Professional Documents

Culture Documents

010-029 Precast Sewer Maintenance Holes Sewers Less or Equal To DN 300 Depth Less or Equal To 1200 and 1200-6000

010-029 Precast Sewer Maintenance Holes Sewers Less or Equal To DN 300 Depth Less or Equal To 1200 and 1200-6000

Uploaded by

Harsha nrOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

010-029 Precast Sewer Maintenance Holes Sewers Less or Equal To DN 300 Depth Less or Equal To 1200 and 1200-6000

010-029 Precast Sewer Maintenance Holes Sewers Less or Equal To DN 300 Depth Less or Equal To 1200 and 1200-6000

Uploaded by

Harsha nrCopyright:

Available Formats

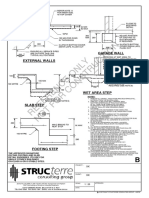

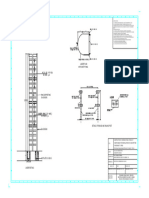

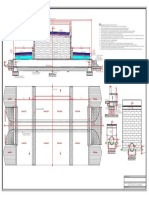

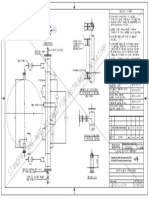

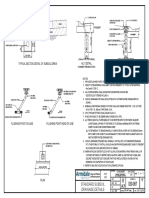

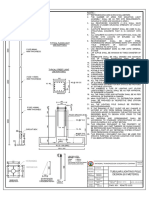

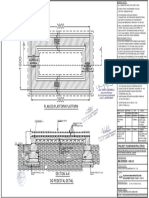

COVER AND SURROUND COVER AND SURROUND

FSL FSL NOTES:

1, ALL PRECAST COMPONENTS TO BE WSA

COMPLIANT.

100 NOM MAKE UP RING(S) 100 NOM

SQUAT CONE Ø 600MIN 600MIN

MAY BE RAISED MAY BE RAISED 2. ALL DIMENSIONS IN MILLIMETRES.

TO 350M MAX(SEE NOTE 6) TO 350M MAX

MASTIC OR RUBBER STRAIGHT BACK TAPER (SEE NOTE 6) 3. PROVIDE ROUNDED NOSING ON INLET AND OUTLET

RING JOINT DN 1050 OR DN 1200 OR CONVERSION SLAB PIPE TO PREVENT DAMAGE BY JETTING EQUIPMENT

OR AS SPECIFIED AND CCTV GUIDES AND CABLES.

MASTIC OR RUBBER

700MAX

SHAFT SECTION RING JOINT 4. CONSTRUCTION MAY BE A COMBINATION OF PRECAST

AND IN-SITU TO SUIT APPLICATION

50 MIN

(50 MIN)

DIM "X"

AUTHORISATION REQUIRED.

SHAFT SECTION DN 1050 OR DN 1200

OR AS SPECIFIED 5. LOCATION OF THE FIRST SHAFT SECTION:

150 MIN STEP IRONS OR LADDER(S) (a) FIRST SHAFT SECTION TO BE BETWEEN 300-600

(SEE NOTE 4) WHERE SPECIFIED LONG TO ALLOW FORMING OF CHANNEL

TO SUIT

AND BENCH.

PROVIDE ROUNDED (b) WHERE STEP IRONS ARE USED,CORRECTLY

CAST IN-SITU BASE NOSING AT INLET & ORIENTATE BOTTOM STEP.

DIM "X" (50 MIN)

(SEE NOTE 9) OUTLET PIPES FIRST SHAFT SECTION (c) PRIME COMPONENT 200 FROM BOTTOM WITH

(SEE NOTE 5) CEMENT SLURRY OR WITH WET AND DRY BONDING

PRECAST MAINTENANCE HOLE AGENT.

150 MIN

(d) FORM CHANNEL IN THE BASE.

FOR COMPONENT DEPTH ≤ 1200 CAST IN-SITU BASE (e) ALLOW BASE TO CURE 7 DAYS BEFORE PLACING

(SEE NOTE 9) ADDITIONAL CHAMBER UNITS.

