Professional Documents

Culture Documents

20-1708 Elevator SJ

20-1708 Elevator SJ

Uploaded by

Rahul M.RCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

20-1708 Elevator SJ

20-1708 Elevator SJ

Uploaded by

Rahul M.RCopyright:

Available Formats

SINGLE JOINT ELEVATOR

OPERATING PROCEDURE MANUAL

20-1708 Rev F (9/7/2005)

Single Joint Elevator Operating Procedure Manual

Table of Contents

Section Page

1 - Introduction 2

1.1 General Information

1.2 Description

2 - Operation 3

2.1 Installation

2.2 Operation

3 - Maintenance 4

3.1 Inspection

3.2 Lubricants

4 - Shop Repairs 5

4.1 Elevator Disassembling and Re-Assembly

4.2 Access Oil Tools, Inc., Factory Tool Repair

Critical Area Drawing 6

Assembly, Parts Breakdown and Replacement Parts 7-8

Certificate of Warranty and Guarantee to Quality 9

20-1708 Rev F (9/7/2005)

Single Joint Elevator Operating Procedure Manual

1

1 - INTRODUCTION

1.1 PURPOSE

This technical manual contains operation and maintenance instructions for Access Oil Tools,

Inc. “SJ” series single joint center latch pick up elevator is designed to replace unsafe rope

slings for hoisting collar type pipe into position to be added to the string. The “SJ” type allows

the crew to handle pipe properly, helping avoid damage to pipe threads and reduce the

chances of accidents or injury. It also provides a guide for proper field use, disassembling

and repair.

1.2 DESCRIPTION

The “SJ” series center latch pick up elevator has a simple, reliable latch that closes

simultaneously when elevator is closed. Safety latch pin then slides into place locking the

elevator again. Size range of “SJ” series elevator is available in 2’-3/8” through 24-1/2” collar

type pipe.

MODEL SHORT TON METRIC TONNES RANGE

SJ 5 4.54 2-3/8” - 24-1/2”

Any overloading of the recommended rating or misuse of this equipment can

cause serious injury or death.

20-1708 Rev F (9/7/2005)

Single Joint Elevator Operating Procedure Manual

2

2 - OPERATION

2.1 INSTALLATION

As with any manual operated elevator the “SJ” is easily installed by the use of swivel

suspension assembly. After the elevator is hoisted to the rig floor and in position follow this

procedure:

1. Remove the bolt from the shackle on the swivel suspension assembly. Attach the

shackle over the lifting eye on the elevator then replace the bolt to the shackle.

2. Repeat the process for the opposite lifting eye. To remove the elevator, simply

reverse the process.

2.2 OPERATION

Operation of the “SJ” elevator is straightforward. The door is opened by removing the safety

latch pin and pulling outward on the latch. When the elevator is properly closed around the

pipe, then install the safety latch pin in place (see “caution”).

CAUTION:

• Elevators are manufactured to operate in a vertical direction when used to pick up or

lay down pipe in a non-vertical position; the operator should ensure that the latch

retainer pin is securely in place.

• “SJ” series elevators should only be used with tubulars having collar type square

shoulder connections.

• Keep hands and fingers clear of elevator bore when installing the elevator on the pipe.

• Make sure the safety latch pin is in position before hoisting.

• Be sure there is ample shoulder width on the pipe to maintain adequate contact area

with elevator face.

• Elevator should only be used on pipe in which the elevator is bored for, not on any

other pipe size.

• Oversized pipe could cause difficulties in the latching or possibly result in the elevator

latching partially or not at all. Undersized pipe could cause uneven stress distribution,

inadequate load bearing area, or possibly allowing the collar to slip through the

elevator.

• Inspect the bore, latch, latch pin and hinge pin regularly for wear. Proper bore codes

and dimensions are given in current catalogs.

