Professional Documents

Culture Documents

IJSER1553

IJSER1553

Uploaded by

Kyriakos MichalakiCopyright:

Available Formats

You might also like

- Steel Design Problems With Solution (Using NSCP 2001, 2010 and 2015) - UPDATED-1 PDFDocument76 pagesSteel Design Problems With Solution (Using NSCP 2001, 2010 and 2015) - UPDATED-1 PDFLC Lee60% (5)

- FEA and Optimization of Telescopic Boom of Mobiles Hydraulic CraneDocument6 pagesFEA and Optimization of Telescopic Boom of Mobiles Hydraulic CraneAzmi Bin A MataliNo ratings yet

- A-level Physics Revision: Cheeky Revision ShortcutsFrom EverandA-level Physics Revision: Cheeky Revision ShortcutsRating: 3 out of 5 stars3/5 (10)

- Slab Design Excel SheetDocument8 pagesSlab Design Excel SheetRajat GargNo ratings yet

- Alucobond Color ChartDocument2 pagesAlucobond Color ChartwilliamsaminNo ratings yet

- Hyundai LiftDocument21 pagesHyundai LiftFian Ardiyana100% (2)

- Swapnil (2016) - Design of Components Used in Hoisting Mechanism of An EOTDocument5 pagesSwapnil (2016) - Design of Components Used in Hoisting Mechanism of An EOTGogyNo ratings yet

- Conventional Design Calculation &3D Modeling of Metal Forming Heavy Duty Hydraulic PressDocument4 pagesConventional Design Calculation &3D Modeling of Metal Forming Heavy Duty Hydraulic Presskandhasamy muthuNo ratings yet

- 2 Vikky Kumhar VSRDIJMCAPE 5555 Research Paper 5 5 May 2015Document7 pages2 Vikky Kumhar VSRDIJMCAPE 5555 Research Paper 5 5 May 2015Kiet Truong AnhNo ratings yet

- Ijsrdv3i110164 PDFDocument6 pagesIjsrdv3i110164 PDFRyadh OtmaneTelbaNo ratings yet

- Design of A Cantilever Beam Under Nonuniform Distributed LoadDocument34 pagesDesign of A Cantilever Beam Under Nonuniform Distributed LoadJoni Carino SuniNo ratings yet

- Measurement: Rakesh Kolhapure, Vasudev Shinde, Vijay KambleDocument7 pagesMeasurement: Rakesh Kolhapure, Vasudev Shinde, Vijay KambleVijay KambleNo ratings yet

- 2.tensile TestDocument14 pages2.tensile TestAmol SawantNo ratings yet

- July 2017 1500123712 109Document2 pagesJuly 2017 1500123712 109ARINDAM SETTNo ratings yet

- Mee-331 Design of Machine Elements Unit I Fundamentals of DesignDocument50 pagesMee-331 Design of Machine Elements Unit I Fundamentals of DesignMuthuvel MNo ratings yet

- Design, Fabrication, Static Testing and Analysis of Composite Wing Box Using E-Glass Epoxy CompositeDocument5 pagesDesign, Fabrication, Static Testing and Analysis of Composite Wing Box Using E-Glass Epoxy CompositeRavinder ReddyNo ratings yet

- Pont Dalle en Ba Groupe Gci ADocument20 pagesPont Dalle en Ba Groupe Gci Aken koemhongNo ratings yet

- Model and Analysis of Desktop Wind Tunnel: Md. Khaleel, S. Alka, & Marampalli ShilpaDocument8 pagesModel and Analysis of Desktop Wind Tunnel: Md. Khaleel, S. Alka, & Marampalli ShilpaTJPRC PublicationsNo ratings yet

- Design For Impact and FatigueDocument7 pagesDesign For Impact and FatigueMuhammed MuhsinNo ratings yet

- Design and Analysis of Column Structure For Jib CraneDocument6 pagesDesign and Analysis of Column Structure For Jib CraneGAURAVNo ratings yet

- Stress Measurement of A Helical Coil Spring Under Static Load Using Strain RosetteDocument7 pagesStress Measurement of A Helical Coil Spring Under Static Load Using Strain RosetteSuresh KumarNo ratings yet

- Vol IV Issue IV Article 7Document4 pagesVol IV Issue IV Article 7Văn Tuấn NguyễnNo ratings yet

- Ijresm V2 I1 51Document3 pagesIjresm V2 I1 51ANIKET MUNDADANo ratings yet

- Chapter 01 Fundamental Terminologies andDocument32 pagesChapter 01 Fundamental Terminologies andBrent FabialaNo ratings yet

- AnswerDocument3 pagesAnswerKUEK KONG BONGNo ratings yet

- DESIGN AND ANALYSIS OF TRAILER FRAME Ijariie8323Document6 pagesDESIGN AND ANALYSIS OF TRAILER FRAME Ijariie8323gii.s.kigasungNo ratings yet

- Static Analysis, Design Modification and Modal Analysis of Structural Chassis FrameDocument5 pagesStatic Analysis, Design Modification and Modal Analysis of Structural Chassis FrameGopinath ChakrabortyNo ratings yet

- GroupE 21929129Document20 pagesGroupE 21929129Bradley GovindasamyNo ratings yet

- Experiment 2Document5 pagesExperiment 2lulamamakarimgeNo ratings yet

- Design and Structural Analysis of An Off Road VehicleDocument7 pagesDesign and Structural Analysis of An Off Road Vehiclegauravme198306No ratings yet

- Considerations of Shocks & Vibration in Switchboard Design (Jul-Sept 06)Document4 pagesConsiderations of Shocks & Vibration in Switchboard Design (Jul-Sept 06)santhoshNo ratings yet

- Give Example A Title: /title, Effects of Self Weight For A Cantilever BeamDocument5 pagesGive Example A Title: /title, Effects of Self Weight For A Cantilever Beamapi-3833671No ratings yet

- Effect of Clamp Structural On The Compressive Force Behavior Based On Finite Element AnalysisDocument5 pagesEffect of Clamp Structural On The Compressive Force Behavior Based On Finite Element AnalysisRahul ENo ratings yet

- Graphical Approach in Optimization of Penstock DiameterDocument6 pagesGraphical Approach in Optimization of Penstock DiameterFseha GideyNo ratings yet

- INDUSTRIAL PROJ-WPS Office 2Document31 pagesINDUSTRIAL PROJ-WPS Office 2Clive Jerison VNo ratings yet

- Lab8 BoundaryElementExerciseDocument9 pagesLab8 BoundaryElementExerciseansariNo ratings yet