MIN

300

6. MAKE-UP RINGS:

OUTSIDE FACE 150 MIN (a) USE MINIMUM ONE MAKE-UP RING (PREFERABLY

OF MAINTENANCE (SEE NOTE 5)

ROUNDED NOSING 100 OR 150) PER MANHOLE DURING

HOLE 1 CLEAN ALL (SEE NOTE 3) CONSTRUCTION TO ALLOW FOR FUTURE SURFACE

1 CLEAN ALL JOINT SURFACES ADJUSTMENT WITHOUT AFFECTING THE SHAFT

SECTION.

JOINT SURFACES 2 PLACE RING ON

SPIGOT WITH RIB

PRECAST MAINTENANCE HOLE (b) USE TAPERED MAKE-UP RING ON SLOPING

2 ATTACH SEALANT GROUND.

STRIP TO EITHER AGAINST CONCRETE FOR COMPONENT DEPTH 1200 TO 6000

SLOPING FACES 7. BACKFILL AROUND MH:

3 RUN SCRAPER (a) THE METHOD OF BACKFILL AND COMPACTION

3 ALIGN COMPONENTS AROUND SPIGOT TWICE AROUND MH TO BE GENERALLY AS FOR PIPE

CONCENTRICALLY AND

CONCRETE DI COVER EMBEDMENT.

LOWER TOP UNIT INTO 4 PUSH RING DOWN (b) TAKE CARE TO RAISE SELECT FILL EQUALLY ALL

COVER MAKE-UP RING

POSITION ON SPIGOT STEP AROUND THE MH TO AVOID UNBALANCED LATERAL

4 SEALING COMPOUND LOADING.

5 APPLY RING LUBRICANT

IS SQUEEZED INTO

TO RING SURFACE AND 8. FOR MH >1200 INSTALL STEP IRONS OR LADDER.

JOINT

SOCKET LEAD-IN

INSPECT COMPONENTS CONCRETE 9. CONCRETE BASE TO BE SPECIAL CLASS.

6 ALIGN COMPONENTS DI FRAME

TO ENSURE THERE IS SURROUND

CONCENTRICALLY AND SQUAT CONE

NO DAMAGE TO JOINT 10. WHERE THERE IS SUFFICIENT RISK OF INFILTRATION

LOWER TOP UNIT INTO

SURFACES OR TREE ROOT INTRUSION APPLY AN EXTERNAL

POSITION

BITUMASTIC SEAL TAPE 150 WIDE OVER THE COAT OF

RUBBER RING JOINT MANUFACTURERS RECOMMENDED PRIME SEAL TO

MASTIC JOINT ALL JOINTS.

DETAILS DETAILS CONVERSION

SLAB 11. ALL NEW MH SHALL HAVE CAST DI COVERS WITH

STRAIGHT BACK

CONCRETE SURROUNDS. ALL INSTALLATIONS SHALL

TAPER

BE CLASS D, ALTERNATE OPTIONS REQUIRE

CALCULATING TOTAL PRECAST COMPONENT DEPTH SHAFT SECTION

COUNCIL APPROVAL.

(REFER NOTE 5)

TOTAL DEPTH D. MAUNDER 31/08/2016

OF

= DEPTH TO INVERT OF HIGHEST NON-DROP INLET PIPE Dept of Public 1 1

PRECAST

MINUS Infrastructure NTS

( ID OF INLET PIPE + PIPE WALL THICKNESS + DIM "X" )

COMPONENT

A3 010-029

PRECAST SEWER MAINTENANCE HOLES GW

SEWERS ≤ DN300

DEPTH ≤ 1200 AND 1200-6000 MW 010-029.dwg 31/08/2016

You might also like

- 造纸英语Document360 pages造纸英语Bruce GNo ratings yet

- Cooling System Guidelines For Waukesha PDFDocument4 pagesCooling System Guidelines For Waukesha PDFFaisal Naeem100% (1)

- Hot Water Circulation - Designers Guide PDFDocument3 pagesHot Water Circulation - Designers Guide PDFAntonio LebrunNo ratings yet

- B FootingsDocument12 pagesB FootingsRiham Massoud SobhyNo ratings yet

- 6.0 Reinforcement 7.0 Concrete 8.0 Post Tensioning: Concrete Mix Performance Criteria TableDocument1 page6.0 Reinforcement 7.0 Concrete 8.0 Post Tensioning: Concrete Mix Performance Criteria Tablenishan_ravinNo ratings yet