20-1708 Rev F (9/7/2005)

Single Joint Elevator Operating Procedure Manual

3

3 - MAINTENANCE

CAUTION:

Practice safety at all times when servicing the equipment and use approved

safety methods, material and tools. Always wear protective gear for eyes,

head and hands.

3.1 INSPECTION

To insure optimum performance from the “SJ” series elevators, the following checks should

be performed once a week:

• Check for worn hinge pin and latch pin and their mating parts. These, if worn, may

hinder proper opening and closing of the door and latch.

• Check the latch retaining pin assembly for worn or damaged parts. (safety latch pin).

• Check for proper latch spring performance.

• Check for proper operation of latch stop mechanism. Latch should not stop against

the body when engaged.

• Check springs for damage, deformation and lack of tension.

Note: It is recommended that elevators undergo factory magnetic particle inspection a

minimum of once every six months and load test once a year.

3.2 LUBRICANTS

Lubricate the elevator regularly during the usage and storage to prevent corrosion. Use an

extreme pressure, multi-purpose, lithium base grease of no. 1 or no. 2 consistency and multi-

weight motor oil. When the elevator is in use, lubricate the elevator according to the following

schedule:

Daily

• Grease hinge pin.

• Lubricate latch pin and latch lock pin.

• Grease underside of lifting eyes.

• Grease bore and seating surface.

• Brush grease on latch spring.

20-1708 Rev F (9/7/2005)

Single Joint Elevator Operating Procedure Manual

4

4 - SHOP REPAIRS

4.1 ELEVATOR DISASSEMBLING AND REASSEMBLY

The “SJ” series elevator requires minimum attention. When it becomes necessary to replace

a part, use the following procedure:

1. To remove the hinge pin, begin by removing the hinge pin retainer pin. Then

drive out the hinge pin from the bottom elevator. Replace the hinge pin and hinge

pin retainer pin.

2. To remove the latch pin, first remove the latch pin retainer pin then drive out the

latch pin from the bottom. Replace latch pin and latch pin retainer pin.

3. To remove latch safety pin, remove the bolt on the elevator door.

4.2 ACCESS OIL TOOLS, INC. FACTORY TOOL REPAIR

Worn elevators are returned to high quality condition with precision factory repair procedures.

When tools are received for repairs, they are dismantled and checked for dimensional

accuracy, and undergo magnetic particle inspection. Worn areas are repaired by welding or

replacing with new parts, and the components are reheat-treated to original hardness

specifications then they are proof load tested and certified. After a second magnetic particle

inspection 24 hours after proof load testing, the tools are reassembled and carefully checked

for dimensional and functional integrity.

CAUTION:

• Do not use any elevator if the latch and latch lock do not function properly.

• Use only parts manufactured and sold by Access Oil Tools, Inc.

• Re-machining and reheat-treating should be performed at Access Oil Tools, Inc. or an

authorized AOT repair facility. Improper machining could result in increased stress

(decreased load carrying capability) of improper alignment of component parts. Either

condition could be hazardous to personnel and equipment.

• Due to the complex metallurgy found in Access Oil Tools, Inc. materials, welding

should be performed only at Access Oil Tools, Inc. or an authorized AOT repair facility.

• Bodies and doors are specifically matched by trained Access Oil Tools, Inc.

professionals. For this reason, a body or door from one elevator should never be

exchanged with a body or door from another elevator.

• Pins retained by riveting or peening must be well secured by upsetting a substantial

amount of material on the pin or mating parts.

• Always wear gloves and eye protection when grinding, striking or handling parts.

