Professional Documents

Culture Documents

Reservas 1990 y Planos Woodlawn

Reservas 1990 y Planos Woodlawn

Uploaded by

Yojan Ccoa CcopaCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Detailed Lesson Plan in Science 10Document6 pagesA Detailed Lesson Plan in Science 10Roldan Ormilla96% (50)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Albert Pope LaddersDocument28 pagesAlbert Pope LaddersMartin Vilas100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 0250042282ENUIBDocument5 pages0250042282ENUIBZivan SekulicNo ratings yet

- Mary Ann Doane - Stillness + Time 22-38Document9 pagesMary Ann Doane - Stillness + Time 22-38MargaridaMedeiros100% (1)

- Heron Resources Limited 2020Document16 pagesHeron Resources Limited 2020Yojan Ccoa CcopaNo ratings yet

- Incline Top-Slicing Method in Coronado MineDocument13 pagesIncline Top-Slicing Method in Coronado MineYojan Ccoa CcopaNo ratings yet

- Heron Resources Limited 2015Document34 pagesHeron Resources Limited 2015Yojan Ccoa CcopaNo ratings yet

- Heron's Woodlawn Project Mineral Resource and Ore Reserve Statement June 2019Document27 pagesHeron's Woodlawn Project Mineral Resource and Ore Reserve Statement June 2019Yojan Ccoa CcopaNo ratings yet

- Heron's Woodlawn Project - New Mineral Resource On Shallow G2 LensDocument20 pagesHeron's Woodlawn Project - New Mineral Resource On Shallow G2 LensYojan Ccoa CcopaNo ratings yet

- Woodlawn Mine Extraction PlanDocument119 pagesWoodlawn Mine Extraction PlanYojan Ccoa CcopaNo ratings yet

- Heron Resources Delivers Robust Feasibility Study For Wooodlawn ProjectDocument45 pagesHeron Resources Delivers Robust Feasibility Study For Wooodlawn ProjectYojan Ccoa CcopaNo ratings yet

- Stress Induced Damage in Tunnels in A Cave Mining Environment in KimberliteDocument6 pagesStress Induced Damage in Tunnels in A Cave Mining Environment in KimberliteYojan Ccoa CcopaNo ratings yet

- Heron Resources Limited 2019Document15 pagesHeron Resources Limited 2019Yojan Ccoa CcopaNo ratings yet

- Report Tecnico Woodlawn 2016Document486 pagesReport Tecnico Woodlawn 2016Yojan Ccoa CcopaNo ratings yet

- Technical Report (Ni43-101) Preliminary Economic Assessment of The Woodlawn ProjectDocument292 pagesTechnical Report (Ni43-101) Preliminary Economic Assessment of The Woodlawn ProjectYojan Ccoa CcopaNo ratings yet

- Ground Support in Strongly Foliated and Faulted RocksDocument6 pagesGround Support in Strongly Foliated and Faulted RocksYojan Ccoa CcopaNo ratings yet

- Article BlockCaving-inducedStrataMovemDocument18 pagesArticle BlockCaving-inducedStrataMovemYojan Ccoa CcopaNo ratings yet

- Longwall Caving in China The Practice of A New ThickDocument5 pagesLongwall Caving in China The Practice of A New ThickYojan Ccoa CcopaNo ratings yet

- Present Situation and Trend in Swedish MiningDocument6 pagesPresent Situation and Trend in Swedish MiningYojan Ccoa CcopaNo ratings yet

- Trackless Mining at Thabazimbi MineDocument7 pagesTrackless Mining at Thabazimbi MineYojan Ccoa CcopaNo ratings yet

- The Role of Mass Concrete in Soft Rock Block Cave MinesDocument6 pagesThe Role of Mass Concrete in Soft Rock Block Cave MinesYojan Ccoa CcopaNo ratings yet

- Volume 163 - Caving Methods - An Experimental Study of Caving and Drawing Large Ore BodiesDocument42 pagesVolume 163 - Caving Methods - An Experimental Study of Caving and Drawing Large Ore BodiesYojan Ccoa CcopaNo ratings yet

- Caving Operations Drift Support DesignDocument6 pagesCaving Operations Drift Support DesignYojan Ccoa CcopaNo ratings yet

- Analysis of The Surface Subsidence Induced by Sublevel Caving Based On GPS Monitoring and Numerical SimulationDocument21 pagesAnalysis of The Surface Subsidence Induced by Sublevel Caving Based On GPS Monitoring and Numerical SimulationYojan Ccoa CcopaNo ratings yet

- From Green Field Site To Block Cave Mine - Results of Northparke's Drill and Blast Design ProcessDocument13 pagesFrom Green Field Site To Block Cave Mine - Results of Northparke's Drill and Blast Design ProcessYojan Ccoa CcopaNo ratings yet

- Design of Caving SystemsDocument4 pagesDesign of Caving SystemsYojan Ccoa CcopaNo ratings yet

- Design of The Second Block Cave at Northparkes E26 MineDocument12 pagesDesign of The Second Block Cave at Northparkes E26 MineYojan Ccoa CcopaNo ratings yet

- A Ventilation System For Large Block Cave MinesDocument7 pagesA Ventilation System For Large Block Cave MinesYojan Ccoa CcopaNo ratings yet

- Sidiq Subandriyanto Setyawan: Statement of ParticipationDocument2 pagesSidiq Subandriyanto Setyawan: Statement of Participationsetyawan punkNo ratings yet

- +++ James Arthur Ray - The Science of Success +++Document92 pages+++ James Arthur Ray - The Science of Success +++simona_simona_1982100% (4)

- Lesson 01 IntroductionDocument36 pagesLesson 01 IntroductionpangnoodNo ratings yet

- Pie Chart by Skill CountDocument3 pagesPie Chart by Skill CountHồng Thắm Nguyễn ThịNo ratings yet

- HSE Calendar 2023 - 221230 - 112723Document13 pagesHSE Calendar 2023 - 221230 - 112723Mkd OfficialNo ratings yet

- National TB Control Program Adaptive PlanDocument42 pagesNational TB Control Program Adaptive PlanJulius Dominique Lagtapon AnjaoNo ratings yet

- Design Optimization of Gating and FeedinDocument9 pagesDesign Optimization of Gating and FeedinJoao LuisNo ratings yet

- Lala National High School: Maranding, Lala, Lanao Del NorteDocument3 pagesLala National High School: Maranding, Lala, Lanao Del NorteYana AcubNo ratings yet

- Cellules À ConcentrationDocument12 pagesCellules À Concentrationmohamed ikbalNo ratings yet

- ENGL 102 Mixed Tense Exercises (8 Tenses)Document22 pagesENGL 102 Mixed Tense Exercises (8 Tenses)na-labbadNo ratings yet

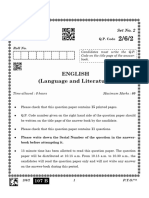

- 2 6 2 English L - LDocument16 pages2 6 2 English L - LAyush RajNo ratings yet

- I Year April, 2019Document2 pagesI Year April, 2019J chandramohanNo ratings yet

- Chemistry XIIDocument18 pagesChemistry XIISayantan DasNo ratings yet

- Maaden MSHEM Safety Documents 8Document143 pagesMaaden MSHEM Safety Documents 8ShadifNo ratings yet

