Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

43 viewsCBT 6

CBT 6

Uploaded by

SUNIL RAJPUTCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- CBT 12Document7 pagesCBT 12SUNIL RAJPUT100% (1)

- CBT 25Document6 pagesCBT 25SUNIL RAJPUTNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Saic-Gi - 2102Document3 pagesSaic-Gi - 2102SUNIL RAJPUTNo ratings yet

- Saic-G - 2019Document2 pagesSaic-G - 2019SUNIL RAJPUTNo ratings yet

- Saic-N - 2019Document3 pagesSaic-N - 2019SUNIL RAJPUTNo ratings yet

- Saic-N - 2017Document2 pagesSaic-N - 2017SUNIL RAJPUTNo ratings yet

- Saic-N - 2007Document4 pagesSaic-N - 2007SUNIL RAJPUTNo ratings yet

- Saic-N - 2013Document2 pagesSaic-N - 2013SUNIL RAJPUTNo ratings yet

- Saic-N - 2005Document2 pagesSaic-N - 2005SUNIL RAJPUTNo ratings yet

- CBT 22Document16 pagesCBT 22SUNIL RAJPUTNo ratings yet

- Saic-N - 2008Document2 pagesSaic-N - 2008SUNIL RAJPUTNo ratings yet

- CBT 8Document5 pagesCBT 8SUNIL RAJPUTNo ratings yet

- InternalDocument2 pagesInternalSUNIL RAJPUTNo ratings yet

- Saic-N - 2002Document1 pageSaic-N - 2002SUNIL RAJPUTNo ratings yet

- CBT 31Document9 pagesCBT 31SUNIL RAJPUT50% (2)

- Liquid CoatingsDocument12 pagesLiquid CoatingsSUNIL RAJPUTNo ratings yet

- CBT 19Document3 pagesCBT 19SUNIL RAJPUTNo ratings yet

- CBT 06.02.2020Document3 pagesCBT 06.02.2020Nidhin Joseph100% (1)

- C - Quality Control Instrumention For Paint and Coating Installations - 2019Document67 pagesC - Quality Control Instrumention For Paint and Coating Installations - 2019SUNIL RAJPUTNo ratings yet

- CBT 2Document2 pagesCBT 2SUNIL RAJPUT100% (2)

- CBT 3Document9 pagesCBT 3SUNIL RAJPUT100% (1)

- CBT 4Document9 pagesCBT 4SUNIL RAJPUTNo ratings yet

- Iso 8502-1Document2 pagesIso 8502-1SUNIL RAJPUTNo ratings yet

- 333 14ssaiDocument60 pages333 14ssaiSUNIL RAJPUTNo ratings yet

CBT 6

CBT 6

Uploaded by

SUNIL RAJPUT0 ratings0% found this document useful (0 votes)

43 views15 pagesOriginal Title

CBT-6

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

43 views15 pagesCBT 6

CBT 6

Uploaded by

SUNIL RAJPUTCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 15

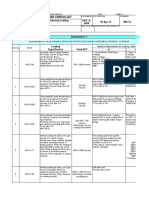

Ahwhieh standard be flow or sre enines of plo chat?

2-0 8504

Alwht she moire content allow btore xt on coeetsurces?

percent (600)

(Ph handed tse?

s-sasmi02

———rt—SO

'5)inwhat sequence the

al blasting wl be done fr thetank ?

2: fam top to btom

6)ininorganic tine sate what fine own 95?

pigment

7} whatis the speed for high voltage holiday detector?

2-300 mmysee (0 m/sec or 0.3 mety/sec

twats he nina relive hurty for coating appeation?

a 80% (.8)

_shwhich standard to be follow tor surtace eanliness for commercl bas cleaning?

anspesp6

40) what tthe percent of clean bas for commercial blast cleaning?

33 percent

18) which standard to be follow for surface cleanliness for near metal whte bast eaning?

2.545 fepesP10)

12) what dos the discontinuity mean?

a-holday

13) in what sequence the Internal lasting willbe done forthe tank ?

