Professional Documents

Culture Documents

F1 in Schools - Engineering Design Score Card

F1 in Schools - Engineering Design Score Card

Uploaded by

AnupCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F1 in Schools - Engineering Design Score Card

F1 in Schools - Engineering Design Score Card

Uploaded by

AnupCopyright:

Available Formats

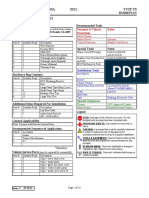

2020 SPECIFICATIONS COMPLIANCE

SCORE CARD – CADET CLASS

R JUDGING SUB CATEGORY SPECIFICATIONS TEAM ID

PRIMARY EVIDENCE PRIMARY RACE CARS TEAM NAME

SECONDARY EVIDENCE ENGINEERING DRAWINGS SCHOOL

CRITERIA 1 COMPETITION CLASS

For clarification on individual regulations, refer to the 2020 Australian Technical Regulations.

Regulation Regulation Overview Quick Guide Penalty Car A Judge 1 Judge 2 Deduction Remarks Rectification

ARTICLE T2 – GENERAL PRINCIPLES Pass/Fail Pass/Fail

T2.4 Safe Construction Visual Check -10

ARTICLE T3 – GENERAL CAR REGULATIONS Pass/Fail Pass/Fail

T3.1.1 Designed and engineered using CAD / CAM Check Portfolio -10

T3.1.2 Body manufactured using CNC only. Check Portfolio -10

T3.1.5 Mirrored Side Machining with 6mm cutter Visual Check -10

T3.1.7 No separately formed balsa parts Check Drawings -10

T3.1.8 Balsa default material for all non-rotating parts Visual Check -10

T3.2.1 Leading Features Min Width – Foremost Extremity (FE) 3mm or R1.5mm -10

T3.2.2 Leading Features Min Width 6mm back from Foremost Extremity 6mm -10

T3.3.3 Hand Finishing Permitted. Max variation to CAD Model 3mm -10

T3.3.4 Hand created features not permitted Visual Check -10

T3.4.2 REA Corporate Partner Decals (REA, DOD, F1iS, Visual Connections) Visual Check -2 ea

T3.4.3.1 REA Corporate Logo Decals Minimum Dimensions 30mm x 15mm -2 ea

T3.4.3.2 Positioning of F1iS A & B Decals on Side Pods Visual Check -2 ea

T3.4.3.3 Positioning of other Corp. Decals visible in top or side view Visual Check -2 ea

T3.5 Undefined features Check T1.6 -4

Points Penalty Page Total - Time Penalties Page Total 0. s

LEGEND Eligibility Regulations/Possible Disqualification Critical Regulations/Time Penalty (0.05s ea)

Criteria 1 Engineering Specifications Compliance: © 2020 Re-Engineering Australia Foundation Page 1 of 4

2020 SPECIFICATIONS COMPLIANCE

SCORE CARD – CADET CLASS

For clarification on individual regulations, refer to the 2020 Australian Technical Regulations.

Regulation Regulation Overview Quick Guide Penalty Car A Judge 1 Judge 2 Deduction Remarks Rectification

T3.6 Overall length Min:170 Max:210 -4

T3.8 Track clearance Min: 2mm -4

T3.9.1 REA balsa default material for non-rotating components Visual Check -4

T3.9.2 Balsa Thickness Min 3mm -1

T3.10 Status during racing – no parts removed/added for racing Visual Check -2

ARTICLE T4 – BODY & SIDE POD REGULATIONS Pass/Fail Pass/Fail

T4.1 Body construction – single continuous balsa between axles Visual & Drawing Check -4

