.5.6. Rule No. 193 of Chapter XIX is on the subject of "Board, plank and

decking". As per Rule No. 193, "The employer shall ensure at a construction site of

a building or other construction work that -

(a) board, plank and decking used in the construction of a working platform is of

uniform size and strength and is capable of supporting the load and number of building

workers in accordance with the relevant national standards, keeping in view the safety of

such building workers;

(b) metal decking, which forms part of a working platform, is provided with non-skid

surface;

(c) no board or plank which forms the working platform is projected beyond its end

support unless it is effectively prevented from tripping or lifting;

(d) board, plank or decking is fastened and secured;

SAFETY MANUAL PAGE 13

DRA AADITHYA

(e) at any one time, not more than two working platforms per bay, are used to

support building workers or materials or articles at such bay;

(f) adequate measures are taken to prevent injury which may be caused by falling

material and objects by using safety nets or other suitable means;

(g) concrete, other debris or materials are not allowed to accumulate at any platform on a

scaffold;

(h) where a work is to be done at the end of a wall, working platform at such workplace

is faced or, wherever practicable, at least zero point sixty metres beyond the end of such

wall.

2.9.5.7 Rule No. 194 of Chapter XIX is on the subject of "Repair of damaged

scaffold". As per Rule No. 194, "The employer shall ensure at a construction site of

a building or other construction work that -

(a) no building worker is permitted to work on a scaffold which has been damaged or

weakened unless adequate safety measures have been taken to ensure the safety of such

building worker;

(b) necessary warning signs are displayed at such places where repairs of scaffold are

undertaken."

2.9.5.8. Rule No. 195 is on the subject of "Opening". As per Rule No. 195,

"The employer shall ensure at a construction site of a building or other construction work

that -

(a) there is no opening in any working platform except for allowing access to such

working platform;

(b) where opening on a platform is unavoidable, necessary measures for protection

against falling of objects of building workers from such platform are taken by providing

suitable safety nets, belts or any other similar means;

(c) access from one working platform to another platform on a scaffold, if required, is

provided with suitable and safe ladder for the use of building workers working on such

platforms."

2.9.5.9 Rule No. 196 is on the subject of "Guardrails". As per Rule No. 196, "The

employer shall ensure at a construction site of a building or other construction work that

every side of a working platform from which a person is liable to fall is provided with

suitable and safe guardrails and toe board of adequate strength to prevent fall of any

building worker, material or tools from such platform."

2.9.5.10 Rule No. 197 is on the subject of "Scaffold used by building workers of

different employers." As per Rule No. 197, "The employer shall ensure at a construction

site of a building or other construction work that, -

(a) where a scaffold or a part of a scaffold is used, which has previously been used by

another employer for his building workers, such scaffold or part thereof is used only after

its inspection and examination by a responsible person for its use

that such scaffold or part is safe and fit for such use;

SAFETY MANUAL PAGE 14

DRA AADITHYA

(b) if any rectification , alteration or modification in a scaffold or part thereof is needed to

suit its use, such rectification, alteration or modification is made in consultation with the

responsible person referred to in clause(a) before using such scaffold or part.”

2.9.5.11 Rule No. 198 is on the subject of “Protection against electric power line”.

As per Rule No. 198, “ The employer shall ensure at a construction site of a building or

other construction work that all necessary and practical measures for protection are taken

to prevent any building worker, working on a scaffold, from coming into contact with the

electric wires or dangerous equipment.”.

2.9.5.12 Rule No. 199 is on the subject of "Screening net and wire nets". As per

Rule No. 199, "The employer shall ensure at a construction site of a building or other

construction work that where a scaffold is erected in an area where the construction

activities may pose hazards to pedestrians or vehicular traffic nearby from the falling of

objects, wire nets or screening nets are used to envelope such scaffold."