{2+ from top to bottom

18) hotday testing fr the external foe coating?

31500-2000 (¢/- 39 volts)

asset

2 prasence of hygroscopic alts

6) werethe dead men ane (hut fa be attached?

a asearestto the not operate ey

27) xcourse repeatape ange?

2 MATE mins ceca)

2064 mkcrons Hore) bgas-2050 MICRONS

a8) hot iia micrometer?

TE

0st gels good esene?

nye

19) iaegelisNOT a good deste?

rast

tet donno?

{the temperature at which the water vapourin tk ar will et condense.

21) which adhesion test shall be dane for fbe coating?

at

22) can new galvanized wil be coated with apes for more protection?

ayes

23) conosion?

2 deeradtion ofa metal by ctemical means

24) preparation of the damage areas known 25?

2 feathering.

25) what is the 4:

ratio for the airless spray pump?

2° the inlet to outlet pump ratio

25) how to store 12-meter length pipe foe coated pipes?

2% Itshall have 3 full encirclements

| 27) what is the maximum height of weld cap or internal root protrusion?

aL3mm

28) sulfate and chloride content for abrasive?

less then 50 ppm,

28) solvent shall not be applied to surface warmer then?

a Sdeg cel

30) thinner can be added to paint?

‘as per paint manufacturer

31) coating pull back n after paint cure happen onthe sharp edges?

true

'32)when surface contamination in stele st spray dust and other debris what

failure will occur?

lack of adhesion AND BLISTERING.

33 during internal blasting of crude oltank what surface preparation required

prior to start blasting?

solvent cleaning

34 wet sponge holiday volts far the internal tank

67.5 volts

'35)before filling the water inside the- tank what tact has to be do

holiday test with repair/water

‘3¢)psint over burted ss pipe? halide liquid tree coating, iqud coating recommended

by rsa

_37)prefile range given in msds,pds,apes specfcation?

38}during water jetting basting which device will protect fom slippery of nozzle

‘whip lork

39)where the trigger safety catch shall be engaged in airless or conventinal?

the trigger safety catch shall be engaged whenever the airless gun is left

unattended

_40)relative humidity can be obtained by

sling pygrometer /PSCHROMETER.

41)what is pot life?

time interval between mixing and application until to use

42)what is induction time?

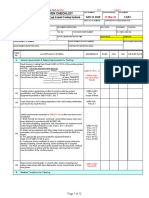

1, blasting and coating shall not be performed if

2) the substrate contains oi, grease, dit, loose coating, loose rust, or other surface

contaminants

) the substrate temperatures less than 3°c (5°) above the dew point.

wind s strong enough o ow sand, salt spray, or other foreign matter onto the

‘surface boing conte,

allofthe above

@

2 the flowing coating defect may be seen immediately ater a thick fm of epoxy coating

sprayed

4) checking and cracking

») sagging

'6) mud cracking and chalking

1) blistering

3. anode, cathode,

a) tue

») false

italic pathway and electrolyte are elements of corrosion cells

ive humidity can be obtained by usha?

2) surface peole gauge

») electronic dt gauge

©) sing psychrometer

©) surface thermometer

5 afte applying paint onthe surface, paint got wetted by raining, as painting inspector

‘what wil you do?

2) recoat painting without removing existing coating

) wait for water dry

a

@) abrade and remove affected area by sanding

5 singe packer pat ding by?