- Electron Scattering For Nuclear and Nucleon Structure John Dirk Walecka Full ChapterDocument51 pagesElectron Scattering For Nuclear and Nucleon Structure John Dirk Walecka Full Chapterwilliam.mcguire766100% (6)

- BIEC - Bengaluru - December 2021 - Exhibitor List - 08.12.2021Document5 pagesBIEC - Bengaluru - December 2021 - Exhibitor List - 08.12.2021JabaneshNo ratings yet

- Regallian DoctrineDocument1 pageRegallian DoctrineMary Joy SumapidNo ratings yet

- QTMS Final Assessment (Spring 2020) PDFDocument6 pagesQTMS Final Assessment (Spring 2020) PDFAbdul RafayNo ratings yet

- Confliect Management - Ogl 220 - ArtifactDocument5 pagesConfliect Management - Ogl 220 - Artifactapi-720145281No ratings yet

- Winsem2020-21 Sts2102 Ss Vl2020210500010 Reference Material I 23-Mar-2021 Permutation and Combination Questions 14Document3 pagesWinsem2020-21 Sts2102 Ss Vl2020210500010 Reference Material I 23-Mar-2021 Permutation and Combination Questions 14john cenaNo ratings yet

- Brochure AqualockDocument2 pagesBrochure AqualockKSRNo ratings yet

- General Geology of RomaniaDocument27 pagesGeneral Geology of RomaniaDana PrisacNo ratings yet

- 2017 Target2017 AbstractsDocument177 pages2017 Target2017 AbstractsLaraNigroNo ratings yet

- 10.1016@j.jsames.2017.02.009 4Document17 pages10.1016@j.jsames.2017.02.009 4dkurniadiNo ratings yet

- Lesson Plan Observation Grade 12 PhysicsDocument4 pagesLesson Plan Observation Grade 12 PhysicsGerald BaculnaNo ratings yet

- ELA Syllabus Grade 2Document19 pagesELA Syllabus Grade 2Farzam GarshasbiNo ratings yet

Reservas 1990 y Planos Woodlawn

Reservas 1990 y Planos Woodlawn

Uploaded by

Yojan Ccoa CcopaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reservas 1990 y Planos Woodlawn

Reservas 1990 y Planos Woodlawn

Uploaded by

Yojan Ccoa CcopaCopyright:

Available Formats

ORE RESERVES ATWOODLAWN MINE

Ore Reserves at Woodlawn Mine, NSW

D J FITZGERALD 1 & R P SINGER 2

1. INTRODUCTION proceeding towards a public float. Denehurst's initial interest in

Woodlawn was in the extensive tailings resource (estimated at 6

This paper discusses recent ore reserve methodology at the million tonnes) from which it was planned to set up a retreatrnent

Woodlawn base metal Mine in New South Wales. The ownership operation and produce metal on site. Denehurst acquired the

of the Mine changed hands in 1987 and a number of revisions to Mine and was listed on the Stock Exchange in August 1987. On

ore reserve practice were instigated by the new operators. While taking over the mine it was determined to continue the operation

the overall modeling and calculation procedure remained of the underground mine while further evaluation of the tatlmgs

essentially unaltered, the modifications and revised assumptions project took place. Based on CRA's reserve at that time a mine

significantly increased the ore reserve. While general ore reserve life of 3 to 4 years for an underground operation was anticipated.

procedures are discussed in this paper, it is the impact of these The sale of the mine coincided with the exhaustion of the open

changed assumptions on the reserves which is our main focus. pit reserves and the reduction of mill throughput to ~50,000

2. EVOLUTION OF OPERATION tonnes per annum. Helped by dramatic improvements m base

metal prices the mine has returned good profits over the last two

The Woodlawn base metal Mine is located 10km west of Tarago years.

in southern NSW. Tarago is 34 km south of the regional centre of

Goulburn (Figure 1). The mineralization was discovered in the

..---------------,

late 1960's by St. Joe Australia Pty Lld following a regional soil

geochemical survey (Malone et al, 1975). Detailed exploration up

to 1978 had demonstrated an open pit insitu resource of complex

ore of 6.3 million tonnes at 1.7% Cu, 5.5% Pb, 14.4% Zn and

89ppm Ag and 3.7 million tonnes of stockwork copper ore

averaging 1.9% Cu.

Woodlawn Mine commenced operations in 1978 as an open pit

mine processing in excess of 900,000 tpa of complex and copper

ore. It was operated initially as a Joint Venture between St. Joe

Minerals, Phelps Dodge and New Broken Hill Consolidated, a

subsidiary of CRA Ltd. At the peak of open pit mining, the

consortium employed 550 people. By 1987 when the open pit

operation was wound down, a total of 8 Mt of ore and 60 Mt of

waste had been mined. Due to the high capital cost in setting up

the mine, a high strip ratio, poor metallurgy and depressed metal

prices, the mine operated unprofitably for most of this period.

With the withdrawal of the other Joint Venture partners, CRA

acquired total control of the Project in 1984 at which time the go

ahead for a feasibility study to look at extending mining

undergrdund was given. This study took approximately two

years to complete. A decline was driven to allow detailed

underground drilling to improve the database for ore reserve

estimation and significant stoping took place to test ground

conditions and provide bulk samples for metallurgical testwork.

Around $10 million was expended on the feasibility study. At the

completion of the study, the mine was at a stage where it could FIG. 1.- Woodlawn Mine Location Map

continue as a fully operational underground mine. The work

force at this time was 230 with consequent greater operational

efficiencies. 3. GEOLOGY A D MI ERALISATIO

By November 1986, although the underground feasibility study The Woodlawn orebody occurs within a sequence of Middle to

had been positive, CRA determined it wished to sell the operation Late Silurian pyroclastics, volcanogenic sediments and

and an active search for a buyer was begun. This purchase carbonaceous shales intruded by diabase sills. Detailed

opportunity coincided with the development of Denehurst descriptions of the geology are provided by Malone et al (1975)

Limited, a technology oriented mining company which was and McKay & Hazeldene (1987). The mineralization is

I Principal, Desmond Fitzgerald & Associates, 30 Wells Street, interpreted to have formed from the precipitation on the sea floor

Brighton Vie. of sulphides from metalliferou fluids associated with

2 Manager Geology for Denehurst Limited , 961 Gl::nhuntly Road, contemporaneous felsic volcanism. This fluid deposition appears

Caulfield South Vie.