2.9.5.13 Rule No. 200 is on the subject of "Tower Scaffold". As per Rule No. 200, "

The employer shall ensure at a construction site of a building or other construction work

that -

(a) the height of every tower scaffold used in building or other construction work is not

more than eight times, the lesser of a base dimension of such scaffold;

(b) a tower scaffold is lashed to a building or a fixed structure before being used by the

building workers;

(c) any tower scaffold which can be moved or castered is -

(i) constructed with due regard to the stability and, if necessary, adequately weighted at

the base;

(ii) used only on plain and even surface; and

(iii) has casters provided with positive locking devices to hold such scaffold in position;

(d) no building worker remains on board scaffold, tools, material when it is being shifted

from one position to another position."

2.9.5.14 Rule No. 201 is on the subject of "Gear for suspension of scaffold". As per

Rule No. 201, "The employer shall ensure at a construction site of a building or other

construction work, that, -

(a) chains, ropes or lifting gears used for suspension of a scaffold are of adequate

strength, made of sound material and suitable for the purposes of their use and are

maintained in good repairs;

(b) chains, wires, ropes or metal tubes used for the suspension of a scaffold are –

(i) properly and securely fastened to every anchorage point and to the scaffold ledgers of

other main supporting members used for the support of such scaffold; and

(ii) so positioned as to ensure stability of the scaffold."

2.9.5.15 Rule No. 202 is on the subject of "Trestle scaffold and cantilever scaffold".

As per Rule No. 202, "The employer shall ensure at a construction site of a building or

other construction work that –

SAFETY MANUAL PAGE 15

DRA AADITHYA

(a) no trestle scaffold is constructed with more than three tiers or if its working platform

is more than four point five metres above the ground or floor or other surface upon which

such scaffold is erected, such trestle scaffold is designed by a professional engineer and

has the approval of the Director General before being taken into use;

(b) no trestle scaffold is erected on a suspended scaffold;

(c) no cantilever or jib scaffold is used unless it is adequately supported, fixed and

anchored on opposite side of its support, has out-riggers of adequate length and where

necessary, sufficiently supported and braced to ensure safety and stability of such

scaffold;

(d) no working platform resting on bearers let in to a wall at one end and without other

support is used unless such bearers are of adequate strength, braced through the wall and

securely fastened on the other side."

2.9.5.16 Rule No. 203 is on the subject of "Scaffold supported by building".

As per Rule No. 203, " The employer shall ensure at a construction site of a building or

other construction work that -

(a) no part of a building is used as support or part of a scaffold unless such part of the

building is made of sufficient strength and made of sound material to afford safe support;

(b) overhanging eaves gutters are not used for supporting scaffold;

(c) suspended scaffold is made in accordance with the relevant national standards before

being used by the building workers."

2.9.5.17 Rule No. 204 is on the subject of "use of winches and climbers for

suspended scaffold." As per Rule No. 204, " The employer shall ensure at a construction

site of a building or other construction work that -

(a) no suspended scaffold is raised or lowered by winches or climbers unless such

scaffold is made of sound material, adequate strength and has been tested and

certified safe for use of winches or climber for such raising or lowering by a

competent person before being taken into use;

(b) all suspended scaffolds counter-balanced by counter-weights are of types, approved

by the Director General before being taken into use for building or other construction

work;

(c) the working platform of a suspended scaffold is securely fastened to the building or

structure as to be safe and to prevent such platform from swinging;

(d) The safe working load which a suspended scaffold can carry, is displayed where such

scaffold is being used."