) chemical curing

©) coalescence

©) solvent evaperation

7. the swedish standard designation for commercial bast cleaning is

©) saZ5

od) sa3

:

(9 nwt tt ates tetas

7 oe as ca nae

concitons

©) 85% ofthe blasted surface grins are in white metal conditions

) 35% of the blasted surface grains are in white metal conditions

“induction” time for a pati the

2) time between the manufacture date and application date

») time between the application ad fully drying of coating

1s amis root ada wich eco aly de fare i no ara

ar

2) snee002

2) ca ooze

uno

_ in aber nat ect by

) connected wih blasting pot

©) contol by crew supervisor

4) control by basting helper

12. when an abrasive blaster is working in an offshore area, he must wear

4) safety shoe, leather gloves and coverall,

») blasting hood with fresh air ine

©) safety bot te jackot

9)

tip sue ofan aes spray guns define as 319

the fan width is 3° and the nazze size is O19"

0

€) the an width is SOC" andthe nozze sie is 019"

«the fan widths 30° andthe nozzle size is 319°

14. the coatrg system thats applied ona splash zone area is

8) epcs-20

GEEEEIED iss Fake reinforces PoyestrEpony Coating Systems for Offshore

‘Structural Stee! at Spash Zone

©) apes.22

@) apes-113

| 15:he coating ial ith ie betnoen

2) the minimum time between the application top coat and color coding

') the minimurr time between the application stripe coat and spray application

©) the minimurr tne Between the application touch-up and full coat system

nding shal te carried out forte following equipment

2) airless spray machine

) aircompressor

)_airreceivertenk

17 conosion can be contol by

8) design and material selection

) protective coatings and catholic protection

‘inhibitors and alteration of the environment

PT

18, wat anchor pats

) Gieeaka andvalona panama

) surface piting

©) milscale

8) allof above

18, whats rust grade ¢on steel surface

28) see! surface covered wih bls il le ad rust

>

©) see! surface completely covered wih adherent mil scale ile or no rust visibNe

9) steel surface completely covered wth ust ite or no pitting visbe

Ivanic corrosion occurs on which ofthe folowing substrate

a) concrete

2) wood

8) foerglass reinforce plastic

PA relive humid s

ay

by the lowest temperature at which moisture forms on a steel surface

©) the temperaure at which moisture forms on a steel eurface

‘d) a measure cf the amount of moisture in the ar compared tothe air temperature

BiG u occ se temperature at ich

2) waler freezes

b) humidity decreacos

)_theairis saturated

1 dstance from nozzle o blotter paper when performed the compressed ar qual test

shall be

3) 30-40 cm

©) 80-/0.0m

0) 5545en

14, high thickness of in sicate cause

2) seggng

©) -curtaining

4) cohesive fare

25.al number represents

2) thinner code

©) atch number

‘solvent code

26 if an airless spray pump ratio 35:1 uid pressure 2800 require for inlet pressure

2) 100 pst

») c0p5)

4) 60ps

227 wich ofthe folowing isnot an information of dally report sheet?

8) dew point

») relative humidity

©) aictemperature

28. what profile range can be measured using x-coarsetestex

2) 2050)

©) 3850

9) 085 y

29, how many microns ar in 4 mile?

a) 1150

») sou

8) 150

‘90, wrat are the characteristics ofan abrasive?

a) density

) hardness.

aii

(stim he gouge ves ormeasuing pessice tte last rozle

8) hyptemicneedl presi gee

) relief pressure gauge

) airressure gauge

9) allo above

32. the air receivers that are used as a surge tank between compressor and basting pot

shallbe hydro tested ata pressure ofa east

a) 150psi

b) 125 psi

) 175 psi

33, eoating materials used for construction site must be cover and the temporary storage

petiod shall not exceed

a) 10days

05 days

07 days

34, the use of recycled abrasives is permitted only in shops provided that the ecycing,

system is

4) inspected and approved by coating inspector

»)_approved by project manager

aD

{approved by project inspection department

35, ater basting the external coating surface chiorde content shallot exceed

@) 30 maim"

b) 15mgim

©) 20 maine

36. after blasting the intemal coating surface chloride content shall nt exceed

2) 80 mgim=

9) 18maim®

Py 40mg

37 incase of brush applicatin, the maximum brush ze shall be ueed

a) 75mm

b) 100mm

150mm

8 ta ade co pte eran sees

oe

2 an

1) cause paint adhesion

8 sp 3 isa standard for

2) white metal bast cleaning

) pickling

‘d) hand tool earning

40, the temperature of which moisture begins to condersate ona see! surface is called