20-1708 Rev F (9/7/2005)

Single Joint Elevator Operating Procedure Manual

5

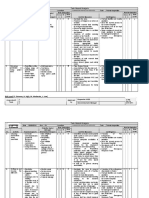

CRITICAL AREAS OF “SJ” ELEVATORS

20-1708 Rev F (9/7/2005)

Single Joint Elevator Operating Procedure Manual

6

AOT SINGLE JOINT ELEVATOR (LARGE FRAME)

AOT# Range Weight

E39-039 2-3/8” - 5-1/2” 51.00

E39-040 5-3/4” - 7-5/8” 69.00

E39-041 8” - 10-3/4” 98.00

E39-042 11-3/4” - 13-3/8” 130.00

E39-043 14” - 20” 213.00

E39-200 2-3/8” - 3-1/2” 35.00

E39-210 4” - 5-3/4” 40.00

REPLACEMENT PARTS FOR SINGLE JOINT ELEVATOR

AOT# Item No. Description Spares Req. Weight

E39-034 1 2 3/8” - 20” Latch Spring 2 1 .08

E39-035 2 2 3/8” - 13 3/8 Latch 1 5.50

E39-050 3 2 3/8” - 24 1/2” Latch Pin 1 .35

E39-051 4 2 3/8” – 20” Latch RET PIN ASSY 1 1 .65

E39-052 5 2 3/8” – 13 3/8” Hinge Pin 1 .75

E39-054 2 14” - 24 1/2” Latch 1 7.00

E39-053 5 14” - 24 1/2” Hinge Pin 1 1.00

E39-055 6 Hinge Pin Retaining Pin 1 .08

E34568 N/P Swivel Suspension Assembly 1 19.00

20-1708 Rev F (9/7/2005)

Single Joint Elevator Operating Procedure Manual

7

AOT SINGLE JOINT ELEVATOR (SMALL FRAME)

AOT# Range Weight

E39-200 2-3/8” –35-1/2” 35.00

E39-210 4” – 5-3/4” 40.00

REPLACEMENT PARTS FOR SINGLE JOINT ELEVATOR

AOT# Item No. Description Spares Req. Weight

E39-190 5 Latch for Single Joint (SF) 1 2.50

E39-196 6 L.L. Pin for Single Joint /w chain (SF) 1 1.00

E39-197 4 Latch Spring for Single Joint (SF) 1 .25

E39-198 3 Latch Pin for Single Joint (SF) 1 15.00

E39-199 1 Hinge Pin for Single Joint (SF) 1 1.00

PR .187x2 2 3/16 X 2” Roll Pin 1

20-1708 Rev F (9/7/2005)

Single Joint Elevator Operating Procedure Manual

8

CERTIFICATE OF WARRANTY AND GUARANTEE TO QUALITY

Seller warrants all materials, products and supplies manufactured or furnished by it to be free

from defects in material and workmanship, under normal use and service, when installed,

used and serviced in the manner provided and intended by seller for a period of twelve (12)

months after installation or delivery, whichever shall occur first. Seller’s obligations under this

warranty are expressly limited to repair or replacement, at its option, of any materials,

products or supplies returned to seller’s plant, Broussard, Louisiana, and which are

determined by seller to be defective. All freight charges for return and reshipment shall be

paid by customer. A new warranty period shall not be established for repaired or replaced

materials, products or supplies; such items shall remain under warranty only for the

remainder of the warranty period on the original materials, products or supplies. This is the

sole warranty of seller and no other warranty is applicable, either expressed or implied, in fact

or by law, including any warranty as to merchantability or fitness for a particular use or

purpose.

In case of goods or parts not wholly of seller’s manufacture, seller shall make available to the

customer whatever warranty or guaranty is extended to seller for such goods or parts by the

supplier or manufacturer thereof.

Seller will not assume responsibility or liability for any repairs, rebuilding, welding or heat

treating done to its material, products or supplies outside of seller’s plants, such work shall

void any all warranties. All parts used in the manufacture and/or final assembly of seller’s

materials, products and supplies are necessary for both safety and operational performance.

Omission of any part or failure to replace any part may result in a malfunction and a

consequent safety hazard for which seller disclaims any responsibility or liability for injuries or

damage as a result thereof.

Buyer’s sole and only remedy in regard to any defective materials, products or supplies shall

be the repair or replacement thereof as herein provided, and seller shall not be liable for any

consequential, special, incidental or punitive damages resulting from or caused by any

defective materials, products or supplies.