2.9.5.18 Rule No. 205 is on the subject of "Safety devices for suspended scaffold."

As per Rule No. 205, " The employer shall ensure at a construction site of a building or

other construction work that every suspended scaffold, raised or lowered by the winches

or climbers, is provided at each of its suspension point with a safety rope with automatic

safety device mounted on each of such rope so that such safety rope with such automatic

safety device supports the platform of such scaffold in the event of failure of the primary

suspension wire ropes, winches, climbers or any part of the

SAFETY MANUAL PAGE 16

DRA AADITHYA

mechanism used for raising or lowering such suspended scaffold. Provided that this rule

shall not apply, -

(a) where the platform of such scaffold is supported at two independent suspension wire

rope at or near each end of such platform so that in the event of failure of one of such

suspension wire rope, the other wire rope is capable of sustaining the weights

of such platform and its load and prevent it from tilting; or

(b) where a system is incorporated which operates automatically to support the platform

of such scaffold and its load in the event of failure of the primary suspension wire rope of

such scaffold."

2.10 LADDERS

2.10.1 All ladders used at the project site shall conform to applicable standards and

regulations. Ladders shall be inspected prior to each use, and a quarterly inspection will

be conducted by a competent person and results noted on the Inspection Log.

2.10.2 Manufactured ladders on the project shall comply with the regulations of Safety

Code for Portable Wood ladders, or as required by relevant code.

2.10.3 Ladders with broken or missing rungs, broken or split side rails, or otherwise

damaged, shall not be used and shall be removed from the project.

2.10.4 All portable ladders shall be equipped with non-skid safety feet and shall be placed

on a stable base. The access areas at the top and bottom of ladders in use shall be kept

clear of obstructions.

2.10.5 The side rails shall extend 36 inches (3 feet) above the landing. When this is not

practical, grab rails shall be installed. All ladders in use shall be tied, blocked, or

otherwise secured to prevent an accidental displacement.

2.10.6 Project job site made ladders shall be fabricated in compliance with the

regulations.

2.10.7 The general rules applying to the use of manufactured ladders also apply to the use

of job made ladders.

2.10.8 Use of ladders constructed of wood or other absorbing material is prohibited in an

exclusion area.

2.10.9 Ladders shall be identified by number and company.

2.10.10 Tripod ladders (ladders with three legs) are prohibited on the project. All folding

ladders shall have four supporting rails or legs.

SAFETY MANUAL PAGE 17

DRA AADITHYA

2.10.11 Only non-metallic, wooden, approved ladders shall be used during electrical

operations where employees may come into contact with electrical circuits or systems.

2.11 FLOOR, ROOF, WALL AND PLATFORM OPENINGS

Proper precautions must be taken to ensure that floor, roof, wall, and platform openings

are guarded or covered and marked to warn all personnel of the potential hazard. This

includes the installation of temporary hand rails, midrails, toe boards, screening,

planking, walkways and providing safe access ways from established guarded or

protected areas to unprotected or unguarded areas.

2.12 CRANES AND MATERIAL HANDLING / LIFTING APPLIANCES AND GEAR

2.12.1 Chapter VII of "The Building and other Construction Workers( Regulation of

Employment and Conditions of Service) Central Rules, 1998 deals with the subject

of "LIFTING APPLIANCES AND GEAR".

2.12.1.1 Rule No. 55 under Chapter VII is titled, "Construction and maintenance of

lifting appliances". As per Rule 55, "The employer shall ensure at a construction site of a

building or other construction work that –

(a) all lifting appliances, including their parts and working gear, whether fixed or

moveable, and any plant or gear used in anchoring or fixing of such appliances, are -

(1) of sound construction, sound material, and of adequate strength to serve the purpose

for which these are to be used and all such appliances shall be free from patent defects;

and

(2) maintained in good repair and working condition.