- Optimization of Axial Flow Turbine For Mean Line Design Using Genetic Algorithm PDFDocument8 pagesOptimization of Axial Flow Turbine For Mean Line Design Using Genetic Algorithm PDFaliNo ratings yet

- RPC HANDOUT 11 DeflectionDocument7 pagesRPC HANDOUT 11 Deflectionricomichaelangelo7No ratings yet

- Paper On Optimisational Design of Pressure VesselDocument12 pagesPaper On Optimisational Design of Pressure VesselEr Pravin V TembeNo ratings yet

- Ijesrt: Optimizing Design of Spring Using Genetic AlgorithmDocument3 pagesIjesrt: Optimizing Design of Spring Using Genetic AlgorithmHabtamu GeremewNo ratings yet

- Lec.2 Similarity of Fluid MachinesDocument25 pagesLec.2 Similarity of Fluid MachinesMechanical EngineeringNo ratings yet

- Application of Optimization Techniques To Weight Reduction of Automobile BodiesDocument6 pagesApplication of Optimization Techniques To Weight Reduction of Automobile BodiesTibebu MerideNo ratings yet

- Design and Analysis of Structural Members of The Jib CraneDocument4 pagesDesign and Analysis of Structural Members of The Jib CraneInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design, Analysis and Development of Hydraulic Scissor LiftDocument8 pagesDesign, Analysis and Development of Hydraulic Scissor Liftmohit talrejaNo ratings yet

- Design Analysis of Industrial Gear Box Casing.: International Research Journal of Engineering and Technology (IRJET)Document5 pagesDesign Analysis of Industrial Gear Box Casing.: International Research Journal of Engineering and Technology (IRJET)Akash NandargiNo ratings yet

- Serviceability Req RCDocument31 pagesServiceability Req RCJoeven DinawanaoNo ratings yet

- M 236 ContentDocument119 pagesM 236 ContentBharath YemireddyNo ratings yet

- Design Analysis of Industrial Gear Box C 221013 042656Document5 pagesDesign Analysis of Industrial Gear Box C 221013 042656Trung ThanhNo ratings yet

- Analysis& Optimizationof Jib Crane Under Influenceof Various Slewing Angles&load Position by Limit State MethodDocument9 pagesAnalysis& Optimizationof Jib Crane Under Influenceof Various Slewing Angles&load Position by Limit State MethodEvodius RweyemamuNo ratings yet

- Designing of All Terrain Eco-Green Vehicle (ATV)Document9 pagesDesigning of All Terrain Eco-Green Vehicle (ATV)JOEL JO THOMASNo ratings yet

- Ansys Project 2 Group-5Document21 pagesAnsys Project 2 Group-5temesgen tesemaNo ratings yet

- Finite Element Project 3-4-2013 Vfinal2Document6 pagesFinite Element Project 3-4-2013 Vfinal2Marcelo ZiulkoskiNo ratings yet

- Really Print MechaDocument1 pageReally Print MechaNicholas NicholasNo ratings yet

- Airport Pavement Design: Airport Classification, and Runway Pavement Design Using Canadian Department of Transport MethodDocument19 pagesAirport Pavement Design: Airport Classification, and Runway Pavement Design Using Canadian Department of Transport MethodNishant AryaNo ratings yet

- ME314 CEP Research GateDocument28 pagesME314 CEP Research GateHuzi MalixNo ratings yet

- Fatigue FailureDocument17 pagesFatigue Failureaiman.mohammadNo ratings yet

- Hbti Ansys Cadcam Centre, KapnurDocument5 pagesHbti Ansys Cadcam Centre, KapnurAjay Kumar OjhaNo ratings yet

- Non Linear AnalysisDocument53 pagesNon Linear AnalysisdpksobsNo ratings yet

- .Knuckle Design For SAE Baja Vehicles Using Real-Life Force DataDocument4 pages.Knuckle Design For SAE Baja Vehicles Using Real-Life Force DataJoshua SajiNo ratings yet

- EXP Performance MV Lab Winch ApparatusDocument5 pagesEXP Performance MV Lab Winch ApparatusMuhammad ZameerNo ratings yet

- Design and Analysis of An Aerial ScissorDocument4 pagesDesign and Analysis of An Aerial ScissorBảo Toàn LêNo ratings yet

- Reinforced Concrete Design: (CIVL 3320)Document24 pagesReinforced Concrete Design: (CIVL 3320)taiman chanNo ratings yet

- Computer Vision Graph Cuts: Exploring Graph Cuts in Computer VisionFrom EverandComputer Vision Graph Cuts: Exploring Graph Cuts in Computer VisionNo ratings yet

- ENG Industrial Cleaning Horticulture LQDocument13 pagesENG Industrial Cleaning Horticulture LQKyriakos MichalakiNo ratings yet

- Brazed Plate Heat Exchangers: 1081 BP SeriesDocument12 pagesBrazed Plate Heat Exchangers: 1081 BP SeriesKyriakos MichalakiNo ratings yet

- Cleaning Guidelines Laude Moulds - 240420 - 171542Document1 pageCleaning Guidelines Laude Moulds - 240420 - 171542Kyriakos MichalakiNo ratings yet

- How To Size A Liquid Control Valve - Blackmonk EngineeringDocument9 pagesHow To Size A Liquid Control Valve - Blackmonk EngineeringKyriakos MichalakiNo ratings yet

- Mixing Valves Application Note Rev August 3 2017 - 230902 - 162913Document14 pagesMixing Valves Application Note Rev August 3 2017 - 230902 - 162913Kyriakos MichalakiNo ratings yet

- HABASIT 04 Guía Ingeniería HabasitLINKDocument100 pagesHABASIT 04 Guía Ingeniería HabasitLINKKyriakos MichalakiNo ratings yet

- How To Improve Hydronic System Performance With PR - 230902 - 175555Document13 pagesHow To Improve Hydronic System Performance With PR - 230902 - 175555Kyriakos MichalakiNo ratings yet

- DeltaPValves Product CatalogDocument24 pagesDeltaPValves Product CatalogKyriakos MichalakiNo ratings yet

- InstrumentationToday - Junio 2015Document23 pagesInstrumentationToday - Junio 2015Kyriakos MichalakiNo ratings yet

- Installed Gain As A Control Valve Sizing Criterion - Valin3Document7 pagesInstalled Gain As A Control Valve Sizing Criterion - Valin3Kyriakos MichalakiNo ratings yet