T4.2 Implants, foreign objects & voids not permitted Visual & Drawing Check -4

T4.3 Side pod surface Min 30mm x 15mm -1

T4.4 Virtual cargo – between centre line of front & rear axles T4.5 -4

T4.5 Virtual cargo identification on Engineering Drawings Drawing Check -1

T4.6 Exclusion zones behind front wheels Min 15mm -4

ARTICLE T5 – NOSECONE REGULATIONS

T5.2 Nose cone non metallic material not behind front axle centre line

ARTICLE T6 – WING RULES Pass/Fail Pass/Fail

T6.1 Identification of wing surfaces -1

T6.2.1 Front wing clear airspace Min 3mm -4

T6.2.2 Rear wing clear airspace Min 3mm -4

T6.3 Front wing/support structure in front of centre line of axle Visual Check -1

T6.6 Front/support structure only connected to the nosecone Visual Check -1

T6.7.1 Front wing span Balsa: Min 34mm -4

T6.7.2 Rear wing span Balsa: Min 34mm -4

Points Penalty Page Total - Time Penalties Page Total 0. s

LEGEND Eligibility Regulations/Possible Disqualification Critical Regulations/Time Penalty (0.05s ea)

Criteria 1 Engineering Specifications Compliance: © 2020 Re-Engineering Australia Foundation Page 2 of 4

2020 SPECIFICATIONS COMPLIANCE

SCORE CARD – CADET CLASS

For clarification on individual regulations, refer to the 2020 Australian Technical Regulations.

Regulation Regulation Overview Quick Guide Penalty Car A Judge 1 Judge 2 Deduction Remarks Rectification

T6.9.1 Front wing chord Min 15mm -2

T6.9.2 Rear wing chord Min 15mm -2

Balsa:

T6.10.1 Front wing thickness -2

Min 3.5mm Max: 9mm

Balsa:

T6.10.2 Rear wing thickness -2

Min 3.5mm Max: 9mm

T6.11 Rear wing positioning behind centre line of rear axle Visual Check -1

T6.12 Rear wing height measured normal to bottom surface > 34mm -4

ARTICLE T7 – WHEEL REGULATIONS Pass/Fail Pass/Fail

T7.1 Number and location, common shared centreline 4, 2 x 2 -4

T7.2.1 Combination of four unmodified REA standard wheels Visual Check -4

T7.5 Full contact width with race track – no camber 80gsm paper -2

T7.6 No tyre tread – consistent diameter & circumference Visual Check -2

T7.7 Freely rotating wheels – forward rolling motion Reasonably minimal effort -4

T7.8 Visibility in front view – permitted height of obstruction Max 15mm -4

T7.9 Visibility from top, bottom & side. No obstruction Min 1mm exclusion zone -4

ARTICLE T8 – WHEEL SUPPORT REGULATIONS Pass/Fail Pass/Fail

T8.3 Four unmodified REA axle grommets Visual Check -4

T8.4.2 2 standard REA axles. No other material to be used. Visual Check -2

T8.5.1 No added parts or modifications to wheel systems Visual Check -2

Points Penalty Page Total - Time Penalties Page Total 0. s

LEGEND Eligibility Regulations/Possible Disqualification Critical Regulations/Time Penalty (0.05s ea)

Criteria 1 Engineering Specifications Compliance: © 2020 Re-Engineering Australia Foundation Page 3 of 4

2020 SPECIFICATIONS COMPLIANCE

SCORE CARD – CADET CLASS

For clarification on individual regulations, refer to the 2020 Australian Technical Regulations.

Regulation Regulation Overview Quick Guide Penalty Car A Judge 1 Judge 2 Deduction Remarks Rectification

ARTICLE T9 – TETHER LINE GUIDE REGULATIONS Pass/Fail Pass/Fail

T9.1 2 guides firmly secured, front and rear underside of car Visual Check -1

T9.2 Longitudinal separation measured inside edges of guides Min 120mm -1

T9.4.1 Guides must be closed for racing Visual Check -4

T9.4.2 No sharp edges Visual Check -4

T9.4.3 Adequate strength & fixing 200g mass -4

T9.5.1 2 Standard REA Tether Line Guides Visual Check -1

T9.5.2 Placement must be within the 6mm x 6mm tether slot feature Visual Check -1