(b) (i) every drum or pulley around which the rope of any lifting appliance is carried, is of

adequate diameter and sound construction in relation to such rope;

(ii) any rope which terminates at the winding drum of a lifting appliance is securely

attached to such drum and at least three dead turns of such rope remain on such drum in

every operating position of such lifting appliance;

(iii) the flange of a drum projects twice the rope diameter beyond the last layer of such

rope and if such projection is not available, other measures like anti-slackness guards

shall be provided to prevent such rope from coming off such drum;

(c) Every lifting appliance is provided with adequate and efficient brakes which -

(i) are capable of preventing fall of a suspended load(including any test load) and of

effectively controlling such load while it is being lowered;

(ii) act without shock;

(iii) have shoes that can be easily removed for running; and

(iv) are provided with simple and easily accessible means of adjustment; Provided that

nothing contained in this clause shall apply to steam winch which can be operated as

safely as with brakes as provided in accordance with this clause;

(e) Controls of every lifting appliance :-

SAFETY MANUAL PAGE 18

DRA AADITHYA

(i) are so situated that the driver of such appliance at his stand or seat has ample room for

operating and has an unrestricted view of building or other construction work, as far as

practicable, and that he remains clear of the load and ropes, and that no load passes over

him;

(ii) are positioned with due regard to ergonomic considerations for proper operation of

such appliance;

(iii) are so located that the driver of such appliance remains above the height of the heel

block during the whole operation of such appliance;

(iv) have upon them or adjacent to them clear markings to indicate their purpose and

mode of operations;

(v) are provided, where necessary, with a suitable locking device to prevent accidental

movement or displacement;

(vi) move, as far as practicable, in the direction of the resultant load movement; and

(vii) wherever automatic brakes are provided, automatically come to the neutral position

in case of power failure."

2.12.1.2 Rule No. 56 under Chapter VII ( LIFTING APPLIANCES AND GEAR) is

titled, "Test and periodical examination of lifting appliances" As per Rule No.56, "The

employer shall ensure at construction site of a building or other construction work that,

(a) all lifting appliances, including all parts and gear thereof, whether fixed or moveable,

are tested and examined by a competent person before being taken into use for the first

time or after it has undergone any alterations or repairs liable to affect its strength or

stability or after erection on a construction site and also once at

least in every five years, in the manner specified in Schedule-I annexed to the Rules.

[Enclosure – 2].

(b) all lifting appliances are thoroughly examined by a competent person once at least in

every twelve months and where the competent person making such examination forms

the opinion that the lifting appliance cannot continue to function safely, he shall

forthwith, give notice, in writing, of his opinion, to the owner

of the lifting appliance;

Explanation - For the purpose of this rule, thorough examination means, a visual

examination, supplemented, if necessary, by other means, such as hammer test, carried

out as carefully as the conditions permit, in order to arrive at a reliable conclusion as to

the safety of the parts examined, and, if necessary, for such examination, parts of the

lifting appliance and gear, shall be dismantled."

2.12.1.3 Rule No. 57 of Chapter VII is on the subject of "Automatic Safe Load

indicators". As per item (a) of Rule 57, " The employer shall ensure, at a construction site

of a building or other construction work that –

(i) every crane, if so constructed that the safe working load may be varied by raising or

lowering of the jib, or otherwise, is attached with an automatic indicator of safe working

loads which gives a warning to the operator wherever the load exceeds the safe working

load;

SAFETY MANUAL PAGE 19

DRA AADITHYA

(ii) cut-out is provided which automatically arrests the movements of the lifting

parts of every crane if the load exceeds the safe working load, wherever possible"; and as

per item(b), " the provisions of sub-clause(I) of clause(a) apply, except where it is not

possible to install an automatic safe load indicator, in which case, provision of a table

showing the safe working loads at the corresponding inclinations or radii of the jib on the

crane shall be considered sufficient."

2.12.1.4 Rule No. 58 of Chapter VII is on the subject of "Installation". As per Rule

58, "(a) The employer shall ensure at a construction site of a building or

other construction work that –

(a) fixed lifting appliances are installed -

(i) by competent persons;

(ii) in a manner that such appliances cannot be displaced by the load, vibration or other

influences;

(iii) in a manner that the operator of such appliances is not exposed to danger from loads,

ropes or drums; and

(iv) in a manner that the operator can either see over the zone of operation or

communicate with all loading and unloading points by signal, or other communication

system;

(b) adequate clearance is provided between parts or loads of lifting appliances and -

(i) the fixed objects such as walls and posts; or

(ii) electrical conductors;

(c) the lifting appliances, when exposed to wind load are given sufficient additional

strength, stability and rigidity to withstand such loading safely.