- Determining The Pressure Drop To Be Used in A Control Valve Sizing Calculation - Valin1Document3 pagesDetermining The Pressure Drop To Be Used in A Control Valve Sizing Calculation - Valin1Kyriakos MichalakiNo ratings yet

- Metrex Valve - How To Size A Water Regulating Valves, R410a Valves, Water Pressure Regulating Valves, Seawater Condensing Valve, Marine ValvesDocument5 pagesMetrex Valve - How To Size A Water Regulating Valves, R410a Valves, Water Pressure Regulating Valves, Seawater Condensing Valve, Marine ValvesKyriakos MichalakiNo ratings yet

- O-Ring-Technical-Handbook-Full 65Document1 pageO-Ring-Technical-Handbook-Full 65Kyriakos MichalakiNo ratings yet

- Jib Crane Calculation As Per BGR RequireDocument10 pagesJib Crane Calculation As Per BGR RequireKyriakos Michalaki100% (1)

- 2016 06 23 Contrx CatalogDocument44 pages2016 06 23 Contrx CatalogKyriakos MichalakiNo ratings yet

- Gorbel Free Standing I Beam Jib Crane ManualDocument24 pagesGorbel Free Standing I Beam Jib Crane ManualKyriakos MichalakiNo ratings yet

- Food Name and Description Density in G/ML (Including Mass and Bulk Density) Specific Gravity Biblioid Update 2.0Document1 pageFood Name and Description Density in G/ML (Including Mass and Bulk Density) Specific Gravity Biblioid Update 2.0Kyriakos MichalakiNo ratings yet

- Various Executions MA: Series Foodstuffs ExecutionDocument17 pagesVarious Executions MA: Series Foodstuffs ExecutionKyriakos MichalakiNo ratings yet

- 3m RTP Design Drawing and BomDocument3 pages3m RTP Design Drawing and Bomadhikaritp9990No ratings yet

- RTS Overview Montreal ASHRAE Chapter 6oct 03Document38 pagesRTS Overview Montreal ASHRAE Chapter 6oct 03thermosol5416No ratings yet

- Pneumatic Flow Regulator Check ValvesDocument8 pagesPneumatic Flow Regulator Check ValvesUzair AnsariNo ratings yet

- Al Dobowi Group Profil-Si NewDocument54 pagesAl Dobowi Group Profil-Si NewdsdsdsdNo ratings yet

- Causes of Over PressurizationDocument2 pagesCauses of Over PressurizationrkubalNo ratings yet

- 750 X Beam ExampleDocument70 pages750 X Beam ExampleianfldNo ratings yet

- Tips For Concrete by Y T Nagaraja PDFDocument54 pagesTips For Concrete by Y T Nagaraja PDFPirpasha UjedeNo ratings yet

- Development of CuZnAl SMADocument5 pagesDevelopment of CuZnAl SMAYudha PradhanaNo ratings yet

- Effect of Eccentricity On Analysis and Design of Isolated FootingsDocument20 pagesEffect of Eccentricity On Analysis and Design of Isolated FootingsAlexandros PapamarinopoulosNo ratings yet

- Table - 1: Ishikawajima-Harima Heavy Industries Co., Ltd. Sharjah Cement Industrial Development CoDocument2 pagesTable - 1: Ishikawajima-Harima Heavy Industries Co., Ltd. Sharjah Cement Industrial Development Cokvinay2003No ratings yet

- Neoprene Barry Controls FAQ ASTM D2000Document3 pagesNeoprene Barry Controls FAQ ASTM D2000MinhddNo ratings yet

- Socket Head Screws Din912Document3 pagesSocket Head Screws Din912weyiheNo ratings yet

- Sub HSE (I&E) : Adnan Ahmad, Kashif AhmadDocument5 pagesSub HSE (I&E) : Adnan Ahmad, Kashif AhmadAdnan AhmadNo ratings yet

- UL 94 - WikipediaDocument2 pagesUL 94 - WikipediaSagar BhokareNo ratings yet

- Duct Calculation Original Xls SheetDocument39 pagesDuct Calculation Original Xls Sheetsaimudduluru88No ratings yet

- Civil Engineering Objective Type Questions by S.S.bhavikattiDocument764 pagesCivil Engineering Objective Type Questions by S.S.bhavikattiShikhin Garg78% (9)

- Radiation Heat TransferDocument28 pagesRadiation Heat TransferJohn Louie GresulaNo ratings yet

- 175 010300 PDFDocument2 pages175 010300 PDFAbu Anas M.SalaheldinNo ratings yet

- Effective Sensible Heat Factors: Room ConditionsDocument2 pagesEffective Sensible Heat Factors: Room Conditionscalvin.bloodaxe4478No ratings yet

- Improve Vacuum Heater Reliability: Hydrocarbon ProcessingDocument4 pagesImprove Vacuum Heater Reliability: Hydrocarbon Processingros56No ratings yet

- HVOF-pump ImpellerDocument4 pagesHVOF-pump ImpellerjohnyNo ratings yet

- TYPE S5 (1-Bedroom Suite) : Unit #02-12 764 SQ FTDocument1 pageTYPE S5 (1-Bedroom Suite) : Unit #02-12 764 SQ FTAdam HudzNo ratings yet

- Building Automation SystemDocument32 pagesBuilding Automation SystemkhadijabugtiNo ratings yet

- Applsci 13 06299 v2Document12 pagesApplsci 13 06299 v2Sa RaNo ratings yet

IJSER1553

IJSER1553

Uploaded by

Kyriakos MichalakiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IJSER1553

IJSER1553

Uploaded by

Kyriakos MichalakiCopyright:

Available Formats

International Journal of Scientific Engineering and Research (IJSER)

www.ijser.in

ISSN (Online): 2347-3878, Impact Factor (2014): 3.05

Design Optimization of Jib Crane Boom Using

Evolutionary Algorithm

Krunal Gandhare1, Prof. Vinay Thute2

1

ME Student SSGM College of Engineering, Shegaon

2

Assisant Prof. SSGM College of Engineering, Shegaon, India

Abstract: Cranes are the material handling equipment’s that are used worldwide. Due the various standards available it is easy for

manufacturers to choose dimensions, most of the time they do it on trial and error basis and chooses dimension that are satisfying the

conditions provided in standards, and it is often found that the dimensions are not optimum, and lesser attention has been given to

optimization of its dimension. In the following paper an attempt has been made to optimize the Boom of 1 ton Jib crane as per Indian

Standards using simple and easily available Excel solver’s Evolutionary Algorithm.