Ore Reserves Estimates Melbourne March 1990 125

DJ FITZGERALD and R P SINGER

to have taken place on an unconformity within a submerged lenses occur in the hanging wall of Zone B including Lens 3A

graben (McKay & Hazeldene, 1987). which was added to the reserves in 1989. Other intersections of

The near surface mineralization mined in the open pit consisted massive sulphides have been obtained in the hanging wall of

of a single massive zone of complex ore (containing massive Lens 2B but are not yet sufficiently drilled to enable inclusion in

pyrite with variable sphalerite, galena and chalcopyrite) and an reserves or resources. The three main ore lenses (ie. IB, lC and

associated zone of footwall copper ore (comprising massive and 2B) appear to be separated by a number of major shears and it is

stockwork chalcopyrite and pyrite). At depth however, the con idered that these are the remnants of a single sulphide zone

orebody comprises a number of discrete lenses. Three major (McKay & Davies, 1989/90; BouffIer 1989).

lenses are currently being exploited by the underground mine and Extensive hydrothermal alteration accompanies the

these are depicted in Figures 2, 3 and 4. The mineralisation mineralisation though its distribution is patchy (Petersen &

mined in the pit continues down plunge and is known as Lens Lambert, 1979). Alteration types include Mg-rich chlorite-talc,

lC. A pair of sub parallel lenses occur approximately 250 metres pervasive silicification and chloritization and sericitization. The

to the north-west of Lens lC. These lenses are referred to as abundant talc and chlorite development in places coupled with

Zone B with the smaller (Lens 2B) being approximately 60-70 the average 45° dip of the orebodies makes for very difficult

metres in the hanging wall of Lens lB. All reserves prior to ground conditions.

1989 were contained within these three lenses. Additional

2100RL. sur race l''ill

I

I

I

"---1--1-- --nn-f;;;:::'C

I

I

2600

2500

rls,n,s

2400 _

r.str'fts

~------- -- ------

Inferred

r'souret - - + t - - -

2200

~ I"'hn,d irt.

1..!.Q.L-

~ Hlln dl,lIne

--- ExlStong d.nt.pr.. nt

z z z z z

0 0 0 0 0

2000 ;: ~ ~

0

:. ~

FiG. 2. - Woodlawn Mine Longitudinal Section (looking West)

126 Melbourne March 1990 Ore Reserve Estimates

ORE RESERVES AT WOODLAWN MINE

4. ORE RESERVE PROCEDURES 1986/1987 nominal 20m sections with toe spacings of 20-25 metres. Drill

spacing is considerably wider in the deeper parts of the orebody

A major part of the 1986 Feasibility Study was the complete

where underground workings were absent. All drill hole collars

recalculation of the underground ore reserves at Woodlawn. As

were surveyed and tied into the Woodlawn Mine grid and regular

the previous database was limited to widely spaced surface holes,

surveys were taken using a single shot downhole camera.

earlier estimates had been of the resource potential only. The

assumptions used in this reserve estimate are summarized in the 4.1.2 Sampling

following sections.

All mineralized core was sawn with half core being sampled.

4.1 DATA COLLECTION PROCEDURES Sampling was in nominal one metre intervals though samples

were broken at obvious mineralogical boundaries where

4.1.1 Drilling appropriate.

Sampling of. the orebody was carried out by diamond drilling 4.1.3 Core Logging

from both the surface and underground openings. Most surface

intersections were obtained with NQ core while underground Core recovery was estimated for each sampled interval as a

intersections were with BQ or TT46 size core. Drilling was on percentage of the total interval. Detailed core logging includes

/"-7

~R;'

~RL~

\ //

1/V

/// /

outline

Iv

I

/

v//

2700 /~

//":

complex

~

~ -~

oreX ./;:/

~

/

/

// g copper

ore

I //

2600 ~/

V

2500 / Lens le

2400

~

t==J

)!

II

///

I f Ore mined in open pit

2300 /I Surfore outline

of ore reserves

.' : .... ....

.,','

: Surf ore outline of

inferred resources

~ Mined areas

2200 .. 92S0N

..

""00 ""

0 ""

0 ""

0 ""

0 ""00 w

0

0.., 0 ..,

0 0

~

'".., .., ..,

r- .., C>"" 0

"" ""

FIG. 3. - Representative Cross Section at 9250N showing lens Ic and its open pit equivalent

Ore Reserves Estimates Melbourne March 1990 127

DJ FI1ZGERALD and R P SL\fGER

2800RL

2700

lens 3

2600 . .:(:::?

, /

:-.;.,

lOO;! rr

2500 /

tt:

2400 1/r?

IVy

lb Cx

2300 ......

r

.... ~ lens lb Cu

/f/ Sur/ore outline

of ore reserves

...::.... 5urfore

-

::>:' outline of

2200 I : inferred resources

Mined uus

jf

9500N

:.: .....

2100

w w w w w w w

0 0 0 0 0 0 0

~

.,

0

N

OD

....

0

OD

0

~

0

.,'" ..,

0

.,

0

.,....

OD

FIG. 4. - Represemative cross section at 9500N showing lenses 1beu, 2b,3

lithology, structure and mineralization. This was routinely done determinations made for every 30th sample. Any gold assay over

on all core and the data stored in the WOODLOG database. This 2 g/tonne was repeated by fire assay.

is used to interpret and to check computer assisted orebody

models. 4.1.5 Specific Gravity

Specific gravities used up to the time of the feasibility study were

4.1.4 Assaying

3.9 for complex ore and 2.9 for copper ore. These were based on

All assaying was undertaken on site at Woodlawn's own NATA determinations over a number of years on material from the open

certified laboratory. Samples were jaw-crushed to less than 6mm, piL A total of 150 determinations of specific gravity on selected

roll-crushed to less than 1.5mm and quartered to obtain a 150 core from the underground drilling programme were specifically

gram cut for pulverising. Part of the sample was acid digested to made for the study to check these values. Both complex and

copper ore were sampled and the means of the two populations of

determine coppe,r, lead, zinc, silver and gold by AAS. Another

4.1 and 2.7 were obtained. It was decided that for the purposes of

portion was compressed for XRF analysis for Fe, Mg, Si, Al and

the feasibility study the historic values of 3.9 and 2.9 would be

Ba. Good assay confidence was obtained through replicate retained.

128 Melbourne March 1990 Ore Reserve Estimates

ORE RESERVES ATWOODLAWN MINE

4.2 MANUAL METHODS The second phase allows the user to refine the model surface to

the desired shape by moving existing control points or by adding

During the initial phases of the underground feasibility study, a

new ones. Additional control points can be digitised from

manual method for estimating the position in space of the

mapped ore outlines ensuring the model is consistent with

surfaces for each lens was developed. This method formed the

observations made during mining and as more information

basis for defining a volume and hence a tonnage, however it

becomes available. Utilizing all information, surfaces for both

proved tedious and time consuming as continuous changes were

the hangingwall and the footwall are constructed by creating

being forced by more up to date data. The need for a more

best-fit triangles between essentially random points in space. The

interactive and responsive computerized method became

triangulation algorithm was initially adapted from the work of

imperative if the timetable for the feasibility study was to be

Akima (1978) but has recently been changed to one derived by

adhered to.