(d) no structural alterations or repairs are made on any part of the lifting appliances that

affect the safety of such appliances without obtaining the opinion of the competent

person to this effect."

2.12.1.5 Rule No. 59 is on the subject of "Winches". As per Rule 59, " The employer

shall ensure at a construction site of a building or other construction work, that. -

(a) (i) winches are not used if control levers operate with excessive friction or play;

(ii) double gear winches are not used unless a positive means of locking the gear shaft is

provided;

(iii) there is no load other than the fall and the hook assembly on the winch while

changing gears on a two gear winch;

(iv) adequate protection is provided to the winch operator against abnormal weather;

(v) temporary seats or shelters for winch operators which may pose hazard to the winch

operator or any other building workers are not allowed to be used;

(vi) control levers are secured in the neutral position and, whenever possible, the power is

shut off, whenever winches are left unattended.

(a) in use of every steam winch -

(i) measures are taken to prevent escaping steam from obscuring any part of the

construction site or other work place or from otherwise hindering or injuring any building

worker;

(ii) extension control levers which tend to fall of their own weight are counter balanced;

SAFETY MANUAL PAGE 20

DRA AADITHYA

(iii) winch operators are not permitted to use the winch control extension levers except

for short handles on wheel type controls and that such levers are of adequate strength,

secure and fastened with metal connections at the fulcrum and at the permanent control

lever;

(b) in use of every electric winch, a building or other construction worker is not permitted

to transfer, alter or adjust electric control circuits in case of any defect in such winch.

(c) Electric winches are not used for building work, where -

(i) the electro-magnetic brake is unable to hold the load; or

(ii) one or more control points, either hoisting or lowering, are not operating properly."

2.12.1.6 Rule No. 60 under Chapter VII deals with the subject of "BUCKETS". As per

Rule 60, "The employer shall ensure at a construction site of a building or other

construction work that tip-up buckets are equipped with a device that effectively prevents

accidental tipping."

2.12.1.7 Rule No. 61 deals with the subject of "Identification and marking of safe

working load". As per Rule 61, "The employer shall ensure at a construction site of a

building or other construction work, that, -

(a) every lifting appliance and loose gear is clearly marked for its safe working load and

identification by stamping or other suitable means;

(b) (i) every derrick (other than derrick crane) is clearly marked for its safe working load

when such derrick is used either in single purchase with a lower block or in union

purchases in all possible block positions;

(ii) the lowest angle to the horizontal, to which the derrick may be used, is legibly

marked;

(c) every lifting appliance having more than one working load is fitted with effective

means to enable the operator to determine safe working load at each point under all

conditions of use;

(d) means to ascertain the safe working load for lifting gears under such conditions in

which such gears may be used are provided to enable a worker using such gears and such

means shall consist of :-

(i) marking the safe working load in plain figures or letters upon the sling or upon a tablet

or ring of durable material attached securely thereto in case of chain slings; and

(ii) either the means specified in sub-clause (I) or notices so exhibited as can be easily

read by any concerned building worker stating the safe working load for the various sizes

of the wire rope slings used in case of wire rope slings."

2.12.1.8 Rule No. 62 deals with the subject of "Loading of lifting appliances and

lifting gears". As per Rule No. 62, " The employer shall ensure at a construction site of a

building or other construction work, that -

(a) no lifting appliance, lifting gear or wire rope is used in an unsafe way and in such a

manner as to involve risk to the life of building workers, and that they are not loaded

beyond their safe working load, except for testing purposes under the direction of a

competent person in the manner as specified in Schedule – I annexed to these rules.