Keywords: Jib Crane, Optimization, Indian Standards, Evolutionary Algorithm

1. Introduction reduce the mass of the jib crane boom without compromising

its strength and keeping design conformed to IS 15419 and

Jib Cranes are used for material handling in many industries. IS 800. For reducing mass it was decided to change the

The purpose it serves is to move Loads from one location to

other in its circular swept area. There are various parts of Jib

Crane like its supporting column or mast, the cantilever

beam or a boom which picks up the load and the hoist which

moves on the boom of the crane. While in operation the

crane and its parts are exposed to various loads like bending

loads, compressive load, tensile load and loads due to

weather i.e. wind loads etc. While designing the class of

operation and classification of the crane has to be known so

that appropriate loads can be considered while designing the

crane, along with that the standard practices of respective

countries has to be followed and design shall conform to the

standards given by the authority of countries. The following

crane design has been considered according to Indian

standards i.e. IS 15419:2004 was followed for Jib crane

design, whereas subsequent details of code of practice were Figure 1: Jib Crane

taken from IS 3177:1999 which is for EOT overhead crane

design, IS 807:2006 (Design, Erection And Testing, Cross-sectional dimension of the boom since it has the

Structural Portion of Cranes And Hoists ), and IS 800:2007 similar cross section throughout its span unlike [4], and

(General Construction In Steel). Out of the various elements hence the cross-sectional area of the boom was selected as

of the Jib crane, the Boom was under consideration for the the objective function. And it is defined as:

optimization. The jib crane boom, for design purpose can be

considered as a cantilever with its one end fixed. The jib 𝐴𝑏 = 2 𝑏𝑎𝑓 × 𝑡𝑓 + 𝑤 × 𝑡𝑤

crane boom under consideration is a simple welded box Where,

beam having same cross section throughout its span. Similar 𝐴𝑏 = Cross sectional area of the boom

type optimization was carried out by [4] for the box beam 𝑏𝑎𝑓 , 𝑡𝑓 = Breadth and thickness of top and

girder for the overhead crane, whereas [5] carried out it for bottom cover plate

the optimization of I section beam used for overhead crane 𝑤 , 𝑡𝑤 = Depth and thickness of web

girder. The optimization technique used here is Evolutionary

nonlinear optimization code for various dimension of the box

beam cantilever or boom of the Jib crane. Evolutionary

nonlinear optimization code is available in MS Excel Spread

Sheet Solver under Data tab available in the software (2010

Version), this Paper is focused on carrying out the

optimization of the boom with evolutionary algorithm

without considering the stiffener design.

2. Design of the Problem

For optimization, objective function has to be defined [6].

The objective for carrying out this optimization was to

Volume 3 Issue 4, April 2015

Paper ID: IJSER1553 5 of 8

Licensed Under Creative Commons Attribution CC BY

International Journal of Scientific Engineering and Research (IJSER)

www.ijser.in

ISSN (Online): 2347-3878, Impact Factor (2014): 3.05

d) (0.6 × Normal plastic shear

resistance )Has to be less than maximum shear force [3]

Where,

𝜎𝑎 = Fundamental allowable stress

It is calculated as,

𝑌𝑖𝑒𝑙𝑑 𝑃𝑜𝑖𝑛𝑡

𝜎𝑎 =

𝛾

Or

𝑇𝑒𝑛𝑠𝑖𝑙𝑒 𝑆𝑡𝑒𝑛𝑔𝑡

𝜎𝑎 =

𝛾

Value of 𝛾 can be chosen from Clause 9 [2].

The weight which has to be applied was calculated as

following.

Figure 2: Boom Cross Section

𝑊 = 𝑆𝐿 + 𝑊𝐿 × 𝜓

The bottom cover plate on which the hoist mechanism moves Where,

has to be greater than the top cover plate and here in this 𝑊 = Total load acting

paper for the simplicity of the problem it is kept as same as 𝑆𝐿 = Static load due to dead weight of boom

that of top cover plate. One can consider the bottom cover to 𝑊𝐿 = Working Load

be greater and design problem has to be changed accordingly 𝜓 = Dynamic Coefficient or Impact Factor

which might yield different results.

The dynamic coefficient depends upon the classification of

For the above objective function the constrained are the crane. The detail classification of the crane has to be

specified as follows, Constraints were chosen as per the specified for other constraints that have to be imposed on the

Indian standard code of practice i.e. IS 807, 25.1, the problem. Here the crane was identified to be from group M6

constraints are as: with class of utilization “C” i.e. regular use on intensive duty

with moderate state of loading/stress.[2]

a) 𝑙 𝑤 Shall not exceed 25

b) 𝑙 𝑏𝑓 Shall not exceed 60 The Dynamic coefficient or Impact factor was selected as 1.4

c) 𝑏𝑓 𝑡𝑓 Shall not exceed 60 for M6 was chosen [2],

d) 𝑤 𝑡𝑤 Shall not exceed 62

The Stress calculation was done as follows:

Where, 𝑀

𝐵𝑒𝑛𝑑𝑖𝑛𝑔 𝑆𝑡𝑟𝑒𝑠𝑠 = × 𝑦

l=Length of boom 𝐼

𝑤 = Height of boom Where,

𝑏𝑓 = breadth of boom 𝑀 = 𝐴𝑝𝑝𝑙𝑖𝑒𝑑 𝑚𝑜𝑚𝑒𝑛𝑡

𝑐 = Thickness of cover plate 𝐼 = 𝑀𝑜𝑚𝑒𝑛𝑡 𝑜𝑓 𝐼𝑛𝑒𝑟𝑡𝑖𝑎

𝑦 = 𝑑𝑖𝑠𝑡𝑎𝑛𝑐𝑒 𝑓𝑟𝑜𝑚 𝑛𝑢𝑡𝑟𝑎𝑙 𝑎𝑥𝑖𝑠 𝑜𝑓 𝑏𝑜𝑜𝑚

For constraint, 𝑏𝑓 , that is breadth of the boom has to be taken

The bending stress acting on the top cover plate will be

as inner distance between web, and for problem design the

tensile in nature while it will be compressive at bottom cover

actual breath has to be written in terms of bf i.e.

plate, both of them calculated separately and restricted as per

the constraints defined.

Breadth of top cover plate

𝑏𝑎𝑓 = 𝑏𝑓 + 2 × 𝑡𝑖𝑐𝑘𝑛𝑒𝑠𝑠 𝑜𝑓 𝑤𝑒𝑏 + 𝑟𝑒𝑞𝑢𝑖𝑟𝑒𝑑 𝑜𝑢𝑡𝑠𝑡𝑎𝑛𝑑

The Bending moment of the boom,

𝑀 ≤ 𝑀𝑑

The 𝑡𝑤 was restricted to 62 [3][5]so that there is no need That is, the M, the bending moment, at any section of the

of checking the buckling resistance of the cross section and Boom shall not exceed Design bending strength of section

cross section won’t be slender.