2) relative humicity

1) maximum surface tamperature

9) minimum surface temperature

41. what standard explains how to measure dy film thickness with magnetic gages?

a) sspepat

CD

€) sspenas

6) sspe-pas

42, what documents wil describe the health and safety of hazard of aceating materat?

a) the job specication

«By material safely data sheets)

6) sepe safely specication

9) otha standard

48. whats the correct storage temperature range for coating?

a) 30t090f

) 40to 1201

) 45to 1004

(Aah mate ter moan sen bye ap et

b) asim 43363,

¢) astm 43360

) asim 3747

45, wet sponge holiday detectors checked with—dc vols for dt not exceeding——

8) 900 600microns

) 69.5 S00microns

4) 67.5u1 1000mierons

48, what dt wil get, when applied 150, wf with 80% of volane solid?

2) 85micron

) 80mieron

©) 100mieron

/&) 7micron

4. what is the feld adhesion test on foe?

2) cross cut adhesion test

) oly toe

4) allof the above

48. what isthe minimum nozzle ai pressure required for abrasive basting?

») 75 psi

©) 100 psi

©) 80psi

48, what would you doi you receive coatings that have exceeded their shal ife?

2) use the casting if i's the apparance ie normal

)_use the materia if there is no hard seting of pigment

0)

1) contact the coating manufacturer fr information about the usablty ofthe coatings.

50, whats the correct formula for computing the wet fm thickness (wf), needed to achieve:

the specified dry fim thickness (at of a coating?

b) wi oftx0.50

©) wit = dx percent of solids by we

©) atxve

5

hich of the folowing characteristics of paints easly tested in the fila?

23) viscosity

(©) dry opacity:

©) entiation of the solvent in the paint

4) entiation ofthe paint resin

52, windy condition can cause which ofthe following pant defects?

3) wrinkling

») sagging

ri

'53 ifthe given dt ls 400 microns and volume of sols is 100% what the wft

a) 450micron|

b)_500mieron

9) 350mieron

(GA grounding wire for biaetng and oosting equipment shall be awe?

2) Sorierger

2) orlager

@) Sorlarger

‘55, what profile range can be measured using coarse testex?

a) 40-65microns

©) 30-TOmicons

4) 15.50mierons

56, what profile range can be measured using x coarse testox?

2) 20.50microns

) 42-70microns

9) 30-70mverons

‘7. the maximum length of field gith weld coating on pipeline shall be?

8) 12inch of 300mm

)15inch oF 200mm

@) ‘finch oF 280mm

(5 forntea oe coating the weld capo intra rot proton sha nt be mare han

2) sam

2) ton

©) 2mm

59, which apes is followed for external foe coating of pipe?

) apes-117

by apes-102 abe

@) apes-113a

60, which apcs is fllowed for internal foe coating of pipe?

2) apes 17

€) apes-104 a,b.0

) apes-113

‘6. what is the de volt ange for holiday testing of oe coating?

23) 1000-1500 ac

)_ 2000-5000 de

8) 2500-4000 ge

| @2ivhat is samss for ietera foe coating?

2) Oiusamss.087

) Oo-sames-087

©)_09-samss-107

3 is sams for extemal foe coating?

8) 09-samss-067

©) 3-samss-107

(64. in which form foe coating material is prior to use?

2) liquid containers

») sold

3) ga

165 spe stands for?

») steel structure painting code

©) society for protective coating

4) steel structure painting committee

166, what the speed of high voltage holiday detector while performed testing?

a) Semisec

b) Bcomisec

) TSemisee

'67whileretairon touch up of galvanized steal surara, what ganarc pant sad as primer?

2) zine phosphate epoxy

) zine siicate

8) maste epoxy

‘68. which information isnot available n tds?

4) volume solids

) fash point

©) dew point

') thining ratio

'60.for basting nozzle sce of 1/2", what ehal be the minim cla of congress?