Watson (1981) which enables a common surface between

4.3 DEVELOPMENT OF COMPUTERIZED ORE ." touching lenses to be assured. These surfaces are manipulated by

RESERVES the geologist for continuity or any other criteria felt appropriate

(e.g. faulting). The surface and contour diagrams are generated at

From the beginning of the 1980's, Woodlawn Mines had been any time during the process quickly enough so that it is practical

active in all aspects of on site technical computing. In particular, to make many revisions and refinements to the interpretation.

the geological database was computerized and supported by in The third phase allows the user to calculate block tonnages and

house developed interactive Basic and then Fortran programs to allocate grades. Block tonnes and grade data from this phase

using a PDP-ll/40. The geological needs of the open pit of the programme are stored in 'reserve' files.

operation were well served by these tools. With the increased

SURFORE has a menu driven orebody plotting optipn used to

demands on the geological staff during the initial phases of the

underground feasibility study, it became apparent that an upgrade produce scale drawings of orebodies or reserve information. The

drawings can include control points, hole data, reserve blocks,

to a more modem and robust computing facility was required.

surface contours, etc as required. This is the basic tool to get

Des Fitzgerald and Associates (DFA) were retained to assist in

working drawings. One strength of the design of this option is the

specifying an approach to meet the needs of the mine. In

abilitY to compose and preview the hard copy drafting on a

particular, the need for interactive computer graphics and more

integrated tools was recognized. A microVax 11 was purchased graphics screen. The displayed information can then be written to

a 'plot' file which can be spooled to a plotter or exported to a

along with two high resolution interactive colour graphics

terminals (Seiko 'and Lexidata). The move to modeling of the drafting package such as AUTOCAD.

orebody required a more sophisticated level of computer software SURFORE has the capability to interrogate ore reserve models

and this was satisfied by the development of the SURFORE and generate tonnes and grade reports. An option for allowing

orebody modeling system by DFA. mining cuts when calculating block tonnes is also available. The

calculated reserves data for a model is stored permanently on a

4.4 SURFORE - ORE RESERVES SOFTWARE disc and can be interrogated by a variety of programs. The data is

designed to be easily imported into spreadsheets such as Lotus.

SURFORE was designed with the following main objectives:

In a recent development SURFORE has been ported to

a) To model the surfaces of underground ore bodies. TECHBASE, a generalised mining package, making it more

b) To compute tonnages and grade for an arbitrary grid of cells accessable to the mining community at large.

within orebody models.

4.5 GEOLOGICAL INTERPRETAnON

c) To simulate established manual methods.

The initial interpretation of the lenses was made by preparing

d) To allow easy manual checking of any or all phases of the cross-sections at intervals ranging from 35 to 60 metres showing

process. hole paths with symbolic rock types and mineralized limits.

e) To use a systematic design approach to allow easy Preliminary interpretations for continuity both on and between

modification and tailorjng. sections for individual lenses were made. SURFORE was used to

project the same information onto an interactive graphics screen.

f) To create a highly productive tool for the professional A more detailed interpretation based upon 20 metre sections was

geologist. then developed.

g) To minimise training requirements for new staff. 4.6 CUT OFF GRADE

The system employs many computer aided engineering Cut off grades were determined on the basis of Equivalent Zinc

techniques to provide an easy to use and productive environment. Units (EZU) for complex ore and Equivalent Copper Units

The central program in the SURFORE system is menu driven (ECU) for copper ore. In practice only the EZU formula was

and it consists of three distinct parts or phases. The first phase used as tlle great bulk of mineralisation was classified as complex

allows the user to nominate points on the footwall and ore. These formulae were based on the relative pricing of the end

hangingwall surfaces of the orebody. Assay data from all products and mill recovery factors operating at the time.

drillholes is displayed in histogram form at right angles to the Initially the following formula was used:

hole trace. Limits to the mineralization are nominated by the

geologist and referred to as control points. Pairs of EZU% = 1.3 x Cu% + 0.1 x Pb% + Zn% +.02 x Ag g/t

footwall/hangingwall points in true three-dimensional space are

thus created for each hole that intersects a lens. These points can

This was changed during the course of the study to:

be viewed freely in any of the three standard orthogonal planes.

The points are stored in 'control point' files which are updated

every time a user exits from phase one. EZU% = 1.6 x Cu% + 0.1 x Pb% + Zn% + Ag/55 g/t - 2.5%

Ore Reserves Estimates Melbourne March 1990 129

DJ FI1ZGERALD and R P SINGER

4.11 RESERVE STAGES

A 10% EZU was used as a cut off for the complex ore in cross A number of stages of reserves were calculated and reported in

section projection at the margin of the mineralization. the feasibility study. The original in situ reserve was adjusted to

Mineralization was considered economic at this grade after eliminate all ore of plan width less than 3 metres. This reserve

consideration of all mining and treatment costs. This cut off was was termed the "3M Reserve" and was essentially equivalent to a

however applied strictly in the modeling procedure independently mineable reserve. A second reserve was calculated and referred

of the proposed mining method. to as the "5M Reserve" which equates to a recoverable reserve.

4.7 REGULAR REVISION OF MODELS This was derived by eliminating all ore of plan width less than 5

; metres and assigning "cut factors" to each block based on the

D~ring the feasibility study, two hydraulic drills were operating projected mining recovery. The resulting layout of blocks was

and producing as much as 100 metres of core a day. This core inspected by the Mining Department which led to som~ bl?cks

was continuously being logged, split and assayed. A turn-around being restored to the reserve so that access could be mamtamed,

of less than two weeks from drilling to incorporation into an ore- whilst others were eliminated due to inaccessibility. A dilution

body model of the complete assay and survey data for a hole was factor of 5% on tonnes was then applied and the in situ grades

regularly achieved. This enabled a continuous re-assessment of were cut by 15% to arrive at a final recoverable reserve.

interpretations and revision of targets for drilling. Rapid

turn-around of data and interpretations proved to be a very 4.12 RESULTS

significant component of the strength of the SURFORE system. The calculation of the reserves was completed on schedule in mid

Data entry, reinterpretation of models and recalculation of 1986, despite severe time constraints, and auditing of the reserves

reserves following new drill data can be achieved typically within by Robertson Research took place in September 1986 (Cotton,

3 hours. 1986).

4.8 GRADE COMPOSITING Reserves reported in the Woodlawn Evaluation were as listed

in Table 1. No breakdown of these reserves was given with

A composite grade for the intercept of each drillhole in an Proven, Probable and Possible reserves being combined in a

orebody was calculated using the following rules. Individual single figure. This was done to facilitate comparison w~th an

sample intervals are length weighted and running totals for each earlier in situ resource estimate that had been the baSIS for

element's mass are maintained. Where there is core loss, it is preliminary assessment of the potential for an underground mine.

assumed that the material lost was of no economic significance The total "3M Reserve" figure of 4.3 million tonnes was reduced

and so the length contributions of Cu, Pb, Zn and Ag assays are to 3.4 million tonnes for the "5M Reserve". Following additional

proportionally cut by the percentage core loss (e.g. length x Cu% drilling completed after the conclusion of the evaluation study, an

x core loss %). The drill hole intercept grades for Cu, Pb, Zn, Ag,

Au, Fe, Mg, AI, Ba and Si are then calculated by dividing the

length contributions for each element by the total intercept length. TABLE 1

Recoveries were in general lowest in the talc rich shear zones and Woodlawn Mine Reserve Estimates 1986/87

it was felt that use of the more conservative grades calculated for

these areas by this method was prudent.

tonnes % Cu % Pb % Zn Ag g/t

4.9 RESERVE CALCULATIONS (millions)

Using SURFORE a two dimensional block grid of dimensions 20

1986 Evaluation

metres long by 5 metres high is superimposed over the long

Study

section trace of the ore-body outline. The width of the blocks is

September 1986

the orthogonal distance between corresponding positions on the

interpolated hangingwall and footwall surfaces. Grades were 5.7 14.3 115

"3M Reserves" 4.3 1.7

assigned into each block by the geologist by deciding on a

(Proven & Prob

combination of the nearest drillhole bulked intercept grades.