ARTICLE T10 – POWER PLANT PROVISIONS REGULATIONS Pass/Fail Pass/Fail

T10.1 Cylinder must interface with launch pod Visual Check -20

T10.2 CO2 cylinder chamber diameter 19mm -1

T10.3 Depth of chamber Min 50mm Max 60mm -1

T10.4 Height of lowest point of chamber above track surface Min 22mm -4

T10.5 CO2 cylinder chamber completely surrounded by balsa Min 3mm -4

T10.6 Paint & other materials not present in CO2 cylinder chamber Visual Check -1

T10.7 CO2 cylinder inserted & withdrawn – no removal of car parts Visual Check -4

Points Penalty Page Total - Points Grand Total /80

Time Penalties Page Total 0. s Time Penalty Grand Total 0. s

LEGEND Eligibility Regulations/Possible Disqualification Critical Regulations/Time Penalty (0.05s ea)

Criteria 1 Engineering Specifications Compliance: © 2020 Re-Engineering Australia Foundation Page 4 of 4

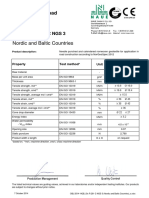

2020 MANUFACTURING (CADET)

SCORE CARD

JUDGING SUB CATEGORY MANUFACTURING TEAM ID

PRIMARY EVIDENCE EXAMINATION OF CAR IN PARC FERME TEAM NAME

SECONDARY EVIDENCE NIL SCHOOL

CRITERIA 3 COMPETITION CLASS

Low Developing Advanced Score

Criteria 012 3456 7 8 9 10 /10

3.6 Quality of Finished Product - Reasonable form with Good overall form and assembly with attention

Exceptional attention to detail across all aspects of form. /10

Geometry/Form some inconsistencies to detail

3.7 Quality of Finished Product - Reasonable finish with Good overall finish quality with attention to

Showcase finish quality. Exceptional attention to detail. /10

Surface finish some inconsistencies detail

Manufacturing GRAND TOTAL /20

Criteria 3 Engineering: Manufacturing CADET © 2020 Re-Engineering Australia Foundation Page 1 of 1

2020 ENGINEERING DESIGN (CADET)

SCORE CARD

JUDGING SUB CATEGORY ENGINEERING DESIGN PROCESS TEAM ID

PRIMARY EVIDENCE TEAM POSTER TEAM NAME

SECONDARY EVIDENCE OPTIONAL TEAM INTERVIEW SCHOOL

CRITERIA 4 COMPETITION CLASS

Low Developing Advanced Score

012 3456 7 8 9 10 /10

Criteria

Multiple concepts with links to

4.1 Ideas Single or basic concepts Several technically inspired ideas for different car features/functions /10

research.

Analysis which is relevant and results Quality analysis methodologies. Accurate results and data linked to design revisions.

4.4 Analysis Little evidence of analysis /10

documented Advanced use of CFD and other design tools.

4.6 Evaluation No or limited evaluation Evaluations at different stages Excellent ongoing evaluations linked to improvement actions /10

4.7 Overall Design Basic design process with little Developed design process with some

Original & clever developed design process with excellent technical merit /10

Technical Merit technical merit technical merit

Design Process GRAND TOTAL /40

Criteria 4 Engineering: Design Process CADET © 2020 Re-Engineering Australia Foundation Page 1 of 1

You might also like

- WSS M2P180 DDocument12 pagesWSS M2P180 DJuan Angel DechimaNo ratings yet

- Nat Aa82 060Document40 pagesNat Aa82 060Biblioteca Brasil AviationNo ratings yet

- CNH Spec FNHA-4-B-010.00 - Eng Requ For Shop PracticeDocument20 pagesCNH Spec FNHA-4-B-010.00 - Eng Requ For Shop PracticeJoe ScopeliteNo ratings yet