2) 800cfm

opaiem

0) Stocim

3 eatin

7D.arame standard safety for basting ad panting

aero»

Tal est?

abrasvedeanines

Bhs of ls

eT

“Pauwhich isnot surfoce preparation method?

74.blasting on concrete surfaces slowiy, quickly thoroughly?

Reersmagee

7 buried stainless steel ines shallbe externally coated with fhe, haldesfreeiguic-contingn

76, abrasive blasting shall be carried out only when the ste! surface is atleastdtebovesthes

“dew point —

7?-coupling used in blasting?

the blasting hose shall be the static dissipating type with external couplings

sFBioni fr adhesion pul off testa per Astm 4541 result

mp kas kg/m?

fife rusting wil start if the humicty levels?

80.the high-pressure hose is ited with a safety device known 25?

Sveti io mir

SMR ase organ

the time between the fist coat and the next coat

83, astm 6 4128 stands for?

fe measurement

{4 hand applied splash zone compounds?

pes 9a

£85.bush of basting standard?

7

‘86.vhere do youfind the surface profle ange?

Tds/pectction af Apes

{Phen the str aout to int which deve es him rom topping the lta?

pean switch

‘8:heminiumtemp diference between metal temp andthe dew pint?

=

ious

plomert

Son whihinsument surtace profile mesurment can be done

‘manu nth eguie fre el pth weld is

20mm

steel surfaces contaminated by water of salts the failure the coating occurs inthe

form of bubbles shape is called?

matic listers

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- CBT 12Document7 pagesCBT 12SUNIL RAJPUT100% (1)

- CBT 25Document6 pagesCBT 25SUNIL RAJPUTNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Saic-Gi - 2102Document3 pagesSaic-Gi - 2102SUNIL RAJPUTNo ratings yet

- Saic-G - 2019Document2 pagesSaic-G - 2019SUNIL RAJPUTNo ratings yet

- Saic-N - 2019Document3 pagesSaic-N - 2019SUNIL RAJPUTNo ratings yet

- Saic-N - 2017Document2 pagesSaic-N - 2017SUNIL RAJPUTNo ratings yet

- Saic-N - 2007Document4 pagesSaic-N - 2007SUNIL RAJPUTNo ratings yet

- Saic-N - 2013Document2 pagesSaic-N - 2013SUNIL RAJPUTNo ratings yet

- Saic-N - 2005Document2 pagesSaic-N - 2005SUNIL RAJPUTNo ratings yet

- CBT 22Document16 pagesCBT 22SUNIL RAJPUTNo ratings yet

- Saic-N - 2008Document2 pagesSaic-N - 2008SUNIL RAJPUTNo ratings yet

- CBT 8Document5 pagesCBT 8SUNIL RAJPUTNo ratings yet

- InternalDocument2 pagesInternalSUNIL RAJPUTNo ratings yet

- Saic-N - 2002Document1 pageSaic-N - 2002SUNIL RAJPUTNo ratings yet

- CBT 31Document9 pagesCBT 31SUNIL RAJPUT50% (2)

- Liquid CoatingsDocument12 pagesLiquid CoatingsSUNIL RAJPUTNo ratings yet

- CBT 19Document3 pagesCBT 19SUNIL RAJPUTNo ratings yet

- CBT 06.02.2020Document3 pagesCBT 06.02.2020Nidhin Joseph100% (1)

- C - Quality Control Instrumention For Paint and Coating Installations - 2019Document67 pagesC - Quality Control Instrumention For Paint and Coating Installations - 2019SUNIL RAJPUTNo ratings yet

- CBT 2Document2 pagesCBT 2SUNIL RAJPUT100% (2)

- CBT 3Document9 pagesCBT 3SUNIL RAJPUT100% (1)

- CBT 4Document9 pagesCBT 4SUNIL RAJPUTNo ratings yet

- Iso 8502-1Document2 pagesIso 8502-1SUNIL RAJPUTNo ratings yet

- 333 14ssaiDocument60 pages333 14ssaiSUNIL RAJPUTNo ratings yet