20-1708 Rev F (9/7/2005)

Single Joint Elevator Operating Procedure Manual

9

You might also like

- DS1 Vol 4Document305 pagesDS1 Vol 4Rahul M.R100% (1)

- Caterpillar Cat GC20K HP Forklift Lift Trucks Service Repair Manual SN AT82E-90011 and Up PDFDocument30 pagesCaterpillar Cat GC20K HP Forklift Lift Trucks Service Repair Manual SN AT82E-90011 and Up PDFfjkskekmdmme0% (1)

- Caterpillar Cat GC25K HP Forklift Lift Trucks Service Repair Manual SN AT82D-90011 and Up PDFDocument30 pagesCaterpillar Cat GC25K HP Forklift Lift Trucks Service Repair Manual SN AT82D-90011 and Up PDFfjkskekmdmme50% (2)

- LF90LS Operations and Service Manual PDFDocument154 pagesLF90LS Operations and Service Manual PDFJose Vidal100% (9)

- L-220F Redats EN A.1.1-ALT PDFDocument24 pagesL-220F Redats EN A.1.1-ALT PDFTatiana JimenezNo ratings yet

- LF90LS Operations and Service Manual PDFDocument154 pagesLF90LS Operations and Service Manual PDFDavid Fino Y. Seguro100% (1)

- EMT3-C10185 Manual (Rev. 1)Document18 pagesEMT3-C10185 Manual (Rev. 1)Matias Contreras KöbrichNo ratings yet

- Slip Type Elevator PDFDocument22 pagesSlip Type Elevator PDFسہۣۗفيہۣۗانشہۣۗينہۣۗوي100% (1)

- Caterpillar Cat GC25K HP Forklift Lift Trucks Service Repair Manual SN AT82E-90011 and Up PDFDocument30 pagesCaterpillar Cat GC25K HP Forklift Lift Trucks Service Repair Manual SN AT82E-90011 and Up PDFfujsjejfksekmem0% (2)

- CAH Small Frame Air Hoist Manual 11720901Document30 pagesCAH Small Frame Air Hoist Manual 11720901cj7man80No ratings yet

- Y' Series Elevator Operating Procedure ManualDocument5 pagesY' Series Elevator Operating Procedure ManualAnonymous ciu3QEjuSNo ratings yet

- G SERIES ELEVATOR Rev EDocument14 pagesG SERIES ELEVATOR Rev ELeonardo Rachen RodriguezNo ratings yet

- 20 1703YSeriesElevatorManualDocument27 pages20 1703YSeriesElevatorManualnjava1978No ratings yet

- SERIES Y ELEVATOR Rev 1 2009Document23 pagesSERIES Y ELEVATOR Rev 1 2009Leonardo Rachen RodriguezNo ratings yet

- Slip Type ElevatorDocument15 pagesSlip Type ElevatorJohn Jairo Simanca100% (1)

- Maintenance Y SERIESDocument10 pagesMaintenance Y SERIESStowartNo ratings yet

- SLX SX Elevator Maintenance ManualDocument7 pagesSLX SX Elevator Maintenance ManualBahman MatouriNo ratings yet

- TA Elevators MaintenanceDocument8 pagesTA Elevators MaintenanceBahman MatouriNo ratings yet

- SINGLE JOINT - Rev H 2007Document13 pagesSINGLE JOINT - Rev H 2007Leonardo Rachen RodriguezNo ratings yet

- Model No. EE-6503 - in Ground Hydraulic Vehicle Lifts LiftDocument33 pagesModel No. EE-6503 - in Ground Hydraulic Vehicle Lifts LiftBảo Toàn LêNo ratings yet

- Manual-18 Rotary Side Door ElevatorDocument12 pagesManual-18 Rotary Side Door ElevatorYesid Cruz Yesid Cruz100% (1)