𝑀𝑑 [3], and

𝛽𝑏 𝑍𝑝 𝑓𝑦

Figure 2 shows the boom crass section under consideration, 𝑀𝑑 =

but as mentioned earlier, the breadth and thick ness of the top 𝛾𝑚0

and bottom cover plate is considered same for the simplicity And to avoid irreversible deformation under serviceability

of the problem. loads 𝑀𝑑 shall be less than 1.5𝑍𝑒 𝑓𝑦 /𝛾𝑚0

Where,

And the deflection of the beam shall not exceed the 𝛽𝑏 = 1.0 for plasic and compact section

following [1]: 𝛽𝑏 = 𝑍𝑒 𝑍𝑝

𝐵𝑜𝑜𝑚 𝐿𝑒𝑛𝑔𝑡 + 𝐻𝑒𝑖𝑔𝑡 𝑜𝑓 𝐶𝑜𝑙𝑢𝑚𝑛 𝑍𝑒 , 𝑍𝑝 = Elastic and plastic section modulus

𝛿𝑚𝑎𝑥 =

300 𝑓𝑦 = Yield stress of the material

And the allowable stresses were taken as follows [2]from IS 𝛾𝑚0 = partial safety factor

807:2006 Clause 9.7 Partial safety factor has to be selected as per clause 5.4.1

a) Tensile stress shall not exceed 𝜎𝑎 (IS800)

b) Compression stress shall not exceed 𝜎𝑎 1.5

c) Shear shall not exceed 𝜎𝑎 3

Volume 3 Issue 4, April 2015

Paper ID: IJSER1553 6 of 8

Licensed Under Creative Commons Attribution CC BY

International Journal of Scientific Engineering and Research (IJSER)

www.ijser.in

ISSN (Online): 2347-3878, Impact Factor (2014): 3.05

Here, in this case the resistance to torsional buckling needs

not to be checked, by clause (8.2.2)[3]

These all the calculations were done for the actual initial

cross section of the boom in a excel sheet.

3. Optimization

For the optimization of the objective function above

designed problem was solved using Evolutionary algorithm

bundled with Microsoft Excel Spread sheet programmer

2010.The designed problem was written on the Excel sheet

and the constraints were fed to the invoked dialog box along

with the target cell.

The weight applied to solve this problem was kept fixed to

18604N, which actually changes along with change in cross

section of the boom.

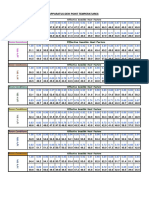

Figure 3: Optimized Area vs. various stress levels

For the solver, the integer optimality was 0.5%, and

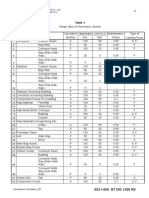

Table 1 shows the comparison between parameters of actual

convergence 0.0001, mutation rate 0.075 was used. Then

crane. The values of the optimized parameter were rounded

solver was asked to solve the problem. It was found that the

off to nearby value. The percentage savings in area without

solver was exploiting the stress level constraint and giving

rounding off the values was 21.34% whereas after rounding

110MPa for compressive stress, which was highest limit for

them off to nearby value it was found to be 18.30%. The

compressive stress, and was showing savings in cross

savings in the weight of boom was found to be 13%. The

sectional area at great extent, which is impractical. Further

results of the optimization model which was fed into the

several trials were made at different stress levels, i.e. the

solver did calculation for the cross section which was not the

constraint of the compressive stress was reduced from

actual one and was considered to be a cross section area with

110MPa to 95, 90, 85 etc. and several optimized Areas for

same bottom and top cover plate having same dimensions. If

respective stress level were found by running the algorithm.

the top and bottom cover plate thickness allowed to change

independently, it was found that the savings were higher.

The obtained various scenarios and obtained solution were

Here the results of only one model that was fed to the excel

compared. Figure 3shows the area for respective stress level.

solver i.e. the thickness of the top and bottom flange not

changing independently has been shown in Table 1.

4. Result and Discussion

Table 1: Comparison of Boom parameters before and after

The obtained various scenarios and obtained solution were optimization

compared. Figure 3 shows the optimized area for respective Parameter Boom Before Boom After

stress level. Whereas the figure 4 shows the bending moment Optimization Optimization

and deflection at optimized area at various stress level. For Breadth of top and bottom300mm 283.89mm

the crane under consideration, during the regular use and for cover plate

the specified life (Fatigue life), the operating stress has to be Thickness of top and bottom 10mm 7.79 mm

between 1/3 to 2/3 of the maximum stress P [2] here the Cover plate

maximum stress selected was 110MPa compressive to which Height of Web 400mm 398.30 mm

the bottom cover plate was reaching even before the Tension Thickness of web 8mm 6.68 mm

i.e. upper cover plate could reach to its maximum stress i.e. Cross section area of boom 12400mm2 9752.60 mm2

165MPa. Considering this the optimized area for stress of Plastic section modulus 1471193.65mm2 1116379.59 mm2

2/3P i.e. 73.34 MPa (Compressive) was selected as Elastic section modulus 1607301.59mm2 1221961.59 mm2

Design Bending Moment 334362193Nmm 253722635Nmm

optimized area.

Bending Moment due to 85735828.81Nmm 89299200Nmm

applied load

Deflection 9.83mm 14.60mm

Bending stress (Tensile) Top 53.34MPa 73.07MPa

cover plate

Bending Stress (Compressive) 53.34MPa 73.07Mpa

Bottom cover plate

Weight of boom 447.76kg 390.44kg

Volume 3 Issue 4, April 2015

Paper ID: IJSER1553 7 of 8

Licensed Under Creative Commons Attribution CC BY

International Journal of Scientific Engineering and Research (IJSER)

www.ijser.in

ISSN (Online): 2347-3878, Impact Factor (2014): 3.05

[3] Indian Standard 800:2007, General Construction In steel-

Code of Practice.

[4] Rehan H Zuberi, Dr. Long Kai, Prof. ZuoZhengxing,

Design Optimization of EOT Crane Bridge, International

Conference on Engineering Optimization, EngOpt

2008,Brazil.

[5] F. Faluyi, C. Arum, Design Optimization of Plate Girder

Using Generalized Reduced Gradient and Constrained

Artificial Bee Colony Algorithms, International Journal

of Emerging Technology and Advanced Engineering,

Volume 2, Issue 7, July 2012.