- Fastrac 3170Document21 pagesFastrac 3170Patka1130% (1)

- Cam Catia v5 - Milling Tutorial 2018-2019Document28 pagesCam Catia v5 - Milling Tutorial 2018-2019ayyatjamel100% (1)

- Toyota Tacoma 2012 - Tvip V5 Part Number: PT398-35121: PreparationDocument22 pagesToyota Tacoma 2012 - Tvip V5 Part Number: PT398-35121: PreparationTomas OrozcoNo ratings yet

- ISO Standards 06 June 2017Document19 pagesISO Standards 06 June 2017ayyaz123No ratings yet

- ETA-01-01 - Manufacture and Testing of Pre-Assembled Glued Insulated Rail Joints PDFDocument8 pagesETA-01-01 - Manufacture and Testing of Pre-Assembled Glued Insulated Rail Joints PDFIvano ForcinaNo ratings yet

- Geometric Dimensioning and Tolerancing: Procedure / Drafting FNHA-3-B-072.00Document69 pagesGeometric Dimensioning and Tolerancing: Procedure / Drafting FNHA-3-B-072.00003689% (9)

- CBT-I Provider List - Updated 06-20-17Document32 pagesCBT-I Provider List - Updated 06-20-17AnupNo ratings yet

- CBT-I Provider List - Updated 06-20-17Document32 pagesCBT-I Provider List - Updated 06-20-17AnupNo ratings yet

- Scrutineering and Specification - Supplementary Competition Regulations - V1Document3 pagesScrutineering and Specification - Supplementary Competition Regulations - V1THE UNBEATABLE LEGENDNo ratings yet

- Cable Marker - WMT 2,4 (15X4) R - 0816281: Key Commercial DataDocument3 pagesCable Marker - WMT 2,4 (15X4) R - 0816281: Key Commercial DataVlad MaziluNo ratings yet

- INSPECT Features and Benefits - CodewareDocument5 pagesINSPECT Features and Benefits - CodewareLibardo Bahamón LiscanoNo ratings yet

- Evaluation of Load-Carrying Capacity of Lubricants Used in Hypoid Final-Drive Axles Operated Under Low-Speed and High-Torque ConditionsDocument18 pagesEvaluation of Load-Carrying Capacity of Lubricants Used in Hypoid Final-Drive Axles Operated Under Low-Speed and High-Torque Conditionsomar TahaNo ratings yet

- 10-000000-0000100595-ACM-ENG-SPC-000430 - Section 032000Document20 pages10-000000-0000100595-ACM-ENG-SPC-000430 - Section 032000ahmad.suliman.saeedNo ratings yet

- TBE Template Small - 22102023 2 2Document106 pagesTBE Template Small - 22102023 2 2Danny LaksonoNo ratings yet

- TATA Quick Reference Guide For Use With Steel RoofDek S220 Technical Information ASSET DOC LOC 951182Document2 pagesTATA Quick Reference Guide For Use With Steel RoofDek S220 Technical Information ASSET DOC LOC 951182Shane ConnellyNo ratings yet

- Report-1683-1 B1 25mm 14 10 2020Document7 pagesReport-1683-1 B1 25mm 14 10 2020sakthi velNo ratings yet

- Guidelines Surface Mount Technology SMT Soldering Application Note MelexisDocument62 pagesGuidelines Surface Mount Technology SMT Soldering Application Note Melexisengenhariatip1No ratings yet

- ES9-54 Fastener Installation Torque Values Rev GDocument34 pagesES9-54 Fastener Installation Torque Values Rev GIfran SierraNo ratings yet

- 014-AC-101A (Rev 01)Document22 pages014-AC-101A (Rev 01)Thinh NguyenNo ratings yet

- WSS M5G58 A2Document5 pagesWSS M5G58 A2Muthu GaneshNo ratings yet

- SR AO Building PDFDocument11 pagesSR AO Building PDFAmit Kumar PandeyNo ratings yet