- Ra Elevatorr Maintenance ManualDocument8 pagesRa Elevatorr Maintenance ManualBahman MatouriNo ratings yet

- Two Post Lift Installation and Owners Manual Capacity 10,000 LbsDocument36 pagesTwo Post Lift Installation and Owners Manual Capacity 10,000 LbsGuilhermeNo ratings yet

- Operating Instructions & Parts Manual: Forklift JackDocument8 pagesOperating Instructions & Parts Manual: Forklift JackAlain DefoeNo ratings yet

- Impeller Inspection and Maintenance ProcedureDocument1 pageImpeller Inspection and Maintenance ProcedureThebe HanyaneNo ratings yet

- SERIES "RA", "MAA", & "AA" ELEVATORS - 125, 150, 250 & 350 TonsDocument11 pagesSERIES "RA", "MAA", & "AA" ELEVATORS - 125, 150, 250 & 350 Tonssergio.medina.pinzon1992No ratings yet

- Cylinder Repair: Safety Precautions Maintenance and RepairDocument21 pagesCylinder Repair: Safety Precautions Maintenance and RepairKiều Văn TrungNo ratings yet

- G Series Elevator Maintenance ManualDocument9 pagesG Series Elevator Maintenance ManualBahman MatouriNo ratings yet

- Manual Hidraulico Montacargas Yale Gp060rcDocument52 pagesManual Hidraulico Montacargas Yale Gp060rcPepe AlNo ratings yet

- Manual de Manutenção Do Elevador BVM Ta-100Document12 pagesManual de Manutenção Do Elevador BVM Ta-100Alexsandro CordeiroNo ratings yet

- NOV - Rotary Slips ManualDocument7 pagesNOV - Rotary Slips ManualbenkaouhaNo ratings yet

- CPE ManualDocument32 pagesCPE ManualSarah PerezNo ratings yet

- ALI Certified Battery MCL ManualDocument27 pagesALI Certified Battery MCL ManualeliasNo ratings yet

- Single Joint Elevator Series "SJ" Elevator - 1.5 & 7.5 TonsDocument12 pagesSingle Joint Elevator Series "SJ" Elevator - 1.5 & 7.5 Tonssergio.medina.pinzon1992No ratings yet

- FOR MODELS LST20, 25, 30 Owners Manual/Parts List: W WA AY YDocument16 pagesFOR MODELS LST20, 25, 30 Owners Manual/Parts List: W WA AY YMeadows TruckNo ratings yet

- DZS Series of Brakes Maintenance Instruction ManualDocument18 pagesDZS Series of Brakes Maintenance Instruction ManualCarlos Prieto100% (1)

- 20-1718 Rig Tongs AOTDocument10 pages20-1718 Rig Tongs AOTRahul M.R100% (1)

- SEBF 8172 пружины толкателей 3500Document6 pagesSEBF 8172 пружины толкателей 3500Jone Bane100% (1)

- RT770E T3-T4i SM CTRL447-05 PDFDocument357 pagesRT770E T3-T4i SM CTRL447-05 PDFDmitryNo ratings yet

- Two Post Lift Installation and Owners Manual: 9000B Capacity 9,000 LbsDocument21 pagesTwo Post Lift Installation and Owners Manual: 9000B Capacity 9,000 LbsGuilhermeNo ratings yet

- Manual 19 PDFDocument9 pagesManual 19 PDFyury1102No ratings yet

- Cilindros de LevanteDocument16 pagesCilindros de LevanteMilton GarcesNo ratings yet

- HESBON HL-26K (Eng)Document34 pagesHESBON HL-26K (Eng)Lim Hendra - PJS BALINo ratings yet

- Kone Step ChainDocument6 pagesKone Step Chaindaniel cooperNo ratings yet

- 20-1701 Slips DCSDocument7 pages20-1701 Slips DCSRahul M.RNo ratings yet

- 20-1700 Slips CMSDocument7 pages20-1700 Slips CMSRahul M.RNo ratings yet

- Instruction Manual Loader 99781 PDFDocument43 pagesInstruction Manual Loader 99781 PDFapostuNo ratings yet