[6] Singiresu S Rao, Engineering Optimization, New Age

International Publisher, Third Edition 2008.

(a)

(b)

Figure 4: a. Optimized area at various stress level v/s Design

Bending Moment, b. Optimized area at various stress level

v/s Deflection

5. Conclusion

Optimization of the jib crane is a nonlinear problem, if this

problem was considered to be solved by classical method

along Kuhn-Tucker condition it becomes too complex and

too difficult to solve, hence automated programming has to

be used. In this paper it was found that evolutionary

algorithm yields satisfactory results and can be used for

obtaining the optimized parameters for the crane and the

values of parameter found to be feasible and within limits.

There are some of the limitation in the presented

optimization model such as the weight applied was kept

fixed which actually changes along with change in cross

sectional area of the boom, which when removed may give

encouraging result. It was also found that by changing the

mathematical model relation the results varied a little. The

crane dimension obtained has to be tested experimentally to

found its validity.

References

[1] Indian Standard 15419:2004, Jib Cranes- Code of

Practice

[2] Indian Standard 807:2006, Design, Erection and Testing

(Structural Portion) of Cranes and Hoists- Code of

Practice.

Volume 3 Issue 4, April 2015

Paper ID: IJSER1553 8 of 8

Licensed Under Creative Commons Attribution CC BY

You might also like

- Steel Design Problems With Solution (Using NSCP 2001, 2010 and 2015) - UPDATED-1 PDFDocument76 pagesSteel Design Problems With Solution (Using NSCP 2001, 2010 and 2015) - UPDATED-1 PDFLC Lee60% (5)

- FEA and Optimization of Telescopic Boom of Mobiles Hydraulic CraneDocument6 pagesFEA and Optimization of Telescopic Boom of Mobiles Hydraulic CraneAzmi Bin A MataliNo ratings yet

- A-level Physics Revision: Cheeky Revision ShortcutsFrom EverandA-level Physics Revision: Cheeky Revision ShortcutsRating: 3 out of 5 stars3/5 (10)

- Slab Design Excel SheetDocument8 pagesSlab Design Excel SheetRajat GargNo ratings yet

- Alucobond Color ChartDocument2 pagesAlucobond Color ChartwilliamsaminNo ratings yet

- Hyundai LiftDocument21 pagesHyundai LiftFian Ardiyana100% (2)

- Swapnil (2016) - Design of Components Used in Hoisting Mechanism of An EOTDocument5 pagesSwapnil (2016) - Design of Components Used in Hoisting Mechanism of An EOTGogyNo ratings yet

- Conventional Design Calculation &3D Modeling of Metal Forming Heavy Duty Hydraulic PressDocument4 pagesConventional Design Calculation &3D Modeling of Metal Forming Heavy Duty Hydraulic Presskandhasamy muthuNo ratings yet

- 2 Vikky Kumhar VSRDIJMCAPE 5555 Research Paper 5 5 May 2015Document7 pages2 Vikky Kumhar VSRDIJMCAPE 5555 Research Paper 5 5 May 2015Kiet Truong AnhNo ratings yet

- Ijsrdv3i110164 PDFDocument6 pagesIjsrdv3i110164 PDFRyadh OtmaneTelbaNo ratings yet

- Design of A Cantilever Beam Under Nonuniform Distributed LoadDocument34 pagesDesign of A Cantilever Beam Under Nonuniform Distributed LoadJoni Carino SuniNo ratings yet

- Measurement: Rakesh Kolhapure, Vasudev Shinde, Vijay KambleDocument7 pagesMeasurement: Rakesh Kolhapure, Vasudev Shinde, Vijay KambleVijay KambleNo ratings yet

- 2.tensile TestDocument14 pages2.tensile TestAmol SawantNo ratings yet

- July 2017 1500123712 109Document2 pagesJuly 2017 1500123712 109ARINDAM SETTNo ratings yet

- Mee-331 Design of Machine Elements Unit I Fundamentals of DesignDocument50 pagesMee-331 Design of Machine Elements Unit I Fundamentals of DesignMuthuvel MNo ratings yet

- Design, Fabrication, Static Testing and Analysis of Composite Wing Box Using E-Glass Epoxy CompositeDocument5 pagesDesign, Fabrication, Static Testing and Analysis of Composite Wing Box Using E-Glass Epoxy CompositeRavinder ReddyNo ratings yet

- Pont Dalle en Ba Groupe Gci ADocument20 pagesPont Dalle en Ba Groupe Gci Aken koemhongNo ratings yet

- Model and Analysis of Desktop Wind Tunnel: Md. Khaleel, S. Alka, & Marampalli ShilpaDocument8 pagesModel and Analysis of Desktop Wind Tunnel: Md. Khaleel, S. Alka, & Marampalli ShilpaTJPRC PublicationsNo ratings yet

- Design For Impact and FatigueDocument7 pagesDesign For Impact and FatigueMuhammed MuhsinNo ratings yet

- Design and Analysis of Column Structure For Jib CraneDocument6 pagesDesign and Analysis of Column Structure For Jib CraneGAURAVNo ratings yet

- Stress Measurement of A Helical Coil Spring Under Static Load Using Strain RosetteDocument7 pagesStress Measurement of A Helical Coil Spring Under Static Load Using Strain RosetteSuresh KumarNo ratings yet

- Vol IV Issue IV Article 7Document4 pagesVol IV Issue IV Article 7Văn Tuấn NguyễnNo ratings yet

- Ijresm V2 I1 51Document3 pagesIjresm V2 I1 51ANIKET MUNDADANo ratings yet

- Chapter 01 Fundamental Terminologies andDocument32 pagesChapter 01 Fundamental Terminologies andBrent FabialaNo ratings yet

- AnswerDocument3 pagesAnswerKUEK KONG BONGNo ratings yet

- DESIGN AND ANALYSIS OF TRAILER FRAME Ijariie8323Document6 pagesDESIGN AND ANALYSIS OF TRAILER FRAME Ijariie8323gii.s.kigasungNo ratings yet

- Static Analysis, Design Modification and Modal Analysis of Structural Chassis FrameDocument5 pagesStatic Analysis, Design Modification and Modal Analysis of Structural Chassis FrameGopinath ChakrabortyNo ratings yet

- GroupE 21929129Document20 pagesGroupE 21929129Bradley GovindasamyNo ratings yet