& Poss)

Investigations into the use of other block sizes (such as lOm x

5m) are currently taking place.

"5M Reserves" 3.4 no grade available

4.10 CLASSIFICATION

Updated "5M

The terminology used was consistent with the 1981 Aus I.M.M. Reserve"

recommendations current at the time of the Study (Joint January 1987

Committee, '1982). The rule for classifying ore reserve blocks

into Proven, Probable and Possible was based on the distance of Proved Reserves 1.02 1.47 4.50 11.31 91

the centroid of the block from a drillhole assay sample in the Probable 1.44 136 5.04 12.19 110

same lens. If this distance was less than 20 metres the block was

considered Proven. If the distance was greater than 20 metres but Proved and Probable

Reserves 2.46 1.41 4.82 11.82 102

less than 40 metres, then the block was classified as probable. If

the distance was greater than 40 metres then the block was

Possible "Reserv~s" 0.71 1.21 4.49 1.76 74

considered possible. The lens was interpreted to extend no more

than 80 metres from the nearest sample data. These rules could Total 3.17 1.37 4.75 1.81 96

however be overridden by the geologist.

130 Melbourne March 1990 Ore Reserve Estimates

ORE RESERVES AT WOODLAWN .MINE

updated reserve calculation was made as at 1st January 1987. No Given the variability of sulphide content in the different ores at

changes were made in the assumptions discussed earlier in this Woodlawn, it was decided to review the use of average specific

paper and the models developed for the feasibility study were gravities as outlined in Section 4.1.5. A programme of density

essentially the same except for the refinement brought about by determinations on samples of core which were subsequently

the additional drilling. This reserve incorporated a breakdown assayed for Cu, Pb, Zn and Fe was carried out. A multiple

into Proven and Probable reserves and Possible "reserves" (see regression of the data revealed a very close correlation between

Table 1). Recoverable reserves (Proven and Probable) at the specific gravity and the Fe and Pb and, to a lesser extent, Zn

beginning of 1987 were estimated at 2.46 million tonnes with a assays. The derived relationship was .

further 0.71 million tonnes classified as possible "reserves". With

the continuation of mining it is estimated that the remaining SG = 2.2118 + 0.0552 x Fe% + 0.0487 x Pb% + 0.0226 x Zn%

Proven and Probable reserves at the time of the hand over of the

Mine to Denehurst were approximately 2.2 million tonnes or just

on four years mine life. Use of this formula on the average grade of each lens produced

the following specific gravities for the complex ores:-

5. ORE RESERVE PROCEDURES 1988/1989 Lens lE 3.67

Following the acquisition of the Mine by Denehurst and after Lens 2B 3.98

some months operating experience, it was recognised by the end Lens 1C 3.92

of 1987 that the existing ore reserve had a number of deficiencies. It was decided that the use of this formula was likely to provide

It was decided in the first half of 1988 to undertake a major a better estimator than the use of average values and this formula

reassessment of the ore reserve procedures. is now used routinely for tonnage estimation. It is proposed to

refine the formula as more data becomes available.

The main factors which necessitated this were:-

a) The dramatic increases in base metal prices in 1987/1988 5.3 CUT OFF GRADE FORMULA

rendering the original EZU cut off grade formula A critical examination of the effects of using a cut off grade

inappropriate. Continued use of this formula meant the formula that composites two or more metals was undertaken. The

elimination from the reserves of moderate to high grade original bias in 1986 was towards the complex ore being

copper ore which had become economic. evaluated in Equivalent Zinc Units. Observations of material that

<

b) Mining experience was indicating that significantly more was less than 10% EZU suggested that considerable thicknesses

ore was being extracted from some areas than suggested by of mineralization were not included in the reserves. The most

the reserves. This was clearly the result of the chosen cut obvious anomalies arose in copper rich portions of the complex

off grade for the reserve (10% EZU) not reflecting mining ore. For example in DDH U148 the 1986 reserve intersection was

practice, which was, wherever possible, to mine to the

natural ore limits. Experience showed that for the mining

method at Woodlawn, mining to an arbitrary cut off grade 269-279m (lOm) @ 2.46% Cu

was not practical. 5.23%Pb

14.38%Zn

c) Adoption of the Aus I.M.M.'s Australasian Code for

56 ppmAg

Reporting ofIdentified Mineral Resources and Ore Reserves

The total observed mineralization was

(Joint Committee, 1988) meant that the Woodlawn reserve

261.7-279m (17.2m)@ 3.51 % Cu

methodology had to be reviewed to ensure that the

3.07% Pb

requirements of the Code were being met. This was

8.81%Zn

particularly so with regard to the classification into Proven

40 ppmAg

and Probable Reserves.

This meant that the material left out of the 1986 reserve was

d) As underground access to more of the orebody became 261.7-269m(7.2m)@ 4.95%Cu

available, further detailed exploration took place. This 0.11% Pb

meant considerably more information on the deeper 1.16%Zn

mineralization became available requiring reassessment of 17ppmAg

reserves in these areas. With significant increases in the prices of Cu and Zn from late

Durin~ the course of this review, many of the 1986 practices

1987 and improved metal recoveries, weightings in the formula

were revised. The following discussion details these changes. had become outdated. In addition the breakeven cut off was too

high in terms of EZU due to the much higher prices.

5.1 DATA COLLECTION PROCEDURES The cut and fill mining practice adopted during the first year of

The original data base remained unchanged with the exception of operation was to stope to a visible cut off or lithological

the addition of some further drilling completed between January boundary. There was no attempt by on-site geological or mining

1987 and June 1988. Drilling, sampling and core logging staff to mark up or to indicate the portions of the orebody that

techniques remained unchanged. Minor refinements to assaying complied with the 10% EZU criteria. It was considered

techniques had taken place in the intervening two years including impractical to mine to an arbitrary cut off. This practice resulted

the introduction of a new combined crusher and splitter and the in significantly higher ore extractions in some areas than was

replacement of AAS with Inductively Coupled Plasma (ICP) expected from the ore reserves. It also meant that the SURFORE

analysis for some elements. derived ore outlines were not able to be used reliably in mine

planning. It became clear that reserve practice in relation to the

5.2 SPECIFIC GRAVITY use of the EZU cut off would have to be drastically changed.

Ore Reserves Estimates Melbourne March 1990 131

DJ FITZGERALD and RP SINGER

As a practical solution to this problem it was decided to The above was entirely empirical in its derivation and was

abandon the use of equivalence formulae for cut off intended to provide an objective rule which could be applied by

determination. In their place all ore was included which fell the computer and yet simulate the classification that would have

within "natural" cut offs to more closely reflect the current been derived using the geologist's judgment. This relatively

mining practice. In the few instances where a "natural" cut off minor technical change had a large impact on the revised reserves

could not be recognised, assay cut offs of 5% Zn or 2% Cu were and the implications of this are discussed in Section 7.

used as these were considered to closely simulate the observable

limit of sulphides. 5.6 ORE RESERVE STAGES

During the 1988 review, all existing holes were checked in the The calculation of the final ore reserve takes place through a

data base and the previous ore reserve intersections reassessed. number of distinct stages. After 12 months of mining experience