- Roads and Earthen FirewallsDocument1 pageRoads and Earthen FirewallsMohamed ElsaneeNo ratings yet

- G FootingsDocument9 pagesG FootingsRiham Massoud SobhyNo ratings yet

- HPC 1x1000 EncasingDocument1 pageHPC 1x1000 EncasingShivam SharmaNo ratings yet

- Section A-A: NotesDocument1 pageSection A-A: NotesYazan MohammadNo ratings yet

- GennotesDocument1 pageGennotesNeil ArmstrongNo ratings yet

- Drawing Sheet 4Document1 pageDrawing Sheet 4Kunal SharmaNo ratings yet

- Khajuripada Phulbani: Longitudinal Section at A-ADocument1 pageKhajuripada Phulbani: Longitudinal Section at A-ACRAPTS BhubanesawarNo ratings yet

- BT4 4Document1 pageBT4 4JasNo ratings yet

- Wing WallDocument1 pageWing WallUdit YaduwanshiNo ratings yet

- U Wall 2 (25-01-2022) - Sheet1Document1 pageU Wall 2 (25-01-2022) - Sheet1Suneel BalaniNo ratings yet

- KPC Medical College & Hospital: 1F, Raja Subodh Chandra Mullick Road, Jadavpur, Kolkata, West Bengal 700 032Document1 pageKPC Medical College & Hospital: 1F, Raja Subodh Chandra Mullick Road, Jadavpur, Kolkata, West Bengal 700 032Kausik DewanNo ratings yet

- Ab 036262 003 - 05312022Document1 pageAb 036262 003 - 05312022JAWAHAR TNo ratings yet

- HPC VupDocument1 pageHPC VupShivam SharmaNo ratings yet

- Flooring Details DrawingDocument1 pageFlooring Details DrawingNilesh WaghNo ratings yet

- AS05Document1 pageAS05Vic NairaNo ratings yet

- Tpl-Yiapl-Ph1&2-An-27 R0Document1 pageTpl-Yiapl-Ph1&2-An-27 R0Ramesh BabuNo ratings yet

- DC 950045 001Document1 pageDC 950045 001Abu Anas M.SalaheldinNo ratings yet

- DC 950045 001Document1 pageDC 950045 001Abu Anas M.SalaheldinNo ratings yet

- SD10102-002 - Pile Cap Bar Bending Schedule and Details PDFDocument1 pageSD10102-002 - Pile Cap Bar Bending Schedule and Details PDFMohammed AdilNo ratings yet

- Cross Drain DrawingDocument1 pageCross Drain DrawingManoj BatraNo ratings yet

- Figure 001 - 53-31-11-300-007 (SHEET 2 - 7) - Fuselage Lightning StrikeDocument1 pageFigure 001 - 53-31-11-300-007 (SHEET 2 - 7) - Fuselage Lightning StrikeArteezyNo ratings yet

- 26 - RT609 - U - TYP - 014 - A MH Cover AdjustingDocument1 page26 - RT609 - U - TYP - 014 - A MH Cover AdjustinganooppattazhyNo ratings yet

- FP PlansDocument4 pagesFP PlansDonita AcuinNo ratings yet

- Typical Shear Link Detail Sectional Elevation: A Scale: 1:30 BDocument1 pageTypical Shear Link Detail Sectional Elevation: A Scale: 1:30 BSamitha SoysaNo ratings yet

- CHB Perimeter Wall 1ADocument1 pageCHB Perimeter Wall 1Aleanne DespaNo ratings yet

- Uecp-Sd-Cul - 10.2-R00Document3 pagesUecp-Sd-Cul - 10.2-R00Anuradha KoswaththaNo ratings yet

- Ebs1-Fsfa11-Sapn-Dwpr-1005-D01-Typical Details Existing Underground Pipeline CrossingDocument3 pagesEbs1-Fsfa11-Sapn-Dwpr-1005-D01-Typical Details Existing Underground Pipeline CrossingAsaad AdnanNo ratings yet

- Slab Layout: DWG No 190811 DDocument14 pagesSlab Layout: DWG No 190811 DSaiful IslamNo ratings yet

- General Notes:: Unit Designation Unit DesignationDocument7 pagesGeneral Notes:: Unit Designation Unit DesignationJerry MaratasNo ratings yet