[Enclosure - 2]

(b) no lifting appliance, lifting gear or any other material handling appliance is used, if

SAFETY MANUAL PAGE 21

DRA AADITHYA

(i) the Inspector having jurisdiction is not satisfied with reference to a certificate of test or

examination or to an authenticated record maintained as provided under these rules; and

(ii) in the view of such Inspector, the lifting appliance, lifting gear or any other manual

handling appliance is not safe for use in building or other construction work;

(iii)no pulley block is used in building or other construction work unless the safe working

load and its identification are clearly marked on such block."

2.12.1.9 Rule No. 63 specifies the requirements on "Operator's cab or cabin". As

per Rule No. 63," The employer shall ensure at a construction site of a building or other

construction work that -

(a) the operator of every lifting machine in outdoor service is provided with a cab or

cabin, which -

(i) is made of fire resistant material;

(ii) has a suitable seat, a foot rest and protection from vibration;

(iii) affords the operator an adequate view of the area of operation;

(iv) affords the necessary access to working parts in cab;

(v) affords the operator adequate protection against the weather;

(vi) is adequately ventilated; and

(vi) is provided with a suitable fire extinguisher."

2.12.1.10 Rule No. 64 specifies the safeguards in connection with "Operation of

lifting appliances". As per Rule No. 64, " The employer shall ensure at a construction site

of a building or other construction work that –

(a) every crane driver or lifting operator possesses adequate skill and training in the

operation of the particular lifting appliance;

(b) no person under eighteen years of age is in control of any lifting appliance, scaffold,

winch, or to give signals to the operator;

(c) precaution is taken by the trained operator to prevent lifting appliance from being set

in motion;

(d) the operation of lifting appliance is governed by signals, in conformity with the

relevant national standards;

(e) the lifting appliance operator's attention is not distracted while he is working;

(f) no crane, hoist, winch or other lifting appliance or any part of such crane, hoist, winch

or other lifting appliance is, except for testing purposes, loaded beyond the safe working

load;

(g) during the hoisting operations, effective precaution is taken to prevent any person

from standing or passing under the load in such operations;

(h) operator does not leave lifting appliance unattended while power is on, or load is

suspended to such appliance;

(i) no person rides on a suspended load or on any lifting appliance;

(j) every part of a load in course of being hoisted or lowered is adequately suspended and

supported to prevent danger;

(k) every receptacle used for hoisting bricks, tiles, slates or other material is suitably

enclosed as to prevent the fall of any such materials;

SAFETY MANUAL PAGE 22

DRA AADITHYA

(l) the hoisting platform is enclosed when loose materials or loaded wheel-barrows are

placed directly on such platform or lowering such materials or wheel-barrows;

(m) no material is raised, lowered or slowed with any lifting appliance in such a way as to

cause sudden jerks to such appliance;

(n) in hoisting a barrow, any wheel of such barrow is not used as a means of support,

unless adequate steps are taken to prevent the axle of such wheel from slipping out of its

bearings;

(o) long objects like planks or girders are provided with a tag line to prevent any

possibility of danger while raising or lowering such objects;

(p) during the process of landing of material, a building worker is not permitted to lean

out into empty space for finding out the loading and unloading of such material;

(q) the hoisting of loads at places where there is regular flow of traffic is carried out in an

enclosed space, or in case such hoisting is impracticable in an enclosed space, measures

are taken to hold up or divert the traffic during the time of such hoisting;

(r) adequate steps are taken to prevent a load, in the course of being hoisted or lowered

from coming into contact with any object to avoid any displacement of such load; and

(s) appliances are provided and used for guiding heavy loads when rising or lowering

heavy loads to avoid crushing of hands of building workers during such rising or

lowering of loads."