- External Safety Audit Check-List For Onshore Drilling RigsDocument30 pagesExternal Safety Audit Check-List For Onshore Drilling RigsSiddhartha ChakradharNo ratings yet

- Fit-Up & Materials Rev1 - tcm109-257536Document2 pagesFit-Up & Materials Rev1 - tcm109-257536joNo ratings yet

- SEIP For 014-AC-101D: Damage History No Service Induced Indication Noticed On Air Cooler None Inspection Area NIL OthersDocument12 pagesSEIP For 014-AC-101D: Damage History No Service Induced Indication Noticed On Air Cooler None Inspection Area NIL OthersThinh NguyenNo ratings yet

- 014-AC-101F (Rev. 01)Document12 pages014-AC-101F (Rev. 01)Thinh NguyenNo ratings yet

- Defroster Air Volume: T-SB-0224-10 August 4, 2010Document2 pagesDefroster Air Volume: T-SB-0224-10 August 4, 2010goombaNo ratings yet

- Acp Testing Acceptance Procedure PDFDocument21 pagesAcp Testing Acceptance Procedure PDFRoland James ArimadoNo ratings yet

- Requirements Manual: Shock Absorber Asm RearDocument13 pagesRequirements Manual: Shock Absorber Asm RearnightweisoNo ratings yet

- General SpecificationsDocument5 pagesGeneral SpecificationsbergeronfNo ratings yet

- Table 1Document2 pagesTable 1rahul BhoirNo ratings yet

- Lubrication and Hydraulic Filter Debris Analysis (FDA) For Condition Monitoring of MachineryDocument21 pagesLubrication and Hydraulic Filter Debris Analysis (FDA) For Condition Monitoring of MachineryasmaNo ratings yet

- Saes J 004Document6 pagesSaes J 004Neeraj kumarNo ratings yet

- Trim Assembly, Enclosed Luggage WSS-M15P32-D Compartment Covering 1. ScopeDocument11 pagesTrim Assembly, Enclosed Luggage WSS-M15P32-D Compartment Covering 1. Scopeerik0007No ratings yet

- TB4092 - Sentido e Unidades de Medição Da RugosidadeDocument2 pagesTB4092 - Sentido e Unidades de Medição Da RugosidadeJosé Francisco Ramos TeixeiraNo ratings yet

- Nato Strap IssueDocument10 pagesNato Strap IssuepaterdaleNo ratings yet

- 03 Iris1Document12 pages03 Iris1AndiosoNo ratings yet

- Boletin Tecnico USA Abs FordDocument5 pagesBoletin Tecnico USA Abs FordjuvenildobusinNo ratings yet

- STN - GMP Powertrain/Carbody Adaptation Interface Assembled Exhaust LineDocument42 pagesSTN - GMP Powertrain/Carbody Adaptation Interface Assembled Exhaust LineAlireza AameriNo ratings yet

- GT-1064-Disconnection and Removal, #1 Bearing Area Probes and TCPLsDocument20 pagesGT-1064-Disconnection and Removal, #1 Bearing Area Probes and TCPLsMadih ElghannamNo ratings yet

- Body Structure Body Identification Body-In-White Mobile Access ElementsDocument4 pagesBody Structure Body Identification Body-In-White Mobile Access ElementsEngenharia APedroNo ratings yet

- NM LCF12 E01Document2 pagesNM LCF12 E01Cy RamosNo ratings yet

- Astm F3329 18Document2 pagesAstm F3329 18Ramin ShojaNo ratings yet

- Iso 4249 1 1985Document8 pagesIso 4249 1 1985faizNo ratings yet

- Mil Metal RemovalDocument20 pagesMil Metal Removalparimalam100% (2)

- Spherical PTR AsssessmentDocument2 pagesSpherical PTR AsssessmentSyafiqah IsmailNo ratings yet