- Experiment 2Document5 pagesExperiment 2lulamamakarimgeNo ratings yet

- Design and Structural Analysis of An Off Road VehicleDocument7 pagesDesign and Structural Analysis of An Off Road Vehiclegauravme198306No ratings yet

- Considerations of Shocks & Vibration in Switchboard Design (Jul-Sept 06)Document4 pagesConsiderations of Shocks & Vibration in Switchboard Design (Jul-Sept 06)santhoshNo ratings yet

- Give Example A Title: /title, Effects of Self Weight For A Cantilever BeamDocument5 pagesGive Example A Title: /title, Effects of Self Weight For A Cantilever Beamapi-3833671No ratings yet

- Effect of Clamp Structural On The Compressive Force Behavior Based On Finite Element AnalysisDocument5 pagesEffect of Clamp Structural On The Compressive Force Behavior Based On Finite Element AnalysisRahul ENo ratings yet

- Graphical Approach in Optimization of Penstock DiameterDocument6 pagesGraphical Approach in Optimization of Penstock DiameterFseha GideyNo ratings yet

- INDUSTRIAL PROJ-WPS Office 2Document31 pagesINDUSTRIAL PROJ-WPS Office 2Clive Jerison VNo ratings yet

- Lab8 BoundaryElementExerciseDocument9 pagesLab8 BoundaryElementExerciseansariNo ratings yet

- Optimization of Axial Flow Turbine For Mean Line Design Using Genetic Algorithm PDFDocument8 pagesOptimization of Axial Flow Turbine For Mean Line Design Using Genetic Algorithm PDFaliNo ratings yet

- RPC HANDOUT 11 DeflectionDocument7 pagesRPC HANDOUT 11 Deflectionricomichaelangelo7No ratings yet

- Paper On Optimisational Design of Pressure VesselDocument12 pagesPaper On Optimisational Design of Pressure VesselEr Pravin V TembeNo ratings yet

- Ijesrt: Optimizing Design of Spring Using Genetic AlgorithmDocument3 pagesIjesrt: Optimizing Design of Spring Using Genetic AlgorithmHabtamu GeremewNo ratings yet

- Lec.2 Similarity of Fluid MachinesDocument25 pagesLec.2 Similarity of Fluid MachinesMechanical EngineeringNo ratings yet

- Application of Optimization Techniques To Weight Reduction of Automobile BodiesDocument6 pagesApplication of Optimization Techniques To Weight Reduction of Automobile BodiesTibebu MerideNo ratings yet

- Design and Analysis of Structural Members of The Jib CraneDocument4 pagesDesign and Analysis of Structural Members of The Jib CraneInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design, Analysis and Development of Hydraulic Scissor LiftDocument8 pagesDesign, Analysis and Development of Hydraulic Scissor Liftmohit talrejaNo ratings yet

- Design Analysis of Industrial Gear Box Casing.: International Research Journal of Engineering and Technology (IRJET)Document5 pagesDesign Analysis of Industrial Gear Box Casing.: International Research Journal of Engineering and Technology (IRJET)Akash NandargiNo ratings yet

- Serviceability Req RCDocument31 pagesServiceability Req RCJoeven DinawanaoNo ratings yet

- M 236 ContentDocument119 pagesM 236 ContentBharath YemireddyNo ratings yet

- Design Analysis of Industrial Gear Box C 221013 042656Document5 pagesDesign Analysis of Industrial Gear Box C 221013 042656Trung ThanhNo ratings yet

- Analysis& Optimizationof Jib Crane Under Influenceof Various Slewing Angles&load Position by Limit State MethodDocument9 pagesAnalysis& Optimizationof Jib Crane Under Influenceof Various Slewing Angles&load Position by Limit State MethodEvodius RweyemamuNo ratings yet

- Designing of All Terrain Eco-Green Vehicle (ATV)Document9 pagesDesigning of All Terrain Eco-Green Vehicle (ATV)JOEL JO THOMASNo ratings yet

- Ansys Project 2 Group-5Document21 pagesAnsys Project 2 Group-5temesgen tesemaNo ratings yet

- Finite Element Project 3-4-2013 Vfinal2Document6 pagesFinite Element Project 3-4-2013 Vfinal2Marcelo ZiulkoskiNo ratings yet

- Really Print MechaDocument1 pageReally Print MechaNicholas NicholasNo ratings yet

- Airport Pavement Design: Airport Classification, and Runway Pavement Design Using Canadian Department of Transport MethodDocument19 pagesAirport Pavement Design: Airport Classification, and Runway Pavement Design Using Canadian Department of Transport MethodNishant AryaNo ratings yet

- ME314 CEP Research GateDocument28 pagesME314 CEP Research GateHuzi MalixNo ratings yet

- Fatigue FailureDocument17 pagesFatigue Failureaiman.mohammadNo ratings yet

- Hbti Ansys Cadcam Centre, KapnurDocument5 pagesHbti Ansys Cadcam Centre, KapnurAjay Kumar OjhaNo ratings yet

- Non Linear AnalysisDocument53 pagesNon Linear AnalysisdpksobsNo ratings yet

- .Knuckle Design For SAE Baja Vehicles Using Real-Life Force DataDocument4 pages.Knuckle Design For SAE Baja Vehicles Using Real-Life Force DataJoshua SajiNo ratings yet

- EXP Performance MV Lab Winch ApparatusDocument5 pagesEXP Performance MV Lab Winch ApparatusMuhammad ZameerNo ratings yet

- Design and Analysis of An Aerial ScissorDocument4 pagesDesign and Analysis of An Aerial ScissorBảo Toàn LêNo ratings yet

- Reinforced Concrete Design: (CIVL 3320)Document24 pagesReinforced Concrete Design: (CIVL 3320)taiman chanNo ratings yet

- Computer Vision Graph Cuts: Exploring Graph Cuts in Computer VisionFrom EverandComputer Vision Graph Cuts: Exploring Graph Cuts in Computer VisionNo ratings yet

- ENG Industrial Cleaning Horticulture LQDocument13 pagesENG Industrial Cleaning Horticulture LQKyriakos MichalakiNo ratings yet

- Brazed Plate Heat Exchangers: 1081 BP SeriesDocument12 pagesBrazed Plate Heat Exchangers: 1081 BP SeriesKyriakos MichalakiNo ratings yet

- Cleaning Guidelines Laude Moulds - 240420 - 171542Document1 pageCleaning Guidelines Laude Moulds - 240420 - 171542Kyriakos MichalakiNo ratings yet

- How To Size A Liquid Control Valve - Blackmonk EngineeringDocument9 pagesHow To Size A Liquid Control Valve - Blackmonk EngineeringKyriakos MichalakiNo ratings yet