Where the existing cut off points were considered inconsistent it was possible to more rigorously define these stages.

with the new cut off criterion, they were replaced by new

5.6.1 In Situ Resources

footwall and hangingwall control points based on a natural cut

off. The revision of this practice had the obvious effect of These resources represent the total global estimate of

dramatically increasing the in situ ore reserves. mineralization contained within the nominated edge polygon

determined by the geologist. No application of minimum mining

5.4 GRADE ASSIGNMENT thicknesses or allowance for ore already mined is made. The

As noted in Section 4.9 assignment of grade to reserve blocks resource is divided into measured, indicated and inferred

prior to 1987 was made on the basis of the nearest drillhole categories along the lines discussed in the previous section.

bulked intercept grade. This was considered to be a crude 5.6.2 Mineable Reserves

estimator and as part of the 1988 review a missing value test was

run for all the lenses to determine the appropriateness of other Mineable ore is defined as those in situ resources which are

grade estimation techniques. A total of 27 variations on inverse considered economically exploitable and are available for mining

after allowing for ore already extracted, minimum mining widths

power rules and power transforms were trialed. This test

and areas sterilized by mining or geological factors. All ore of

~onfirmed that the inverse distance squared weighting in three width less than 3 metres is excluded from the reserve. Ore along

dimensions with no power transform gave the best estimates of strike from a mined area is treated as sterilised by the mining

grade at a known point. This weighting was subsequently method and is also eliminated. For marginal blocks or blocks

adopted. affected by pre- existing mining, a factor of between 0 and 1 is

assigned by the geology and mining staff to represent the

5.5 RESERVE AND RESOURCE CLASSIFICATION percentage of a block available for mining. Only measured or

Considerable thought was given to the most appropriate method indicated resources are considered in assessing mineable reserves

for the categorisation of the various reserve and resource blocks and these are classified as Proven and Probable reserves

to ensure that it was realistic and that it satisfied the new Aus respectively.

I.M.M. Guidelines (Joint Committee, 1988). These guidelines 5.6.3 Recoverable Reserves

state simply that for resources to be considered as measured (or

Recoverable reserves represent that tonnage of mineable reserves

reserves as Proven), sample data (in this case drilling) must be which is estimated to be able to be recovered. All blocks in the

closely enough spaced to confirm continuity. mineable reserve are assessed for their potential mining

Examination of the distribution of reserve blocks of the various recoveries after taking into account the mining method, pillar

categories under the then existing rule (see Section 4.10) locations, ground conditions, and geological structures.

suggested that in many areas material was classified as Proven Historical recovery factors are used in areas where previous

and Probable where continuity could not be assured. This was mining has taken place. In areas remote from mining,

particularly so with some of the deeper holes which were often conservative recovery factors ranging from 50% to 70% are used.

The calculation of the recoverable reserve is achieved by

widely spaced from other holes. In an attempt to ensure that the

applying the estimated recovery factor for each block to the

categorisation of the reserves and resources related more to the

equivalent block tonnage in the mineable reserve. Inferred

density of drilling rather than to the distance to the nearest drill resources are not adjusted for mining recovery.

hole, the rule for classifying an ore-block into measured and

indicated (or Proven and Probable) was changed. This had the 5.6.4 Diluted Recoverable Reserves

effect of creating larger, more continuous areas of one An estimated dilution factor is applied to the total recoverable

classification rather than the more patchy distribution of blocks reserve to arrive at the final diluted recoverable reserve. Based

under the old rule. It was also considered to better represent the on observations during the first year of operation, dilution has

confidence levels and more particularly the likely continuity. The been found to be highly variable. While it generally falls in the

new rule is as follows:- range of 8-10% in individual stopes where ground conditions are

If the centroid of a block is within 20 metres average poor it may reach 20-30%. An average figure of 10% has been

distance to the nearest 3 drillholes, then the block is classed accepted. Nil grade has been assumed for this material on the

as measured (or Proven). assumption that most of the dilution derives from footwall or

hangingwall overbreak. In practice this material will carry some

If the block, is greater than 20 metres and less than 40 metres grade. Allowance for dilution has the effect of increasing the

average distance to the nearest 4.drill holes, then the block is reserve tonnage and decreasing the reserve grade. It is these

considered indicated (or Probable). diluted recoverable reserves which are quoted in releases to the

All other blocks within the bounds of the interpretation are Australian Stock Exchange in line with the Aus LM.M.

considered as inferred resource. guidelines. No dilution is applied to inferred resources.

132 Melbourne March 1990 Ore Reserve Estimates

ORE RESERVES ATWOODLAWN MlNE

6. RESULTS OF ORE RESERVE REVISION The second major factor effecting significant change to the

reserves is of perhaps more fundamental significance. A

The results of the 1988 reserve recalculation are given in Table 2 relatively minor change to the categorization procedure such as

and they can be seen to differ markedly from those calculated in

was introduced at Woodlawn has the potential to make a

1986 and 1987 (fable 1). The increase in the reserves (ie. Proven

and Probable) to 3.15 million tonnes is despite the mining of significant change in the final reserves figure. The problem here

approximately 700,000 tonnes in the intervening period. The is that such categorization procedures cannot be standardised by

grade of this reserve was however significantly lower for Pb and the imposition of industry wide guidelines. They derive from the

Zn but higher for Cu - reflecting the abandonment of the EZU cut geologist's judgment and may be different for different orebodies

off formula. An additional complex inferred resource of 1.95 depending on the geology, orebody geometry and overall level of

million tonnes was also recognised along with a newly calculated understanding. At Woodlawn the changes were introduced after a

copper inferred resource of 0.88 million tonnes. Because of the significant period of mining had led to increased confidence in

dramatic increase in the reserve position Robertson Australia correlations between drillholes and projected continuity.

The experience at Woodlawn highlights another important

TABLE 2 feature of ore reserve estimation, namely the stage in the life of

Woodlawn Mine Reserves and Resource Estimates - June 1988 the mine at which the estimate is made. Perceptions are often

dramatically different at the pre-feasibility or feasibility stage of

tonnes %Cu a mine's development compared with those after a mine has been

%Pb %Zn Ag g/t.

(millions) operating for some time. This is not simply a result of the

increased level of understanding that comes with an operating

Proven 2.01 mine but may also be a function of the different economic

1.66 4.56 10.53 119

Probable 1.14 1.57 imperatives. At the feasibility study stage there is a natural

4.25 10.65 92

tendency for inbuilt conservatism in the resource assessment.

Total Proven and This is to ensure that the investment necessary to commence a

Probable Reserves 3.15 mine is not predicated on an ore reserve which later turns out to

1.63 4.46 10.59 109

be over optimistic. On the other hand if the mine is operating and

Inferred Resources the investment has been sunk the emphasis becomes one of

Complex 1.95 1.1 maximising the return from the available resource.