- Surge ArresterDocument5 pagesSurge Arresterlkt_pestechNo ratings yet

- ES9-54 Fastener Installation and Torque Value Rev JDocument35 pagesES9-54 Fastener Installation and Torque Value Rev Jganesh100% (1)

- Scope TestsDocument4 pagesScope TestsGonzalo TelleríaNo ratings yet

- Formal Service Report: General InformationDocument7 pagesFormal Service Report: General Informationjamel SibugNo ratings yet

- Oil Seal DesignDocument10 pagesOil Seal DesignRavindra PawarNo ratings yet

- 016B - PCP - Rev-4 04.07.2020 R-4Document36 pages016B - PCP - Rev-4 04.07.2020 R-4Aashish MoyalNo ratings yet

- B53 3106 Replaces B53 3110Document4 pagesB53 3106 Replaces B53 3110LucasNo ratings yet

- Def Stan 03-32 Part 3 Paint-Systems For Aluminium ArmourDocument10 pagesDef Stan 03-32 Part 3 Paint-Systems For Aluminium ArmourDeepto BanerjeeNo ratings yet

- 03304001en Revl PDFDocument10 pages03304001en Revl PDFRissi CHNo ratings yet

- Material Specifications: (Process Specification) ScopeDocument7 pagesMaterial Specifications: (Process Specification) ScopeIvy LiNo ratings yet

- Multiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...From EverandMultiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...No ratings yet

- Connection-Oriented Networks: SONET/SDH, ATM, MPLS and Optical NetworksFrom EverandConnection-Oriented Networks: SONET/SDH, ATM, MPLS and Optical NetworksNo ratings yet

- Broadband Wireless Mobile: 3G and BeyondFrom EverandBroadband Wireless Mobile: 3G and BeyondWillie W. LuNo ratings yet

- Visual Media Coding and TransmissionFrom EverandVisual Media Coding and TransmissionAhmet KondozNo ratings yet

- Rapidity Racing - Enterprise PortfoliopdfDocument11 pagesRapidity Racing - Enterprise PortfoliopdfAnupNo ratings yet

- Expert Tips Hints Design Process 4X4Document27 pagesExpert Tips Hints Design Process 4X4AnupNo ratings yet

- Visual Connections Australia Style GuideDocument8 pagesVisual Connections Australia Style GuideAnupNo ratings yet

- Sponsorship Workshop - 15 June 2016Document38 pagesSponsorship Workshop - 15 June 2016AnupNo ratings yet

- Schools F1 Project V6aDocument24 pagesSchools F1 Project V6aAnupNo ratings yet

- F1 in Schools - Team Sokudo Race For Speed and SustainabilityDocument3 pagesF1 in Schools - Team Sokudo Race For Speed and SustainabilityAnupNo ratings yet

- Celeritas Racing Sponsorship ProspectusDocument15 pagesCeleritas Racing Sponsorship ProspectusAnupNo ratings yet

- Non Newtonian FluidsDocument5 pagesNon Newtonian FluidsAnupNo ratings yet

- Expert Tips Hints Off Road Performance Tyres Suspension 1Document16 pagesExpert Tips Hints Off Road Performance Tyres Suspension 1AnupNo ratings yet

- The Future of Security in SpaceDocument105 pagesThe Future of Security in SpaceAnupNo ratings yet

- IJSO Statutes EDocument28 pagesIJSO Statutes EAnupNo ratings yet

- Bringing Space Down To EarthDocument52 pagesBringing Space Down To EarthAnupNo ratings yet

- Emerging Space EconomyDocument42 pagesEmerging Space EconomyAnupNo ratings yet

- Nesto - Circle Mall - Midweek - Crazy FiguresDocument15 pagesNesto - Circle Mall - Midweek - Crazy FiguresAnupNo ratings yet

- GM13 Geosynthetic PDFDocument11 pagesGM13 Geosynthetic PDFRicardo RodriguezNo ratings yet