- 2019-018 Knestric BLDG A C E Foundation Plan SealedDocument2 pages2019-018 Knestric BLDG A C E Foundation Plan Sealedghalib2014No ratings yet

- Fire Suppression System: Raaw Courtyard Riffa - BahrainDocument1 pageFire Suppression System: Raaw Courtyard Riffa - BahrainemaarbrothersNo ratings yet

- PDW-TB-487 Paved Area Detail For A-Type Store at Kotri-Pdw-Tv-487 Iso A3Document1 pagePDW-TB-487 Paved Area Detail For A-Type Store at Kotri-Pdw-Tv-487 Iso A3ihsan ul haqNo ratings yet

- Jurucita ConsultantDocument1 pageJurucita ConsultantHong Jin YaoNo ratings yet

- HPC 2x1000Document1 pageHPC 2x1000Shivam SharmaNo ratings yet

- Jayamangal Dining BlockDocument4 pagesJayamangal Dining BlockShiwani SahNo ratings yet

- Water ReservoirDocument1 pageWater Reservoirrajeev kumarNo ratings yet

- Legend:: Service EntranceDocument1 pageLegend:: Service EntranceRODEAN HOPE LACSINo ratings yet

- JERSD J 0071 Instrument StandpipesDocument1 pageJERSD J 0071 Instrument StandpipescesarvalenciaperdomoNo ratings yet

- Standard Subsoil Drainage DetailsDocument1 pageStandard Subsoil Drainage DetailsAnonymous ptLRLiNNNo ratings yet

- Warf Wall (Cutting Section)Document1 pageWarf Wall (Cutting Section)soumodip SahaNo ratings yet

- Ab 036029 001 - 05312022Document1 pageAb 036029 001 - 05312022JAWAHAR TNo ratings yet

- Cemex Solid K4 - Raw Meal SiloDocument3 pagesCemex Solid K4 - Raw Meal Silojoselito navarroNo ratings yet

- Turbo Submittal At200-0.8s g5p Cargill (1) (2) - 1Document2 pagesTurbo Submittal At200-0.8s g5p Cargill (1) (2) - 1ivantellez-famNo ratings yet

- CULVERT 2m X 2mDocument1 pageCULVERT 2m X 2mNISHIMONNo ratings yet

- Chauraghat Road Structural GAD R1Document18 pagesChauraghat Road Structural GAD R1Aicons Engineering Pvt. Ltd.No ratings yet

- S-106 Concrete LayoutDocument1 pageS-106 Concrete Layoutarno assassinNo ratings yet

- Typical Column Details: Column Footing Section Column Footing PlanDocument1 pageTypical Column Details: Column Footing Section Column Footing PlanMark Christian EsguerraNo ratings yet

- PDW-TZ-1133 Tubular Lighting Pole DesignDocument1 pagePDW-TZ-1133 Tubular Lighting Pole Designihsan ul haqNo ratings yet

- QP10-Q-610 Rev0 Typical Yard Shaft - General ArrangementDocument1 pageQP10-Q-610 Rev0 Typical Yard Shaft - General ArrangementnawajhaNo ratings yet

- Sewer Cover NewDocument1 pageSewer Cover NewJulius Dean DumaguingNo ratings yet

- Uecp SD Cul 11.1 R00Document3 pagesUecp SD Cul 11.1 R00Anuradha KoswaththaNo ratings yet

- Column ND Footing DetailsDocument1 pageColumn ND Footing Details025Karthik ReddyNo ratings yet

- DHP As Built Fire Protection FP 01 - 16 Dec 2022Document1 pageDHP As Built Fire Protection FP 01 - 16 Dec 2022Angelo EndozoNo ratings yet

- 1 Dg-MahilaDocument1 page1 Dg-MahilaRohit JangidNo ratings yet

- Typ 1Document1 pageTyp 1aedlk.cpwdNo ratings yet

- HPC1 X 1000Document1 pageHPC1 X 1000Shivam SharmaNo ratings yet

- Me1 MotoDocument1 pageMe1 MotoarchtgozarNo ratings yet

- Selective Supply Record - Domestic Orders Segregated Phase BusductDocument8 pagesSelective Supply Record - Domestic Orders Segregated Phase BusductManoj SinghNo ratings yet

- Oxirane (Ethylene Oxide) PDFDocument134 pagesOxirane (Ethylene Oxide) PDFMuhammad Irfan Malik100% (1)