- AAX Tong MaintenanceDocument7 pagesAAX Tong MaintenanceBahman Matouri100% (1)

- Tire ChangingDocument28 pagesTire ChangingJed GawanNo ratings yet

- Hydraulic Stacker - Model No. Mn397: Operating Instructions and Parts ListDocument9 pagesHydraulic Stacker - Model No. Mn397: Operating Instructions and Parts ListAJ MusicNo ratings yet

- Deltorq Series - 21 Actuator: Installation, Operation and Maintenance ManualDocument8 pagesDeltorq Series - 21 Actuator: Installation, Operation and Maintenance ManualProcess Controls & ServicesNo ratings yet

- Operations and Service Manual: MKT1723 Rev 4Document38 pagesOperations and Service Manual: MKT1723 Rev 4Percy RivaNo ratings yet

- Gives You The Techlock System AdvantageDocument8 pagesGives You The Techlock System AdvantageMTK2016No ratings yet

- QJYJ30-CB Scissor Vehicle Lift Operation ManualDocument26 pagesQJYJ30-CB Scissor Vehicle Lift Operation Manualvipper king2012100% (1)

- Yale PSB Lever Hoist - PSB-680Document16 pagesYale PSB Lever Hoist - PSB-680elmosawidaNo ratings yet

- JET 120112 User ManualDocument4 pagesJET 120112 User ManualmoathNo ratings yet

- 16 August 2021 Vimec E10 EcoVimec Lifting PlatformDocument20 pages16 August 2021 Vimec E10 EcoVimec Lifting Platformmohammed.ranaNo ratings yet

- 6.38 10M EH Single Shear Seal BOPDocument19 pages6.38 10M EH Single Shear Seal BOPpramodptvpm_65797156No ratings yet

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 pagesJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeNo ratings yet

- Manual Controlador EC25N2Document199 pagesManual Controlador EC25N2Claudio Galvez RojasNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- 20-1701 Slips DCSDocument7 pages20-1701 Slips DCSRahul M.RNo ratings yet

- 20-1700 Slips CMSDocument7 pages20-1700 Slips CMSRahul M.RNo ratings yet

- Dencon Catalog 2004-2005Document24 pagesDencon Catalog 2004-2005Rahul M.RNo ratings yet

- NOV HT Manual Tong-50006190 MAN 001-Rev GDocument68 pagesNOV HT Manual Tong-50006190 MAN 001-Rev GRahul M.R100% (1)

- 20-1718 Rig Tongs AOTDocument10 pages20-1718 Rig Tongs AOTRahul M.R100% (1)

- Damaged / Lost Equipment Report: Date Division MIS Country Der No. KSADocument1 pageDamaged / Lost Equipment Report: Date Division MIS Country Der No. KSARahul M.RNo ratings yet

- JSA TubularDocument4 pagesJSA TubularRahul M.RNo ratings yet

- Manual Usuario Licuadora Hamilton BeachDocument2 pagesManual Usuario Licuadora Hamilton BeachAnonymous Oh6az4No ratings yet

- MC We GTB EnglishDocument15 pagesMC We GTB EnglishKavin CorlNo ratings yet

- The Anglo-Saxon ChronicleDocument137 pagesThe Anglo-Saxon ChronicleAlejandra Gheorghiu0% (1)

- Owner's Manual: Pianos PianosDocument32 pagesOwner's Manual: Pianos PianosVera FedeNo ratings yet

- Barton 199 DPU Data SheetDocument4 pagesBarton 199 DPU Data Sheetmfg_serviciosNo ratings yet

- Maquina de Anestesia Mindray Wato Ex 35 Manual de Usuariopdf DLDocument326 pagesMaquina de Anestesia Mindray Wato Ex 35 Manual de Usuariopdf DLBiomedico CozumelNo ratings yet