- Venus School, CollegeDocument2 pagesVenus School, Collegethaxina548No ratings yet

- Building Survey Report SampleDocument91 pagesBuilding Survey Report SampleabcNo ratings yet

- October Week Equations of Motion WorksheetDocument2 pagesOctober Week Equations of Motion Worksheetmatthewlaw107No ratings yet

- Titroline Dystar Indigo Vat 40% Solution: Automatic Titrator For Determination of Indigo and Sodium DithioniteDocument4 pagesTitroline Dystar Indigo Vat 40% Solution: Automatic Titrator For Determination of Indigo and Sodium DithionitefernandolimaNo ratings yet

- 4 Evenness (ITF CS 02/02) : ApparatusDocument4 pages4 Evenness (ITF CS 02/02) : ApparatusmarictomNo ratings yet

- Jet Engine IntegrationDocument8 pagesJet Engine IntegrationZeeshan100% (1)

- Hafen CityDocument7 pagesHafen CityAndree MosqueraNo ratings yet

- Application: Cavalier & Sunfire 4T40-EDocument72 pagesApplication: Cavalier & Sunfire 4T40-Ejuan gomezNo ratings yet

- ISTQB TestAnalystDocument2 pagesISTQB TestAnalystReshma RanganNo ratings yet

- API 674 Positive Displacement PumpsDocument67 pagesAPI 674 Positive Displacement PumpsFrancisco Pérez ChaniqueNo ratings yet

- ZI 01 InterfaceDocument4 pagesZI 01 InterfaceAdrian Oprisan100% (1)

- IC IT Project Evaluation 11342 - WORDDocument5 pagesIC IT Project Evaluation 11342 - WORDAliNo ratings yet

- 16 - Guinea Iron OreDocument25 pages16 - Guinea Iron OreBisto MasiloNo ratings yet

- TurboNest 2 ManualDocument90 pagesTurboNest 2 Manualdoshi78100% (2)

- Oracle Database 12c R2: Administration Workshop Ed 3: DurationDocument6 pagesOracle Database 12c R2: Administration Workshop Ed 3: Durationjackomito100% (1)

- Class List Third Year Bachelor of Technical Education in Eletrical and Eletronics Engineering-1Document9 pagesClass List Third Year Bachelor of Technical Education in Eletrical and Eletronics Engineering-1Pascal LugataNo ratings yet

- Worksheet Science 2 º Unit 5Document20 pagesWorksheet Science 2 º Unit 5Kyo Toey0% (1)

- 33 Unreliable Speed Pitot Blocked SaDocument8 pages33 Unreliable Speed Pitot Blocked SaDhruv Joshi100% (1)

- Enza CT - ENP3 Series 75-500ADocument2 pagesEnza CT - ENP3 Series 75-500Aanbuchelvam96No ratings yet

- C Range Anchor: CompositionDocument1 pageC Range Anchor: CompositionDejan JanevNo ratings yet

- The T Motor Protector Is Designed To Protect Single PhaseDocument3 pagesThe T Motor Protector Is Designed To Protect Single PhaserayNo ratings yet

- Basic EE PrelimDocument3 pagesBasic EE PrelimJohnCris B. FornilosNo ratings yet

- Wetroom Design - WEBDocument44 pagesWetroom Design - WEBanirudha acoNo ratings yet

- Proposal Defence - Farah Wahida Corrected Ss 2Document19 pagesProposal Defence - Farah Wahida Corrected Ss 2Farah Wahida JusohNo ratings yet

- Arch 448m Project 4eDocument6 pagesArch 448m Project 4eapi-610095042No ratings yet

- SECUTEX R 201 Ficha TécnicaDocument1 pageSECUTEX R 201 Ficha TécnicaMax FerrolNo ratings yet

- MFJ 1020CDocument4 pagesMFJ 1020Cmark777mark100% (1)