2.12.1.11 Rule No. 65 is on the subject of "HOISTS". As per Rule No. 65, "The

employer shall ensure, at a construction site of a building or other construction work, that

-

(a) hoist towers are designed according to relevant national standards;

(b) hoist shafts are provided with rigid panels or other adequate fencing-

(i) at the ground level on all sides of such shafts; and

(ii) at all other levels on all sides of the access to such shafts;

(c) the wall of hoist shafts, except at approaches, extends at least two metres above the

floor or platform of access to such shafts;

(d) approaches to a hoist are provided with gates which are -

(i) gridded to maintain visibility;

(ii) at least of two metres height; and

(iii) equipped with a device which requires such gate to be closed before the platform of

such hoist can leave the landing and prevents the gate from being opened unless

such platform, is at the landing;

(e) approaches to a hoist are adequately lit;

(f) the guides of hoist platforms offer sufficient resistance to bending and, to bucking, in

the case of jamming, by providing a safety catch;

(g) overhead beams and their supports are capable of holding the total maximum live and

dead loads that such beams and supports will be required to carry, with a safety factor of

at least five;

(h) a clear space is provided –

(i) above the highest stopping place of a cage or platform to allow sufficient

unobstructed travel of such cage or platform in case of over-winding; and

(ii) below the lowest stopping place of such cage or platform;

SAFETY MANUAL PAGE 23

DRA AADITHYA

(i) adequate covering is provided above the top of hoist shafts to prevent materials from

falling into such shafts;

(j) outdoor hoist towers are erected on adequately firm foundations and are securely

braced, guyed and anchored;

(k) a ladder way extends from the bottom to the top of every outdoor hoist tower in case

no other ladder way exists within easy reach and such ladder way complies with the

relevant national standards;

(l) the rated capacity of a hoisting engine is at least one and a half times the maximum

load that such engine will be required to move;

(m) all gearing on a hoisting engine is securely enclosed;

(n) steam piping of a hoisting engine is adequately protected against accidental contact of

such piping with a building worker;

(o) electrical equipment of a hoisting engine is effectively earthed;

(p) a hoist is provided with suitable devices to stop a hoisting engine as soon as the

platform of such hoist reaches its highest stopping place;

(q) a hoisting engine is protected by a suitable cover against weather and falling objects;

(r) a hoisting engine set up in a public thoroughfare is completely enclosed;

(s) all exhaust steam pipes discharge steam in such a manner that the steam so discharged

does not scald any person or obstruct the operator's view;

(t) the motion of a hoist is not reversed without first bringing it to rest to avoid any harm

from such reverse motion;

(u) a hoist , not designed for the conveyance of persons, is not set in motion from the

platform of such hoist;

(v) Pawls and ratchet wheels of a hoist, requiring disengagement of such pawls from such

ratchet wheels, before the platform of such hoist is lowered, are not used;

(w) a platform of a hoist is capable of supporting such maximum load, that such platform

may carry, with a safety factor of at least three;

(x) a platform of a hoist is equipped with suitable safety gear which can hold such

platform with its maximum load, in case its hoisting rope breaks;

(y) on platform of a hoist, the wheelbarrows or truck are efficiently blocked in a safe

position;

(z) a cage of a hoist or a platform, where the building workers are required to enter into

such cage or to go on such platform at landing level, is provided with a locking

arrangement to prevent such cage or platform from moving during the time a worker

enters or leaves such cage or platform;

(za) the sides of a platform of a hoist which, are not used for loading or unloading, are

provided with toe-board and enclosures of a wire mesh or any other suitable means to

prevent the fall of any part of a load from such platform;

(zb) a platform of a hoist, which has any probability of falling of any part of load from it,

is provided with an adequate covering with such fall;

(zc) the counter-weights of a hoist consisting of an assemblage of several parts are so

constructed that such parts are rigidly connected together;

(zd) the counter-weights of a hoist run between guides;

(ze) at every level of work, the building workers are provided with adequate platforms for

performing such work;

SAFETY MANUAL PAGE 24

DRA AADITHYA

(zf) a legible notice in Hindi as well as in a local language is displayed at -