- Mixing Valves Application Note Rev August 3 2017 - 230902 - 162913Document14 pagesMixing Valves Application Note Rev August 3 2017 - 230902 - 162913Kyriakos MichalakiNo ratings yet

- HABASIT 04 Guía Ingeniería HabasitLINKDocument100 pagesHABASIT 04 Guía Ingeniería HabasitLINKKyriakos MichalakiNo ratings yet

- How To Improve Hydronic System Performance With PR - 230902 - 175555Document13 pagesHow To Improve Hydronic System Performance With PR - 230902 - 175555Kyriakos MichalakiNo ratings yet

- DeltaPValves Product CatalogDocument24 pagesDeltaPValves Product CatalogKyriakos MichalakiNo ratings yet

- InstrumentationToday - Junio 2015Document23 pagesInstrumentationToday - Junio 2015Kyriakos MichalakiNo ratings yet

- Installed Gain As A Control Valve Sizing Criterion - Valin3Document7 pagesInstalled Gain As A Control Valve Sizing Criterion - Valin3Kyriakos MichalakiNo ratings yet

- Determining The Pressure Drop To Be Used in A Control Valve Sizing Calculation - Valin1Document3 pagesDetermining The Pressure Drop To Be Used in A Control Valve Sizing Calculation - Valin1Kyriakos MichalakiNo ratings yet

- Metrex Valve - How To Size A Water Regulating Valves, R410a Valves, Water Pressure Regulating Valves, Seawater Condensing Valve, Marine ValvesDocument5 pagesMetrex Valve - How To Size A Water Regulating Valves, R410a Valves, Water Pressure Regulating Valves, Seawater Condensing Valve, Marine ValvesKyriakos MichalakiNo ratings yet

- O-Ring-Technical-Handbook-Full 65Document1 pageO-Ring-Technical-Handbook-Full 65Kyriakos MichalakiNo ratings yet

- Jib Crane Calculation As Per BGR RequireDocument10 pagesJib Crane Calculation As Per BGR RequireKyriakos Michalaki100% (1)

- 2016 06 23 Contrx CatalogDocument44 pages2016 06 23 Contrx CatalogKyriakos MichalakiNo ratings yet

- Gorbel Free Standing I Beam Jib Crane ManualDocument24 pagesGorbel Free Standing I Beam Jib Crane ManualKyriakos MichalakiNo ratings yet

- Food Name and Description Density in G/ML (Including Mass and Bulk Density) Specific Gravity Biblioid Update 2.0Document1 pageFood Name and Description Density in G/ML (Including Mass and Bulk Density) Specific Gravity Biblioid Update 2.0Kyriakos MichalakiNo ratings yet

- Various Executions MA: Series Foodstuffs ExecutionDocument17 pagesVarious Executions MA: Series Foodstuffs ExecutionKyriakos MichalakiNo ratings yet

- 3m RTP Design Drawing and BomDocument3 pages3m RTP Design Drawing and Bomadhikaritp9990No ratings yet

- RTS Overview Montreal ASHRAE Chapter 6oct 03Document38 pagesRTS Overview Montreal ASHRAE Chapter 6oct 03thermosol5416No ratings yet

- Pneumatic Flow Regulator Check ValvesDocument8 pagesPneumatic Flow Regulator Check ValvesUzair AnsariNo ratings yet

- Al Dobowi Group Profil-Si NewDocument54 pagesAl Dobowi Group Profil-Si NewdsdsdsdNo ratings yet

- Causes of Over PressurizationDocument2 pagesCauses of Over PressurizationrkubalNo ratings yet

- 750 X Beam ExampleDocument70 pages750 X Beam ExampleianfldNo ratings yet

- Tips For Concrete by Y T Nagaraja PDFDocument54 pagesTips For Concrete by Y T Nagaraja PDFPirpasha UjedeNo ratings yet

- Development of CuZnAl SMADocument5 pagesDevelopment of CuZnAl SMAYudha PradhanaNo ratings yet

- Effect of Eccentricity On Analysis and Design of Isolated FootingsDocument20 pagesEffect of Eccentricity On Analysis and Design of Isolated FootingsAlexandros PapamarinopoulosNo ratings yet

- Table - 1: Ishikawajima-Harima Heavy Industries Co., Ltd. Sharjah Cement Industrial Development CoDocument2 pagesTable - 1: Ishikawajima-Harima Heavy Industries Co., Ltd. Sharjah Cement Industrial Development Cokvinay2003No ratings yet

- Neoprene Barry Controls FAQ ASTM D2000Document3 pagesNeoprene Barry Controls FAQ ASTM D2000MinhddNo ratings yet

- Socket Head Screws Din912Document3 pagesSocket Head Screws Din912weyiheNo ratings yet

- Sub HSE (I&E) : Adnan Ahmad, Kashif AhmadDocument5 pagesSub HSE (I&E) : Adnan Ahmad, Kashif AhmadAdnan AhmadNo ratings yet

- UL 94 - WikipediaDocument2 pagesUL 94 - WikipediaSagar BhokareNo ratings yet

- Duct Calculation Original Xls SheetDocument39 pagesDuct Calculation Original Xls Sheetsaimudduluru88No ratings yet

- Civil Engineering Objective Type Questions by S.S.bhavikattiDocument764 pagesCivil Engineering Objective Type Questions by S.S.bhavikattiShikhin Garg78% (9)

- Radiation Heat TransferDocument28 pagesRadiation Heat TransferJohn Louie GresulaNo ratings yet

- 175 010300 PDFDocument2 pages175 010300 PDFAbu Anas M.SalaheldinNo ratings yet

- Effective Sensible Heat Factors: Room ConditionsDocument2 pagesEffective Sensible Heat Factors: Room Conditionscalvin.bloodaxe4478No ratings yet

- Improve Vacuum Heater Reliability: Hydrocarbon ProcessingDocument4 pagesImprove Vacuum Heater Reliability: Hydrocarbon Processingros56No ratings yet

- HVOF-pump ImpellerDocument4 pagesHVOF-pump ImpellerjohnyNo ratings yet

- TYPE S5 (1-Bedroom Suite) : Unit #02-12 764 SQ FTDocument1 pageTYPE S5 (1-Bedroom Suite) : Unit #02-12 764 SQ FTAdam HudzNo ratings yet

- Building Automation SystemDocument32 pagesBuilding Automation SystemkhadijabugtiNo ratings yet

- Applsci 13 06299 v2Document12 pagesApplsci 13 06299 v2Sa RaNo ratings yet