3.9 10.6 58

Copper 0.88 4.1 Mineralization which may have been ignored for earlier

1.2 3.7 26

assessments may be considered as economic once underground

Total Inferred development is in place. This is certainly the case at Woodlawn

Resource 2.83 where as part of the 1989 reserve update ore reserves were

2.1 3.1 8.4 48

included from Lens 3 which had not earlier been considered in

the reserves or resources despite the knowledge of potentially

were again asked to audit the changes in procedure. They

economic mineralization. Drilling is taking place on other lenses

concluded that the procedures used gave a "fair representation of

the material to be mined" and that "the categorization of the not currently in the reserves or resources and it is hoped that

reserves and resources conform to the Aus I.M.M. Guidelines" further reserves will be identified.

(Leahey, 1988). These revised reserves indicate a significantly The importance in ore reserve estimation of keeping

longer mine life than had been anticipated. assumptions under constant review cannot be overestimated.

Any change in a reserve estimate can have a large impact on the

7. CONCLUSIONS

perceptions of the mine or its controlling company to those

The main factors which have contributed to the increase in outside. In the case of Woodlawn the re-evaluation of the

reserves at Woodlawn are changed assumptions in the cut off reserves has changed the mine from one with a life of not much

grade criteria and in the categorization rules. Other alterations to more that three years at the time of Denehurst's acquisition to an

procedures such as modifications to the treatment of specific operation in 1989 with a projected six year life and with

gravities have had only a minor or neutral effect. While drilling additional resources which give the expectation of the Mine

carried out prior to the 1988 review resulted in the upgrading of continuing for some years beyond that.

some mineralization to reserves, the bulk of the change was due

to the two factors highlighted above. The orebody modeling 8. ACKNOWLEDGEMENTS

procedure or calculation techniques have not been altered and the

database is unchanged except for the addition of the drilling just The assistance and support of Dr w.J. McKay and R.H. Davies

referred to. who contributed to fundamental and helpful discussions of

The data presented in this paper serves to emphasize the SURFORE algorithms used in the underground feasibility study

is gratefully acknowledged. The dedicated team work of the staff

fundamental importance of assumptions such as these in the ore

at Woodlawn has been a very significant factor in the success of

reserve estimation process. It also demonstrates the need to keep

the mine operation today. The authors wish to record their thanks

these assumptions under constant review. The use of an EZU cut to Denehurst Limited for their support in the preparation of the

off grade formula, as originally applied at Woodlawn, does enable paper and permission to publish and to Dr w.J. McKay and MJ.

account to be taken of changes in price levels, recoveries and Bouffler who reviewed the manuscript and provided many

operating costs provided such reviews are regular and timely. The helpful comments.

relevance however of such a cut off in terms of practical

considerations needs to be kept in mind. At Woodlawn the 9. REFERENCES

adopted cut off became inappropriate essentially because of the Akima, H., (1978). A Method of Bivariate Interpolation and

unrealistic levels of grade control which would have been Smooth Surface Fitting for Irregularly Distributed Data Points.

required to comply with such a cut off coupled with the fact that ACM Trans. on Mathematical Software Vol. 4, No 2.

mining was taking place to the obvious sulphide limits.

Ore Reserves Estimates Melbourne March 1990 133

DJ FI1ZGERALD and R P SINGER

Bouffler, M (1989). Recent Developments at the Woodlawn Metals, Mono 5 (ed C.L. Knight) pp 701-710. Aus LM.M.:

Mine. Abstract in Base Metal Update Some Australian Base Melbourne.

Metal Projects - Exploration and Recent Developments. NSW McKay, W.J., 1989. A study of the Geological Setting. Nature

Dept. Minerals and Energy, Sydney Mineral Exploration and Genesis of the Woodl awn Base Metal Deposit NSW.

Discussion Group Symposium, Sydney, October 1989. Australia. PhD Thesis (unpublished), Australian National

Cotton, R. E., (1986). Assessment of geological model and University.

method used to establish underground in situ ore reserves, McKay, WJ., and Davies, R.H., (1989/90). Woodlawn - A

Woodlawn Mine, NSW. Robertson Research Australia Synthesis of Exploration and Structural Geology. In Geological

(unpublished report). Aspects of the Discovery of Some Important Minerals in

Joint Committee of the Australasian Institute of Mining and Australia (Draft Title). ed. K.R. Glasson (in press). Aus

Metallurgy and the Australian Mining Industry Council, 1982. LMM.: Melbourne.

Reporting of Ore Reserves, Aus LM.M.: Melbourne. McKay, WJ., and Hazeldene, R.K., 1987. The Woodlawn

Joint Committee of the Australasian Institute of Mining and Zn-Pb-Cu Sulfide Deposit, New South Wales, Australia: An

Metallurgy and the Australian Mining Industry Council, 1988. Interpretation of Ore Formation from Field Observations and

Australasian Code for Reporting of Identified Mineral Metal Zoning, Econ Geo!., v. 82: 141-164.

Resources and Ore Reserves. Aus LM.M.: Melboume. Petersen, M.D., and Lambert, I.B., 1979. Mineralogical and

Leahey, TA., 1988. Audit of Ore Reserve Procedures Used at Chemical Zonation around the Woodlawn Cu-Pb-Zn Ore

Woodlawn Mines, Tarago, NSW. Robertson Australia Deposit, Southwestern New South Wales. J. Geo!. Soc Aust.,

(unpublished report). 26: 169- 186.

Malone, EJ., Olgers, E, Cucchi, E G., Nicholas, T., & McKay, Watson, D.E (1981) ACORD: Automatic Contouring of Raw

W.J., 1975. Woodlawn Copper-lead-zinc Orebody. In Data. CAGEO Vol. 8, No.1

Economic Geology of Australia and Fapua New Guinea 1,

134 Melbourne March 1990 Ore Reserve Estimates

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Detailed Lesson Plan in Science 10Document6 pagesA Detailed Lesson Plan in Science 10Roldan Ormilla96% (50)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Albert Pope LaddersDocument28 pagesAlbert Pope LaddersMartin Vilas100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 0250042282ENUIBDocument5 pages0250042282ENUIBZivan SekulicNo ratings yet

- Mary Ann Doane - Stillness + Time 22-38Document9 pagesMary Ann Doane - Stillness + Time 22-38MargaridaMedeiros100% (1)

- Heron Resources Limited 2020Document16 pagesHeron Resources Limited 2020Yojan Ccoa CcopaNo ratings yet

- Incline Top-Slicing Method in Coronado MineDocument13 pagesIncline Top-Slicing Method in Coronado MineYojan Ccoa CcopaNo ratings yet

- Heron Resources Limited 2015Document34 pagesHeron Resources Limited 2015Yojan Ccoa CcopaNo ratings yet

- Heron's Woodlawn Project Mineral Resource and Ore Reserve Statement June 2019Document27 pagesHeron's Woodlawn Project Mineral Resource and Ore Reserve Statement June 2019Yojan Ccoa CcopaNo ratings yet

- Heron's Woodlawn Project - New Mineral Resource On Shallow G2 LensDocument20 pagesHeron's Woodlawn Project - New Mineral Resource On Shallow G2 LensYojan Ccoa CcopaNo ratings yet

- Woodlawn Mine Extraction PlanDocument119 pagesWoodlawn Mine Extraction PlanYojan Ccoa CcopaNo ratings yet

- Heron Resources Delivers Robust Feasibility Study For Wooodlawn ProjectDocument45 pagesHeron Resources Delivers Robust Feasibility Study For Wooodlawn ProjectYojan Ccoa CcopaNo ratings yet