- 13 Fin-Cat P166-180 enDocument15 pages13 Fin-Cat P166-180 enMorched TounsiNo ratings yet

- Coaxial DipoleDocument2 pagesCoaxial Dipolejregmalos1No ratings yet

- AM FShpEmbreak2168 - EN 1Document1 pageAM FShpEmbreak2168 - EN 1NAEEM AKBARNo ratings yet

- EN 288-3xDocument38 pagesEN 288-3xSyah Reza Maulana0% (1)

- TDS 805 PT SG NewDocument2 pagesTDS 805 PT SG NewWahyudi Rendiana NyotoNo ratings yet

- Marbocote-Bouche pores-GRP SealerDocument1 pageMarbocote-Bouche pores-GRP SealerWafa AjiliNo ratings yet

- Field Inspection and Test Plan For Above Ground Piping Work: Petronas Rapid Project Rapid Package 6A Lldpe ProjectDocument38 pagesField Inspection and Test Plan For Above Ground Piping Work: Petronas Rapid Project Rapid Package 6A Lldpe Projectgerosuca800100% (1)

- C6097a 2310 SpecificationDocument5 pagesC6097a 2310 SpecificationR NandakumarNo ratings yet

- TDS Majestic SupremeDocument4 pagesTDS Majestic SupremeHasan Chandra WijayaNo ratings yet

- Creative Recycling: ProjectsDocument5 pagesCreative Recycling: ProjectsV S MadhavanNo ratings yet

- Marking SchemesDocument387 pagesMarking SchemesTSS DTNo ratings yet

- Potter & Brumfield T90 Series, 30A PCB Relay: General Purpose High Power PCB RelaysDocument3 pagesPotter & Brumfield T90 Series, 30A PCB Relay: General Purpose High Power PCB RelaysNdambuki DicksonNo ratings yet

- Spare BushingDocument39 pagesSpare BushingHoa Nguyen VanNo ratings yet

- 5.0 Microfine Cement Grout Laboratory Testing and ResultsDocument25 pages5.0 Microfine Cement Grout Laboratory Testing and ResultsTATATAHERNo ratings yet

- 455M 10942, 11057, 11007, 11152, 11203, 11311 & 11312Document26 pages455M 10942, 11057, 11007, 11152, 11203, 11311 & 11312Jaime ArreolaNo ratings yet

- Influence of Concentration of NaOH On Fly Ash Based Geopolymer Concrete With Concrete Demolition WasteDocument56 pagesInfluence of Concentration of NaOH On Fly Ash Based Geopolymer Concrete With Concrete Demolition Wasteankita mukherjee100% (1)

- Organisation Study Report at EiclDocument75 pagesOrganisation Study Report at EiclSangeeth Thomas100% (1)

- W2 Day 1Document97 pagesW2 Day 1ANCHAL SINGHNo ratings yet

- Ea 682808 001 R05Document7 pagesEa 682808 001 R05anbarasusivaprakasam100% (1)

- NASA - sp8126 - Space Vehicle Design Criteria - Glossary of Terms and Table of Conversion Factors Used in Design of Chemical Propulsion Systems PDFDocument104 pagesNASA - sp8126 - Space Vehicle Design Criteria - Glossary of Terms and Table of Conversion Factors Used in Design of Chemical Propulsion Systems PDFKhoa VũNo ratings yet

- AWWA M11 - 4th Edition - Steel Pipe - A Guide For Design and Installation (PREVIEW)Document17 pagesAWWA M11 - 4th Edition - Steel Pipe - A Guide For Design and Installation (PREVIEW)vuong17% (12)

- Technical Data Sheet Steel Fibers With Hooked Ends: PerformanceDocument2 pagesTechnical Data Sheet Steel Fibers With Hooked Ends: PerformanceviolettaNo ratings yet

- D1 HNR62 ZNK SDocument17 pagesD1 HNR62 ZNK Sabderrahim ouladaliNo ratings yet

- Lead Pollution Removal From Water Via Clinoptilolite Fixed Bed ColumnDocument3 pagesLead Pollution Removal From Water Via Clinoptilolite Fixed Bed ColumnfonsynickNo ratings yet

- EOR Screening For Ekofisk-2000Document11 pagesEOR Screening For Ekofisk-2000danonninoNo ratings yet