- Full Download Test Bank For Roachs Introductory Clinical Pharmacology 10th Edition by Susan M Ford MN RN Cne Sally S Roach PDF Full ChapterDocument28 pagesFull Download Test Bank For Roachs Introductory Clinical Pharmacology 10th Edition by Susan M Ford MN RN Cne Sally S Roach PDF Full Chapternervous.vielle60lnwy100% (25)

- StucchiDocument132 pagesStucchiCentral Hydraulics100% (1)

- Warranty Against Hidden Defects - This Refers To The Implied Warranty That TheDocument12 pagesWarranty Against Hidden Defects - This Refers To The Implied Warranty That TheSk SynzerNo ratings yet

- Abbyy® Finereader® 12 SprintDocument12 pagesAbbyy® Finereader® 12 Sprintoffice komputer3No ratings yet

- Pressure Switch/Reed Switch Type: SeriesDocument4 pagesPressure Switch/Reed Switch Type: SeriesDaniel Mauro Inga SalazarNo ratings yet

- Quotation A-180164Document15 pagesQuotation A-180164MantenimientoNo ratings yet

- A Study On The Application of Sale of Goods Act in BangladeshDocument3 pagesA Study On The Application of Sale of Goods Act in BangladeshMd. Abul Hossen MilonNo ratings yet

- Quincy QR25 Pump ManualDocument44 pagesQuincy QR25 Pump ManualEduardo100% (2)

- Instant Download Strategic Staffing Global 3rd Edition Phillips Test Bank PDF Full ChapterDocument10 pagesInstant Download Strategic Staffing Global 3rd Edition Phillips Test Bank PDF Full ChapterDeniseFosterjicr100% (10)

- READ ME - Mapping File Install Guide-V1001Document14 pagesREAD ME - Mapping File Install Guide-V1001Christian SalasNo ratings yet

- Due Diligence ReportDocument26 pagesDue Diligence ReportLindsay LinNo ratings yet

- SAFC Biosciences - Technical Bulletin - L-Glutamine StabilityDocument2 pagesSAFC Biosciences - Technical Bulletin - L-Glutamine StabilitySAFC-GlobalNo ratings yet

- 51 JointventureDocument82 pages51 JointventureCavinti LagunaNo ratings yet

- Users Guide: Installation, Operation, and Maintenance For Your Wine CoolerDocument10 pagesUsers Guide: Installation, Operation, and Maintenance For Your Wine CoolerAleck BartockNo ratings yet

- JinkoSolar-Global Limited Warranty - (Rev061120-LINEAR) - V3Document8 pagesJinkoSolar-Global Limited Warranty - (Rev061120-LINEAR) - V3Stefan BusoiNo ratings yet

- Unfair Trade Practices Business LawDocument13 pagesUnfair Trade Practices Business Lawsnigdha banerjeeNo ratings yet

- LPG VALVE TEST BENCH 20210114 - 副本Document8 pagesLPG VALVE TEST BENCH 20210114 - 副本Taha HusNo ratings yet

- Electronic Arts End User License AgreementDocument5 pagesElectronic Arts End User License AgreementMarkoNo ratings yet

- Visual Studio 2017 Image Library EULADocument3 pagesVisual Studio 2017 Image Library EULAmokeNo ratings yet

- Định mức siliconDocument2 pagesĐịnh mức siliconHuy Dao NgocNo ratings yet

- GZT Leaders Laggers Indicator User Manual 20160627Document10 pagesGZT Leaders Laggers Indicator User Manual 20160627krishna rNo ratings yet

- Craftsman Mower 18.0 HP 917272751 - Owners - ManualDocument56 pagesCraftsman Mower 18.0 HP 917272751 - Owners - Manualcharles blairNo ratings yet

- Specification Concrete and Cmu WallsDocument6 pagesSpecification Concrete and Cmu WallsBaugh Graphic DesignNo ratings yet