- Stress Induced Damage in Tunnels in A Cave Mining Environment in KimberliteDocument6 pagesStress Induced Damage in Tunnels in A Cave Mining Environment in KimberliteYojan Ccoa CcopaNo ratings yet

- Heron Resources Limited 2019Document15 pagesHeron Resources Limited 2019Yojan Ccoa CcopaNo ratings yet

- Report Tecnico Woodlawn 2016Document486 pagesReport Tecnico Woodlawn 2016Yojan Ccoa CcopaNo ratings yet

- Technical Report (Ni43-101) Preliminary Economic Assessment of The Woodlawn ProjectDocument292 pagesTechnical Report (Ni43-101) Preliminary Economic Assessment of The Woodlawn ProjectYojan Ccoa CcopaNo ratings yet

- Ground Support in Strongly Foliated and Faulted RocksDocument6 pagesGround Support in Strongly Foliated and Faulted RocksYojan Ccoa CcopaNo ratings yet

- Article BlockCaving-inducedStrataMovemDocument18 pagesArticle BlockCaving-inducedStrataMovemYojan Ccoa CcopaNo ratings yet

- Longwall Caving in China The Practice of A New ThickDocument5 pagesLongwall Caving in China The Practice of A New ThickYojan Ccoa CcopaNo ratings yet

- Present Situation and Trend in Swedish MiningDocument6 pagesPresent Situation and Trend in Swedish MiningYojan Ccoa CcopaNo ratings yet

- Trackless Mining at Thabazimbi MineDocument7 pagesTrackless Mining at Thabazimbi MineYojan Ccoa CcopaNo ratings yet

- The Role of Mass Concrete in Soft Rock Block Cave MinesDocument6 pagesThe Role of Mass Concrete in Soft Rock Block Cave MinesYojan Ccoa CcopaNo ratings yet

- Volume 163 - Caving Methods - An Experimental Study of Caving and Drawing Large Ore BodiesDocument42 pagesVolume 163 - Caving Methods - An Experimental Study of Caving and Drawing Large Ore BodiesYojan Ccoa CcopaNo ratings yet

- Caving Operations Drift Support DesignDocument6 pagesCaving Operations Drift Support DesignYojan Ccoa CcopaNo ratings yet

- Analysis of The Surface Subsidence Induced by Sublevel Caving Based On GPS Monitoring and Numerical SimulationDocument21 pagesAnalysis of The Surface Subsidence Induced by Sublevel Caving Based On GPS Monitoring and Numerical SimulationYojan Ccoa CcopaNo ratings yet

- From Green Field Site To Block Cave Mine - Results of Northparke's Drill and Blast Design ProcessDocument13 pagesFrom Green Field Site To Block Cave Mine - Results of Northparke's Drill and Blast Design ProcessYojan Ccoa CcopaNo ratings yet

- Design of Caving SystemsDocument4 pagesDesign of Caving SystemsYojan Ccoa CcopaNo ratings yet

- Design of The Second Block Cave at Northparkes E26 MineDocument12 pagesDesign of The Second Block Cave at Northparkes E26 MineYojan Ccoa CcopaNo ratings yet

- A Ventilation System For Large Block Cave MinesDocument7 pagesA Ventilation System For Large Block Cave MinesYojan Ccoa CcopaNo ratings yet

- Sidiq Subandriyanto Setyawan: Statement of ParticipationDocument2 pagesSidiq Subandriyanto Setyawan: Statement of Participationsetyawan punkNo ratings yet

- +++ James Arthur Ray - The Science of Success +++Document92 pages+++ James Arthur Ray - The Science of Success +++simona_simona_1982100% (4)

- Lesson 01 IntroductionDocument36 pagesLesson 01 IntroductionpangnoodNo ratings yet

- Pie Chart by Skill CountDocument3 pagesPie Chart by Skill CountHồng Thắm Nguyễn ThịNo ratings yet

- HSE Calendar 2023 - 221230 - 112723Document13 pagesHSE Calendar 2023 - 221230 - 112723Mkd OfficialNo ratings yet

- National TB Control Program Adaptive PlanDocument42 pagesNational TB Control Program Adaptive PlanJulius Dominique Lagtapon AnjaoNo ratings yet

- Design Optimization of Gating and FeedinDocument9 pagesDesign Optimization of Gating and FeedinJoao LuisNo ratings yet

- Lala National High School: Maranding, Lala, Lanao Del NorteDocument3 pagesLala National High School: Maranding, Lala, Lanao Del NorteYana AcubNo ratings yet

- Cellules À ConcentrationDocument12 pagesCellules À Concentrationmohamed ikbalNo ratings yet

- ENGL 102 Mixed Tense Exercises (8 Tenses)Document22 pagesENGL 102 Mixed Tense Exercises (8 Tenses)na-labbadNo ratings yet

- 2 6 2 English L - LDocument16 pages2 6 2 English L - LAyush RajNo ratings yet

- I Year April, 2019Document2 pagesI Year April, 2019J chandramohanNo ratings yet

- Chemistry XIIDocument18 pagesChemistry XIISayantan DasNo ratings yet

- Maaden MSHEM Safety Documents 8Document143 pagesMaaden MSHEM Safety Documents 8ShadifNo ratings yet

- Electron Scattering For Nuclear and Nucleon Structure John Dirk Walecka Full ChapterDocument51 pagesElectron Scattering For Nuclear and Nucleon Structure John Dirk Walecka Full Chapterwilliam.mcguire766100% (6)

- BIEC - Bengaluru - December 2021 - Exhibitor List - 08.12.2021Document5 pagesBIEC - Bengaluru - December 2021 - Exhibitor List - 08.12.2021JabaneshNo ratings yet

- Regallian DoctrineDocument1 pageRegallian DoctrineMary Joy SumapidNo ratings yet

- QTMS Final Assessment (Spring 2020) PDFDocument6 pagesQTMS Final Assessment (Spring 2020) PDFAbdul RafayNo ratings yet

- Confliect Management - Ogl 220 - ArtifactDocument5 pagesConfliect Management - Ogl 220 - Artifactapi-720145281No ratings yet

- Winsem2020-21 Sts2102 Ss Vl2020210500010 Reference Material I 23-Mar-2021 Permutation and Combination Questions 14Document3 pagesWinsem2020-21 Sts2102 Ss Vl2020210500010 Reference Material I 23-Mar-2021 Permutation and Combination Questions 14john cenaNo ratings yet

- Brochure AqualockDocument2 pagesBrochure AqualockKSRNo ratings yet

- General Geology of RomaniaDocument27 pagesGeneral Geology of RomaniaDana PrisacNo ratings yet

- 2017 Target2017 AbstractsDocument177 pages2017 Target2017 AbstractsLaraNigroNo ratings yet

- 10.1016@j.jsames.2017.02.009 4Document17 pages10.1016@j.jsames.2017.02.009 4dkurniadiNo ratings yet

- Lesson Plan Observation Grade 12 PhysicsDocument4 pagesLesson Plan Observation Grade 12 PhysicsGerald BaculnaNo ratings yet

- ELA Syllabus Grade 2Document19 pagesELA Syllabus Grade 2Farzam GarshasbiNo ratings yet